Pretreatment method of coastal soft foundation water gate pile foundation

A technology for weak foundations and sluices, applied in infrastructure engineering, construction, soil protection, etc., can solve the problems of endangering the stability of the sluice chambers on both sides of the bank wall, the lateral displacement of the sluice bank wall, and the settlement is difficult to control, etc., to achieve convenience Effects of construction organization design, uniform site settlement, and reduction of civil engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

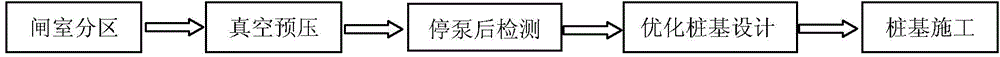

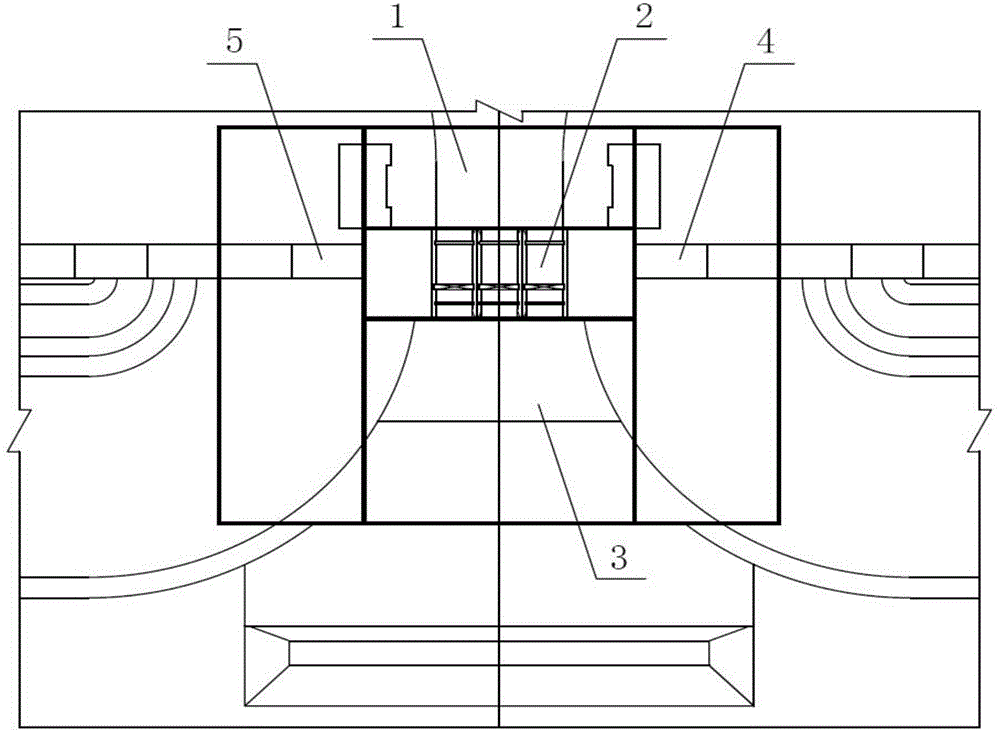

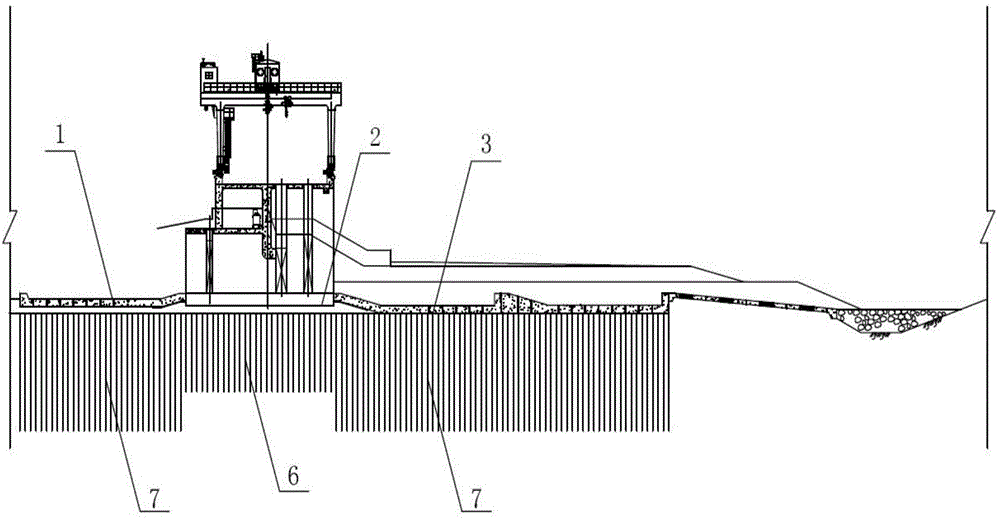

[0019] Such as Figure 1 to Figure 4 As shown, a pretreatment method for the pile foundation of the coastal weak foundation sluice. Before the construction of the pile foundation of the sluice, the soft soil foundation of the sluice is treated first, and the entire sluice area is divided into the upstream connection area 1, the downstream connection area 3, and the left bank connection area 4 , the right bank connection area 5 and the chamber foundation 2, all areas adopt vacuum preloading; the horizontal drainage of vacuum preloading adopts the cushion layer 10 to directly connect the drainage filter pipe 12 for drainage; the vertical drainage adopts drainage inserts, and the plane of the drainage inserts is square Or triangular arrangement, with a spacing of 0.8m to 1.0m, and the exposed mud surface is about 50cm. The upstream connection area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com