Patents

Literature

49results about How to "Engineering quality is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat insulation wall integral pouring material and construction method

InactiveCN101376582AImprove insulation effectEarly benefitsSolid waste managementFiberCrack resistance

The invention discloses an insulation wall body integral-casting material and a construction method thereof. The insulation wall body integral-casting material is characterized in that the ratio of a binder, an insulation aggregate and an additive is 1000:(5-5000):(0-300); the binder is a cement-based binder or a gypsum-based binder; the constitutes of the cement-based binder are 300-1000 parts of cement, 0-200 parts of silica fume, 0-400 parts of fly ash, 0-700 parts of slag powder, 0-300 parts of zeolite powder, 0-200 parts of ash-calcium powder and 0-40 parts of gypsum; the constituent of the gypsum-based binder is 1000 parts of gypsum; and the constituents of the insulation aggregate are 0-100 parts of expanded polystyrene granules, 0-1500 parts of expanded perlite, 0-1500 parts of expanded vermiculite, 0-1500 parts of expanded vitrified microspheres, 0-5000 parts of expanded ceramisite and 0-200 parts of sepiolite fibers. The invention also comprises the construction method. The wall bodies casted by the insulation wall body material have good insulating and thermal performances, higher strength, and good water resistance, crack resistance and permeability resistance performances, as well as good compatibility and good security towards the subsequent decorating process.

Owner:湖南江盛新型建筑材料有限公司

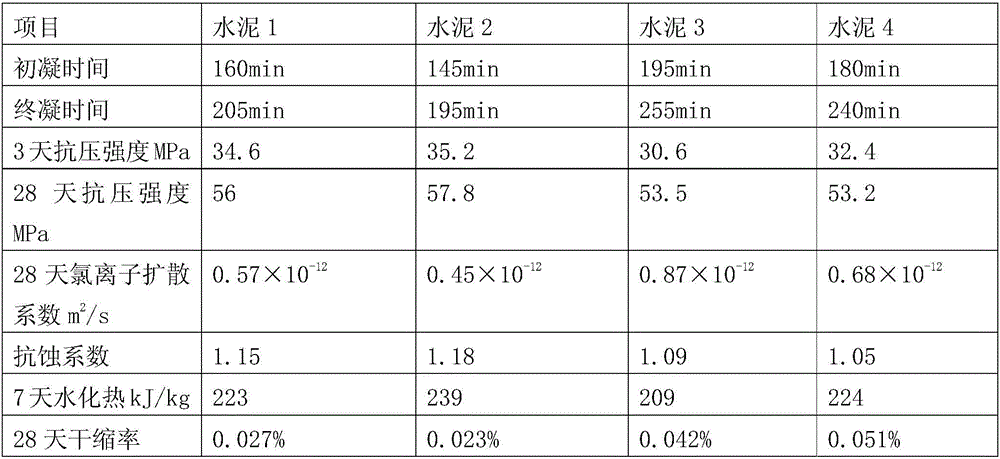

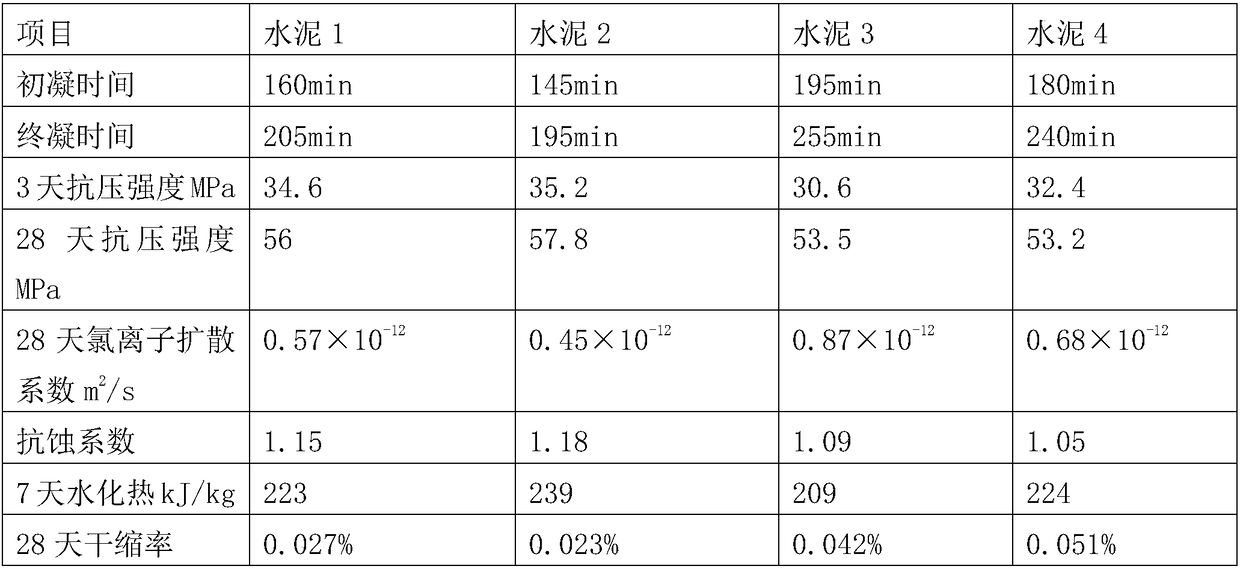

High early strength and high corrosion resistant Portland cement and preparation method thereof

ActiveCN106082724AReduce tricalcium contentExtended service lifeClinker productionMass ratioPortland cement

Belonging to the field of cement production and also relating to the field of building materials, the invention provides a high early strength and high corrosion resistant Portland cement and a preparation method thereof. The high early strength and high corrosion resistant Portland cement is mainly applied to engineering projects in complex marine environments and the west harsh environments. The high early strength and high corrosion resistant Portland cement is characterized by containing, by weight percentage, 60%-90% of a high iron and low calcium cement clinker mineral component, 2%-10% of an auxiliary functional component, 5%-25% of an auxiliary cementitious component, and 3%-7% of industrial gypsum. The high iron and low calcium cement clinker mineral component is mainly prepared from high iron and low calcium Portland cement clinker and high iron and low calcium Q phase cement clinker in a mass ratio of 5-15:1. The cement not only has strong seawater erosion resistance and high early strength, but also has the characteristics of low shrinkage and low hydration heat.

Owner:WUHAN UNIV OF TECH

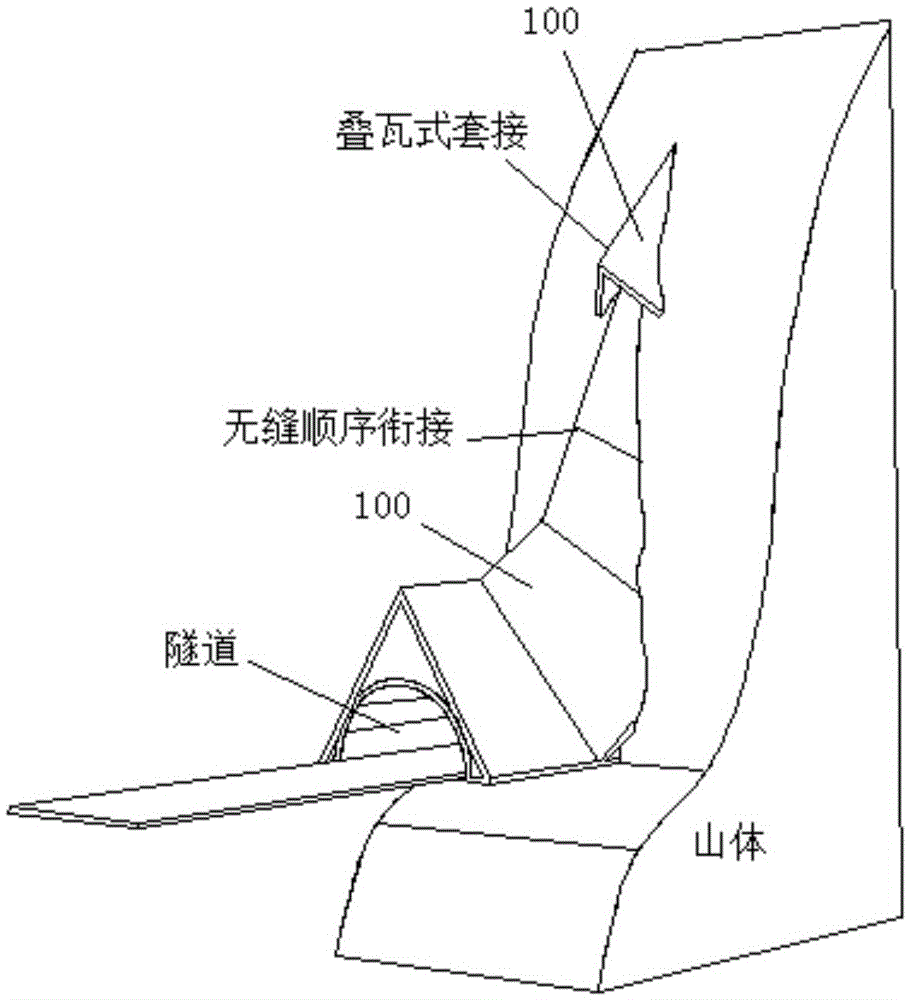

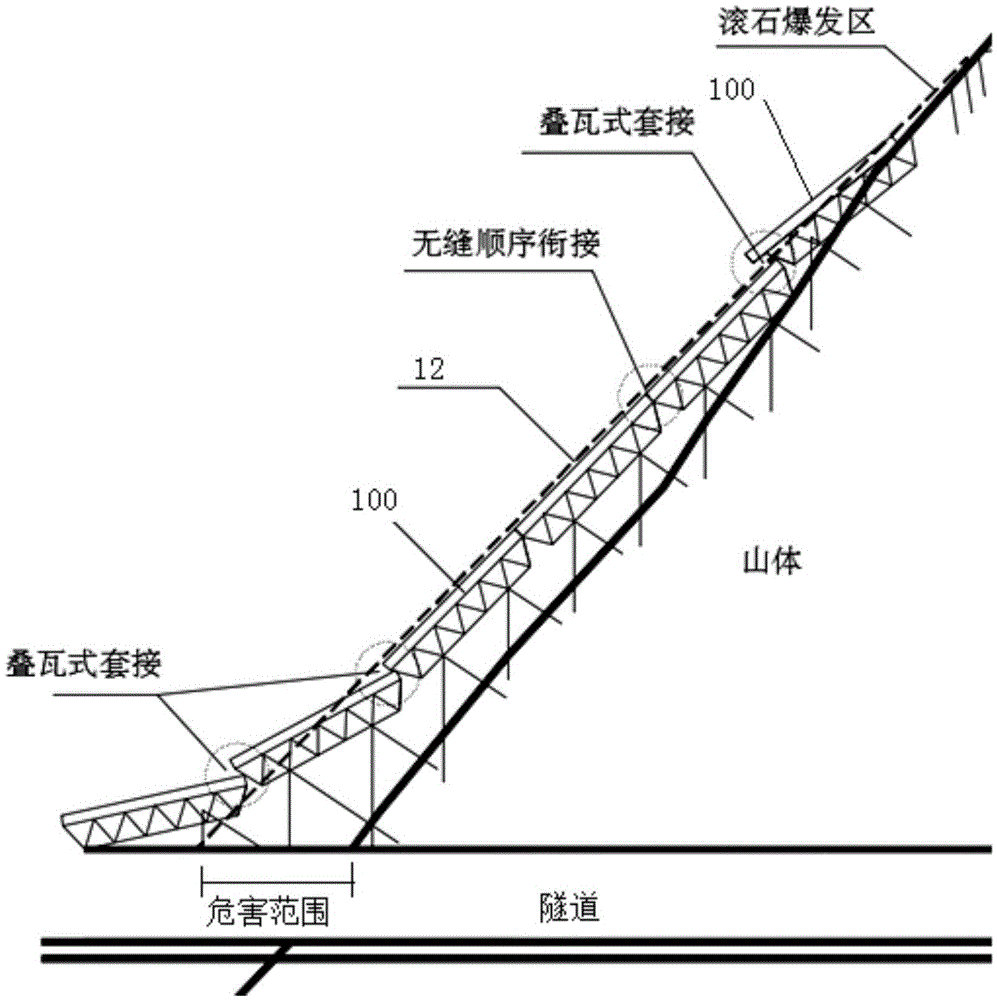

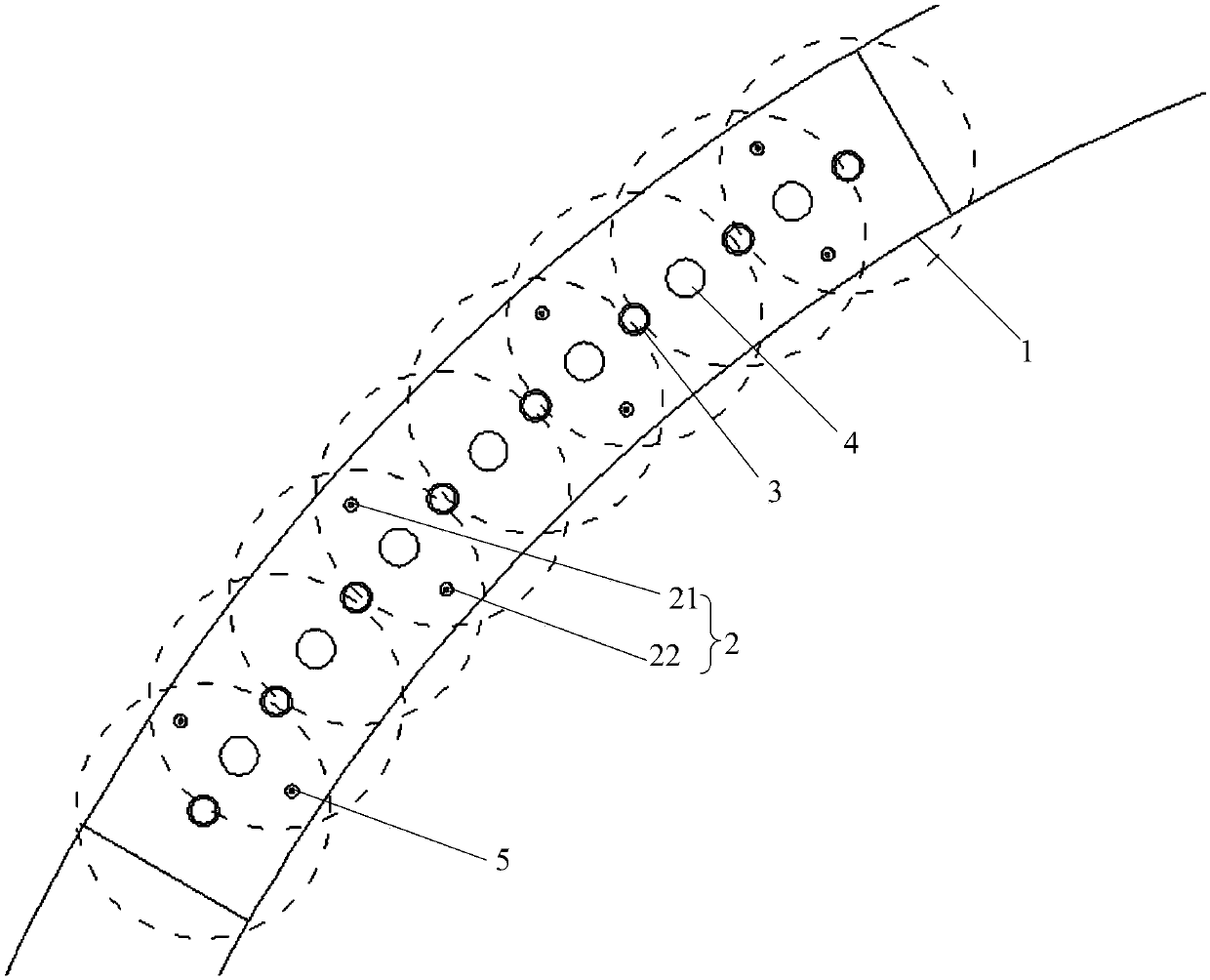

Tunnel portal flexible nose-shaped rolling stone discharging and guiding shed tunnel structure and designing method thereof

The invention belongs to the field of hydraulic engineering and rolling stone prevention and control engineering and relates to a tunnel portal flexible nose-shaped rolling stone discharging and guiding shed tunnel structure and a designing method thereof. The structure comprises multiple lambdoidal prevention and control individuals which are arranged along a slope, every two adjacent prevention and control individuals are in stacked-tile socketed connection or seamless sequential connection, each prevention and control individual comprises two truss structure ceilings which are mounted on a slope energy-consuming damping anchoring base through a supporting structure, and a composite energy-consuming cover plate covers each truss structure ceiling. The designing method aims to determine integral structural size and spatial position of a discharging and guiding shed tunnel and thickness of an energy-consuming damping material of a bearing platform. The tunnel portal flexible nose-shaped rolling stone discharging and guiding shed tunnel structure is simple in structure, unitary in component, standard in size, conducive to factory-scale production and quality control, beneficial to transporting and mounting in alpine canyon areas and good for subsequent maintenance due to modularized structure.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

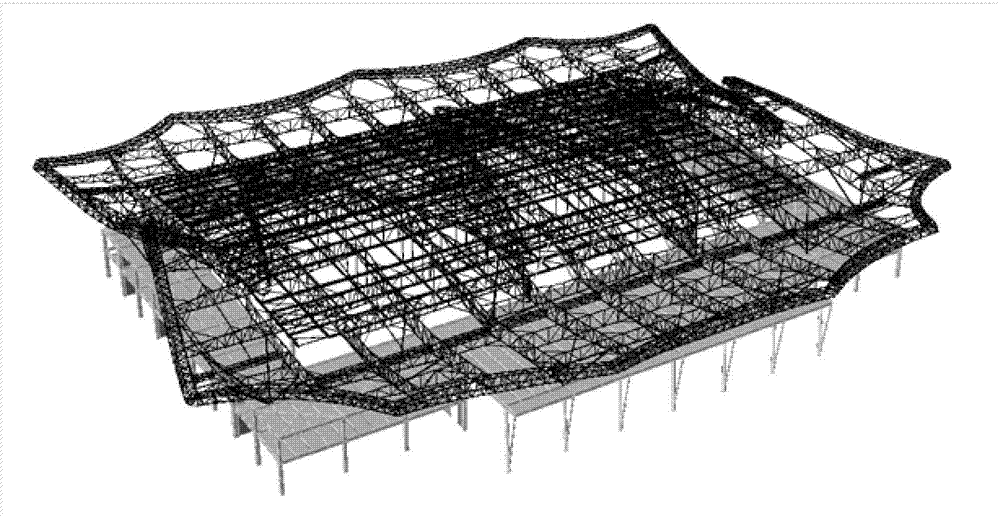

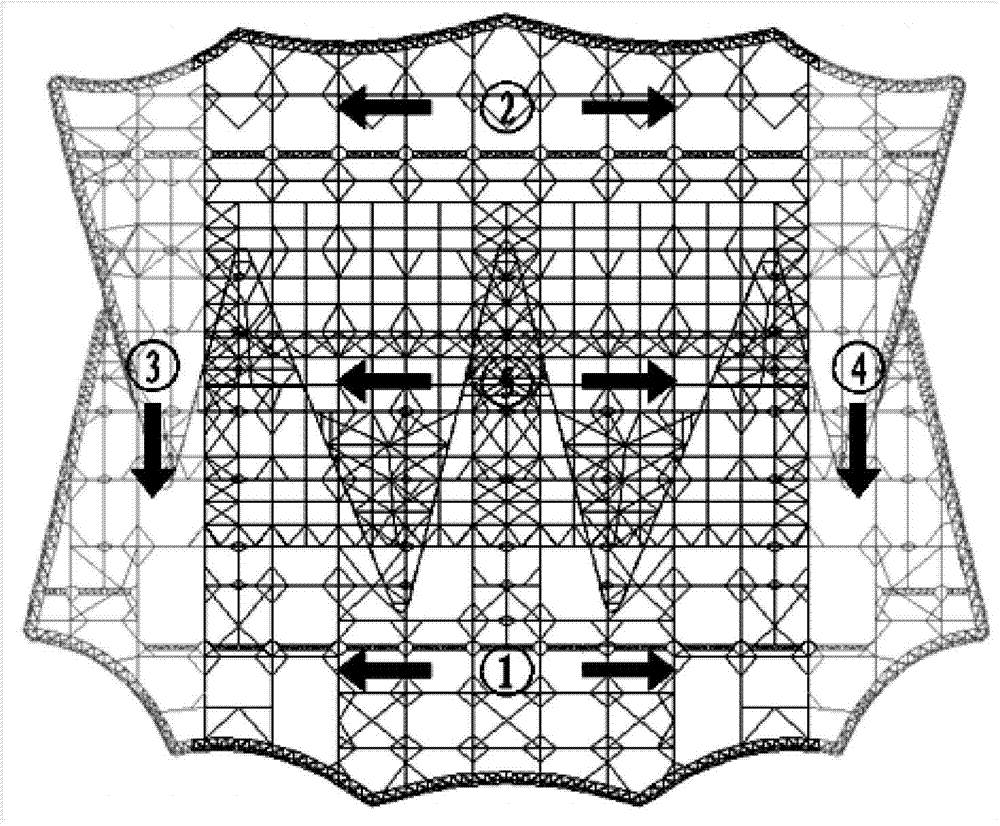

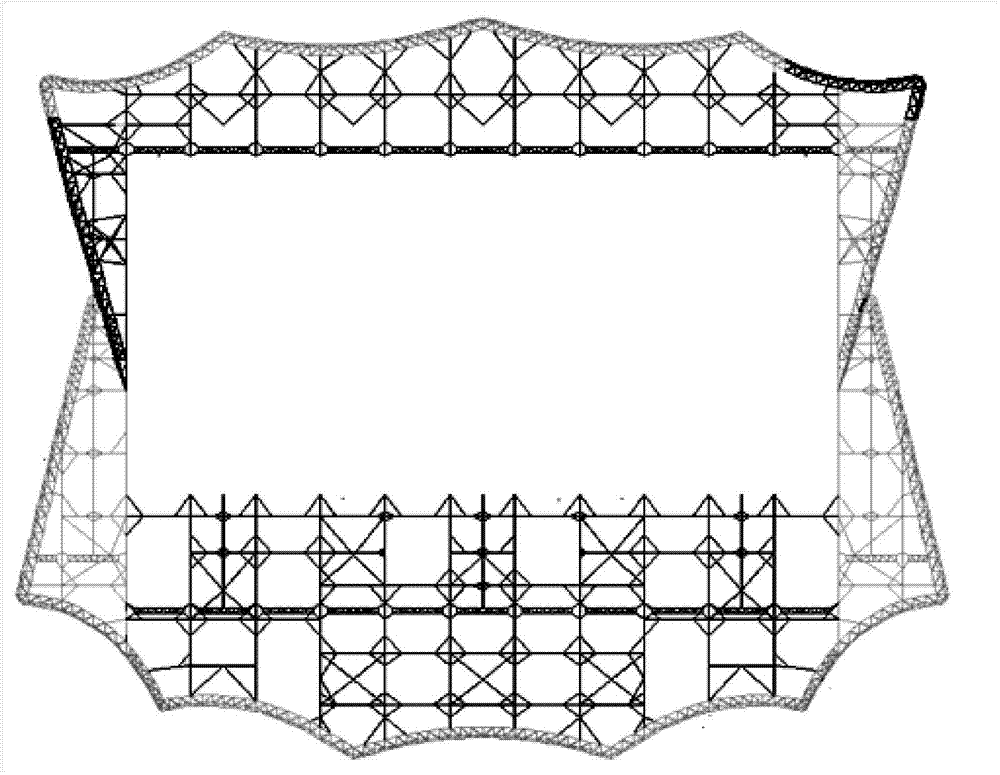

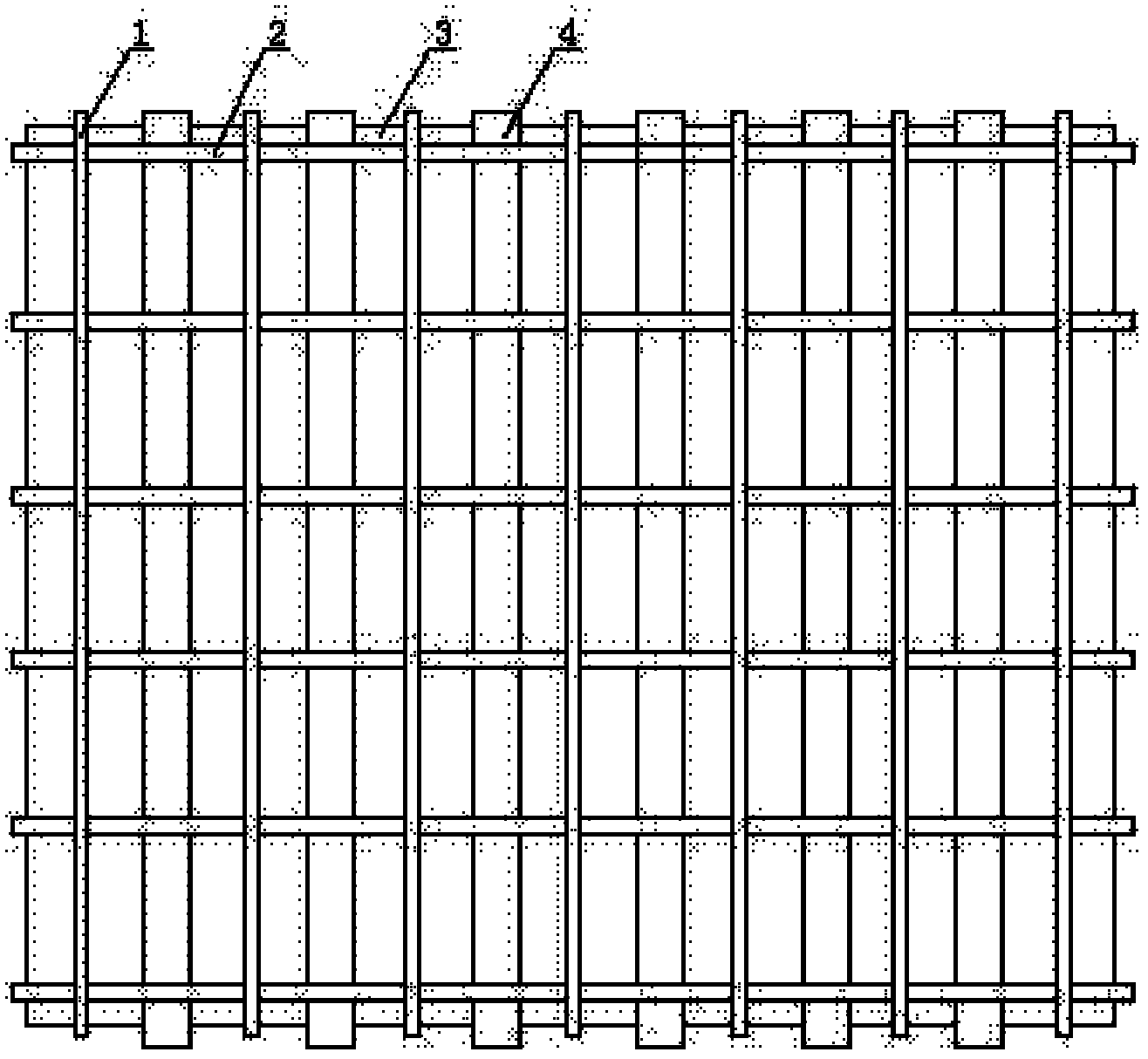

Computer control hydraulic synchronous hoisting construction method for complex space truss structure

ActiveCN103696494AImprove work efficiencyImprove construction accuracyBuilding constructionsControl engineeringHydraulic pressure

The invention relates to a computer control hydraulic synchronous hoisting construction method for a complex space truss structure. According to the method, computer control hydraulic pressure is adopted for synchronously hoisting the combination of an interior roof truss and a lower ceiling platform system. The computer control hydraulic synchronous hoisting construction method mainly comprises the following construction steps: assembling a perpheral roof truss and an interior hoisting truss in turn in an assembling sequence according to an onsite condition and a design demand; wholly hoisting after completely assembling an interior roof structure according to design elevation; welding and closing a perpheral roof, assembling other roofs, and meanwhile, detaching a hoisting device; in a root position for assembling, vertically unloading some temporary jig frame structures adopted in the process of detaching the assembly. The computer control hydraulic synchronous hoisting construction method for the complex space truss structure overcomes the defects of large high-altitude bulk welding quantity, low precision and high safety risk of a steel structure roof and shortens the construction period.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

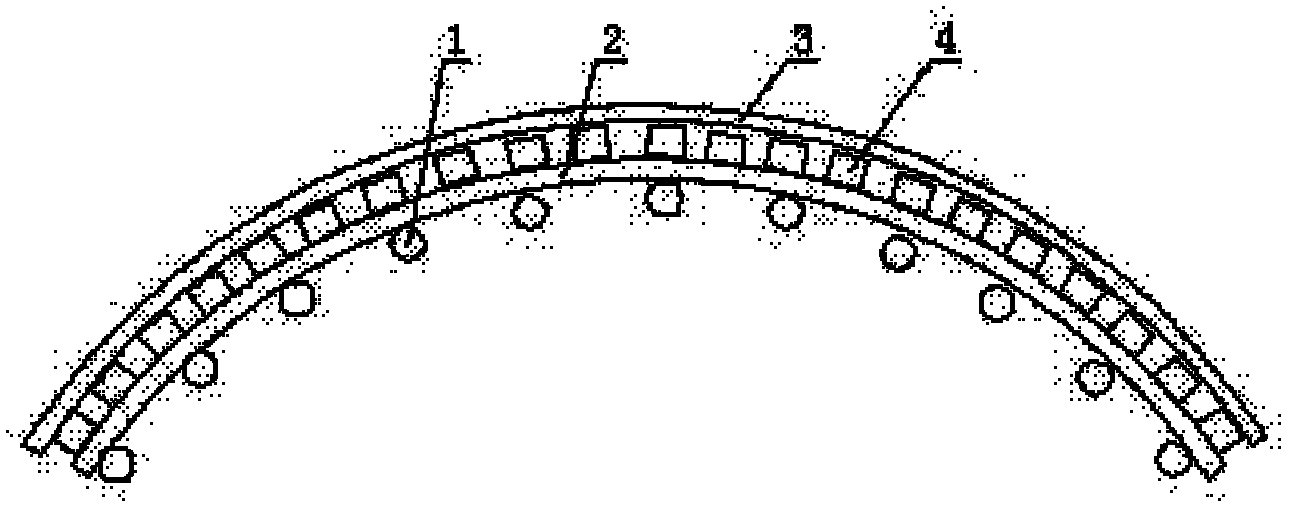

Arc-shaped mold plate for casting arc-shaped shear wall of industrial factory building and manufacture method of arc-shaped mold plate

The invention relates to an arc-shaped mold plate for casting an arc-shaped shear wall of an industrial factory building. The arc-shaped mold plate comprises arc-shaped net frames, battens and an arc-shaped mold plate body, wherein the arc-shaped net frames, which are the same in shape, are fixedly mounted on the arc-shaped mold plate; the battens are vertically and fixedly mounted between the arc-shaped net frames and the arc-shaped mold plate body in the cross direction; and the distance between each two adjacent battens is 300 mm. The invention further provides a manufacture method of the arc-shaped mold plate, which mainly comprises the steps: (1), processing a wood mold plate into the arc-shaped mold plate according to the shape of the arc-shaped shear wall; (2), processing the arc-shaped net frames; (3), fixing the battens in such a manner that the 50 multiplied by 100mm battens are vertically fixed on the arc-shaped net frames and the distance between each two adjacent battens is 300 mm, so that the battens and the arc-shaped net frames form an integral body; and (4), forming the arc-shaped mold plate for casting the arc-shaped shear wall of the industrial factory building. The arc-shaped mold plate has the advantages that the structure is simple; the design is scientific and reasonable; the weight is light; the cost is low; the assembly is convenient; the cost of hoist equipment during mounting is effectively reduced; and the use is safe and reliable.

Owner:MCC TIANGONG GROUP

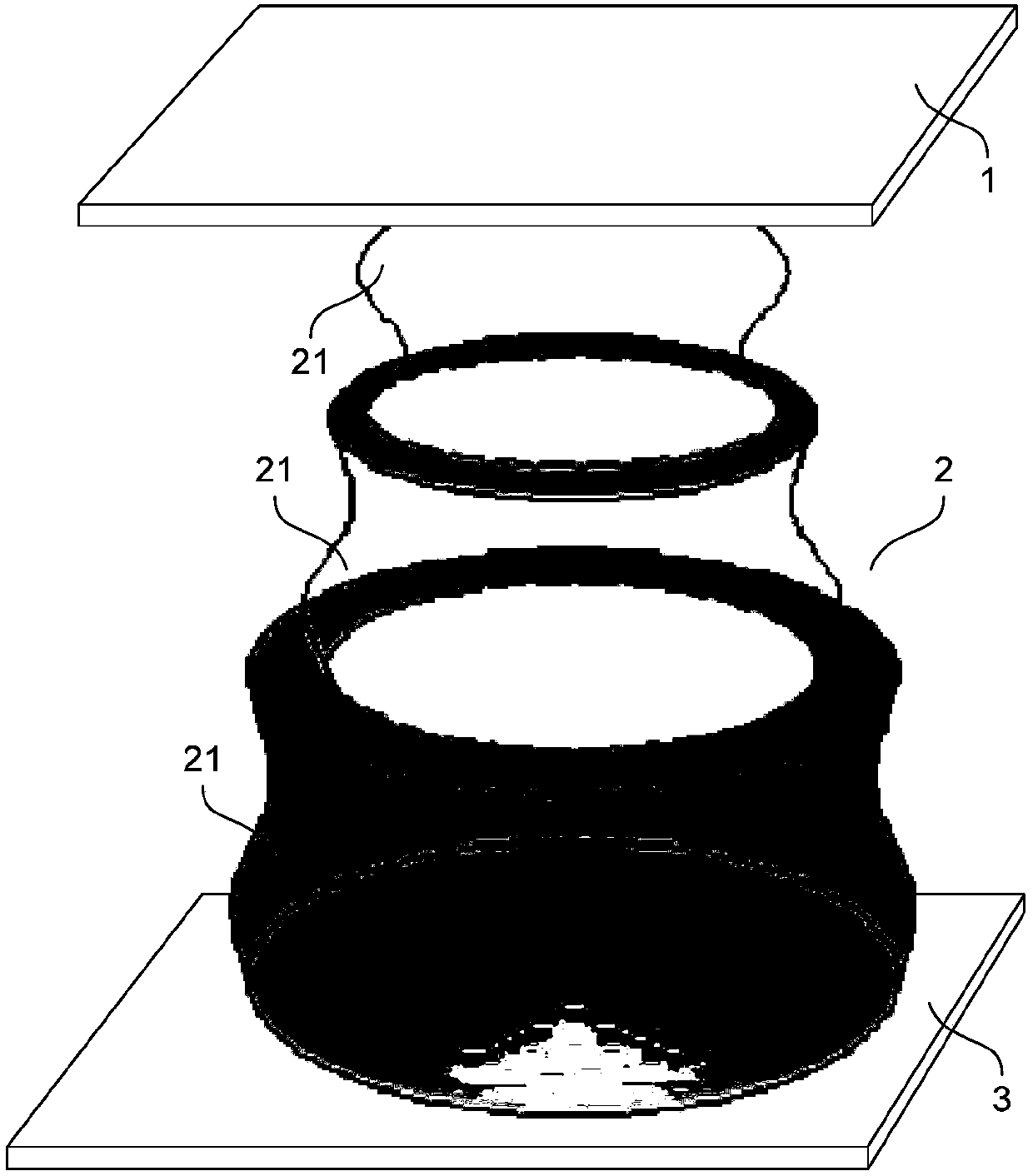

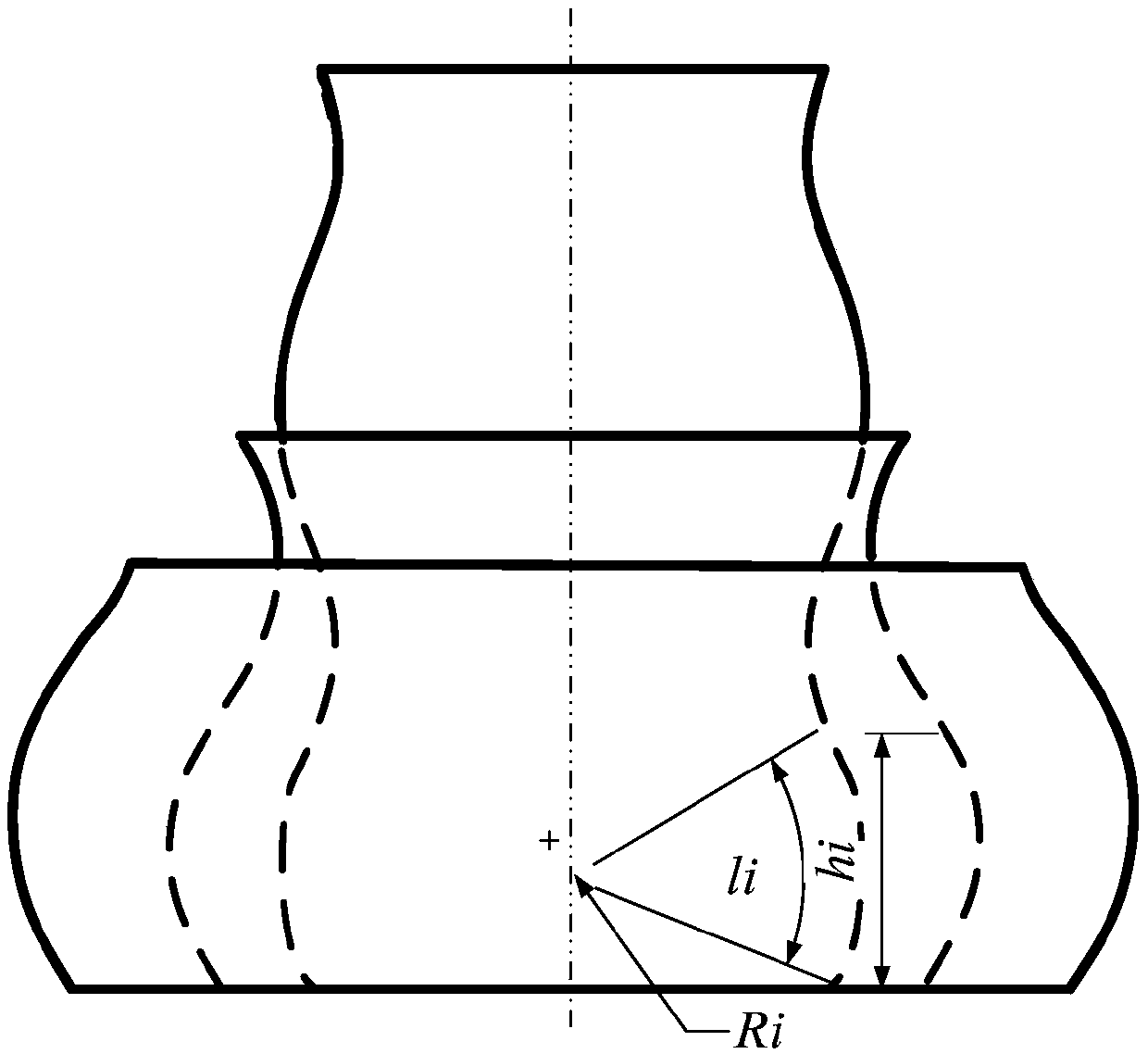

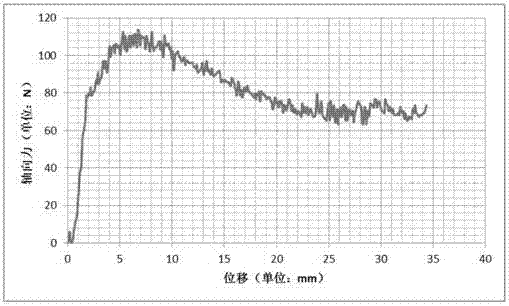

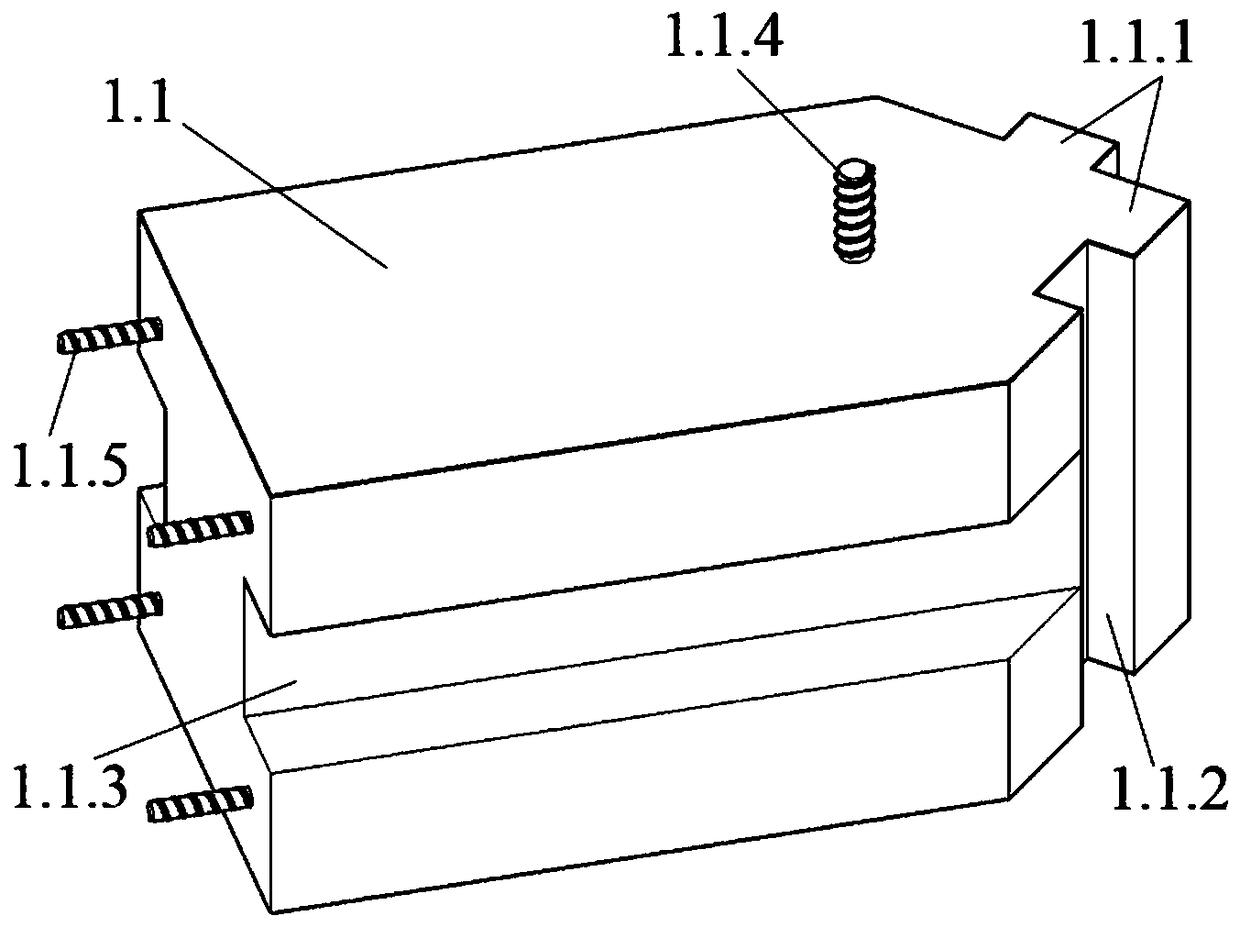

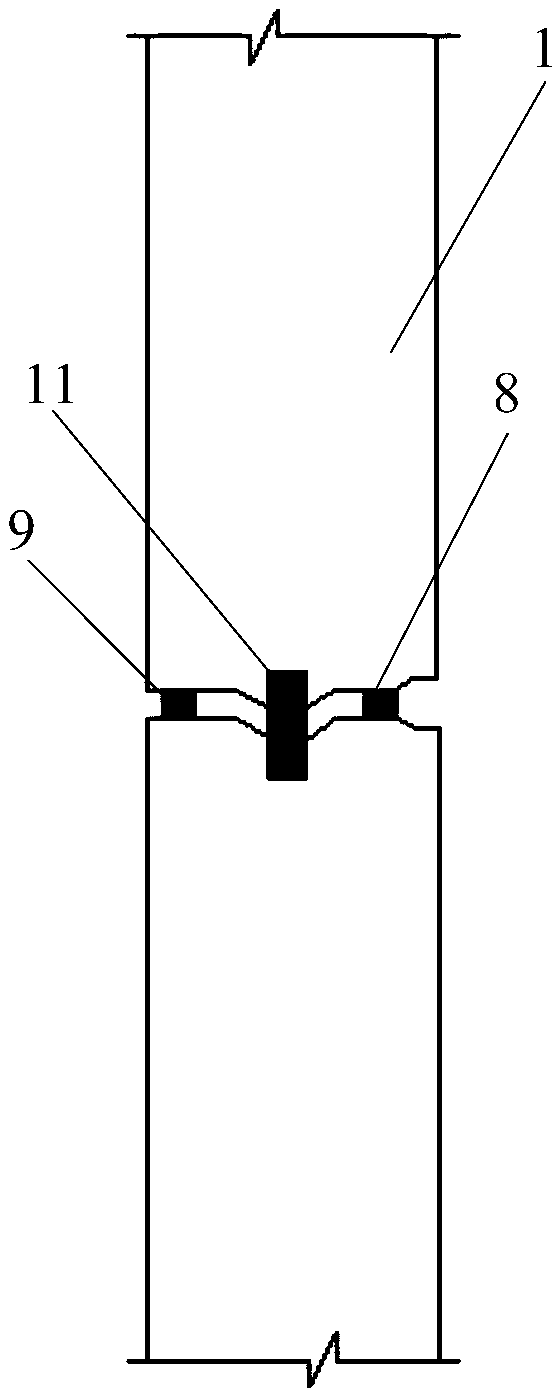

Shrink sleeve damping device, rockfall vibration damping shed tunnel and design method thereof

ActiveCN108035267AImprove vibration damping effectOvercoming "weak" flawsProtective constructionSustainable transportationEngineeringProtection system

The invention discloses a shrink sleeve damping device aiming at solving the problems in the prior art that direction protection of the top of a rockfall protection shed tunnel is limited, or maintenance thereof is complex. The provided shrink sleeve damping device is characterized in that the shrink sleeve damping device comprises an upper bearing plate, a vibration damping sleeve and a lower bearing plate; the lower bottom surface of the upper bearing plate is in static connection with the top of the vibration damping sleeve; the bottom of the vibration damping sleeve is in static connectionwith the upper top face of the lower bearing plate; the vibration damping sleeve is composed of metal shrink tubes of multiple layers in inner and outer coaxial socket; the inner-layer metal shrink tubes are higher than the outer-layer metal shrink tubes; the metal shrink tubes at adjacent layers are closely connected. A rockfall vibration damping shed tunnel, and design methods of the shrink sleeve damping device and the rockfall vibration damping shed tunnel are also provided. The shrink sleeve damping device, rockfall vibration damping shed tunnel and design methods thereof have the advantages that the shrink damping device has an ingenious design, realizes classification of energy consumption and repeated multiple energy dissipation and vibration reduction functions and improves damping efficiency of the device; the rockfall vibration damping shed tunnel can solve the problem that traditional shed tunnel protection systems are not easy to repair and maintain; design methods are simple and practical.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

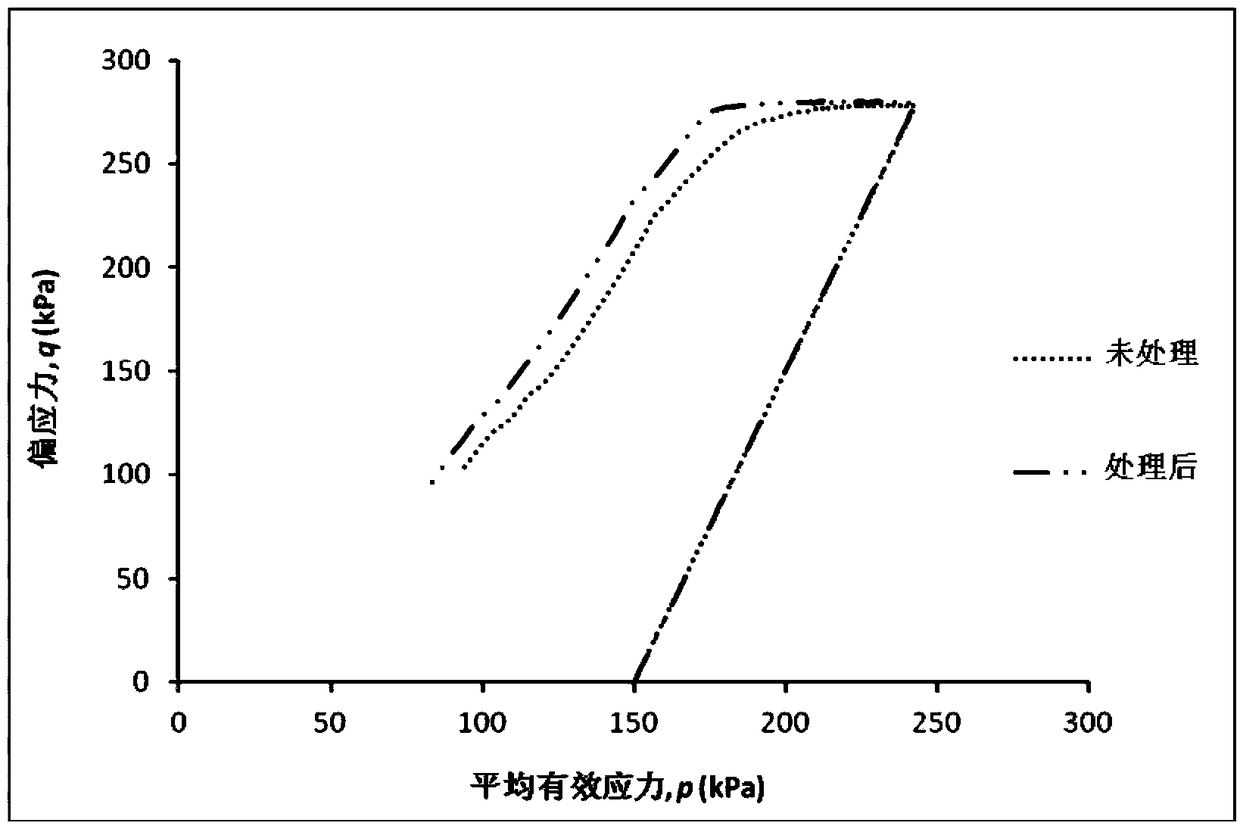

Slope strengthening method based on plant urease reinforcing liquid

The invention discloses a slope strengthening method based on plant urease reinforcing liquid. Grouting treatment is carried out on the interior of a slope through the plant urease reinforcing liquid,and spraying treatment is carried out on the surface layer of the slope. The plant urease reinforcing liquid is prepared from bean flour rich in urease, processing powder and water, and constituentsof the processing powder include urea and calcium salt, wherein the mass ratio of the bean powder to the processing powder is 1:1-1:2, and the mass ratio of the bean powder to the water is 1:10-1:20.The plant urease reinforcing liquid obtained by adding the water into the bean powder and the processing powder is fed into the slope and sprayed onto the surface of the slope, crystallization of calcite is promoted through carbonate generated in a urea hydrolysis reaction and the rising of ph in the reaction process, low-carbon and environment-friendly crystal matter high in strength and adhesivestrength is formed and is filled and adhered among soil particles of the slope, the soil strength can be remarkably improved, the effect that the slope is strengthened is achieved, and the overall stability of the slope is improved.

Owner:HOHAI UNIV

Fully assembled light abutment and construction method thereof

PendingCN108442239AHigh strengthLight weightBridge structural detailsBridge erection/assemblyPre stressAbutment

The invention discloses a fully assembled light abutment. The abutment comprises a pile foundation, a cushion cap, an abutment cap, double baffle blocks, a back wall bracket and a wing wall, the double baffle blocks are connected with the back wall bracket and installed on the cushion cap, the cushion cap, the abutment cap, the double baffle blocks, the back wall bracket and the wing wall are UHPCprefabricated components internally provided with reinforcement cages, the pile foundation is an NC prefabricated component or a UHPC prefabricated component internally provided with reinforcement cages, the cushion cap is connected with the pile foundation through an H-shaped steel plate with a sealing end cover plate, the abutment cap, the wing wall and the back wall bracket are connected withthe cushion cap through H-shaped steel plates with sealing end cover plates, the double baffle blocks are in tensile connection with the abutment cap through prestress reinforcing bars, and the back wall bracket is in tensile connection with the wing wall through prestress reinforcing bars; the construction method of the structure is included. According to the fully assembled light abutment, a fully assembled structure is adopted, the abutment has the advantages of being fast in construction speed, simple in process, easy to control in engineering project quality, less in occupation space of construction sites and the like, and the existing problem of slow construction process, the quality problem brought by hydration heat when large volume concrete construction is conducted, the problemsof large occupation space and environmental pollution and the like of traditional abutments can be effectively solved.

Owner:XIANGTAN UNIV

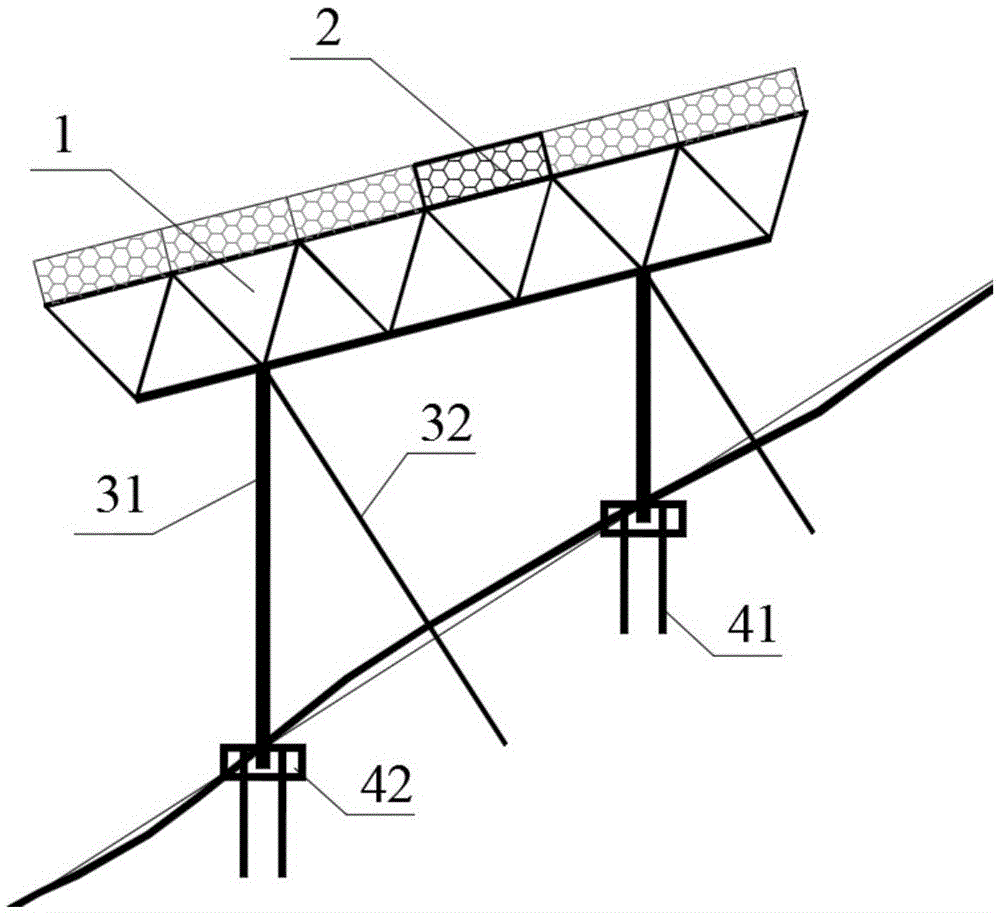

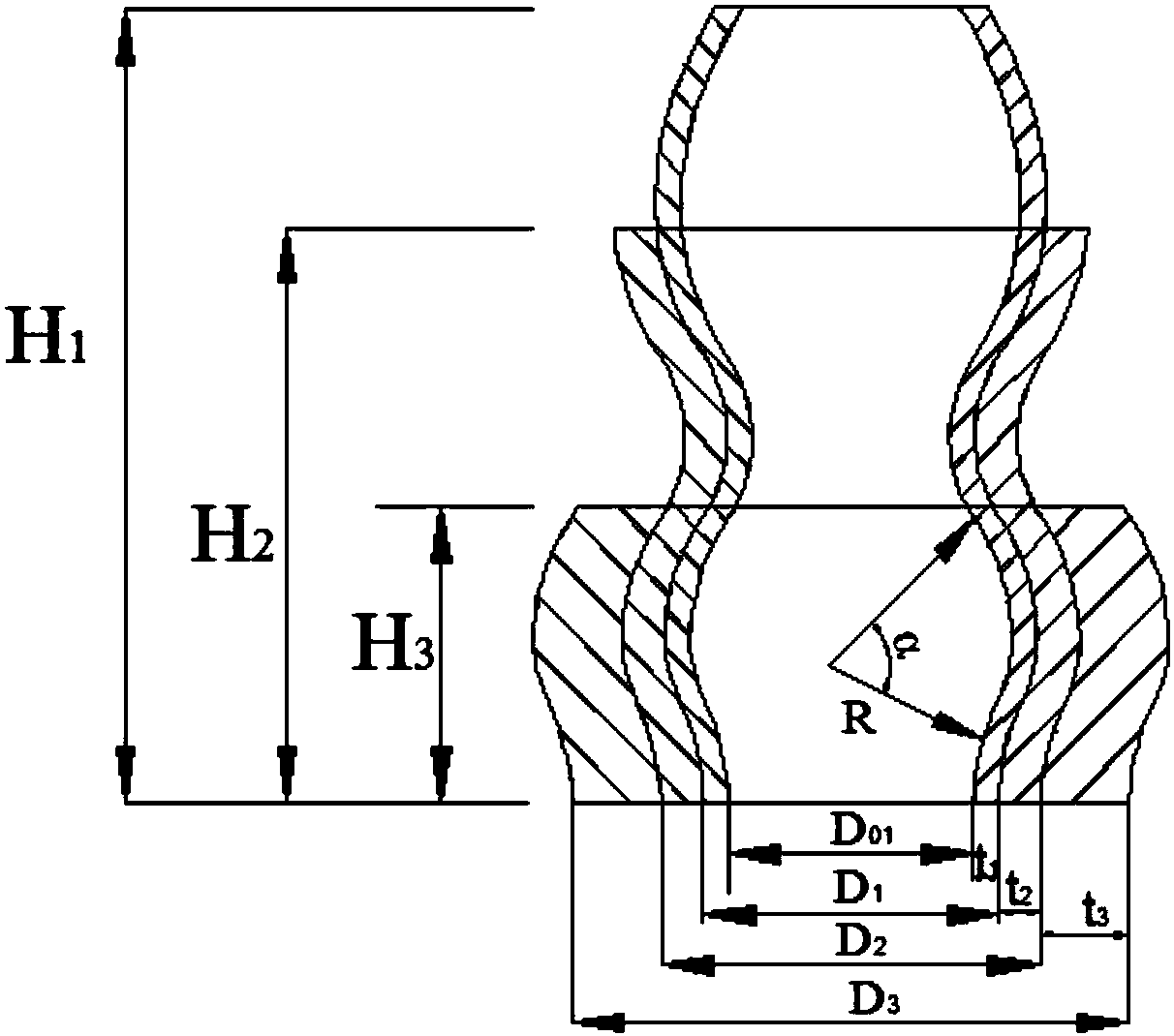

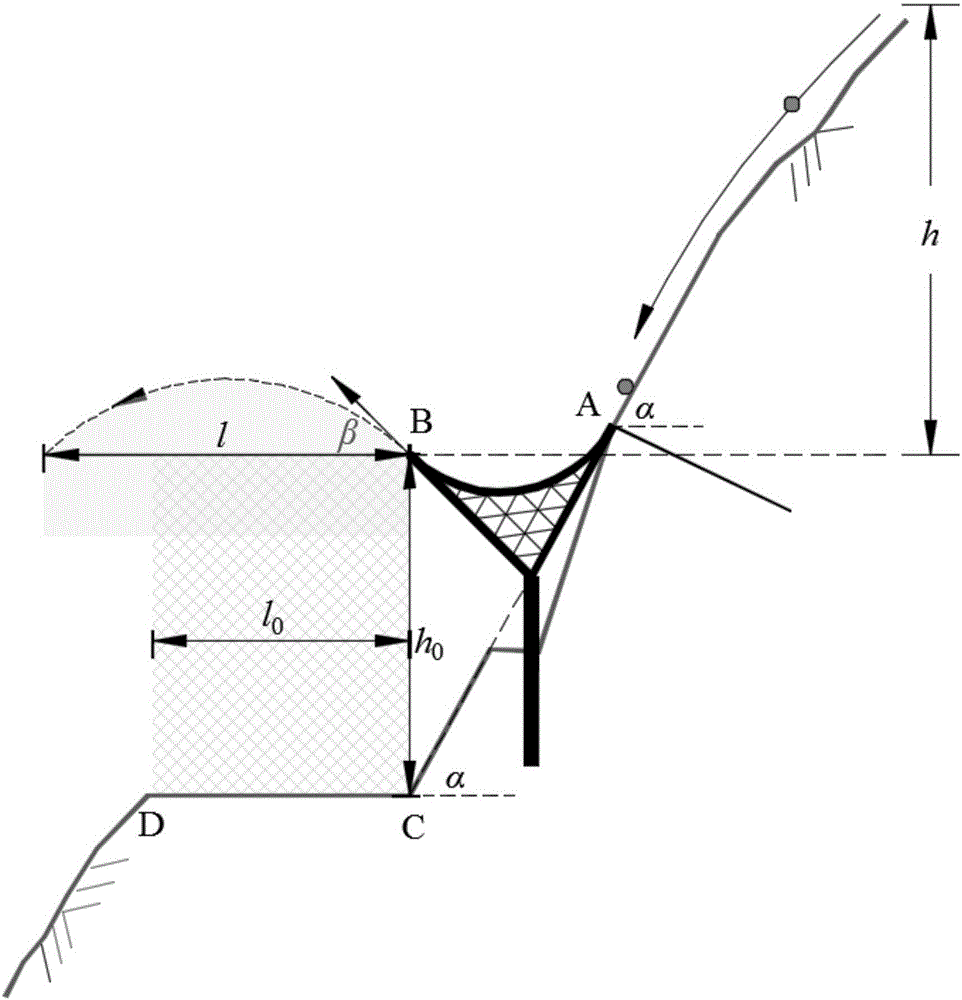

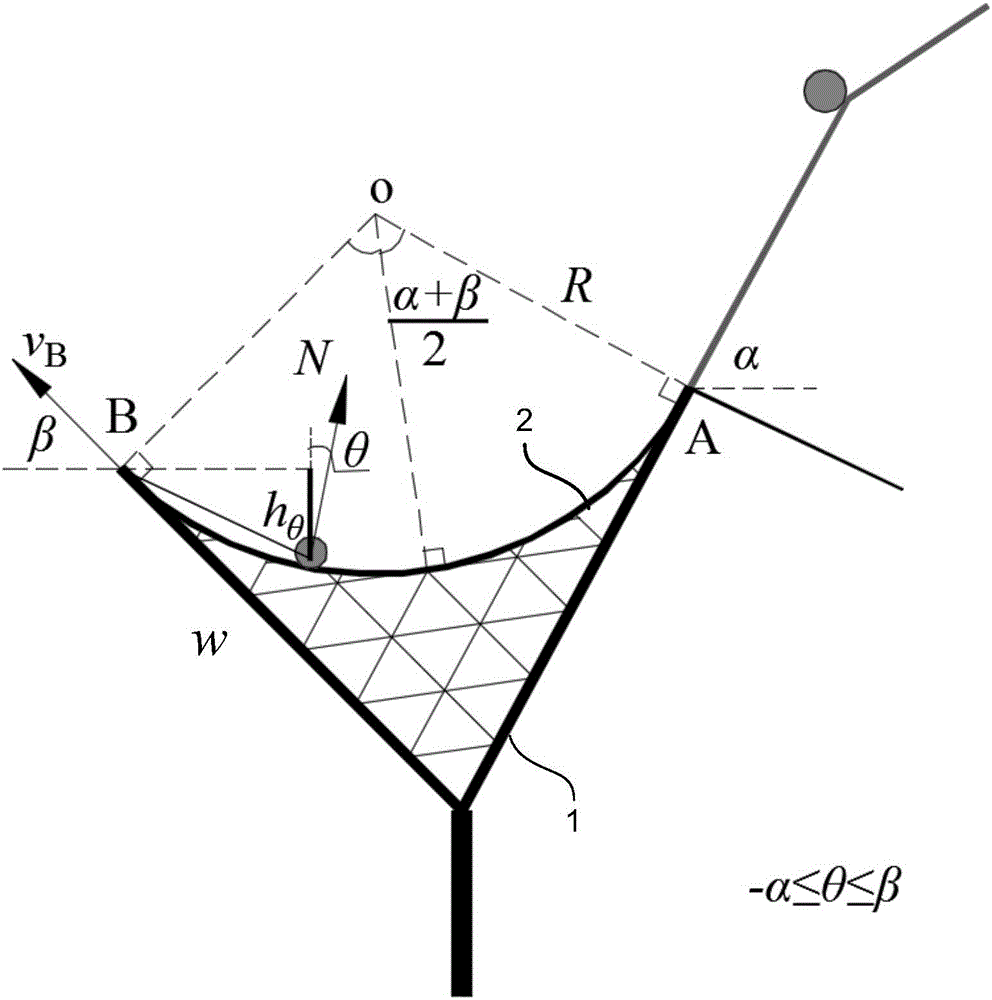

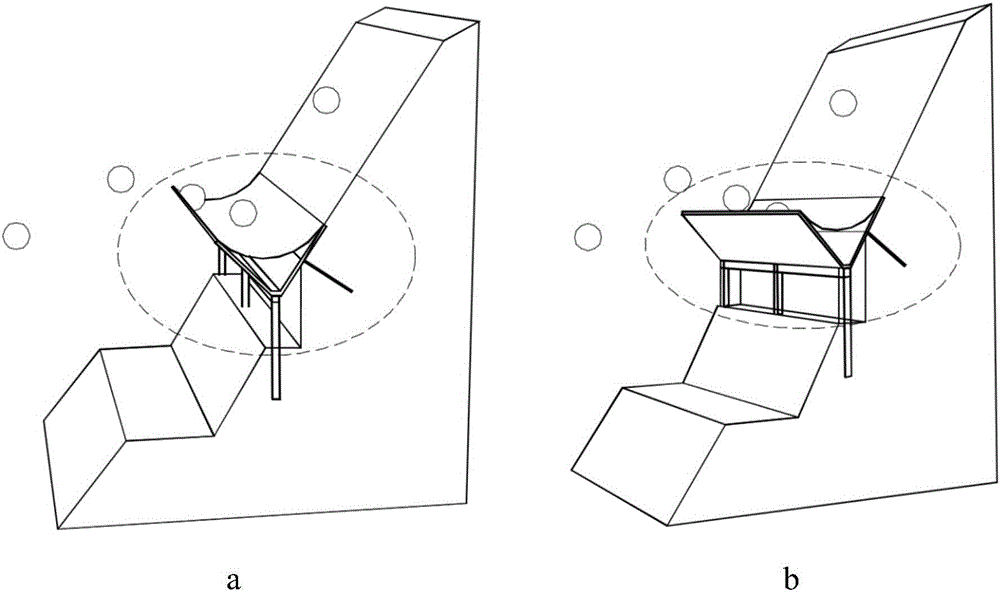

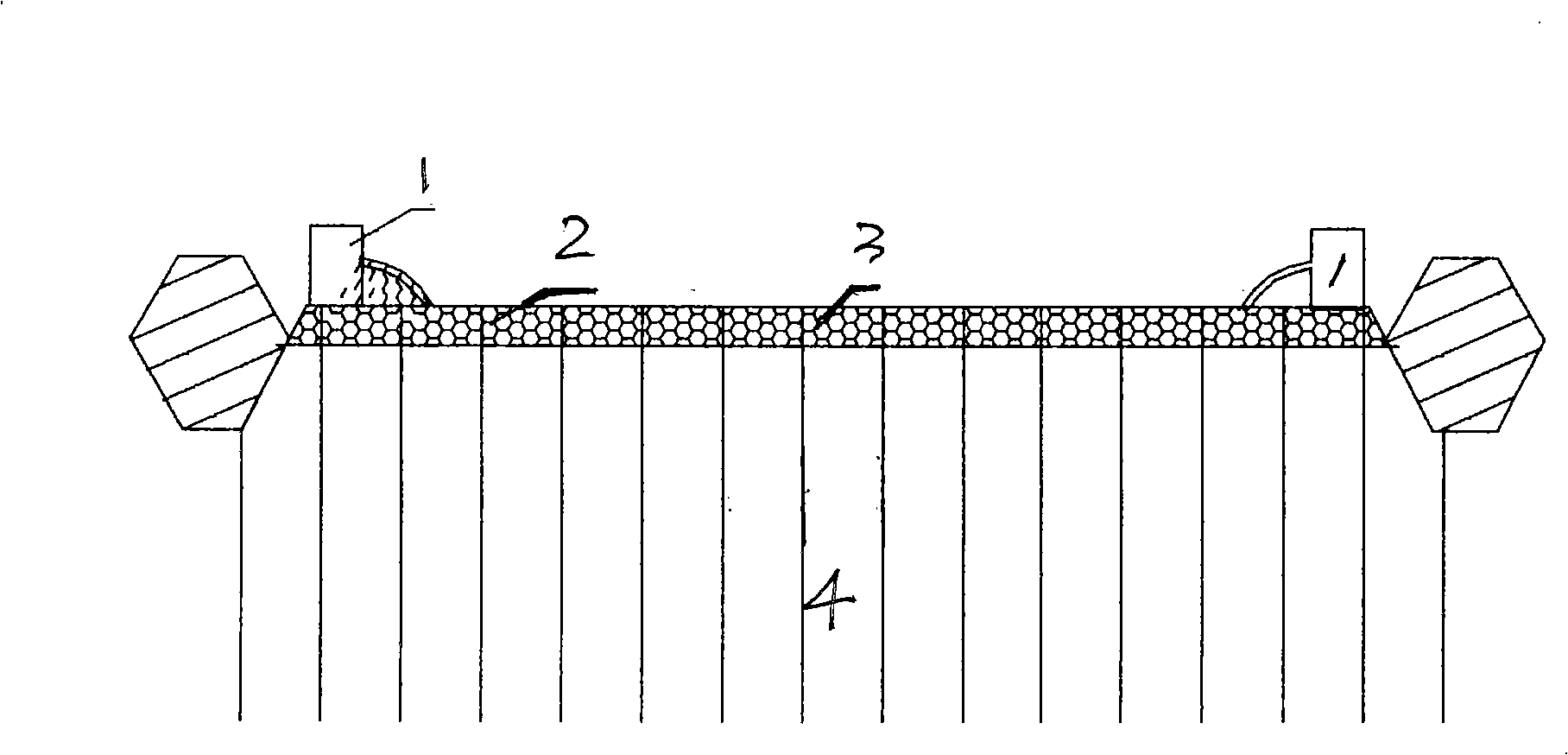

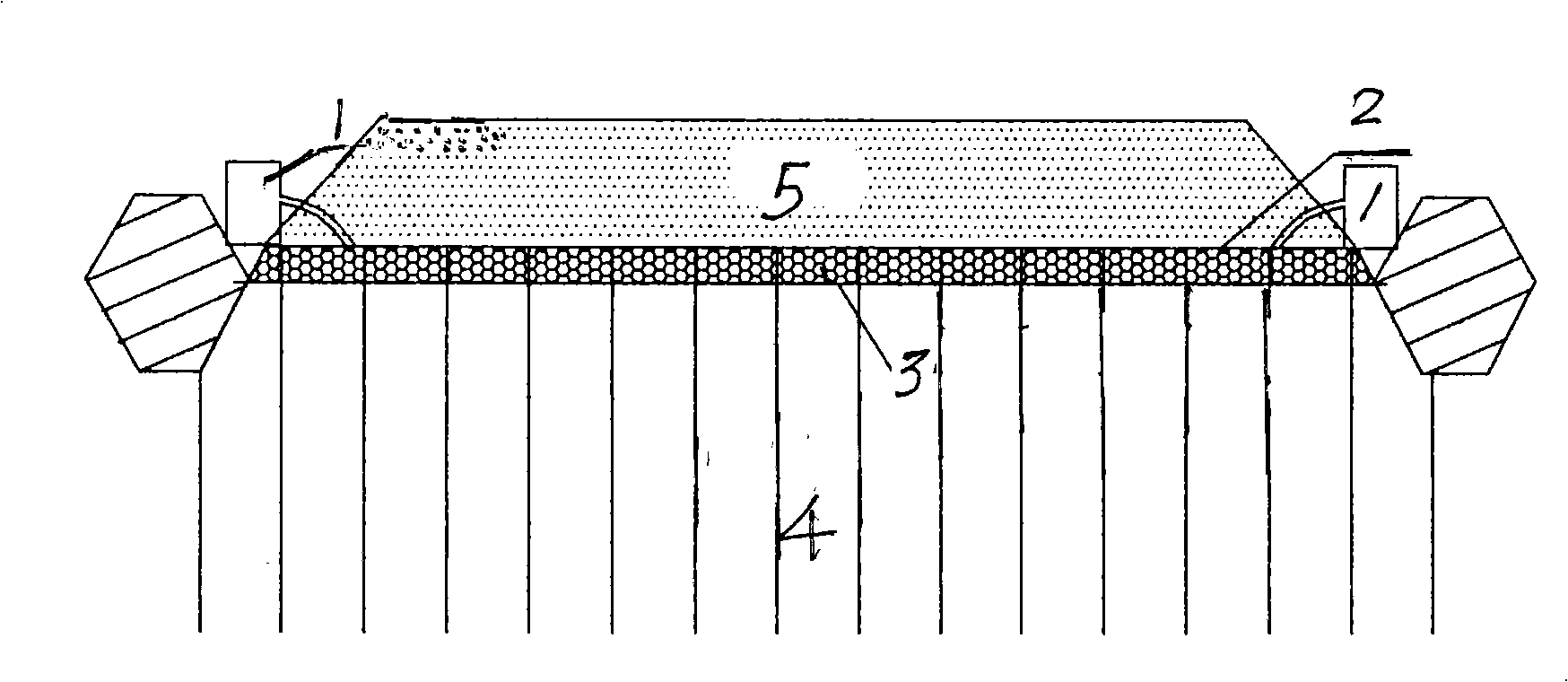

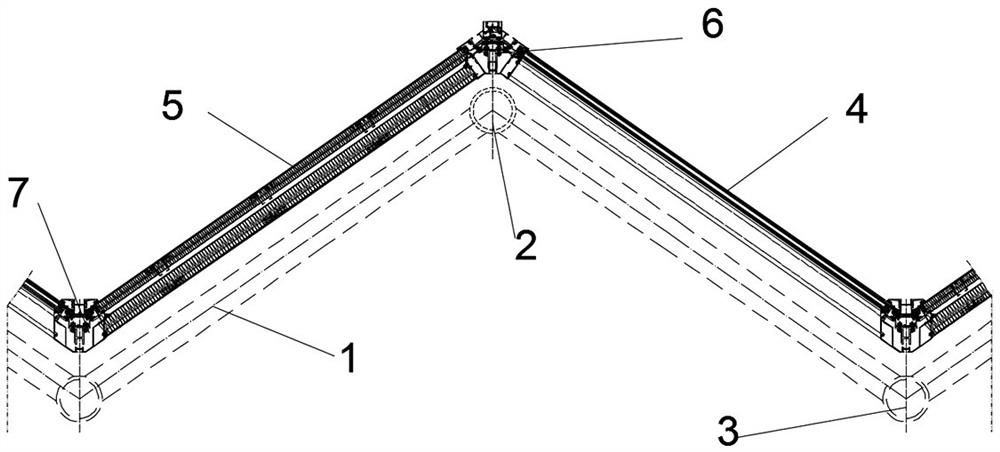

Shed tunnel and shed tunnel design method

ActiveCN106400708ASimple structureNot easy to fixProtective constructionClimate change adaptationSubgradeCantilever

The invention provides a shed tunnel structural body. By adoption of the shed tunnel structural body, the defects that the control effect of existing wall type, arch type, cantilever type and column type shed tunnel structures or other shed tunnel structures on high-speed and high-impact rolling stones breaking out in large-scale and grouped modes is limited, the construction cost is high, and the applicability is poor are solved. A shed tunnel is arranged between a roadbed and a mountain slope in a mountainous area, and comprises a Y-shaped frame beam. The top of the Y-shaped frame beam is connected with a downward-concave arc-shaped cover plate. The fixed side edge of the cover plate is tangent to the mountain slope, and the included angle beta between the tangent line of the top end of the free side edge of the cover plate and the horizontal plane is smaller than or equal to 45 degrees. The cover plate of the shed tunnel is of a sandwich structure which is formed by filling the space between an upper skin plate and a lower skin plate with energy dissipating materials. The invention further provides a shed tunnel design method. The shed tunnel design method is used for designing the curvature radius value R of the cover plate, the burial depth value Lp of a structural stand column of a grouted steel pipe pile of the shed tunnel, and the anchor depth values Lb of the side edges of the cover plate of the shed tunnel. According to the shed tunnel, a novel skid-jumping self-throwing removal and guide technical concept is adopted, and the shed tunnel has advantages on the aspect of preventing impact damage of high-altitude rolling stones on the slope to a road. The shed tunnel is simple in structure and high in environment adaptability.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

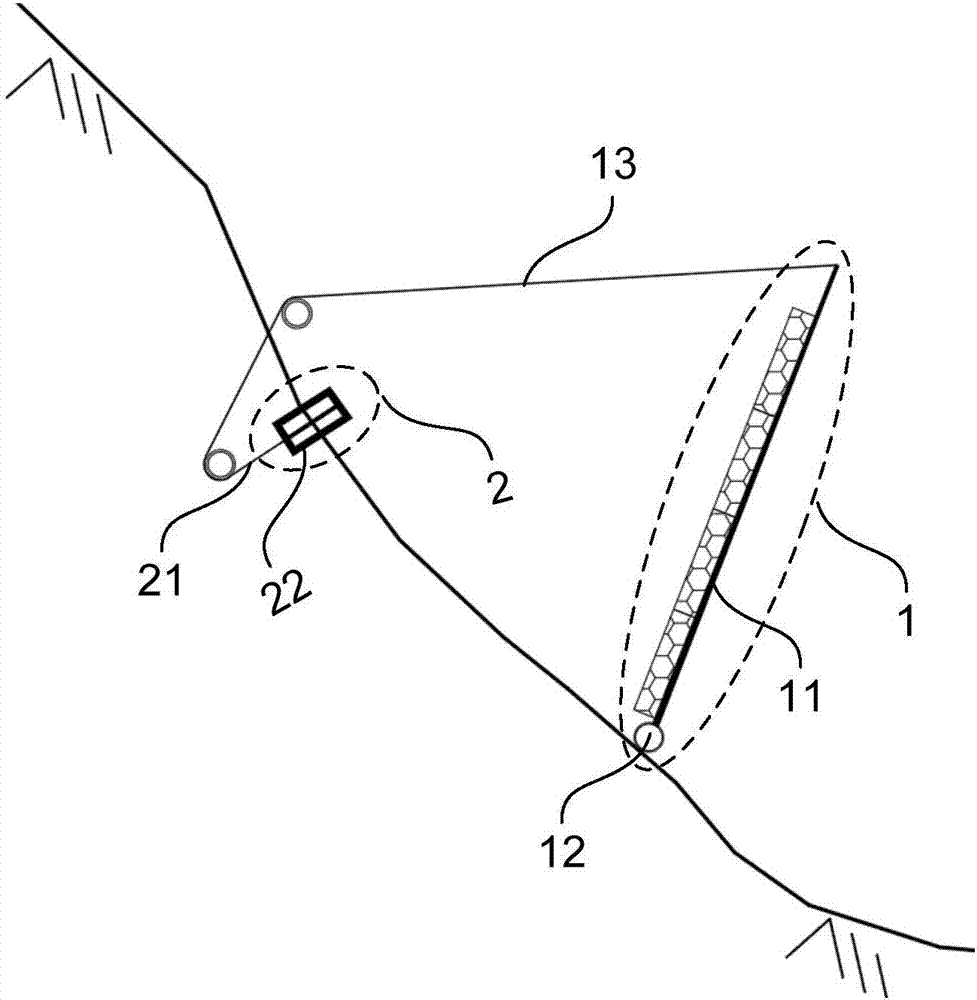

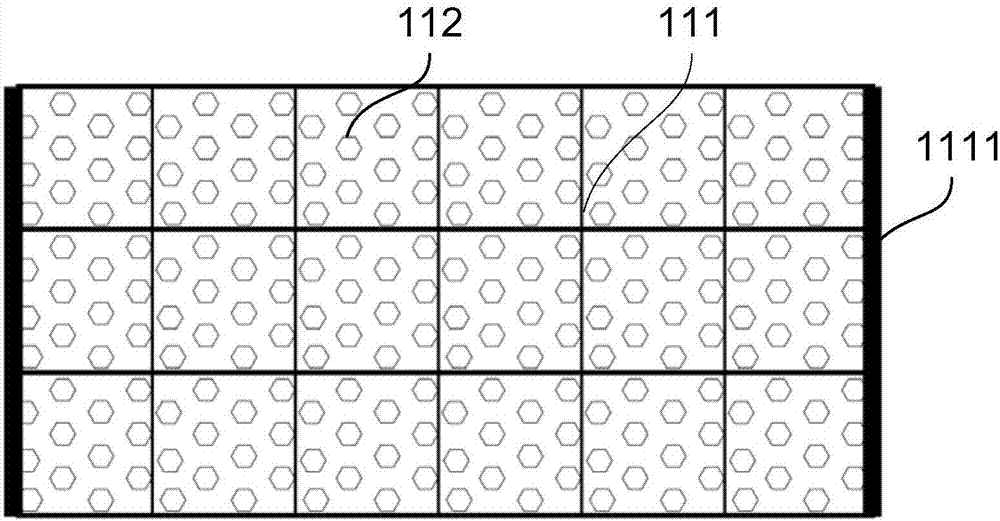

Energy consumption type rolling stone protection system and energy consumption type rolling stone protection system design method

ActiveCN107326817AImprove energy efficiencyImprove stabilityProtective constructionControl engineeringProcess engineering

The invention discloses an energy consumption type protection system. The product is arranged on the slope surface of a massif where rolling stone happens. The energy consumption type protection system comprises two levels of energy consumption structures. The first-level energy consumption structure is an energy consumption plate device, and the second-level energy consumption structure is an energy consumption piston device. The energy consumption plate device comprises an energy consumption panel facing the slope aspect, the energy consumption panel is fixed to a rolling stone impact area through a hinge frame, and the energy consumption panel is formed in the manner that a metal grid frame is filled with energy consumption material block single bodies. The energy consumption panel is connected with a piston rod of the energy consumption piston device through an inhaul cable. A piston air cylinder of the energy consumption piston device is fixed to the non-rolling-stone impact area, and the piston air cylinder is provided with a vent valve. According to the system, different energy consumption principles are comprehensively adopted for acting, and the overall energy consumption efficiency is high. The invention further provides an energy consumption type protection system design method. In cooperation with the design method, a standard part can be adopted in the system for designing and machining, the field construction speed is high, the project quality is easy to control, the energy consumption type protection system and the energy consumption type protection system design method can be applied to alpine and gorge regions where construction is hard through a traditional structure, and rescue and relief work is convenient.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

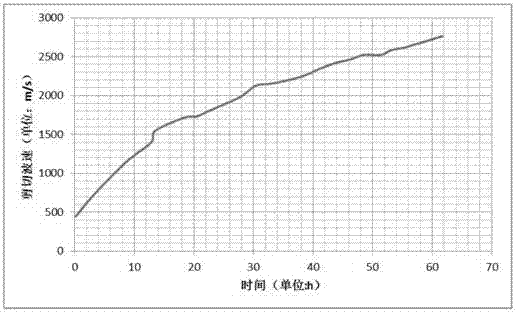

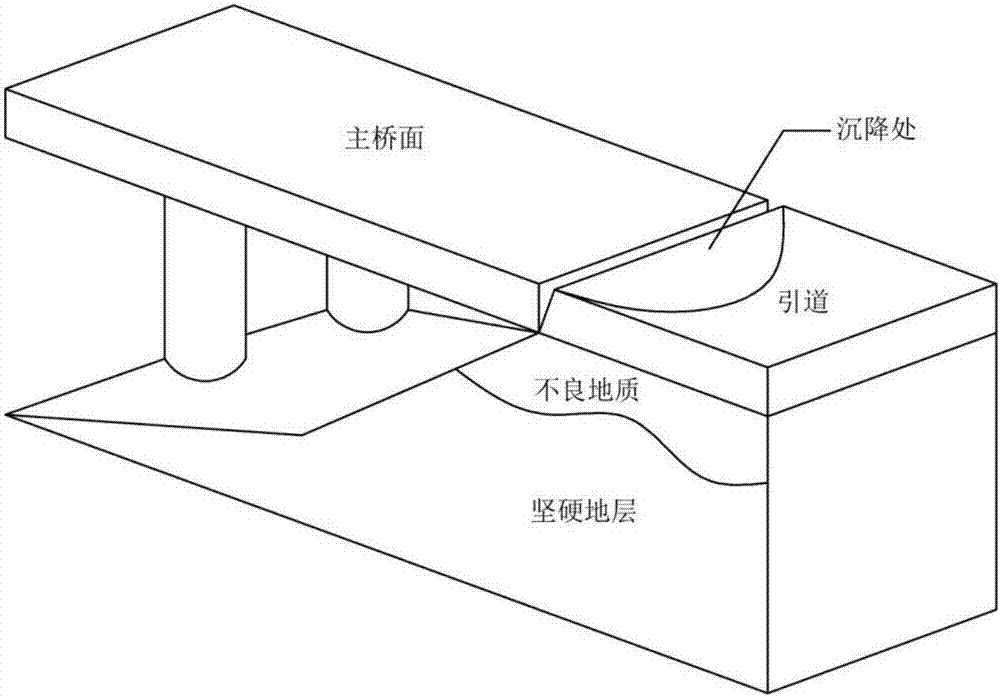

Method for preventing and treating bridge abutment trip by using microorganism consolidation liquid and microorganism consolidation liquid

The invention discloses a method for preventing and treating bridge abutment trip by using microorganism consolidation liquid and the microorganism consolidation liquid. Microbial flora powder, treatment powder and water are adopted; the microbial flora powder is obtained by drying a bacterial enzyme solution; the treatment powder is obtained by drying inorganic cementing liquid treatment liquid;the bacterial enzyme solution is obtained by adding aerobic bacterial liquid subjected to enrichment culture into a buffer solution and performing ultrasonic crushing; the mass ratio of the microbialflora powder to the treatment powder is (1: 10) to (1: 20); and the mass of the water is 5 to 10 times that of the treatment powder. The method comprises the following steps: delivering the microbialflora powder to the site, mixing and stirring the microbial flora powder with the treatment powder, and adding the water to obtain the microorganism consolidation liquid; and performing consolidationtreatment on bridge abutment soil and bridge back soil for multiple times by using the microorganism consolidation liquid. According to the method, by use of cementation generated by microorganism consolidation, the strength and the rigidity of backfilling soil of the bridge back are greatly improved, so that non-uniform settling is avoided, and occurrence of the bridge abutment trip can be effectively prevented.

Owner:HOHAI UNIV

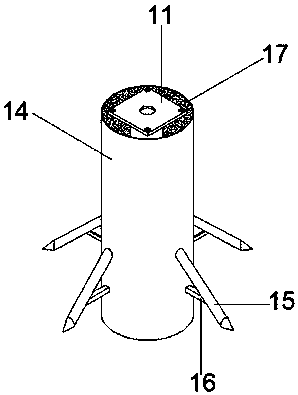

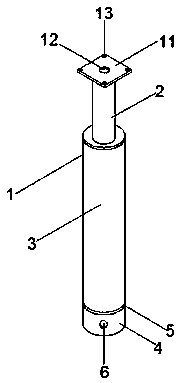

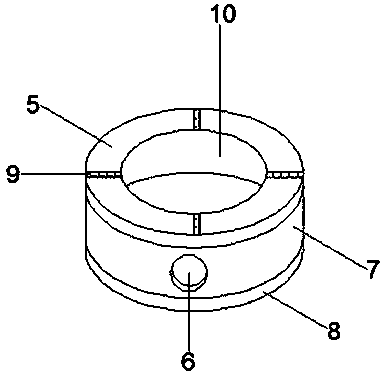

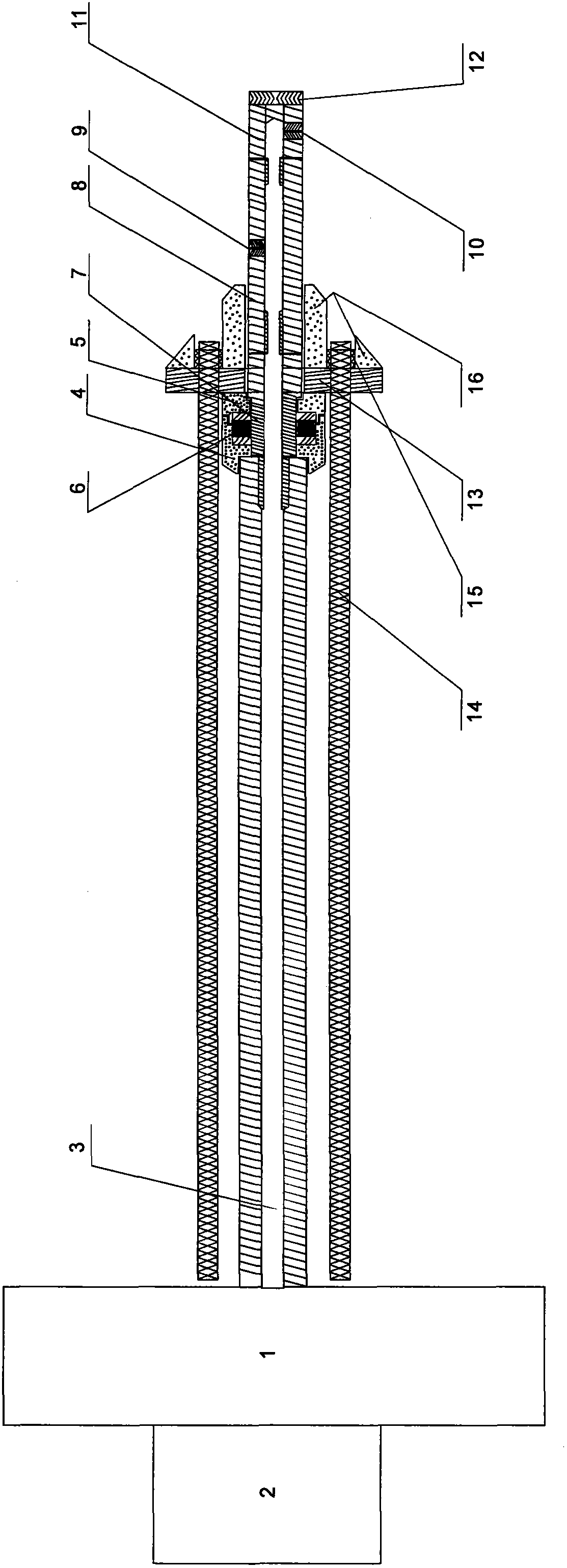

Drill-buried type prefabricated pipe pile for electric transmission line

InactiveCN110241813AReduce earthwork volumeLess foundation excavationBulkheads/pilesAcoustic transmission lineTransmission line

The invention relates to a drill-buried type prefabricated pipe pile for an electric transmission line. The drill-buried type prefabricated pipe pile comprises an internal flow-guiding component, a flow-guiding steel pipe, a prefabricated miniature pipe pile, a grouting head, a grouting head top plate, a grouting hole, a grouting steel pipe, a grouting head bottom plate, reinforcing ribs, an open hole, a top plate, a pore, bolt holes, an external positioning nesting component, four fork feet, angle steel and mortar, the internal flow-guiding component and the external positioning nesting component are connected through the grouted mortar, the internal flow-guiding component comprises the flow-guiding steel pipe, the prefabricated miniature pipe pile and the grouting head, the reinforcing ribs are welded into the grouting steel pipe, the open hole is formed in the grouting steel pipe, the top plate is welded to the top of the flow-guiding steel pipe and provided with the pore, the bolt holes are formed in the four corners of the top plate, and the four fork feet are welded to the outer wall of the external positioning nesting component through the angle steel at equal distances. The drill-buried type prefabricated pipe pile has the advantages of small environmental influence, high construction efficiency, reliable quality and low cost, and is suitable for being used and promoted.

Owner:STATE GRID CORP OF CHINA +1

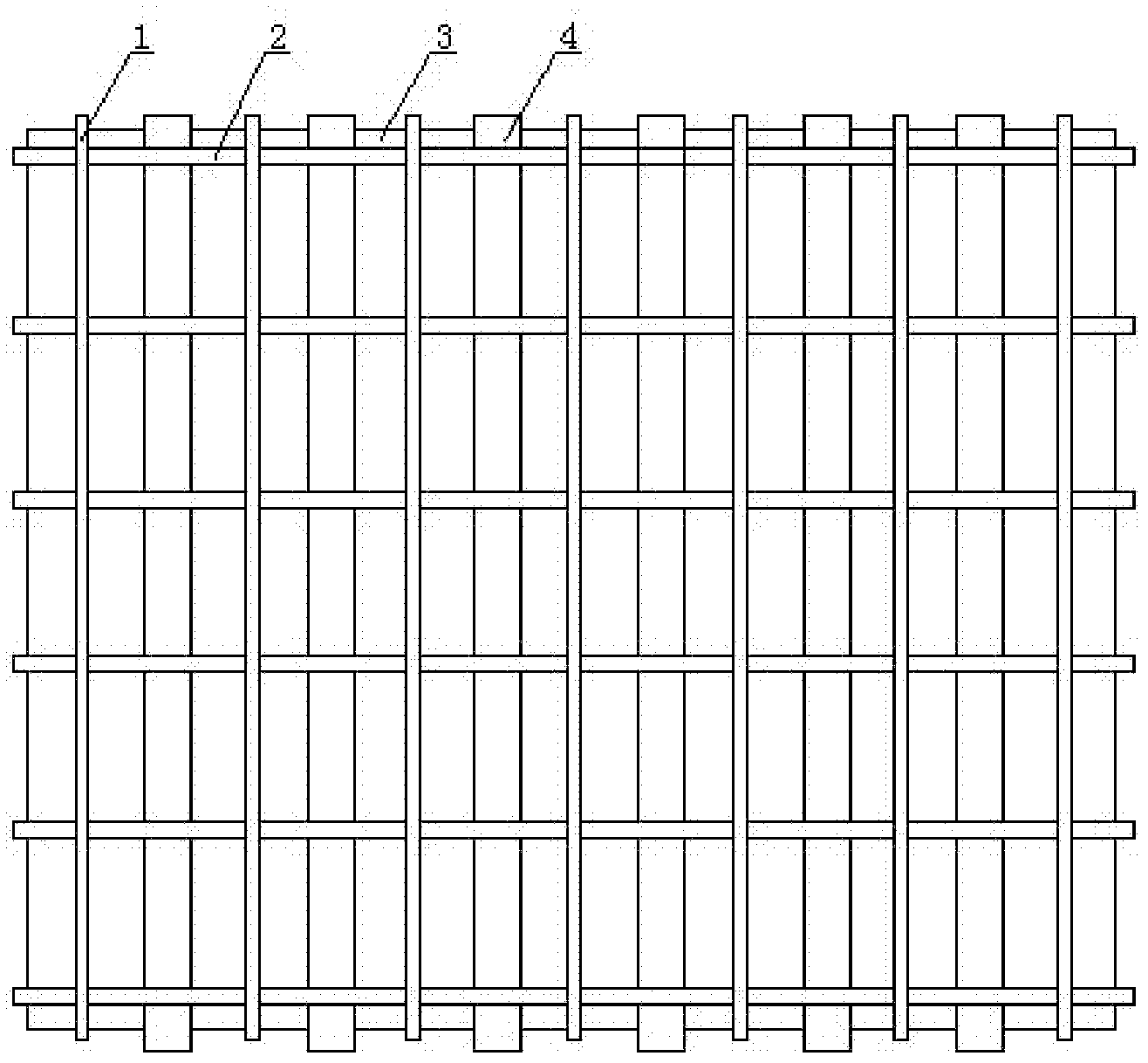

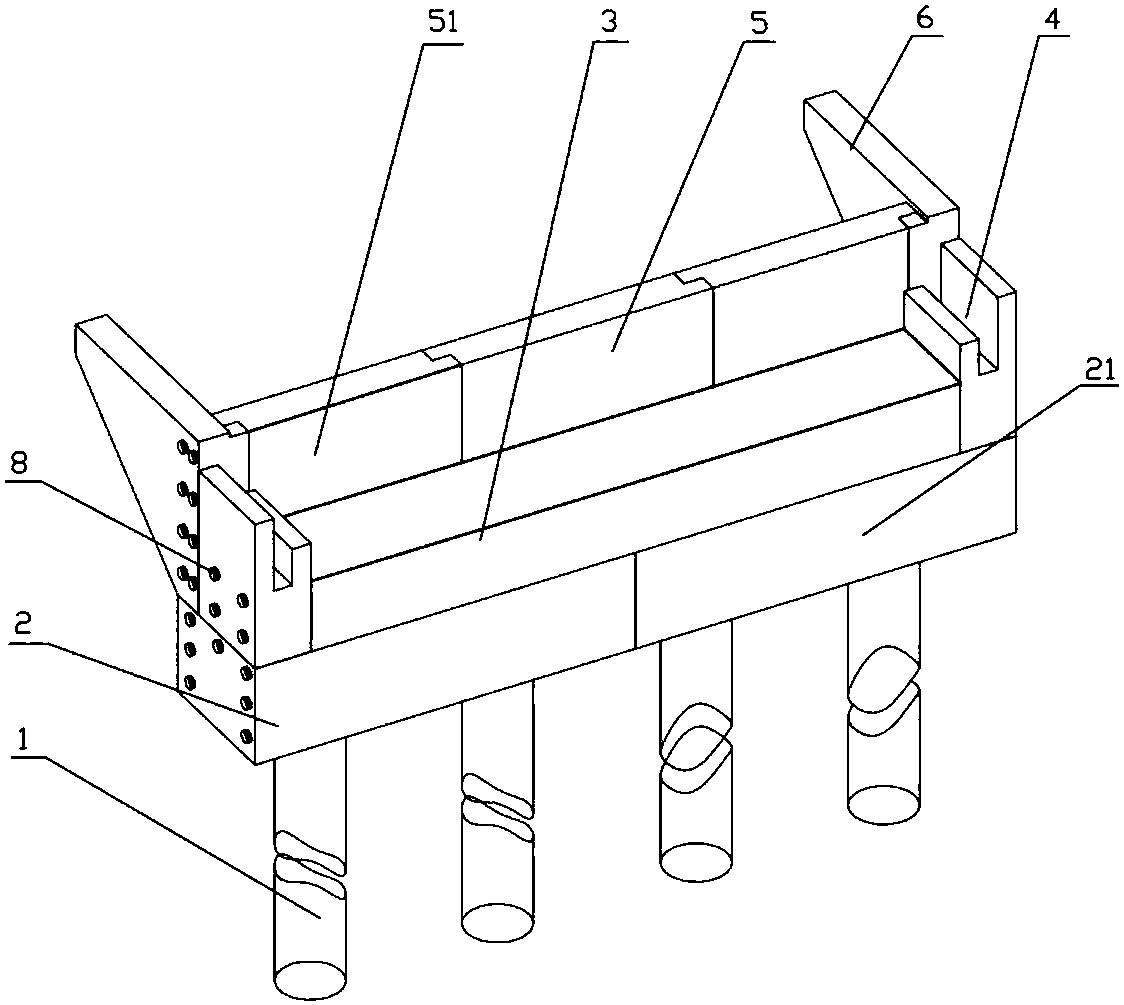

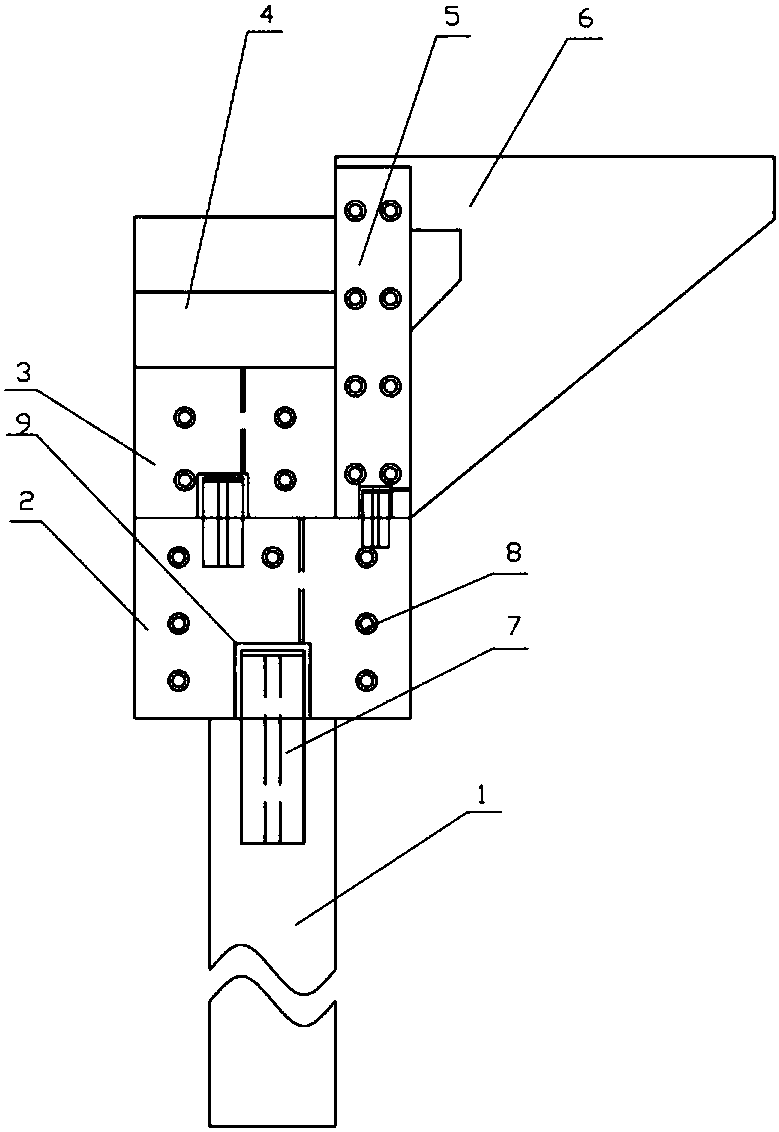

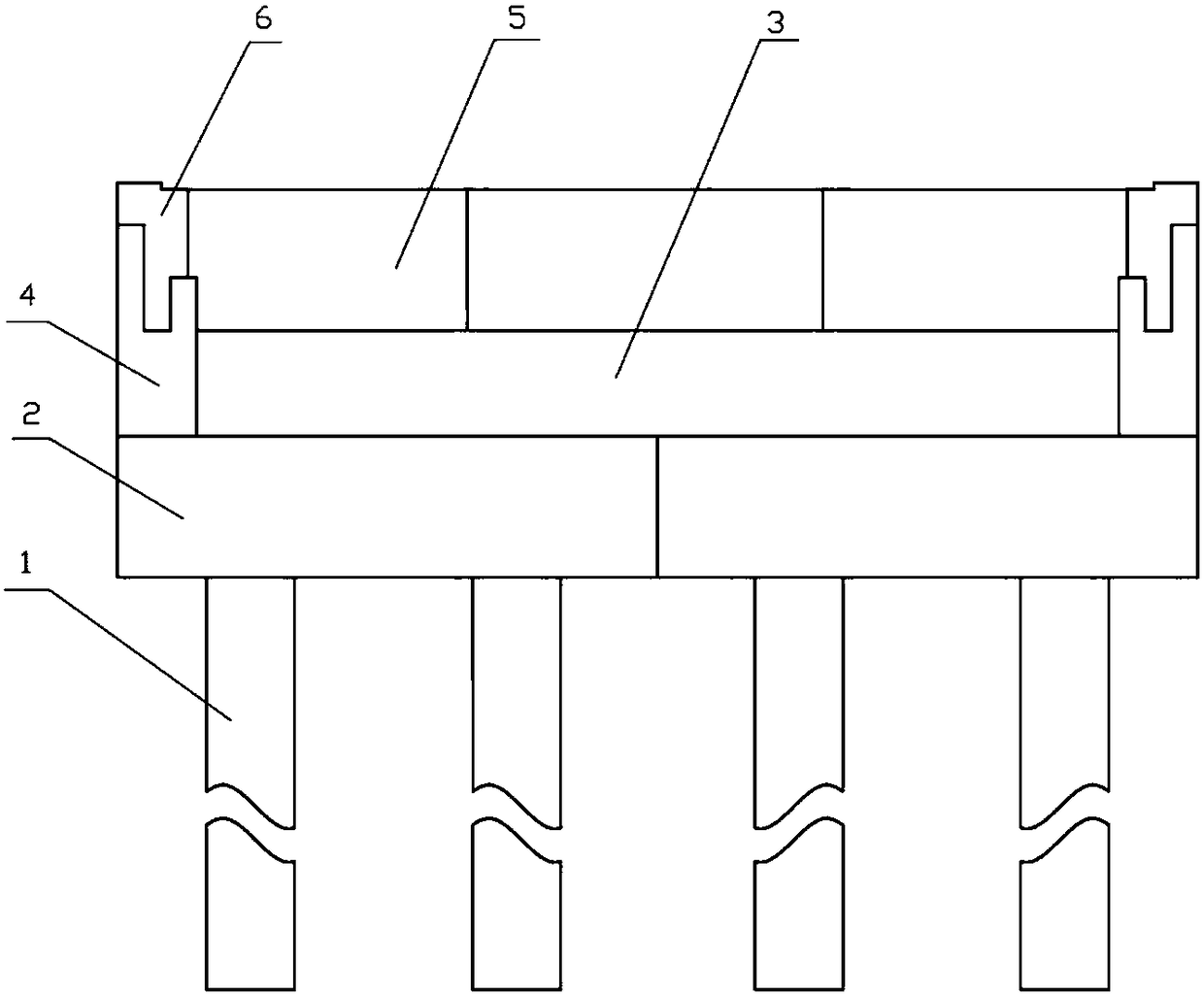

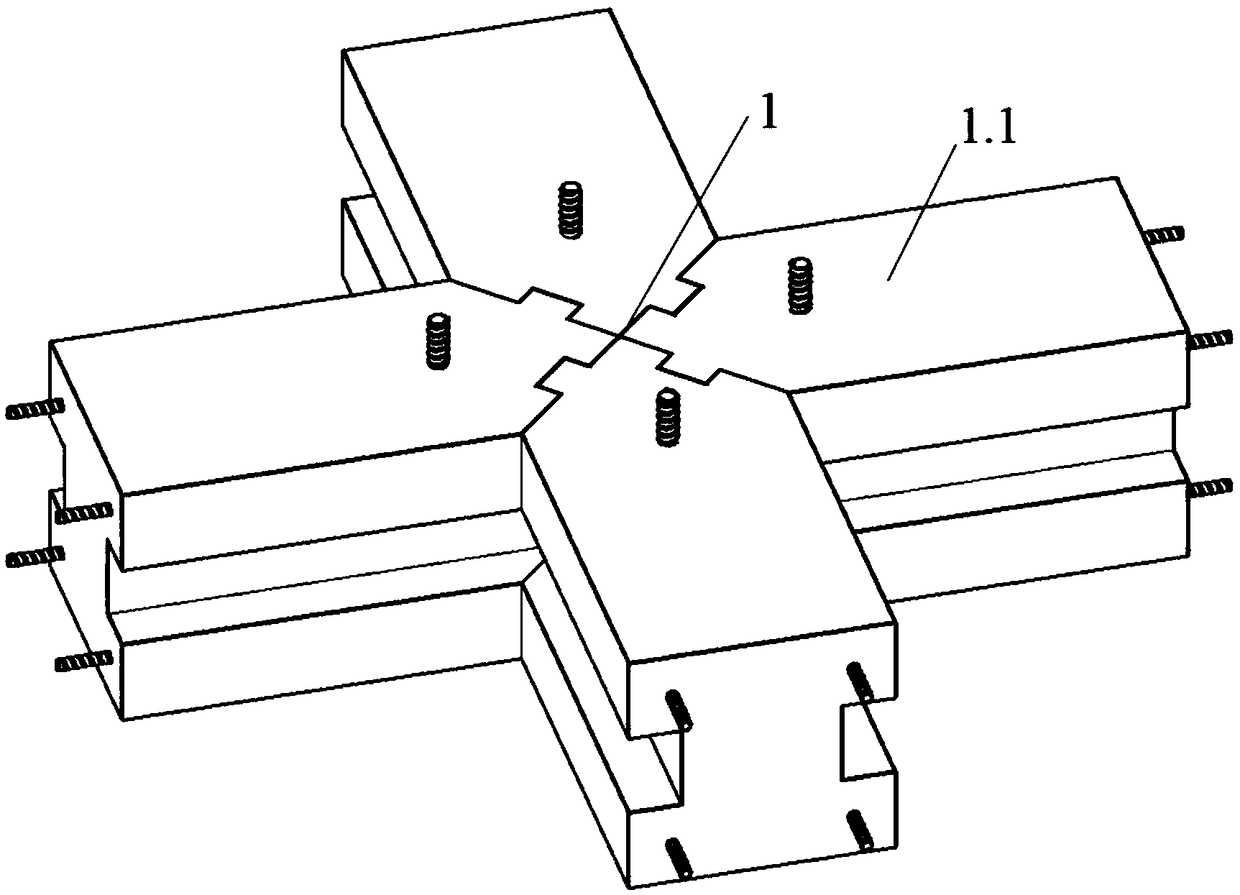

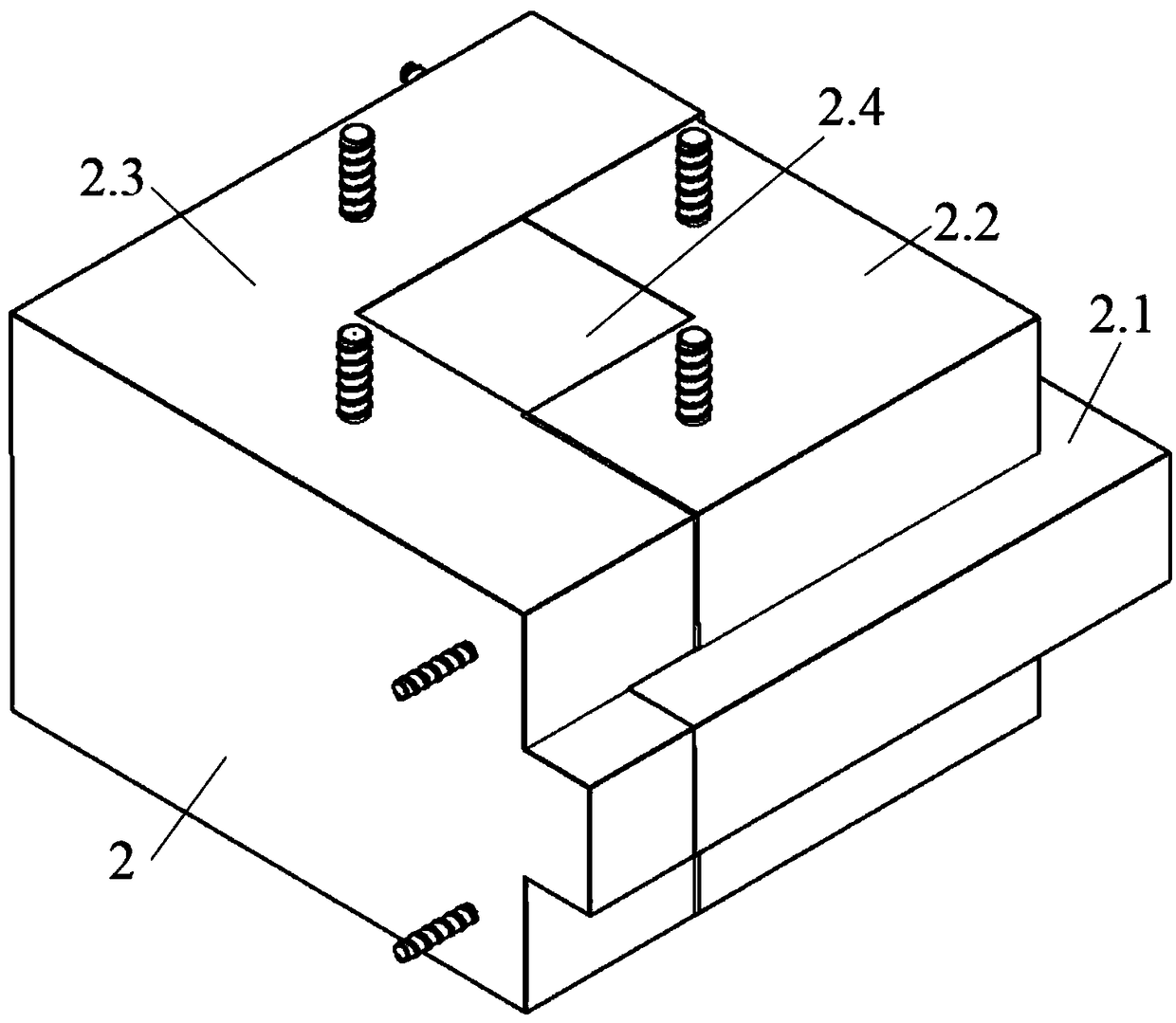

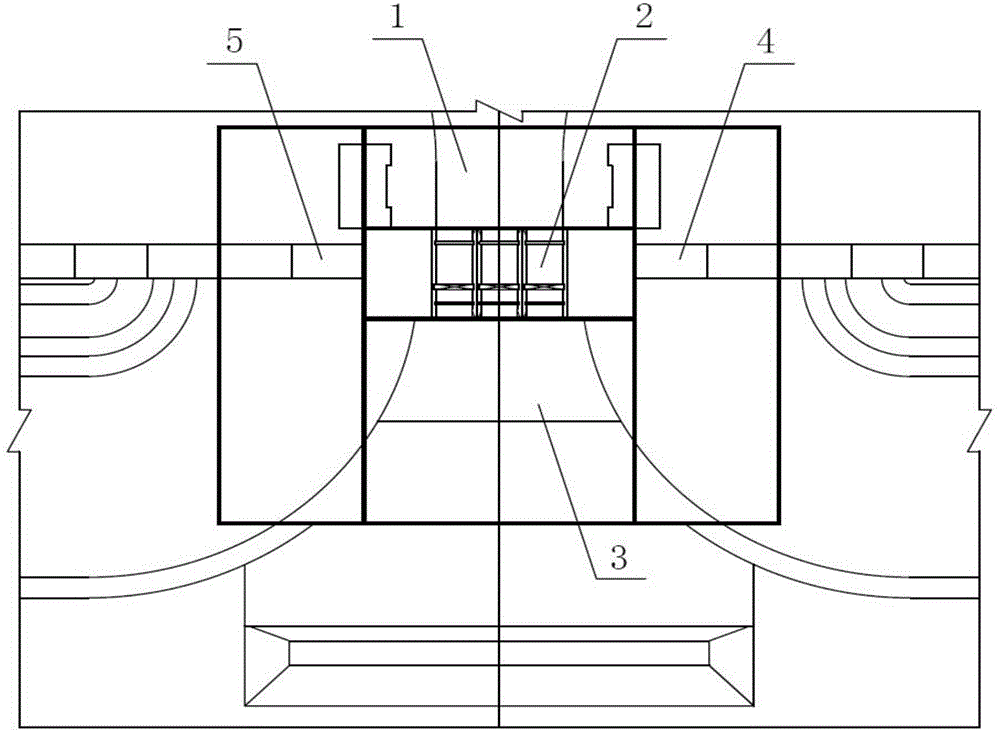

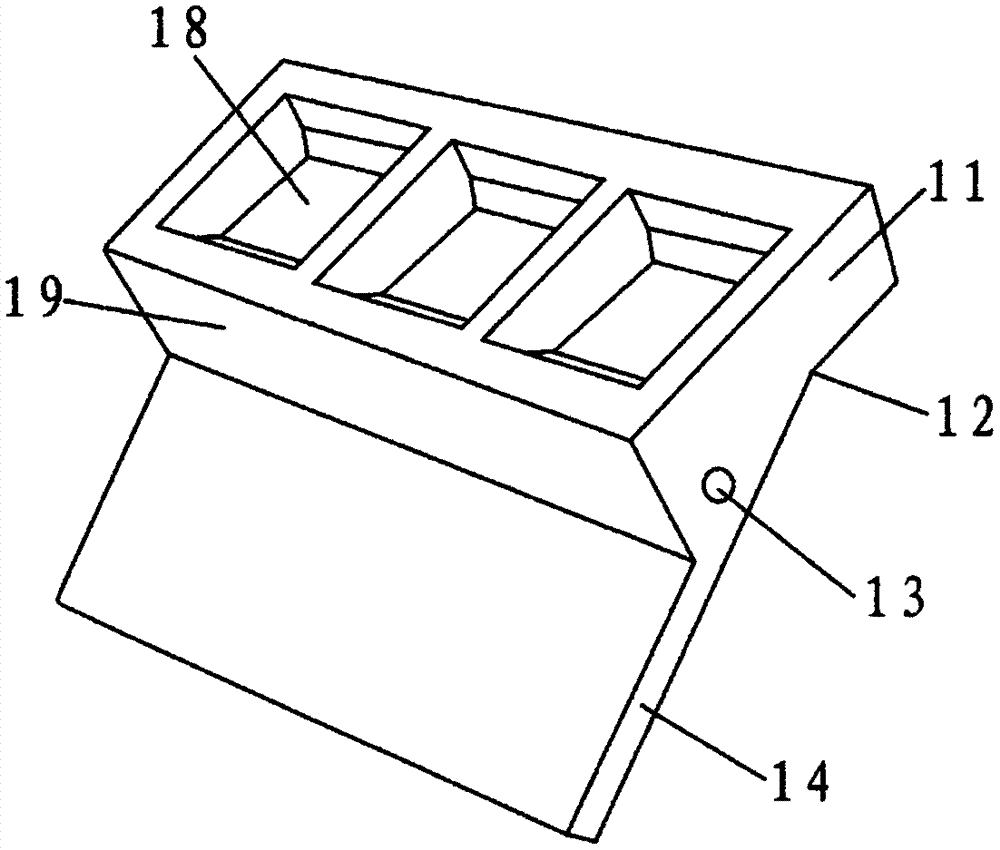

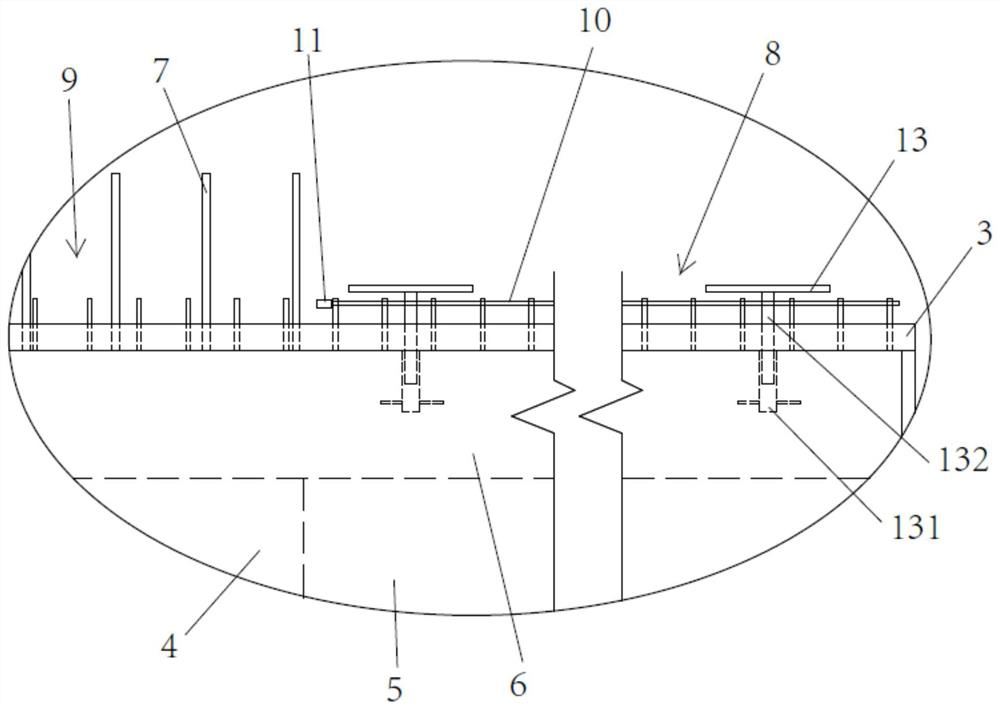

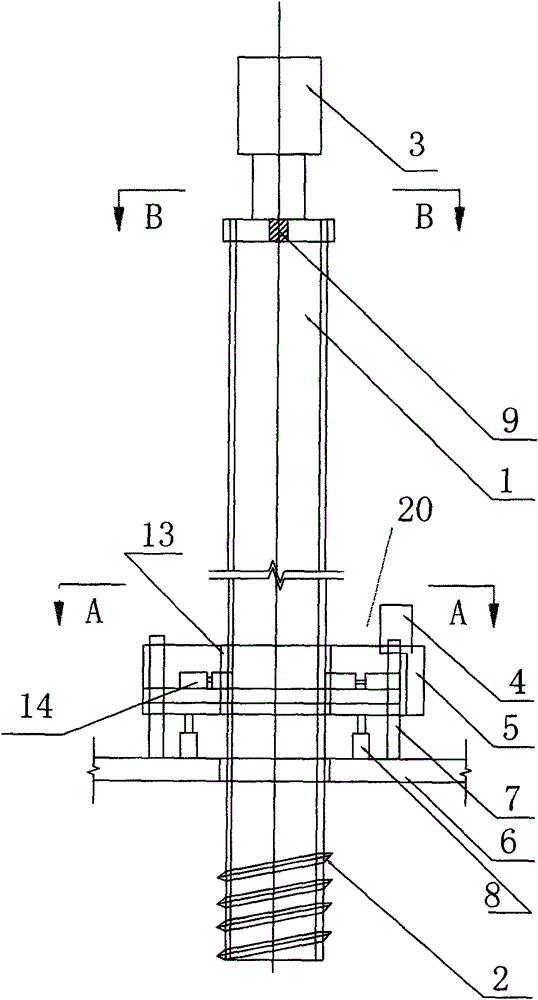

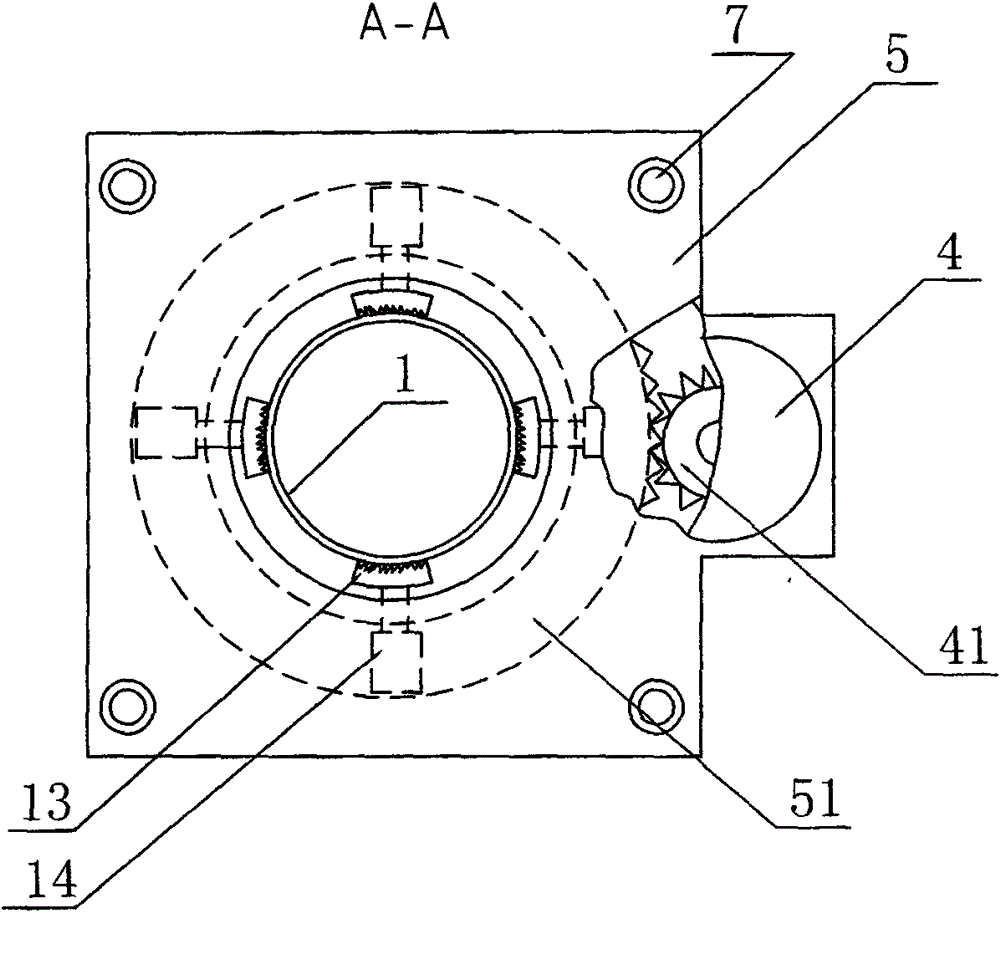

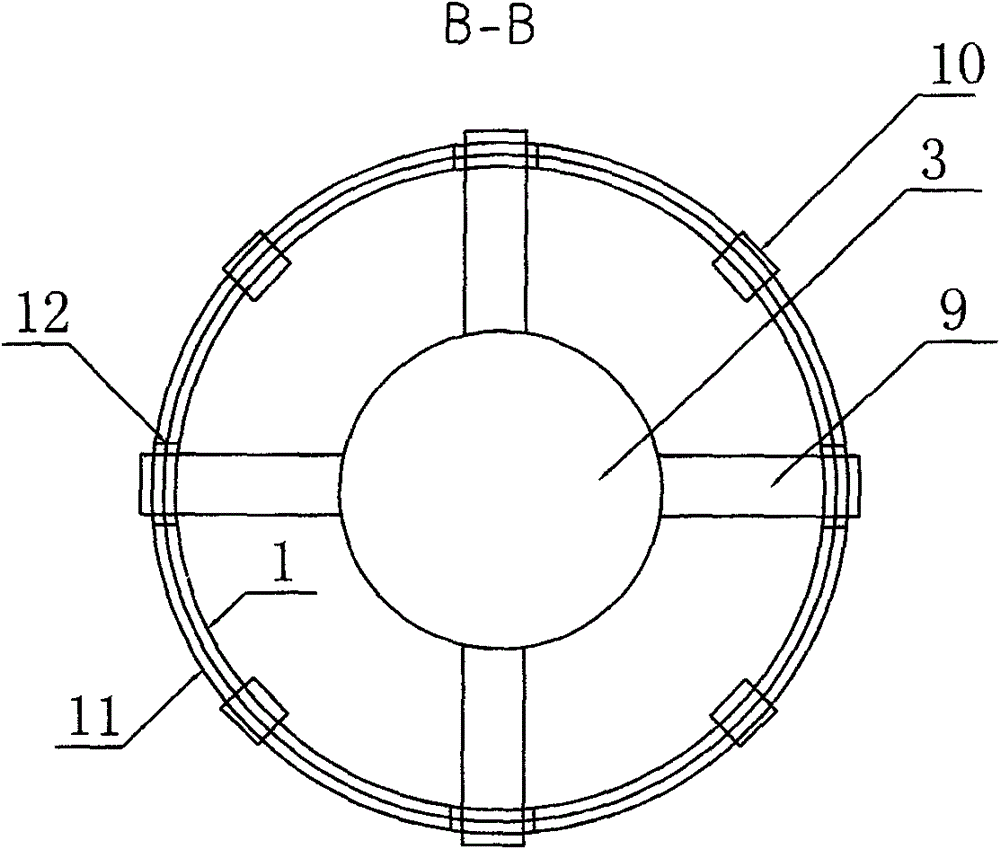

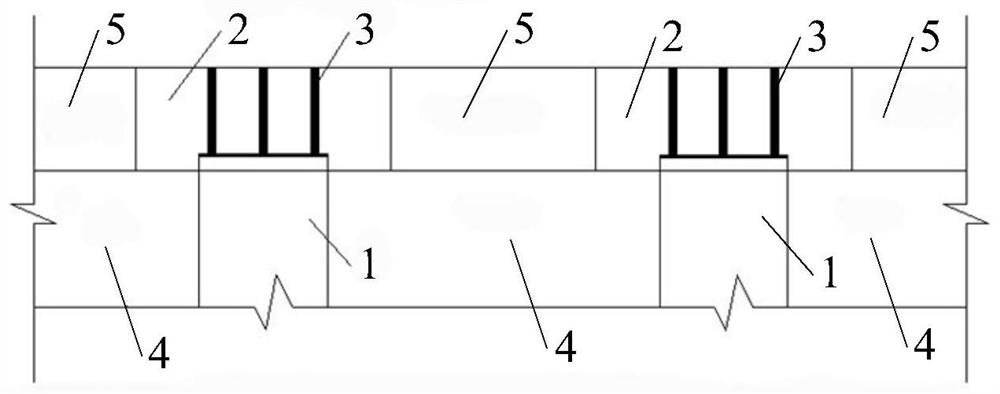

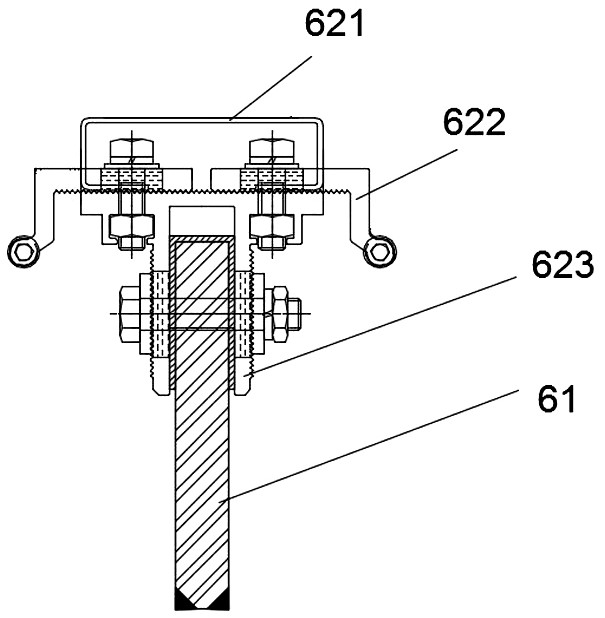

Assembly type power transmission line anchor rod static pressure miniature pile foundation and construction method thereof

ActiveCN108643219ASmall amount of workNo vibrationFoundation engineeringMaterial resourcesEngineering

The invention relates to an assembly type power transmission line anchor rod static pressure miniature pile foundation. The foundation comprises a first connecting main body and second connecting mainbodies, wherein the first connecting main body and the second connecting main bodies form a square bearing table, the first connecting main body is in a cross shape, and is formed by splicing the same four parts in a mutual embedding mode, the number of the second connecting main bodies is four, the four second connecting main bodies are distributed in a crossed grid of the first connecting mainbody and are spliced with the first connecting main body in a mutual embedding mode, each second connecting main body is in a concentric square shape and is formed by splicing two parts in a mutual embedding mode, and the two sides of each splicing joint between the side wall of the first connecting main body and the side wall of the corresponding second connecting main body are connected and fixed through a connecting steel plate, a pre-buried screw rod and a nut. All components of the assembly type power transmission line anchor rod static pressure miniature pile foundation with the design are prefabricated in factories and assembled on site, the construction is simple, convenient and fast, the influence on the environment is small, manpower and material resources are saved, and full-mechanical construction of the power transmission line foundation is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Method for producing metal decorating surface heat-insulating plate with anti-thermal deformation structure

InactiveCN106149908AAvoid stress deformationGuaranteed flatnessCovering/liningsLaminationAluminium foilElectric heating

The invention discloses a method for producing a metal decorating surface heat-insulating plate with an anti-thermal deformation structure. The method comprises the following steps: (1) feeding an aluminium alloy plate or a zinc plated or aluminium and zinc plated steel plate which forms a metal decorating surface layer into a pressing moulding machine through a screen open-type unwinding machine for performing pressing moulding treatment; (2) uniformly mixing isocyanate and premixed polyether polyol according to the ratio of 1:1 in a polyurethane pouring machine, coating the metal decorating surface layer with a mixture to form a polyurethane heat-insulating layer, then, covering the polyurethane heat-insulating layer with an aluminium foil, a glass fibre fabric, a cement base fabric, an embossed steel plate or an embossed aluminium foil which forms an interlayer, and sizing through a laminating machine; (3) feeding a cured and moulded plate into an electric heating treatment box through a conveying belt for performing heat treatment, wherein the heating temperature in the heat treatment box is at least 50 DEC G, and the heat treatment time is at least one minute; (4) uniformly pouring phenolic foam resin on the bottom surface of the plate which is produced in the step (3) through a pouring metering pump to form a base layer, feeding the base layer in a laminating conveying machine, and cutting the moulded plate into required sizes through a cutting machine.

Owner:URUMQI QIXIN NUOLANGDA ENERGY SAVING TECH CO LTD

A kind of Portland cement with high early strength and high corrosion resistance and preparation method thereof

ActiveCN106082724BReduce tricalcium contentExtended service lifeClinker productionPortland cementClinker (cement)

Owner:WUHAN UNIV OF TECH

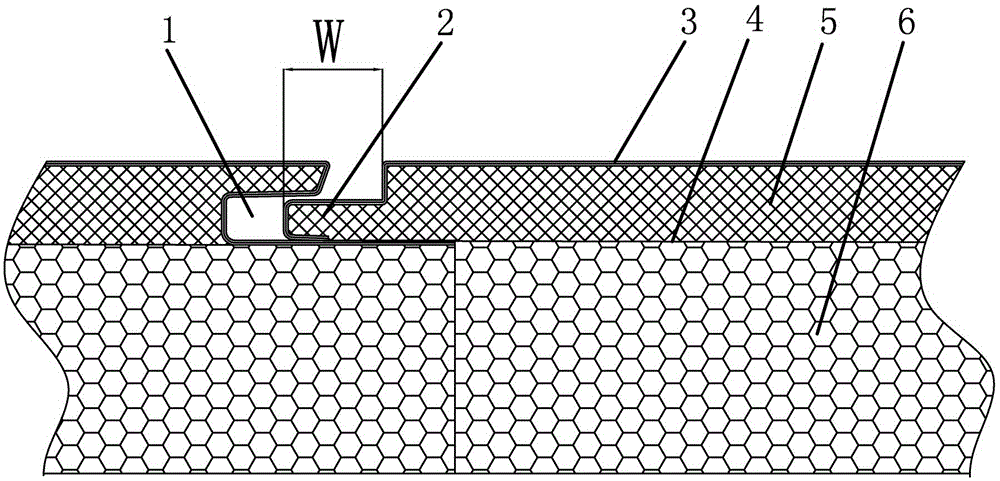

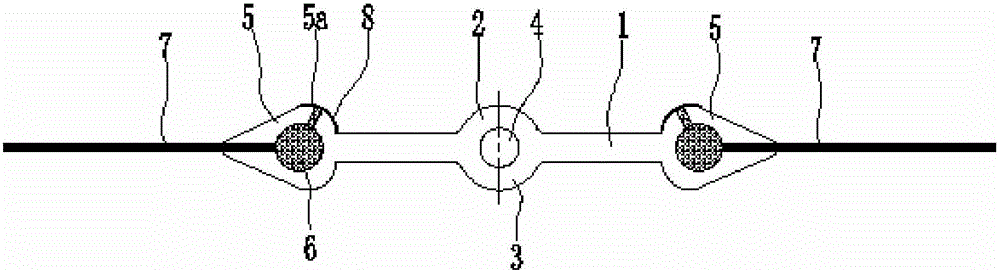

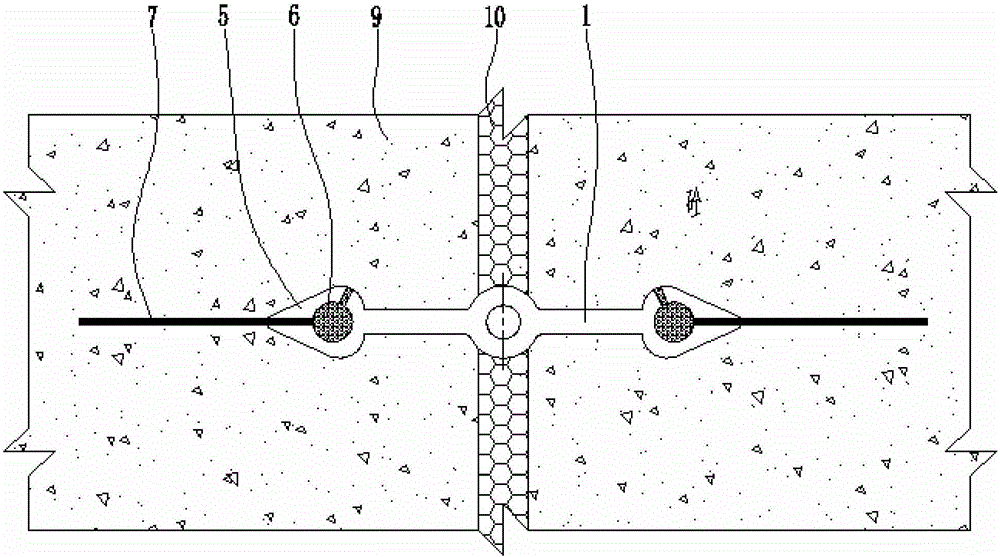

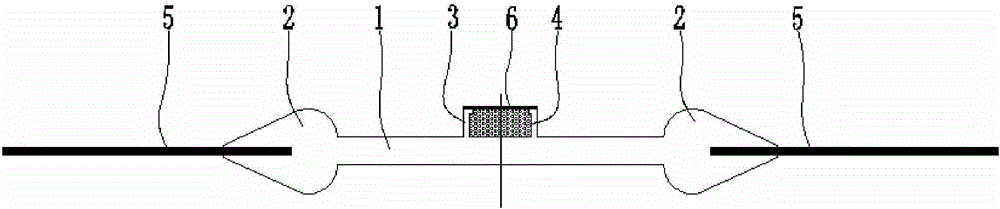

Active and passive integrated water-stopping middle-buried type water-stopping strip structure for deformation joint

ActiveCN106049550AEasy to implementEngineering quality is easy to controlArtificial islandsUnderground chambersWater contactMetal

The invention discloses an active and passive integrated water-stopping middle-buried type water-stopping strip structure for a deformation joint. The active and passive integrated water-stopping middle-buried type water-stopping strip structure is characterized in that an upper boss and a lower boss are integrally formed in the middle of a main strip body; a cavity is formed between the upper boss and the lower boss; side bags are arranged at the two ends in the width direction of the main strip body; water inlets communicating with inner cavities of the side bags are formed in the upper parts of the side bags; water-contact expansion bodies adapted to the side bags are arranged in the inner cavities of the side bags; and metal locating pieces are fixedly arranged on the outer sides of the side bags on the two sides. According to the active and passive integrated water-stopping middle-buried type water-stopping strip structure, active water plugging of the main strip body, the side bags and the metal locating pieces is realized, and passive water plugging is realized when the water-contact expansion bodies in the side bags expand after being contacted with water, so that the multipass water plugging goal is achieved; with the combination of the active water plugging and the passive water plugging, multipass water plugging is realized, and the water plugging effect is good; the side bags have protection and restraint functions on the water-contact expansion bodies, so that the water plugging effect can be improved; the active and passive integrated water-stopping middle-buried type water-stopping strip structure is simple and feasible; the construction cost can be saved; the engineering quality is easy to control; and the water is stopped on the water coming side, so that the durability of a concrete structure is good.

Owner:中铁二院重庆勘察设计研究院有限责任公司

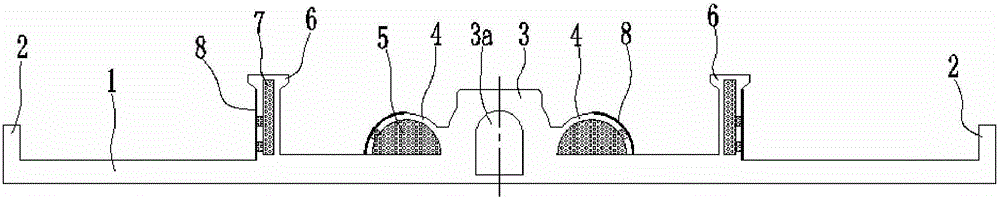

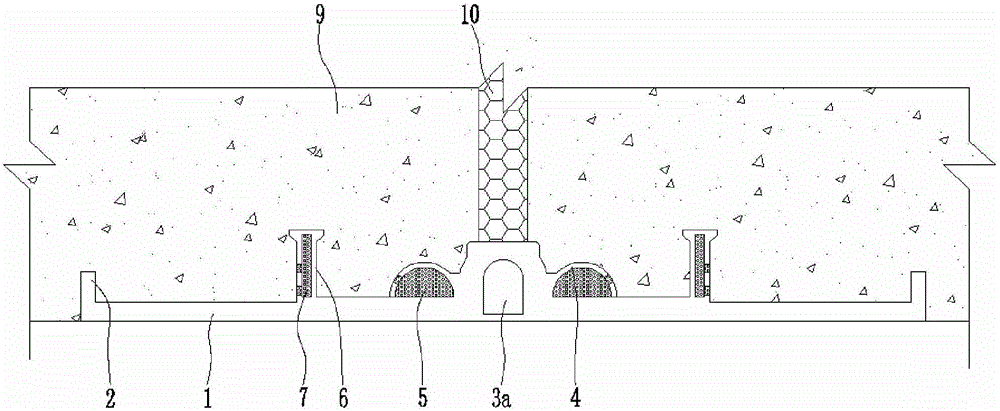

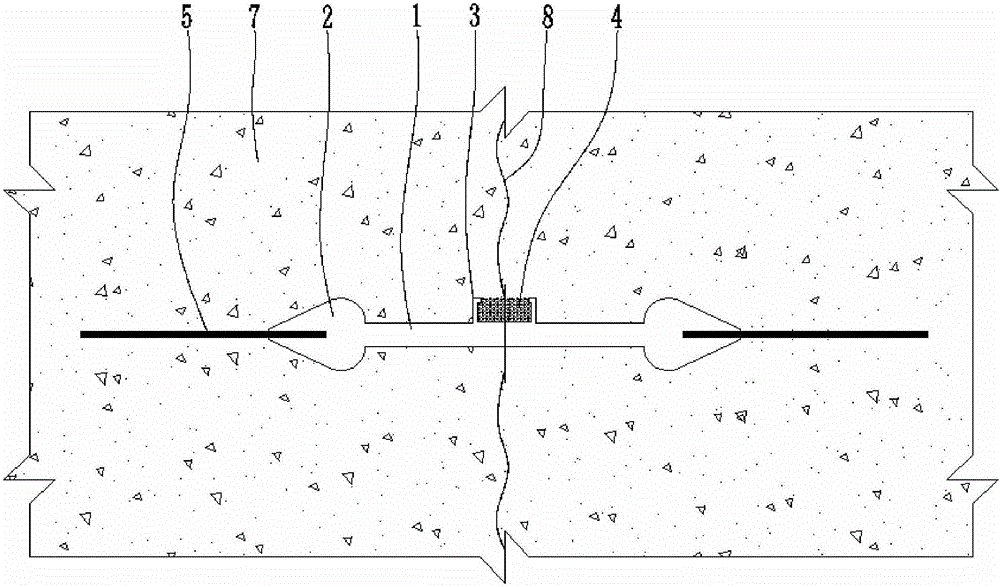

Externally bonded water-stop belt structure for integrated active and passive water stop of deformation joint

ActiveCN106013258AEasy to implementEngineering quality is easy to controlArtificial islandsUnderground chambersEngineeringWater resistance

The invention discloses an externally bonded water-stop belt structure for integrated active and passive water stop of a deformation joint. Upward raised edge covex bodies are arranged on two ends of a main belt body along a width direction; a boss is integrally formed in the middle part of the top face of the main belt body; middle convex bags are symmetrically arranged at two sides of the boss; water inlet holes are formed on outer side walls of the middle convex bags; middle convex bag water-swelling bodies are arranged in inner cavities of the middle convex bags; a side convex bag is arranged between each middle convex bag and the corresponding edge convex body at the same side; water inlet holes are formed on outer side walls of the side convex bags; side convex bag water-swelling bodies are arranged in inner cavities of the side convex bags. According to the externally bonded water-stop belt structure for integrated active and passive water stop of the deformation joint provided by the invention, active water resistance and passive water resistance are combined, and multiple water resistance and shutoff is provided, so that the water shutoff effect is good; the convex bags have a protection and restriction function on the water-swelling bodies, so that the water shutoff effect can be improved; the externally bonded water-stop belt structure for integrated active and passive water stop of the deformation joint provided by the invention is simple and feasible to apply, the construction cost can be saved, the engineering quality can be controlled easily, water is shut off from the outer contour of the structure, and the concrete structure is good in durability.

Owner:中铁二院重庆勘察设计研究院有限责任公司

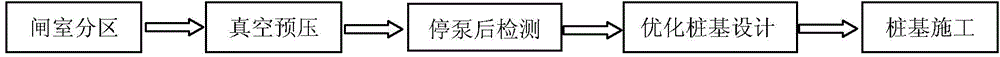

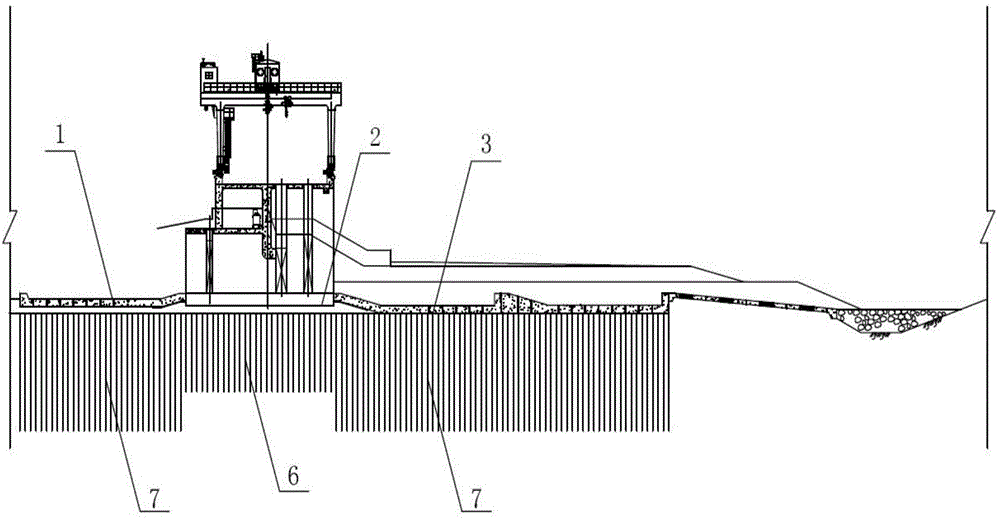

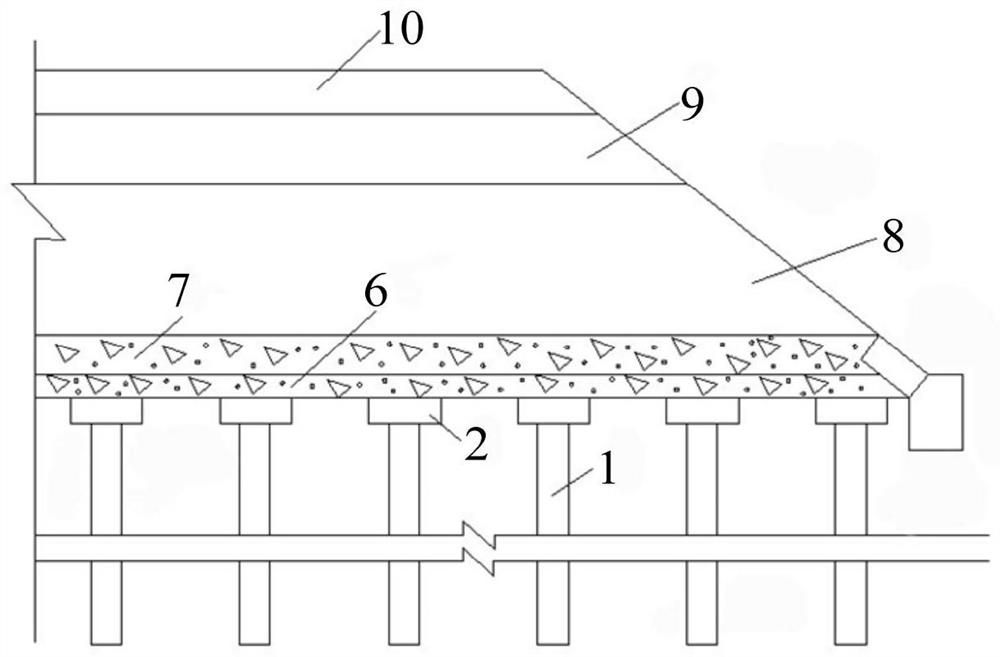

Technical method for reinforcing foundation by circulating bedding course drainage preloading

InactiveCN101514555ALow costEngineering quality is easy to controlSoil preservationEngineeringVacuum pump

The invention relates to a technical method for reinforcing a foundation by circulating bedding course drainage preloading. The method comprises the following steps: paving a horizontal drainage bedding course, which is made of a circulating water permeable material and has a sealing film on the outer surface thereof, on the surface of a foundation; inserting a plastic drainage plate vertically into the foundation; connecting the upper end of the drainage plate with the inside of a horizontal drainage layer; and vacuumizing and draining the horizontal drainage layer by a vacuum pump to achieve the aim of reinforcing the foundation, wherein after the reinforcement, the horizontal drainage bedding course can be recycled. The horizontal drainage bedding course in the technique is made of the circulating water permeable material and can be reused for multiple times so as to reduce the manufacturing cost for the drainage preloading; when an ultra-soft soil foundation is reinforced, the prior drainage preloading needs to pave a large amount of wattle fences, geotextiles and the like as bearing stratums, but the assembled type horizontal drainage bedding course in the technique can be completely competent for the function and is safer and more reliable; the horizontal drainage layer made of permeable materials is produced by a factory and is assembled on site, and the quality thereof is easier to control compared with a bedding sand paved on site; and natural sandstone materials are not adopted, thus the method is more environment-friendly.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +1

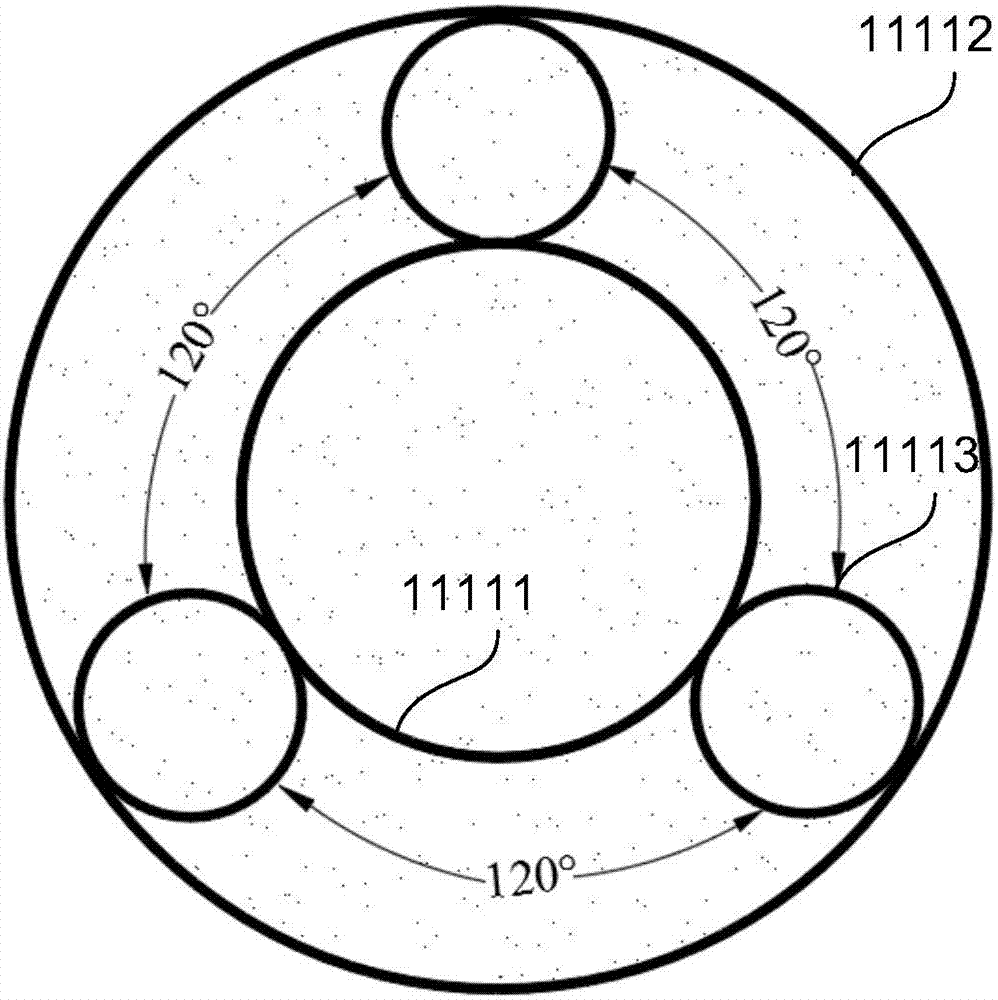

Equipment and method for constructing high-pressure rotary jet stiffening pile by using ribbed drilling method

The invention relates to equipment and a method for constructing a high-pressure rotary jet stiffening pile by using a ribbed drilling method. The technical scheme is that: the equipment comprises an end bearing plate which is adjacent to a bearing; the bearing is provided with a protective cover; and a tapered propelling body is arranged on the non-bearing side of the end bearing plate. The equipment also comprises a vibroflot on one side, which is not provided with a drive drill pipe, of a power head. Due to the adoption of the technical scheme, the equipment and the method have the beneficial effects that the bearing is effectively protected; the protective cover is arranged outside the bearing, so that sand cannot enter the bearing; the sectional protective cover has a splicing surface which is a folding surface, and can be split through the splicing surface; the bearing can be replaced, and the sand and the like can be effectively prevented from entering the bearing through the folding surface; the tapered propelling body is arranged on the non-bearing side of the end bearing plate, so that obstacles on a propelling path can be effectively eliminated, and the end bearing plate can be smoothly propelled to finish construction; in addition, the vibroflot is arranged, so that the stratum on the propelling path can be effectively loosened, and the construction can be smoothly finished; and manpower and material resources are saved, work hours are reduced, complex procedures are eliminated, and pore-forming, rib insertion and grouting can be finished at one time.

Owner:王忠友

A prefabricated shaft wall structure and its construction method

ActiveCN105862990BReduced excavation enclosure exposure timeSimplify complex processesSewerage structuresWater supply tanksPre stressEngineering

Owner:SHANGHAI MECHANIZED CONSTR GRP

Passive and inactive integrated water stop middle buried type water stop belt structure for construction joint

InactiveCN106149762AHigh resistance to water pressureStrong expansion pressureArtificial islandsUnderground chambersEngineeringWater block

The invention discloses a passive and inactive integrated water stop middle buried type water stop belt structure for a construction joint. A middle convex bag protruding upwards is integrally formed at the middle portion of the top face of a main belt body. An opening or a water inlet hole is formed in the top of the middle convex bag. A convex bag water encountering expansion body matched with the inner cavity of the middle convex bag is arranged in the inner cavity of the middle convex bag. Side bosses are arranged at the two ends of the main belt body in the width direction. Metal positioning pieces are fixedly arranged on the outer sides of the side bosses on the two sides. According to the passive and inactive integrated water stop middle buried water stop belt structure, active water blocking of the main belt body of a water stop belt, the middle convex bag and the metal positioning pieces is achieved, the water encountering expansion body in the middle convex bag expands when encountering water to passively block water, and the multi-way water blocking target is achieved. Active waterproofing and passive waterproofing are combined, water is blocked in multiple ways, and the water blocking effect is good. The middle convex bag has protecting and restraining effects on the water encountering expansion body, and the water blocking effect can be improved. The passive and inactive integrated water stop belt structure is easy and feasible to implement, the construction cost can be saved, the project quality is easy to control, water is blocked outside the water incoming side, and durability of a concrete structure is good.

Owner:中铁二院重庆勘察设计研究院有限责任公司

Pretreatment method of coastal soft foundation water gate pile foundation

InactiveCN104631426AEven settlement of the siteControl differential settlementSoil preservationSoil horizonMechanical index

The invention discloses a pretreatment method of a coastal soft foundation water gate pile foundation. Before the water gate pile foundation is constructed, a soft foundation shallow layer of a water gate is processed firstly, namely the whole water gate area is divided to an upstream connection area, a downstream connection area, a left bank connection area, a right bank connection area and a lock chamber foundation area, and vacuum preloading is conducted on all the areas, so that the consolidation degree and the horizontal resistance coefficient of a foundation soil layer are improved; then, according to the physical-mechanical indexes of the foundation soil layer which is improved after vacuum preloading, the design of the pile foundation is optimized, and the pile foundation is constructed. The pretreatment method solves the problem that a traditional soft foundation water gate pile foundation is too low in horizontal bearing capacity, the horizontal resistance coefficient of the soft foundation is effectively improved, the foundation bearing capacity is improved, and the differential settlement between connection sections between the water gate and the two banks is reduced.

Owner:浙江省水利水电勘测设计院有限责任公司

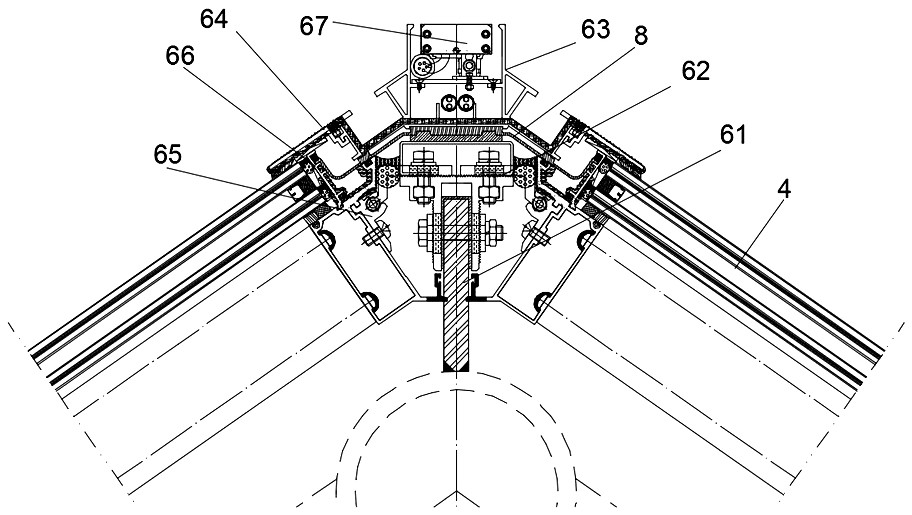

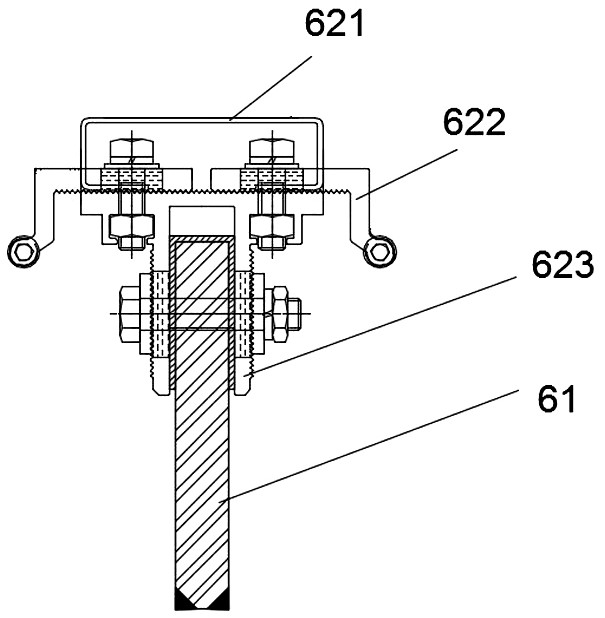

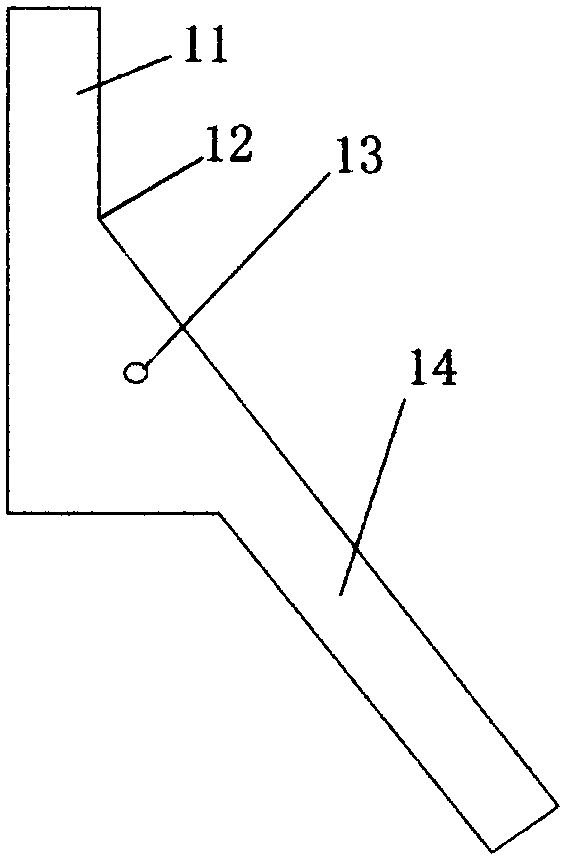

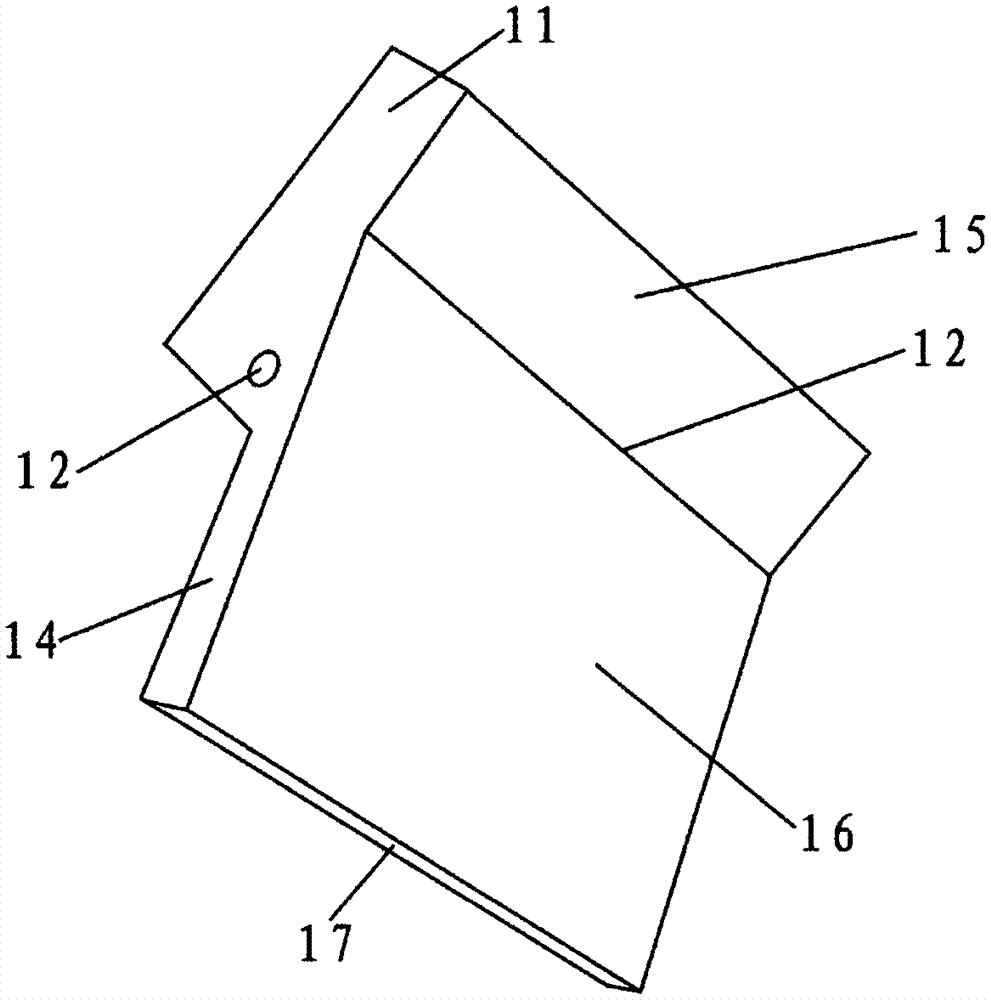

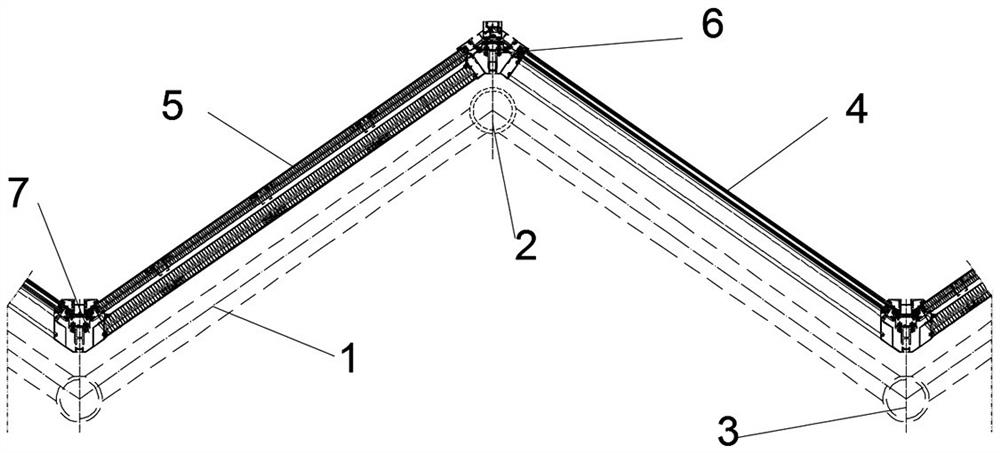

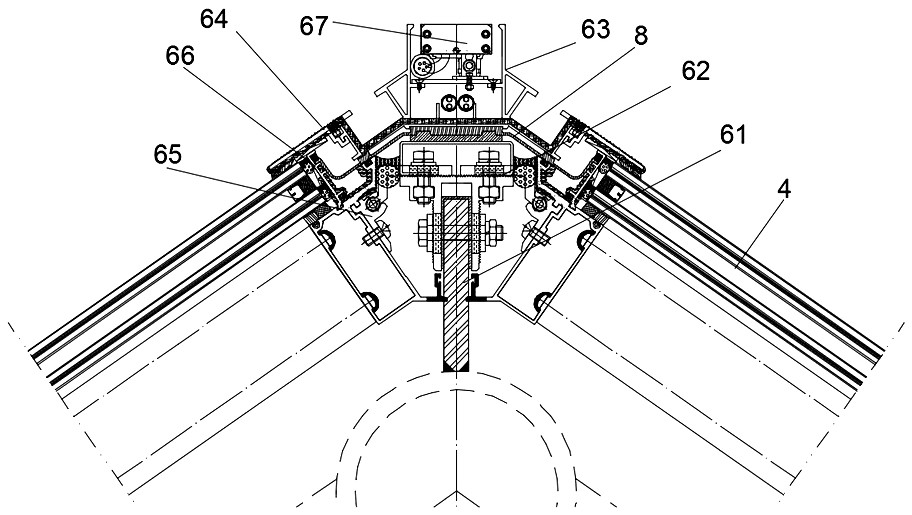

Semi-unit type daylighting roof glass curtain wall mounting system and construction method thereof

ActiveCN111980266AGood for fixing and sealingMeet the visual effectBuilding roofsBuilding insulationsLight fixtureSealant

The invention discloses a semi-unit type daylighting roof glass curtain wall mounting system and a construction method thereof. The mounting system comprises a W-shaped roof slope surface, glass or panel connected to the roof slope surface, a top connecting piece which is connected to the upper portion of a ridge, a lamp which is connected to the top connecting piece and a valley connecting piecewhich is connected to a valley. During construction, by arranging the top connecting plate and a top adapter at the ridge, the glass or panels at the ridge can be conveniently connected, a detachableframe connecting piece is connected with the glass or panels on the two sides, and the installation angle can be easily adjusted on site; a valley connecting plate and a valley adapter are arranged atthe valley so that glass or panels at the valleys can be conveniently connected; through the arrangement of a valley buckle cover and a valley sealing edge, sealing of the joint of the house valley is facilitated; through the arrangement of a valley end connecting piece, fixing and sealing of the end of a waterproof belt are facilitated, and through connection of a sealant, the structure of the connecting position is more integral.

Owner:DECORATION CO LTD OF CHINA CONSTR 3RD ENG BUREAU

Rubber ballast baffle

The invention provides a rubber ballast baffle. The rubber ballast baffle is characterized by comprising an integrally formed ballast baffle body; the ballast baffle body includes a baffle block and a bottom plate which are fixedly connected into a whole; the baffle block is arranged at the upper end of the ballast baffle body; the bottom plate is arranged at the lower end of the ballast baffle body; the included angle between the baffle block and the bottom plate is 105-175 degrees; and the side face of the ballast baffle body is provided with a connection through hole penetrating through the two sides of the ballast baffle body; a plurality of stabilizing grooves are formed in the positions, at the upper end of the ballast baffle body, of the back face of the baffle block; the lower end of the baffle block is provided with the bottom face of the baffle block; and the bottom of the bottom plate is provided with a bottom plate bottom, and the front face of the bottom plate is provided with a bottom plate protective face. The rubber ballast baffle is quite suitable for being applied to subgrades beside railways, high speed railways, urban rail transits and other rails, has a protective effect, and has the advantages of being high in safety, good in protective effect, high in stability and long in service life.

Owner:陈世宗

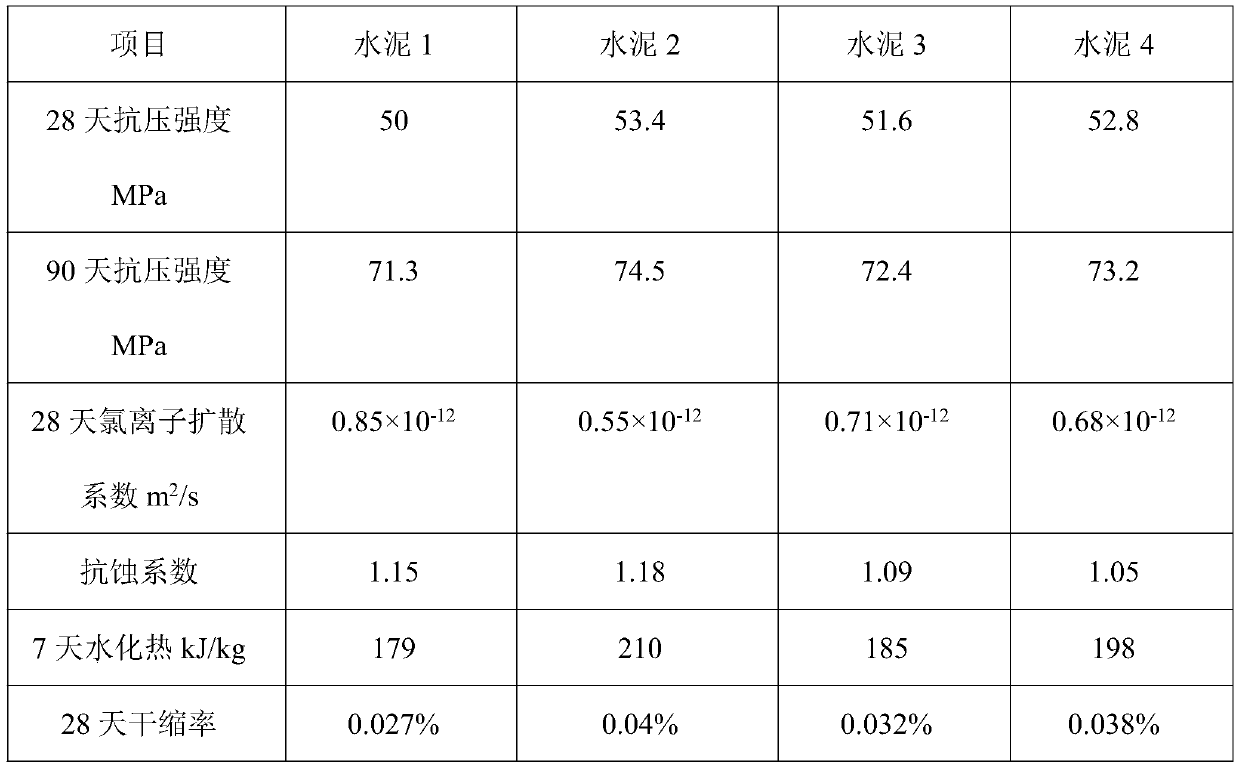

Low-heat high-corrosion-resistance Portland cement and preparation method thereof

InactiveCN109734340AReduce tricalcium contentExtended service lifeCement productionApatiteMaterials science

The invention discloses low-heat high-corrosion-resistance Portland cement and a preparation method thereof. The low-heat high-corrosion-resistance Portland cement is made from, by weight, 62-80 partsof limestone, 0-20 parts of carbide slag, 4-10 parts of clay, 2-5 parts of slag, 2-6 parts of sulfuric acid slag or copper slag, 3-5 parts of lead zinc ore, 3-5 parts of apatite or chlorine salt residue, 1-3 parts of an activator, 1-3 parts of a mineralizing agent, and 0.1-4 parts of a stabilizer. The preparation method includes the steps of grinding the materials, delivering the powders into a homogenizing base for homogenizing; conveying the homogenized material to a suspended preheater and a cracking furnace with the temperature of 850-870 DEG C; transferring to a rotary kiln for calcining, wherein the rotary kiln rotates at 3.2-3.5 rmp, a grate cooler has rod push rate of 9-17 per min, and calcining temperature is 1250-1350 DEG C. The low-heat high-corrosion-resistance Portland cementand the preparation method thereof have the advantages that compressive strength over 28 days is not less than 50 Mpa; compressive strength over 90 days is not less than 70 Mpa; hydration heat over 7days is not higher than 210 KJ / kg; drying shrinkage over 28 days is less than 0.04%; chloride ion diffusion resistant coefficient is less than 0.85*10-12 m<2> / s.

Owner:WUHAN UNIV OF TECH

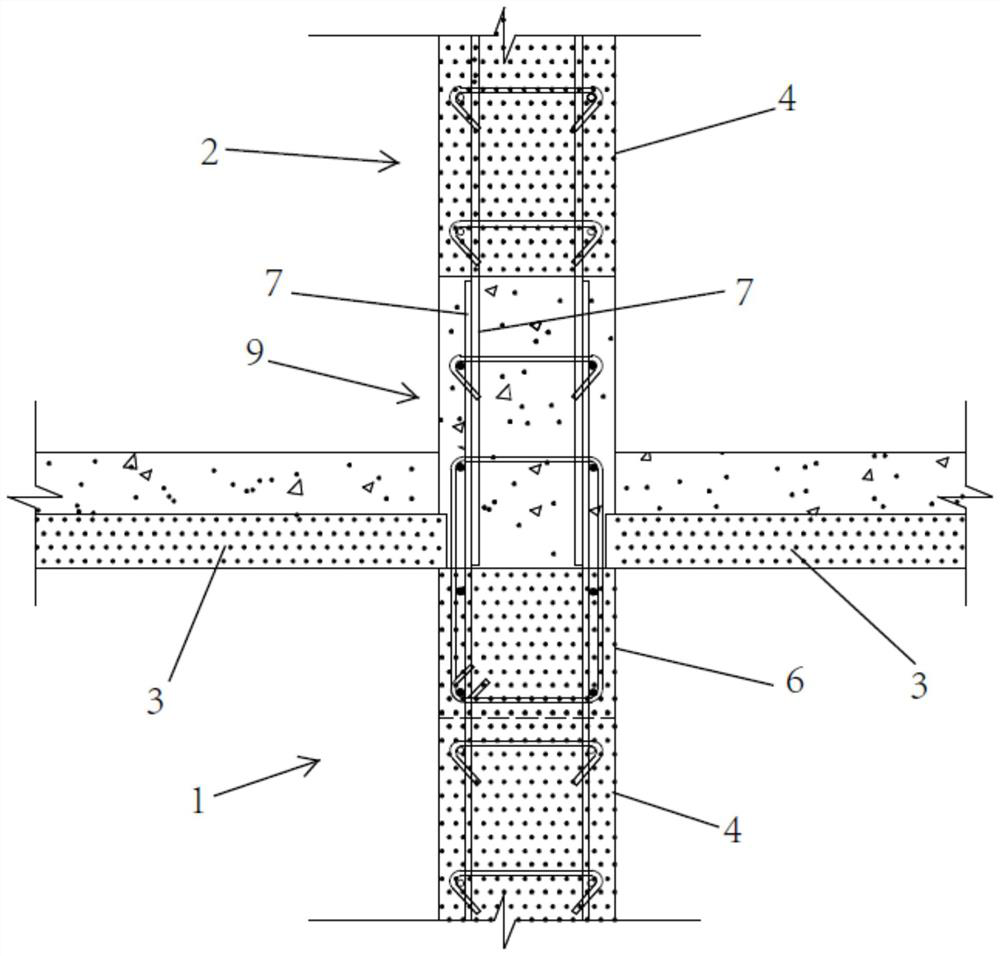

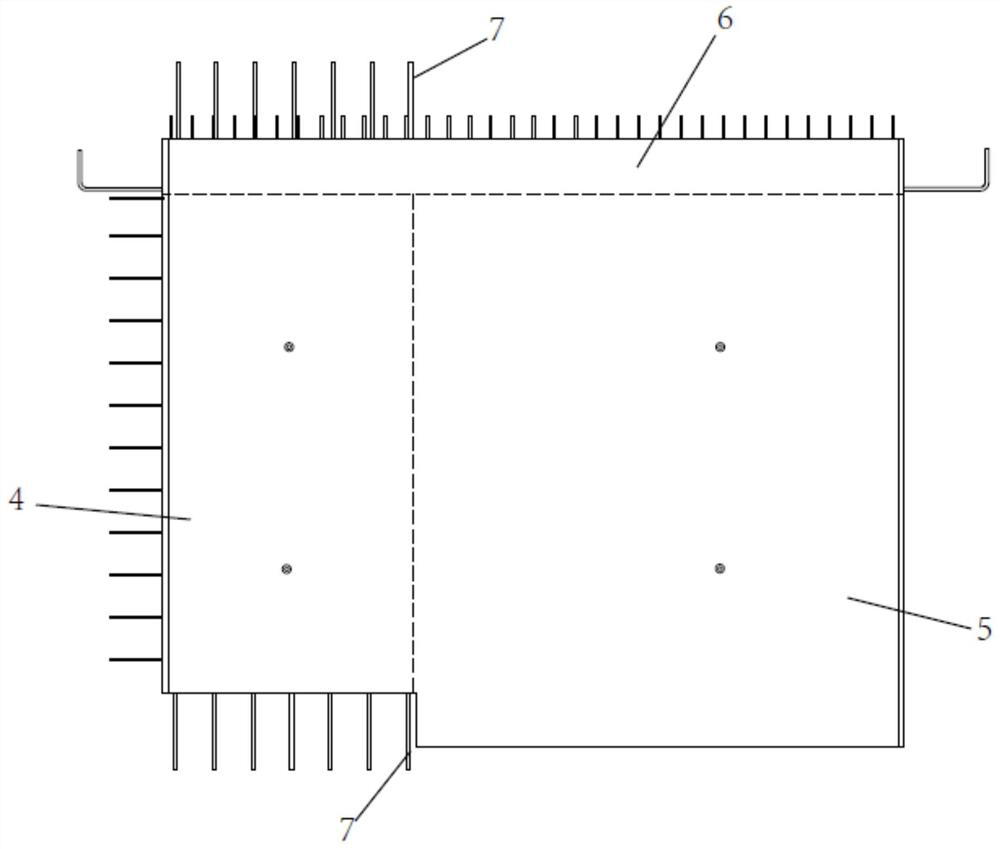

Construction method of interlayer connection joints of combined prefabricated concrete walls

ActiveCN113006321AImprove connection installation qualityConvenient pouring constructionWallsFloorsArchitectural engineeringPrecast concrete

The invention discloses a construction method of interlayer connection joints of combined prefabricated concrete walls. The construction method comprises the steps that the two combined walls and laminated slab prefabricated bottom plates on the two sides are assembled in a matched mode and poured to form the interlayer connection joints, each combined wall comprises a shear wall, a light filling wall and a laminated beam prefabricated bottom beam which are integrally prefabricated, and the bottom of each shear wall is provided with a retraction part and matched with the corresponding light filling wall to form a step structure; during construction, the tops of the laminated beam prefabricated bottom beams corresponding to the light filling walls are poured and serve as first supporting connection parts, then the upper-layer combined wall is hoisted to the position overlapped with the upper portion of the lower-layer combined wall, the bottoms of the light filling walls of the upper-layer combined wall are placed on the first supporting connection parts, then stabilizing is conducted through oblique supporting, and pouring is conducted through second post-poured concrete after the perpendicularity is adjusted; and finally, the light filling walls and the first supporting connection parts are subjected to joint filling, and construction is completed. According to the construction method, the construction sequence is reasonable, the process is convenient, fast and efficient, and the joint connection quality is easy to control.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT +1

Dry-soil-removed reinforced concrete screw pile forming device and method

ActiveCN102561341BImprove bearing capacityImprove pile qualityBulkheads/pilesReinforced concreteDry soil

Owner:孔超

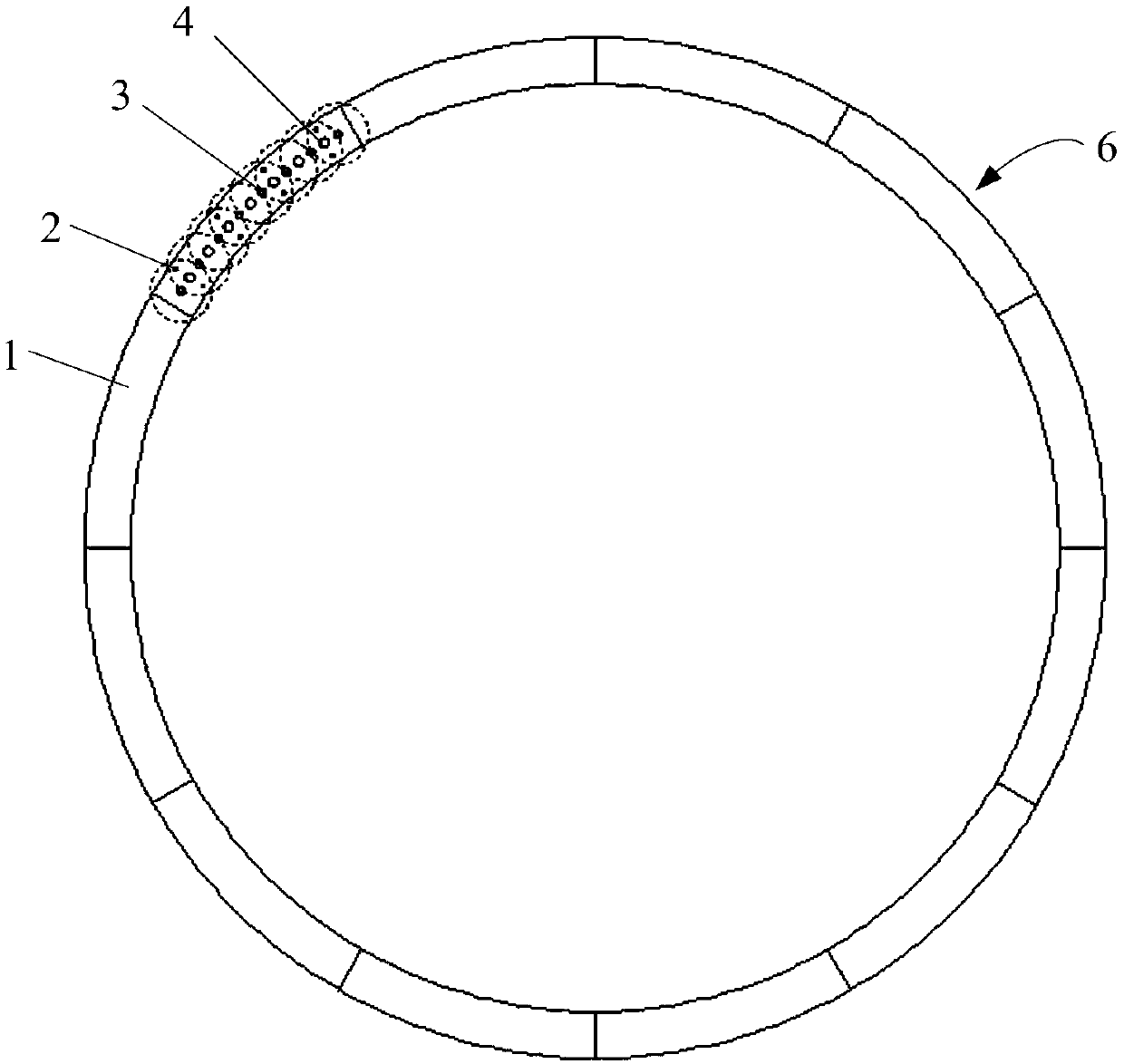

High-water-pressure-resistant shield segment bolt hole composite sealing structure

PendingCN113294172AIncrease contact extrusion forceImprove waterproof performanceUnderground chambersTunnel liningShield tunnelingAnchor bolt

The invention relates to a high-water-pressure-resistant shield segment bolt hole composite sealing structure. The high-water-pressure-resistant shield segment bolt hole composite sealing structure comprises a sealing element, a step anchoring bolt, a bolt anchoring end segment structure and a bolt non-anchoring end segment structure, wherein the sealing element comprises a cylindrical compaction section and an annular gasket; the step anchoring bolt comprises a small-head anchoring section, a small-head free section, a large-head free section and a fastener; and an anchoring end groove which is matched with the small-head anchoring section is formed in the bolt anchoring end segment structure, and a T-shaped groove which is matched with the sealing element and a through groove which is matched with the large-head free section are formed in the bolt non-anchoring end segment structure. The high-water-pressure-resistant shield segment bolt hole composite sealing structure is suitable for the waterproof design of a shield segment bolt hole in the high-water-pressure environment, the active and passive composite waterproof purpose is achieved under the mutual extrusion action of the sealing element and the free section of the step anchoring bolt and under the assistance of a water swelling type material layer, the process is simple, the feasibility is high, and the anti-corrosion capability and durability of a shield tunnel in the high-water-pressure environment can be increased.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST

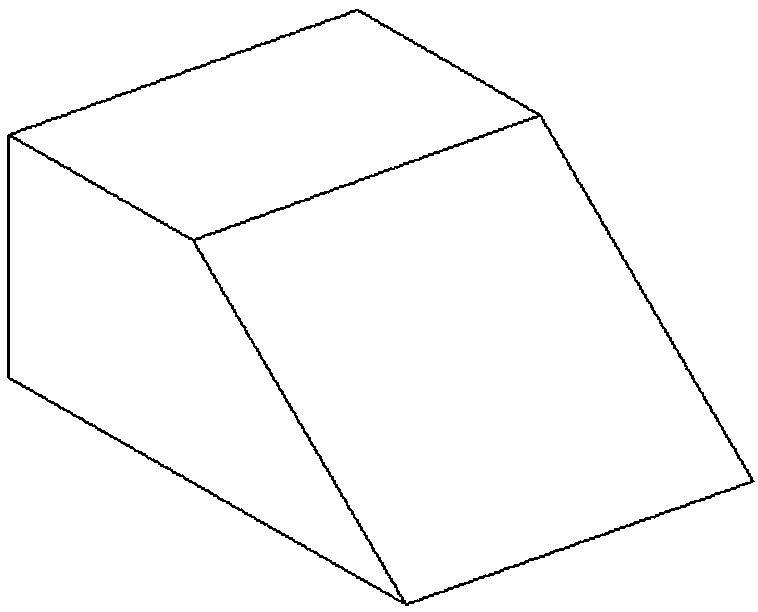

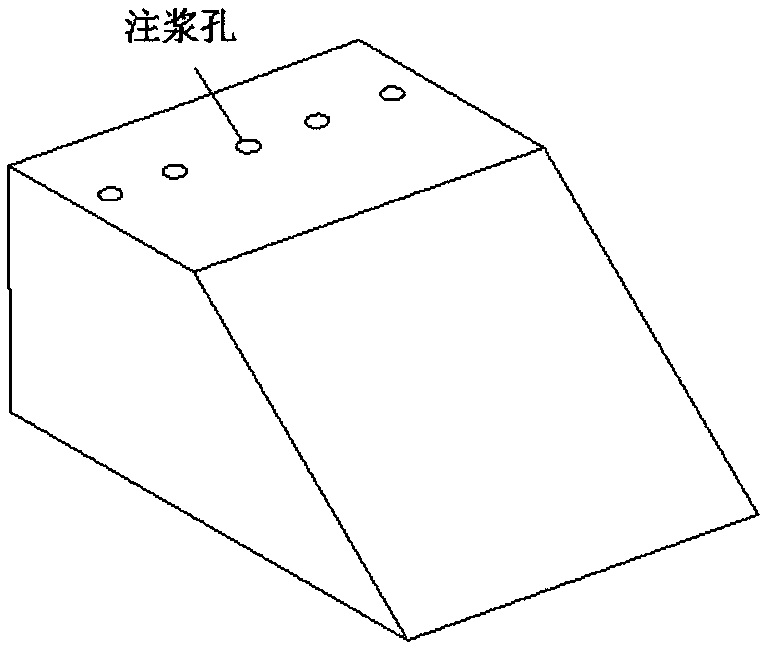

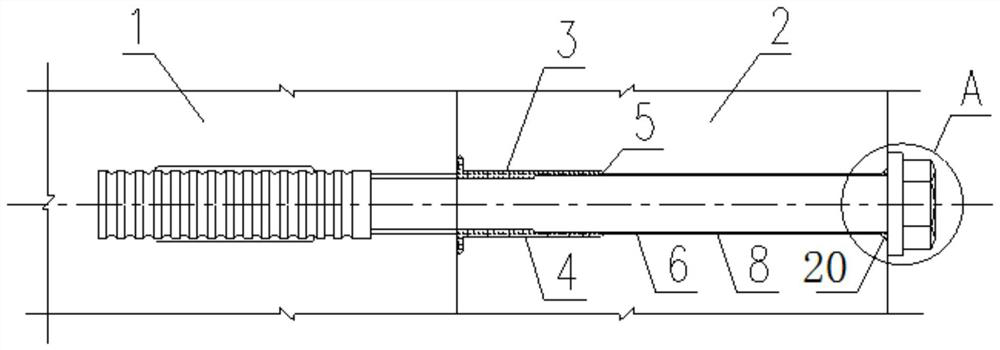

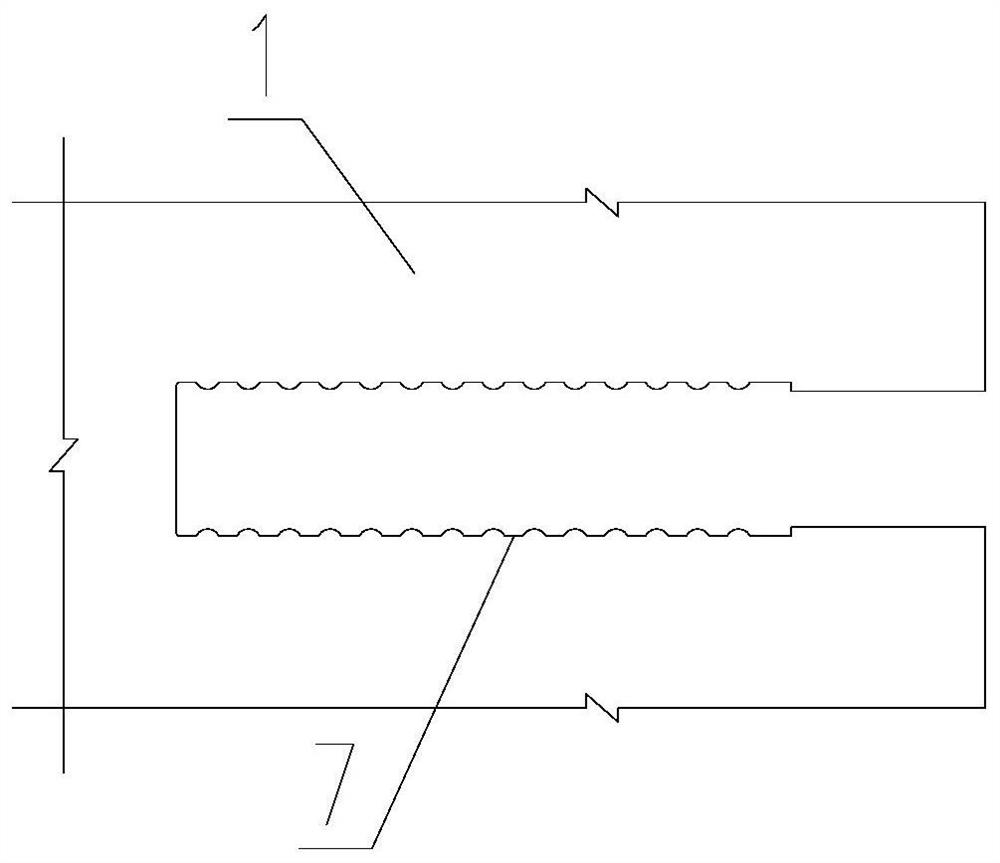

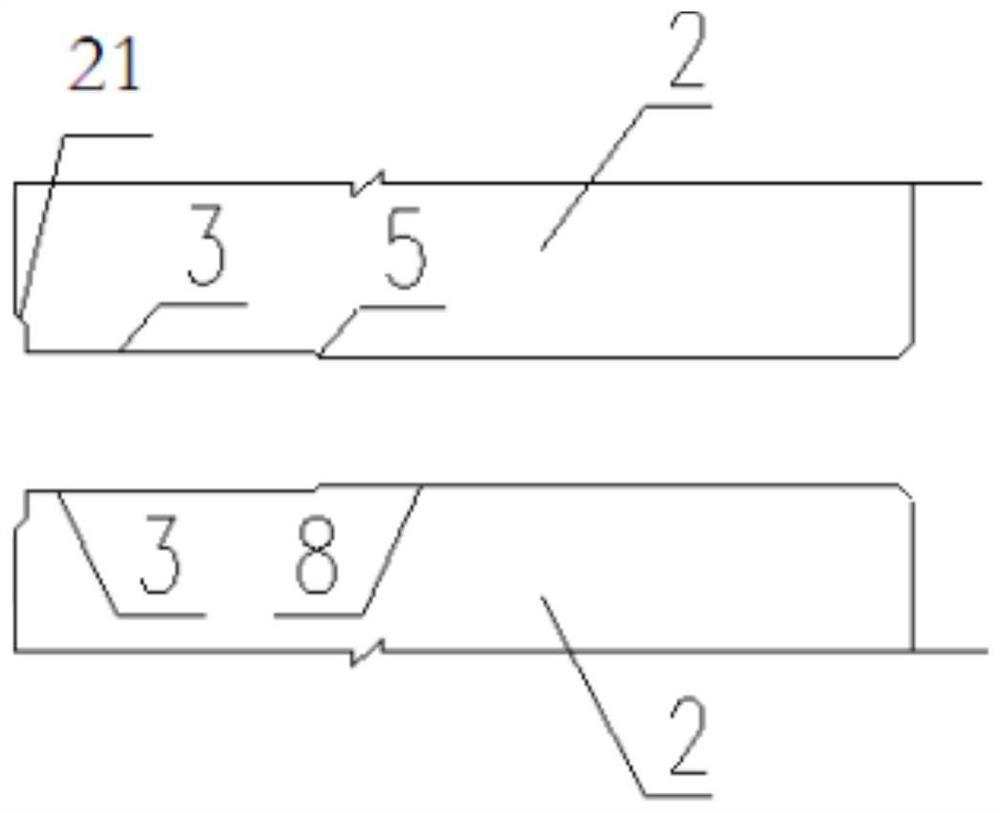

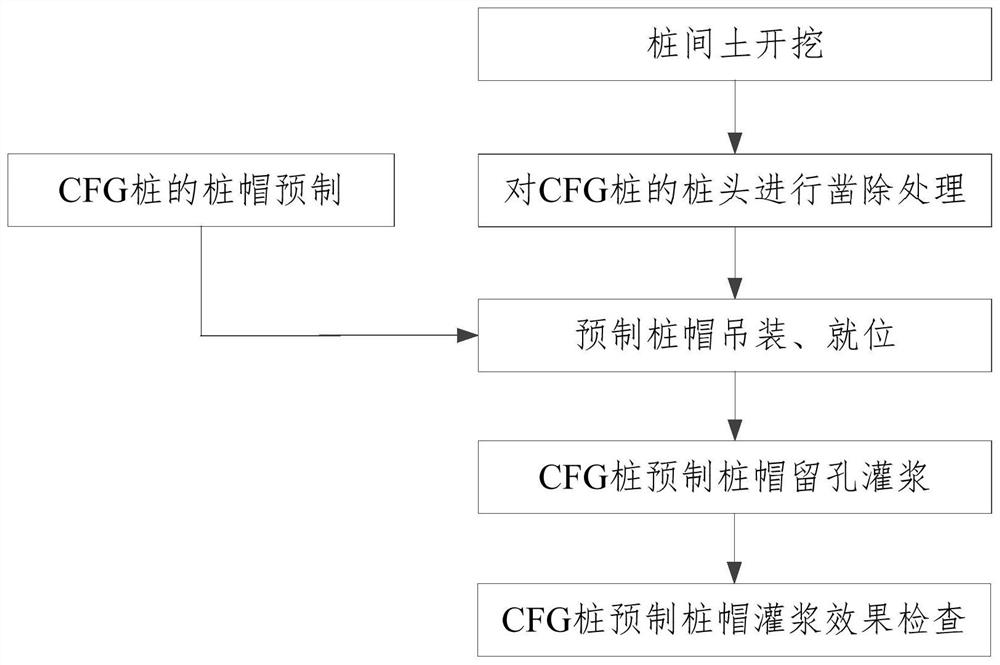

CFG pile precast pile cap reserved hole grouting construction method

InactiveCN113463622AComplete combinationGuarantee the quality of the projectBulkheads/pilesPile capArchitectural engineering

The invention relates to the technical field of building construction, in particular to a CFG pile precast pile cap reserved hole grouting construction method. According to the CFG pile precast pile cap reserved hole grouting construction method, a grouting hole and a groove are reserved in a precast pile cap, after the pile head of a CFG pile is chiseled away and cleaned, the precast pile cap is hoisted to the position above the CFG pile, the groove reserved in the precast pile cap is aligned with the pile head of the CFG pile and then put down, the precast pile cap is installed in place, and after the precast pile cap is installed in place. A non-shrinkage grouting material is poured from a grouting hole reserved in the precast pile cap, the grouting material is automatically leveled by means of self weight and fills a contact surface gap between the pile head of the CFG pile and the precast pile cap and the grouting hole reserved in the precast pile cap, so that the pile head of the CFG pile and the precast pile cap can be completely combined together, and the effect of transmitting foundation stress is achieved; and compared with a cast-in-place pile cap construction method, the CFG pile precast pile cap reserved hole grouting construction method can better guarantee the engineering quality and the construction period requirement, and has the characteristics of high construction speed, relatively simple process, easiness in quality control and the like.

Owner:CHINA RAILWAY 19TH BUREAU GRP 3RD +1

A semi-unitized lighting roof glass curtain wall installation system and its construction method

ActiveCN111980266BConducive to paving and installationEasy to adjust and install on siteBuilding roofsBuilding insulationsArchitectural engineeringSealant

The invention discloses a semi-unitized daylighting roof glass curtain wall installation system and a construction method thereof. The installation system includes a W-shaped roof slope, glass or panels connected to the roof slope, and a roof connector connected to the roof ridge , the lamps connected to the top connector, and the valley connector connected to the valley. During construction, the present invention facilitates the connection of glass or panels at the ridge by setting the top connecting plate and top adapter at the ridge, and connects with the glass or panels on both sides through detachable frame connectors, and is easy to adjust the installation angle on site; It is convenient to connect the glass or panel at the valley through the setting of the valley connecting plate and the valley adapter at the valley; through the setting of the valley button cover and the valley edge sealing, it is conducive to the sealing of the valley connection; through the setting of the valley end connector It is conducive to the fixing and sealing of the end of the waterproof belt, and the connection through the sealant makes the structure of the connection more integrated.

Owner:DECORATION CO LTD OF CHINA CONSTR 3RD ENG BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com