Arc-shaped mold plate for casting arc-shaped shear wall of industrial factory building and manufacture method of arc-shaped mold plate

A technology of arc-shaped formwork and industrial workshops, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve the problems of large lifting equipment, high engineering cost, and complicated installation, and achieve the goal of manufacturing Low cost, low cost, easy hoisting and installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

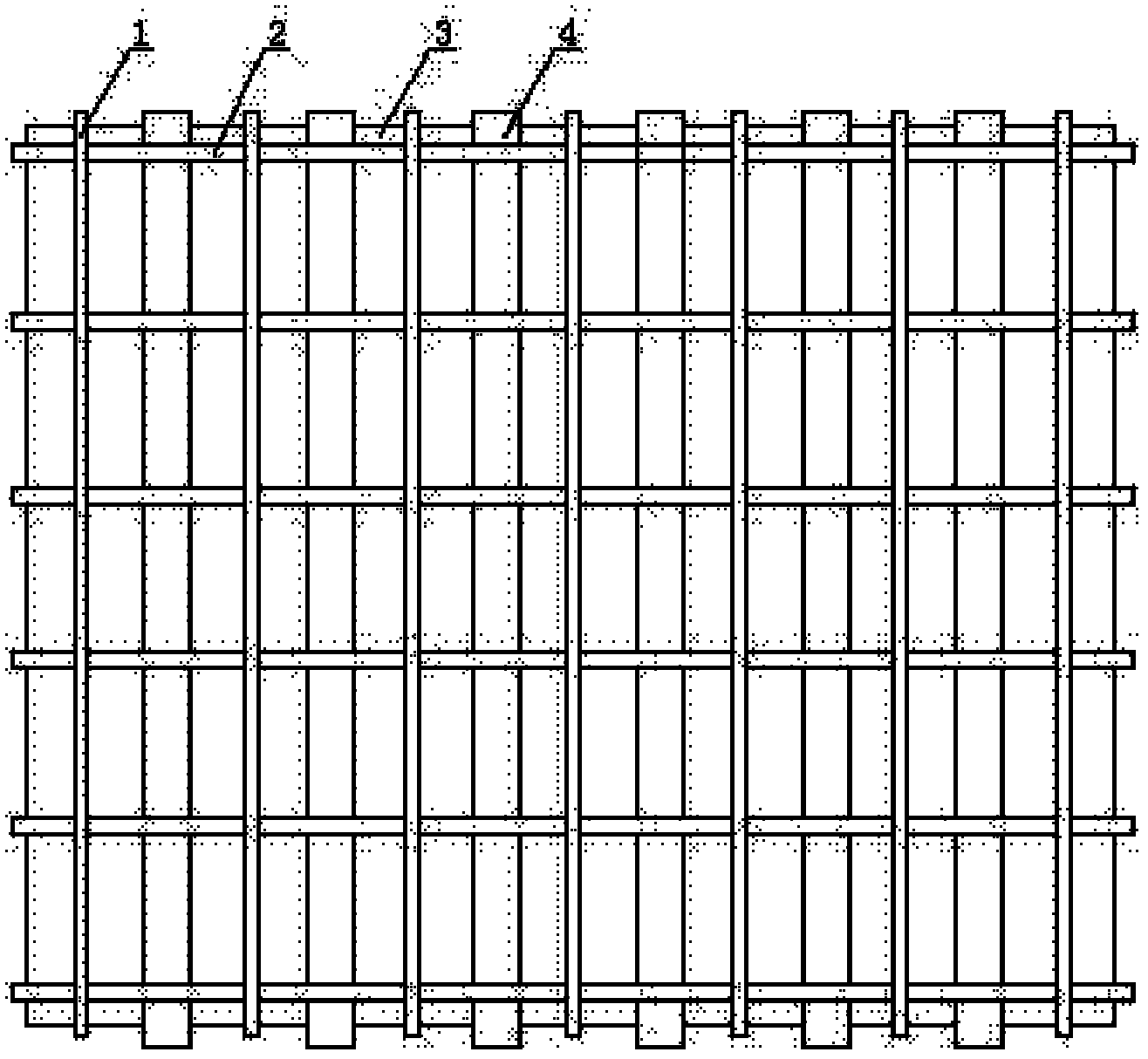

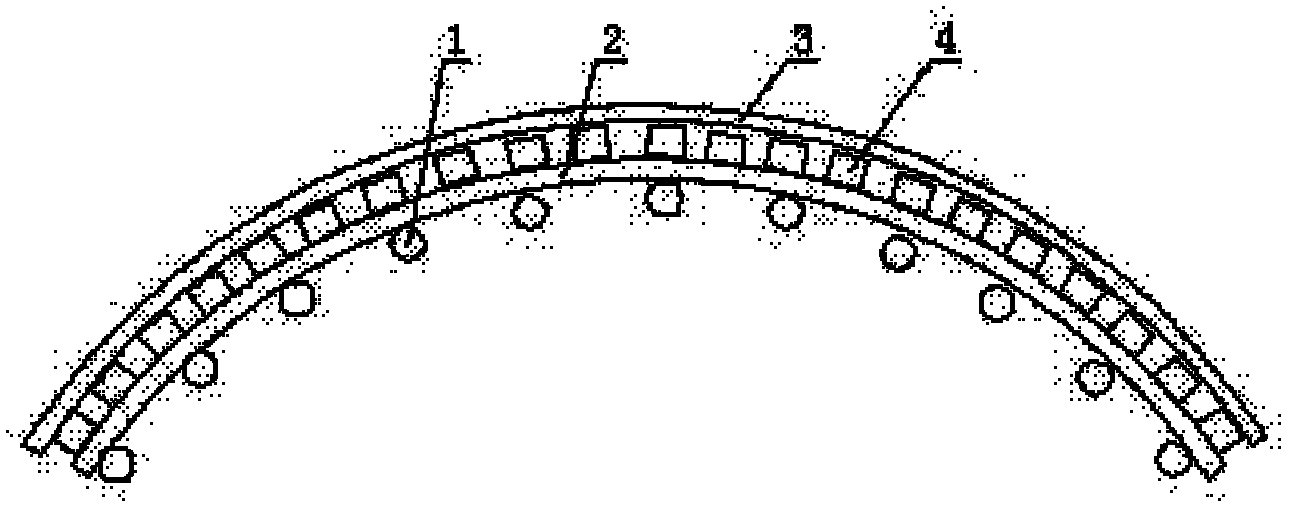

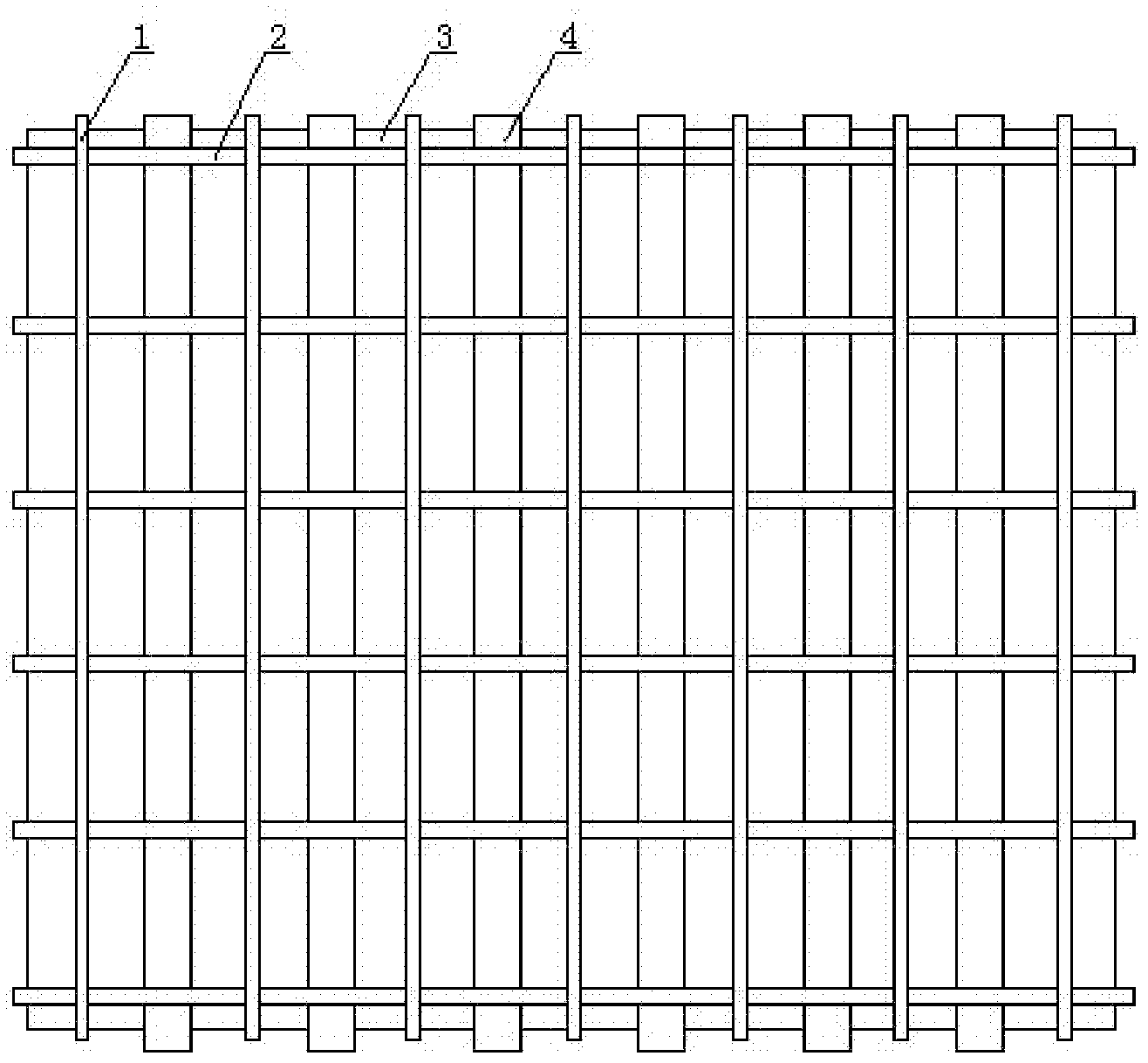

[0021] An arc-shaped formwork for pouring an arc-shaped shear wall of an industrial factory building, which includes an arc-shaped grid, wooden squares 4, and an arc-shaped formwork. The steel pipe 1 is formed, and the arc-shaped grid frame and the arc-shaped formwork of the same shape are fixed, and the wooden squares are vertically fixed every 300mm in the horizontal direction between the arc-shaped grid frame and the arc-shaped formwork.

[0022] A method for manufacturing a curved formwork for pouring a curved shear wall in an industrial factory building: the steps of the method are:

[0023] (1), processing arc formwork: processing and molding the wooden formwork according to the arc size of the shear wall to form an arc formwork;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com