Shed tunnel and shed tunnel design method

A design method and shed-hole technology, applied in protective equipment, buildings, etc., can solve problems such as high stiffness, overall structural damage, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] As shown in the figure, a kind of shed hole is processed and installed, which is arranged between the roadbed in the mountainous area and the slope of the mountain to prevent the rolling stones on the slope from harming the roadbed. The road is located in Kangding County, Ganzi Tibetan Autonomous Prefecture, Sichuan. When it crosses Zheduo Mountain, it is forced to develop along a section of high and steep slope in Guzan Town due to the large slope drop. The slope in this section is high in altitude, low in temperature, and develops freeze-thaw collapses at the top of the mountain. Rolling stone disasters have the characteristics of "multiple points", "wide area" and "frequent high-level occurrences", which cause serious harm to road traffic safety and need to be dealt with urgently.

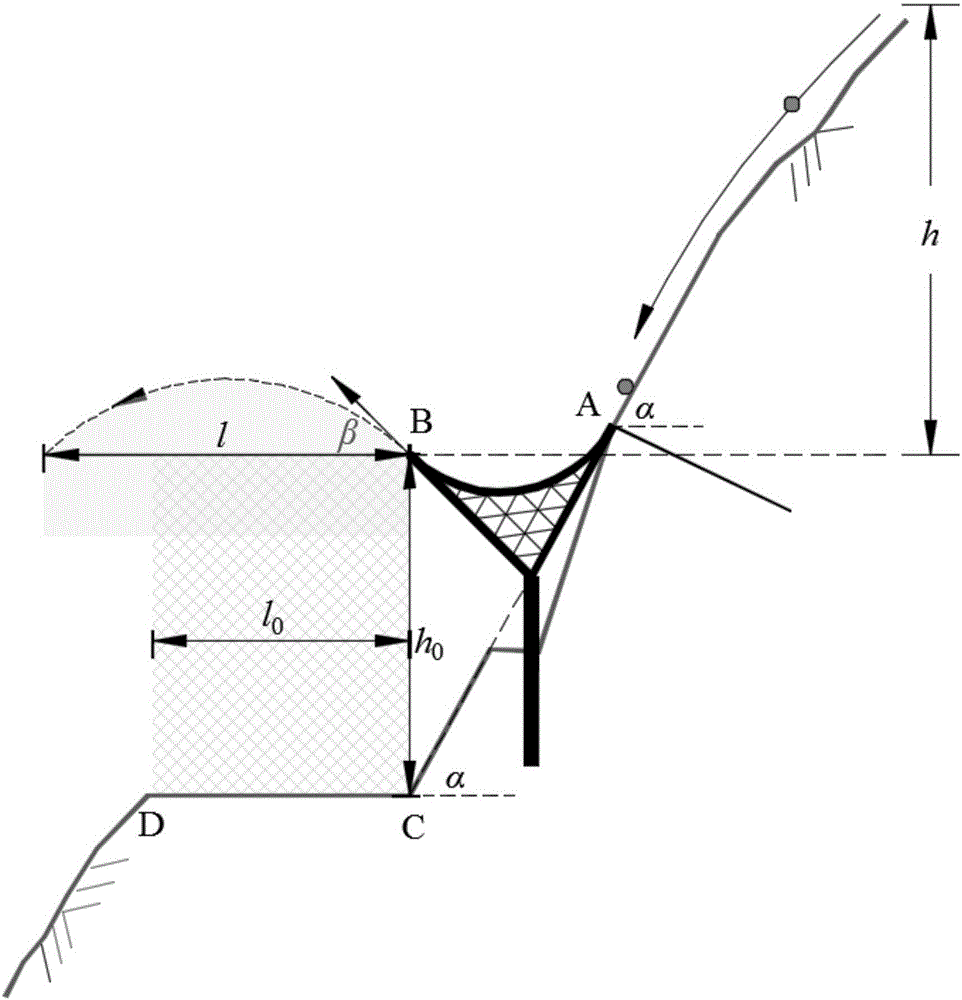

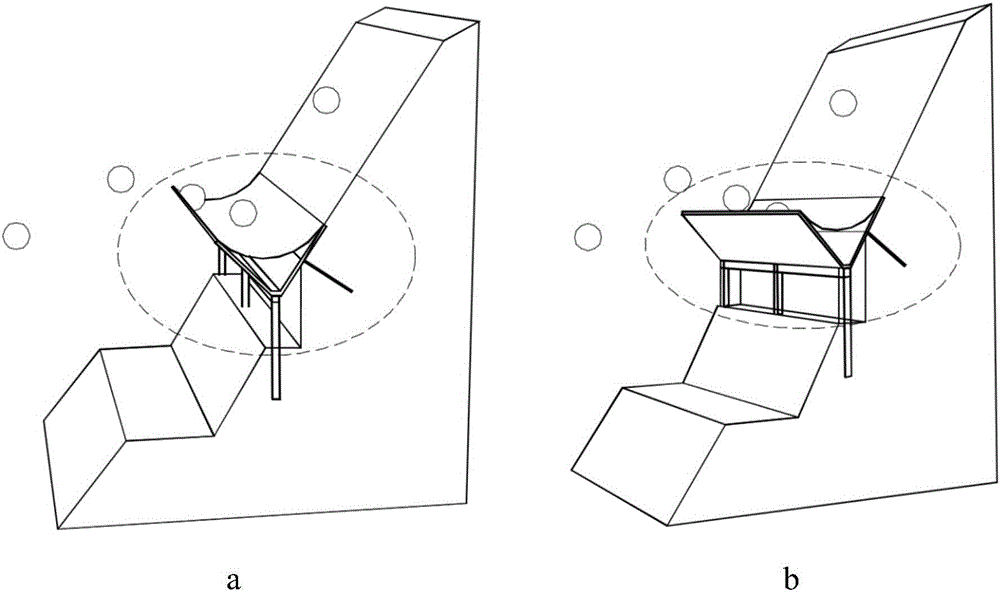

[0111] figure 1 It is a side view of the installation position of the shed hole, image 3 a. image 3 b is a three-dimensional schematic diagram of the installation position of the shed...

Embodiment 2

[0117] Adopt the design method of the present invention to complete the design of the shed hole in Embodiment 1, determine the value R of the curvature radius of the cover plate, and the buried depth value L of the column of the grouted steel pipe pile structure p , Anchorage depth value L in the anchorage system b parameter design.

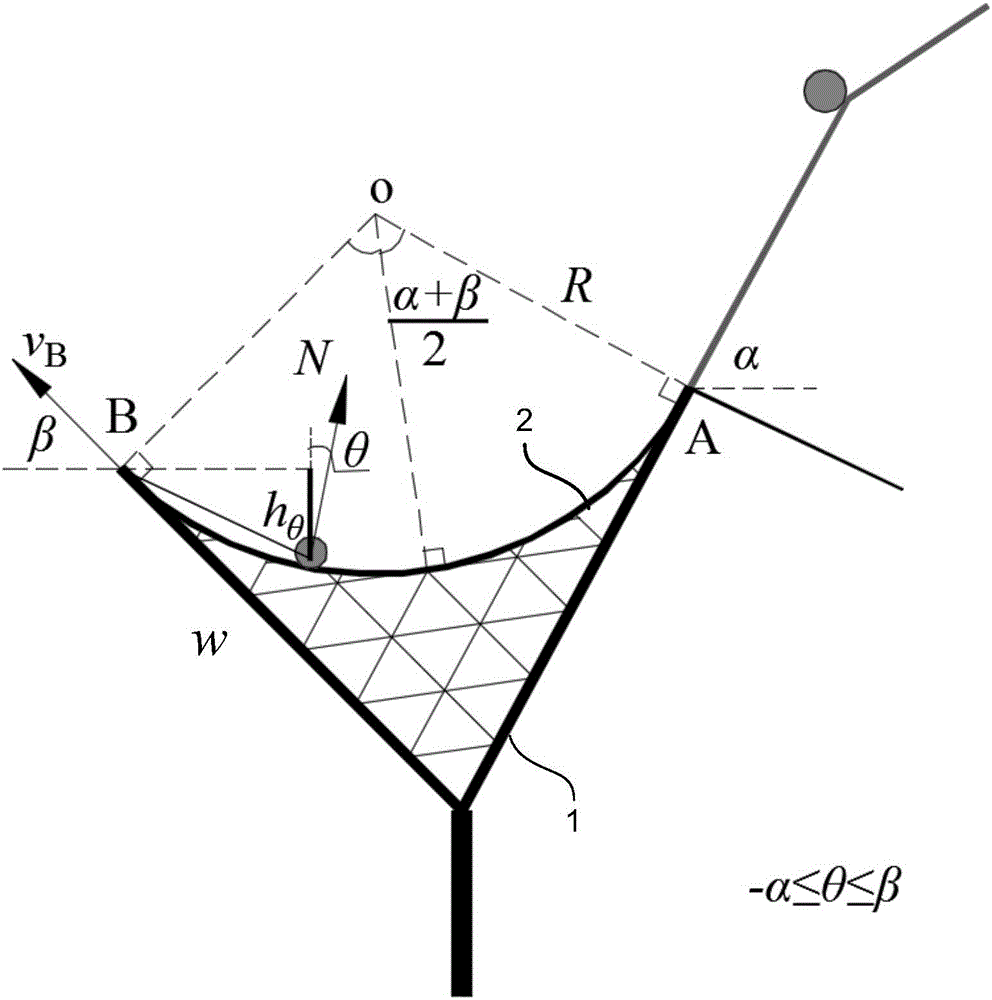

[0118] After investigation, the road section endangered by landslides and rolling rocks is 1.2km long, and the effective width of the safe airspace of the roadbed to be controlled is l 0 = 10m, effective height h 0 = 6m. The inclination angle of the inner slope of the road is α=55°, and the collapse mainly occurs in the seasonal ice and snow-covered belt near the elevation of 250m above the road, resulting in a fall height from h min = 150m to h max = 300m are distributed collapse rolling stone groups. The rolling stone particles are uniformly small as a whole, with a particle size of about 0.1m and a maximum of 0.5m, corresponding to the ma...

Embodiment 3

[0128] The main structure design of the truss structure ceiling is completed on the basis of the second embodiment.

[0129] Figure 8 Is the schematic diagram of the truss structure ceiling. The truss structure ceiling includes a rigid ring beam 121 for fixing the cover plate, a vertical truss triangular surface 122 connected under the rigid ring beam 121, a transverse main beam 123 perpendicular to the vertical truss triangular surface 122, necessary side frames, and auxiliary beams.

[0130] Figure 9 It is a cross-sectional structure diagram of a monolithic truss ceiling. The angle at the bottom of the triangular surface 122 of the vertical truss = π - (α + β) = 100°, and the length of the side frames 124 on both sides of the triangular surface 122 of the vertical truss is determined according to formula 2:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com