High-water-pressure-resistant shield segment bolt hole composite sealing structure

A technology of shield segment and sealing structure, which is applied in the direction of wellbore lining, tunnel lining, underground chamber, etc., and can solve the problem of space limitation for bolt holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

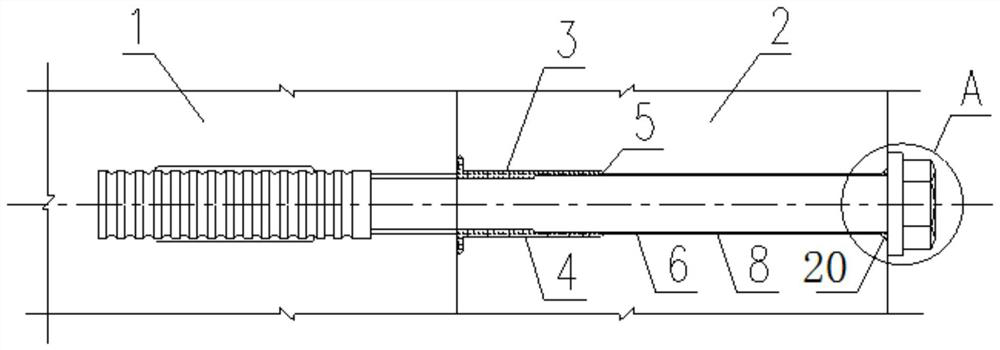

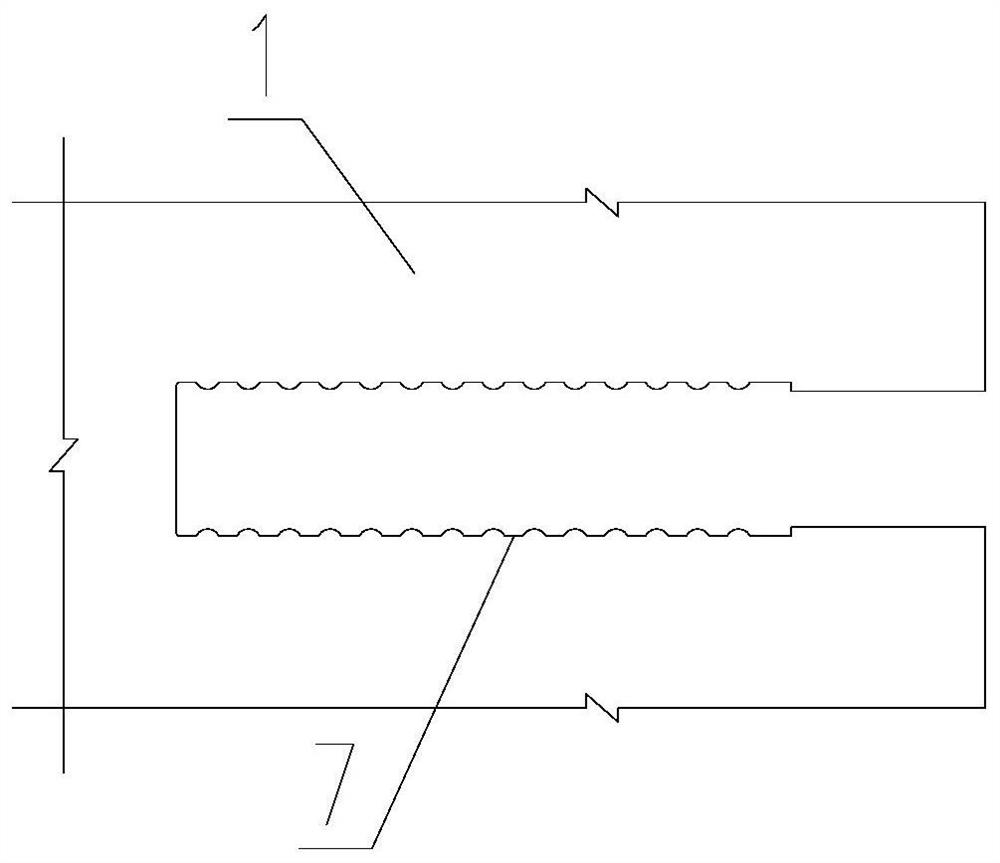

[0037] Embodiment 1: as Figures 1 to 7 As shown, a high water pressure resistant shield segment bolt hole composite sealing structure, including sealing element 4, step anchor bolt 6, bolt anchor end segment structure 1 and bolt non-anchor end segment structure 2; wherein:

[0038] The sealing element 4 includes a cylindrical compacting section 15, and an annular gasket 14 is provided at the bottom of the cylindrical compacting section 15; , large head free section 11 and fasteners; the bolt anchoring end segment structure 1 is provided with an anchoring end groove 7 matching the small head anchoring segment 9; the bolt non-anchor end segment structure 2 is provided with There is a T-shaped groove 3 matching the sealing element 4 and a through groove 8 matching the big head free section 11; the sealing element 4 is set in the T-shaped groove 3, and the stepped anchor bolts 6 are inserted in sequence The segment structure 1 at the bolt anchoring end and the segment structure ...

Embodiment 2

[0041] Embodiment 2: as Figures 1 to 10 As shown, in order to further improve the waterproof and sealing performance of the shield tunnel segment joints, on the basis of the high water pressure resistant shield segment bolt hole composite sealing structure described in Example 1, the following improvements are continued:

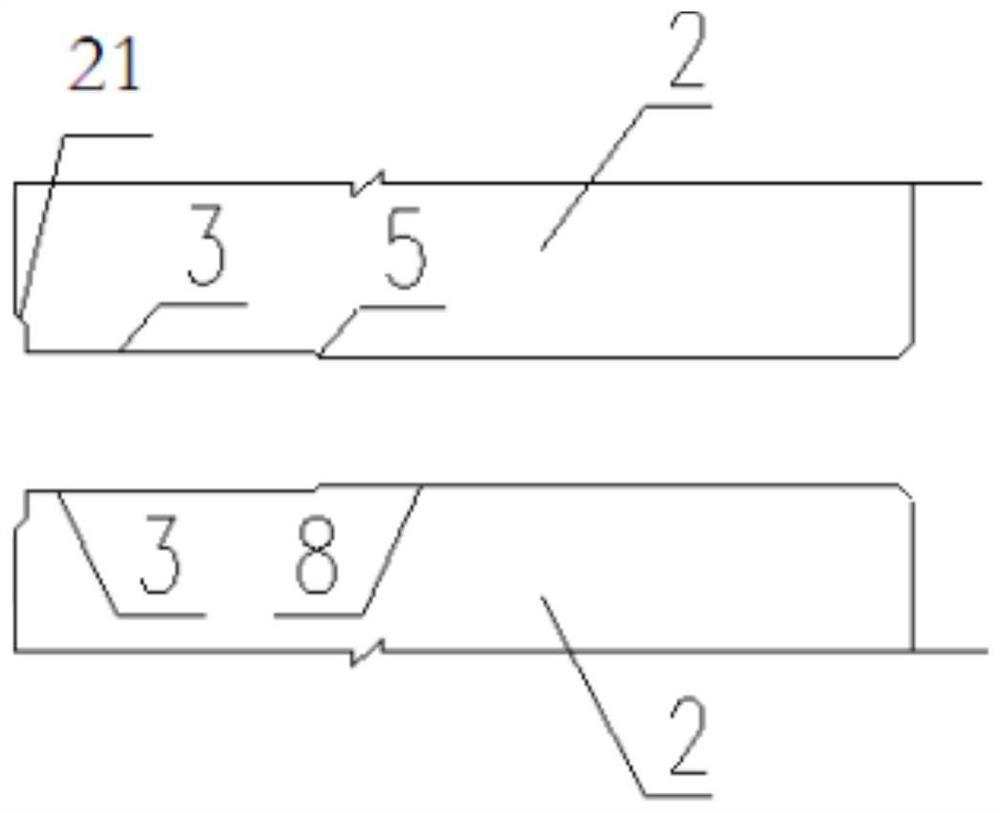

[0042] Such as image 3 As shown, since the local corner of the T-shaped groove 3 is usually the weakest point of force, one end of the T-shaped groove 3 is provided with a 45° slope 5 connected to the through groove 8, and the other end is provided with the The tapered groove 21 matched with the ring gasket 14, the slope of the tapered groove 21 is set to 45°; the above settings can effectively increase the bearing capacity of the structure.

[0043] In this embodiment 2, if figure 1 , 2 , 3, 4, and 5, the cylindrical compaction section 15 is glued into the T-shaped groove 3, when the step anchor bolt 6 connects the two shield segment structures, the sm...

Embodiment 3

[0044] Embodiment 3: as Figures 1 to 10 As shown, a high water pressure resistant shield segment bolt hole composite sealing structure differs from Embodiments 1 and 2 in that the fastener consists of a bolt washer 12, a nut 13 and a high resilience rubber ring 20 Composition, the high resilience rubber ring 20 is arranged at the end of the through groove 8 of the segment structure 2 at the non-anchor end of the bolt.

[0045] Such as Figure 8 , 9 , 10, in the present embodiment 3, the outer diameter of the high-resilience rubber ring 20 is 52mm, the inner diameter is 40mm, and the thickness is 6mm, which is in the shape of a truncated cone; The tapered groove matching the elastic rubber ring 20, when the high-resilience rubber ring 20 is fixed with the segment structure 2 at the non-anchor end of the bolt, it plays an active waterproof role through mutual extrusion force. Wherein, the sectional view of the high resilience rubber ring 20 is as Figure 9 As shown, the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com