Dry-soil-removed reinforced concrete screw pile forming device and method

A reinforced concrete screw and dry borrowing technology, which is applied to sheet pile walls, buildings, infrastructure engineering, etc., can solve the adverse effects of surrounding environment and pile quality, difficult to control the position and quality of steel bars, and cannot be applied to flat-bottomed screw piles. and other problems, to achieve the effect of easy control of engineering quality, improvement of pile quality, and improvement of bearing capacity value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

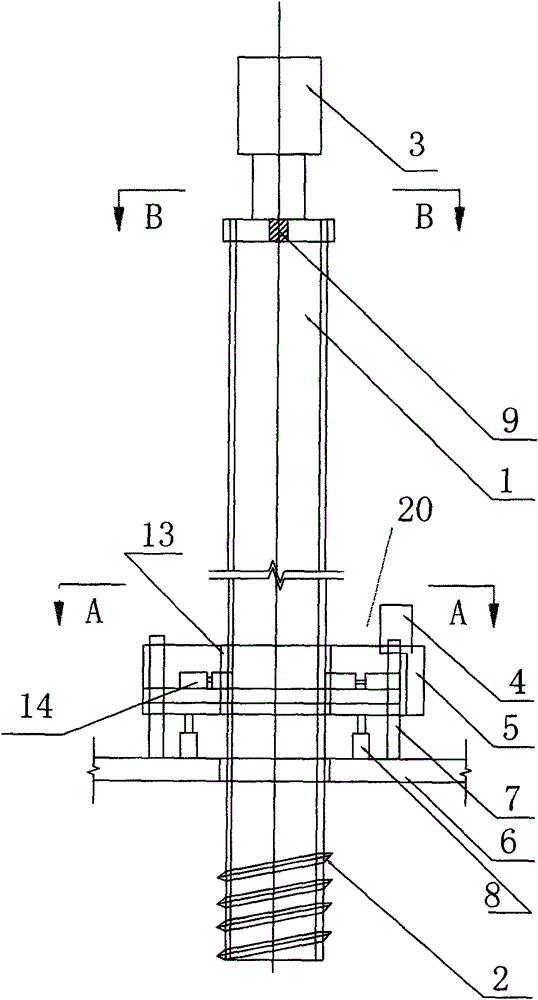

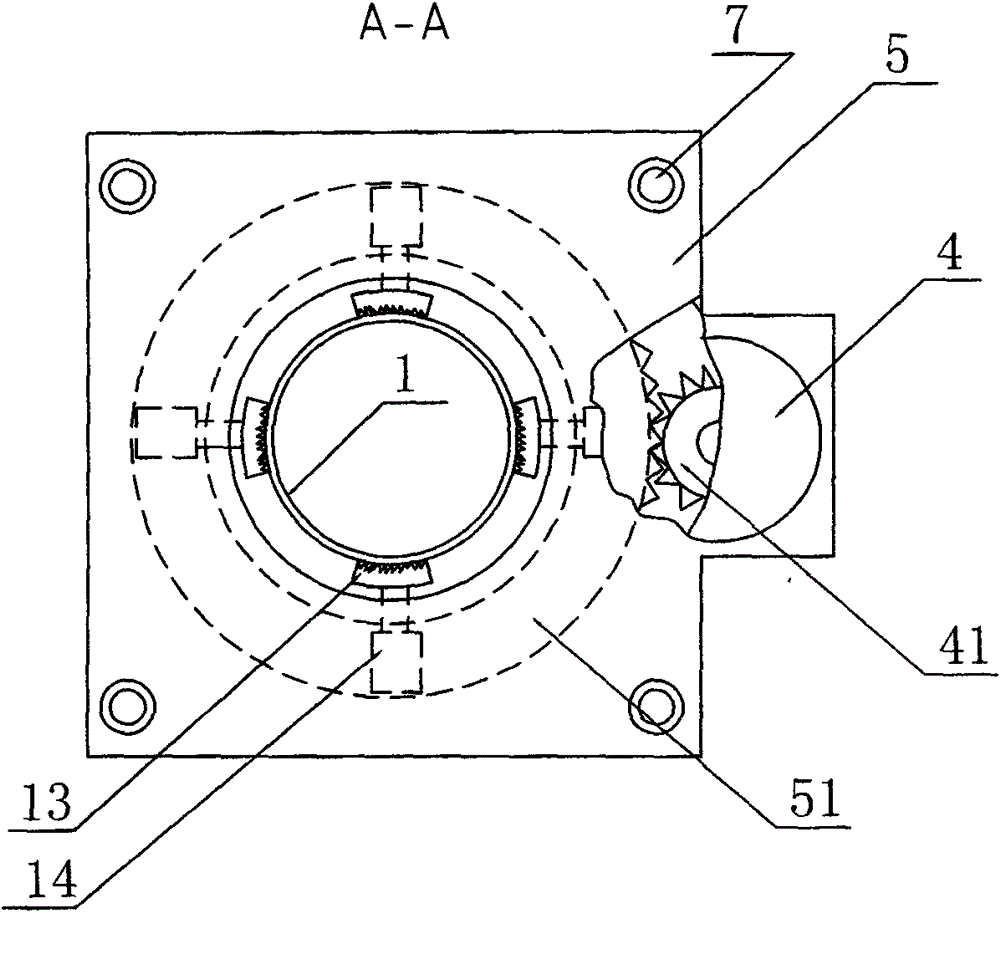

[0027] Figure 1 to Figure 4 An embodiment of the present invention is shown, which includes a steel mold tube 1 passing through the pile driver base 6, and a rotary power head 3 is arranged at the upper end of the steel mold tube.

[0028] The steel mold tube 1 is set as an opening at the bottom, and is welded with a threaded triangular steel bar 2 from the bottom of the tube to form a steel mold tube with an external helix. In order to ensure the pile reliability of the reinforced concrete screw pile, the external The number of turns of the spiral body must be greater than 3 turns;

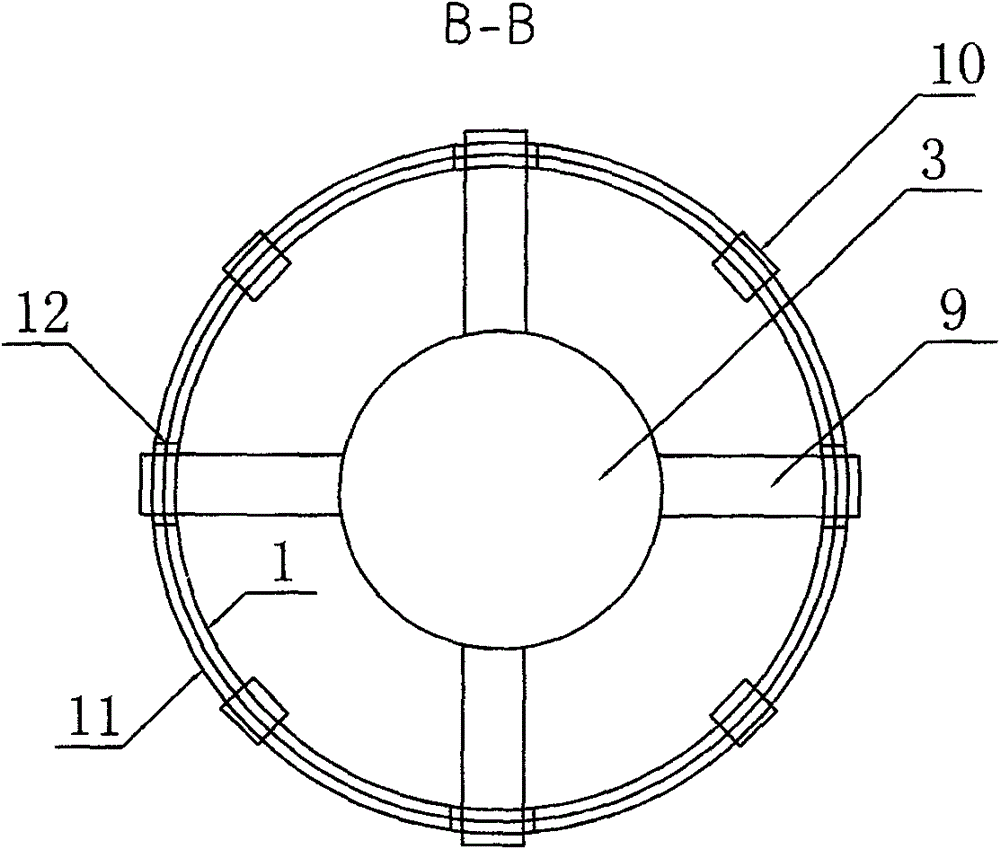

[0029] The top of the steel mold pipe 1 is provided with a rotary power head 3, and the bottom of the rotary power head 3 is connected with a cross-shaped connector 9, which can be welded with a cross-shaped steel bar, such as image 3 shown;

[0030] A steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com