Integral abutment structure and construction method of earth pressure and filling settlement behind console

An integral abutment and earth pressure technology, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of increasing bridge maintenance costs, reducing the flatness of road pavement, and bridge head jumping, etc. Bearing capacity, maintaining beauty and tidiness, and preventing road surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

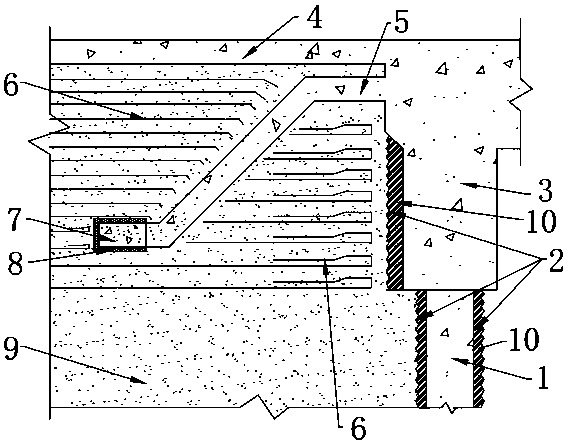

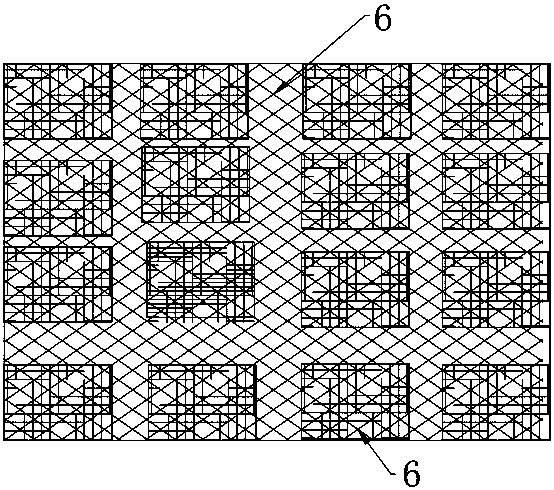

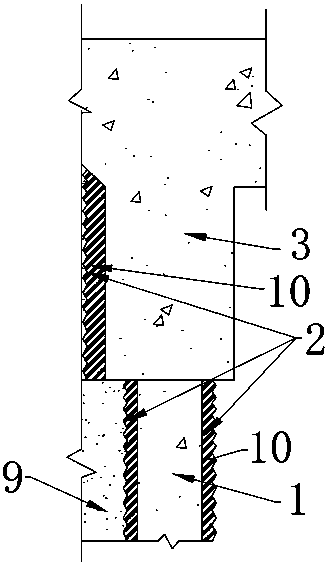

[0029] Such as figure 1 As shown in ~3, the embodiment of the present invention provides an integral abutment structure with earth pressure and filling settlement behind the control console, an integral abutment structure with earth pressure and filling settlement behind the control console, including the abutment body And the anti-Z-shaped butting plate connected with the abutment body, the upper and lower sides of the said butting plate are respectively vertically laid with an upper filling layer and a lower filling layer reinforced by several layers of geogrids. The upper filling layer is extended upwards to the road surface, and the lower filling layer is extended downwards to the foundation; a first gap; the end of the horizontal end of the strap is open and rigidly connected to the abutment body; the end of the lower horizontal end of the strap is sealed by a rectangular steel sleeve, and the rectangular steel sleeve is horizontally sleeved on the strap The outer side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com