Seamless curved bridge adopting semi-rigid integral abutments

An integral bridge abutment and seamless curved bridge technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems such as the damage of the shockproof block and the poor seismic performance of the seamless curved bridge, so as to improve the seismic performance and solve the horizontal problem. Bridge shear force and deformation, simple effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

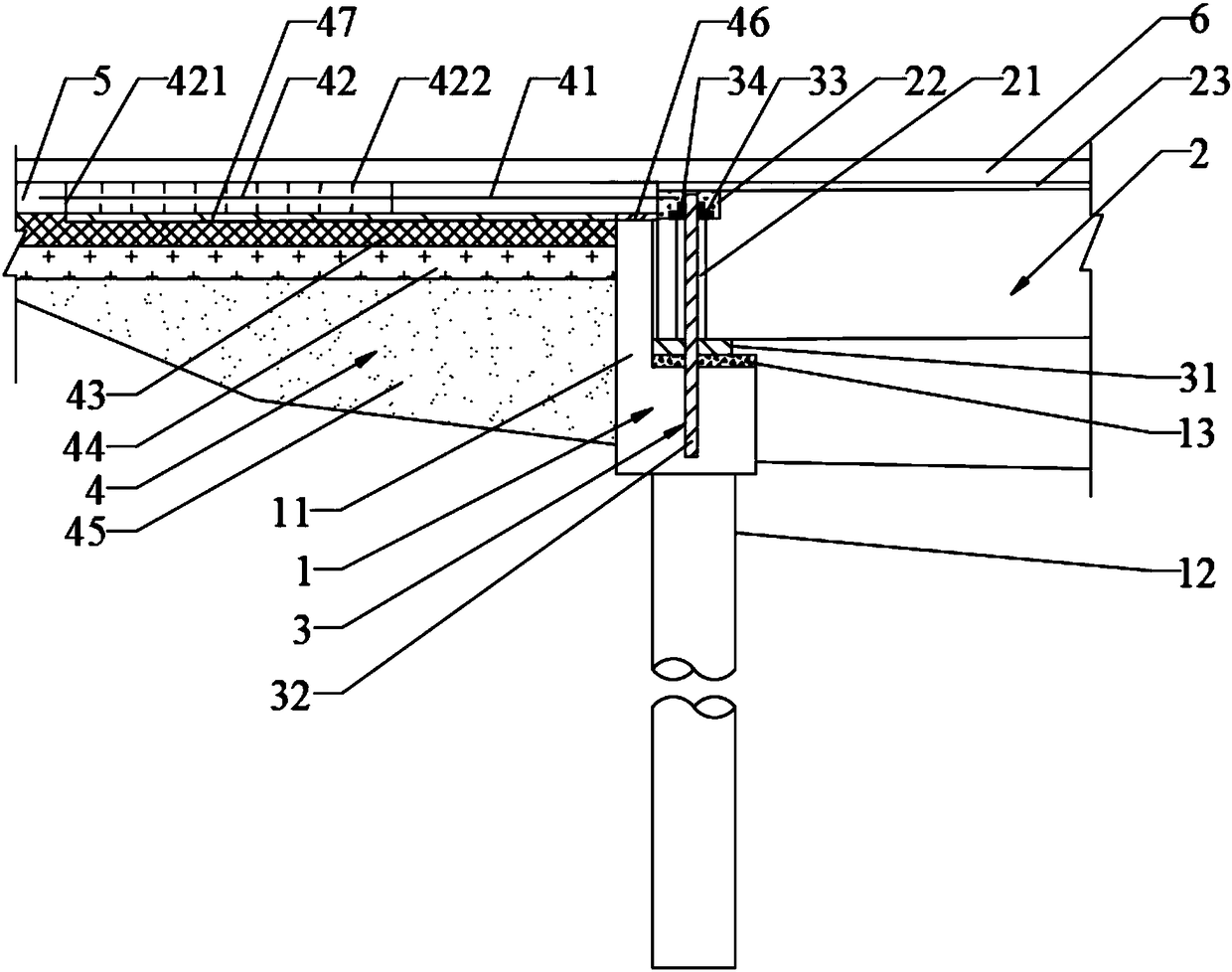

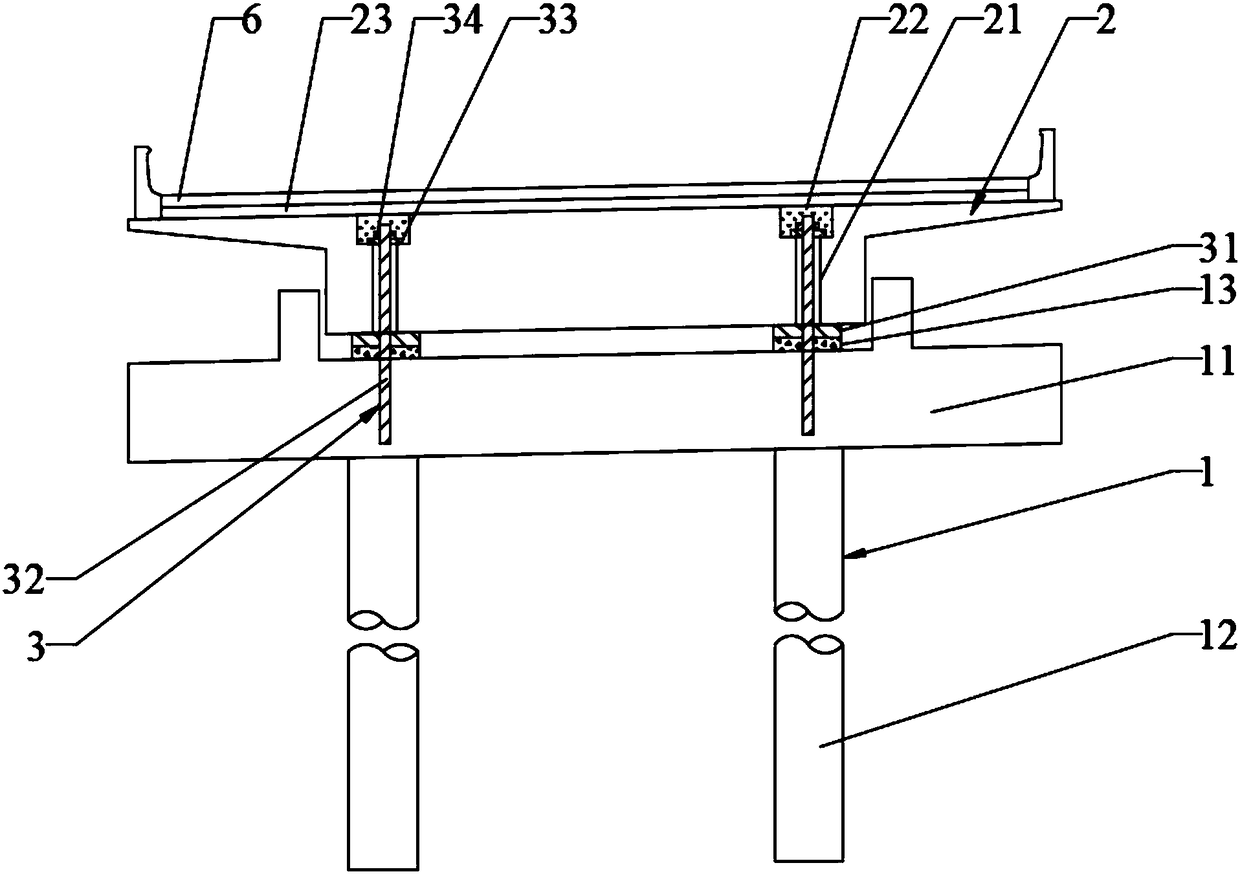

[0054] Please refer to figure 2 As shown, a seamless curved bridge using a semi-rigid integral abutment includes an abutment 1, a main girder 2 and a semi-rigid structure 3 connecting the abutment 1 and the main girder 2, and the abutment 1 It includes a platform cap 11 and a pile foundation 12 arranged under the platform cap 11, the platform cap 11 is provided with a groove opening upward, and the groove is provided with a supporting pad stone 13, and the main beam The lower end of 2 is provided with a protrusion suitable for the groove, and the main beam 2 is arranged on the support pad stone 13 of the groove through the protrusion;

[0055] The semi-rigid structure 3 includes a rubber cushion 31, a steel rod 32, a steel plate 33 and a bolt 34, and the rubber cushion 31 is arranged between the support pad stone 13 and the main beam 2; the steel rod 32 runs through the rubber pad 31 and the support stone 13 and the lower end of the steel rod 32 is inserted into the table ca...

Embodiment 2

[0060] It is the same as other structures of the seamless curved bridge using semi-rigid integral abutment in Embodiment 1, the difference is that the seamless curved bridge using semi-rigid integral abutment also includes a rear wiring system 4, and the rear The wiring system 4 includes a horizontally arranged board 41, a transition board 42, a base layer located below the board 41 and the transition board 42, and a backfill layer 45. One end of the board 41 and the main beam 2 connection, the other end of the strapping plate 41 is connected to one end of the transition plate 42, the other end of the transition plate 42 is connected to the external wiring line surface 5, and the base layer includes roller compacted concrete base layers 43 and A graded crushed stone cushion layer 44 , and the backfill layer 45 is arranged below the graded crushed stone cushion layer 44 .

[0061] A rubber sliding layer 46 is provided between the board 41 and the back wall of the platform cap 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com