Improvement method of high liquid limit soft soil directly used as prefabricated roadbed filling material

A subgrade filling material and prefabricated assembly technology, applied in packaging, construction, roads, etc., can solve the problems of the construction period being greatly affected by the environment, the construction process is not easy to control, and the project cost is increased, so as to solve the problem of insufficient stability and realize recyclability. Take advantage of effects that improve stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The soil sample 1 of the present embodiment is taken from the coastal area of Wenzhou;

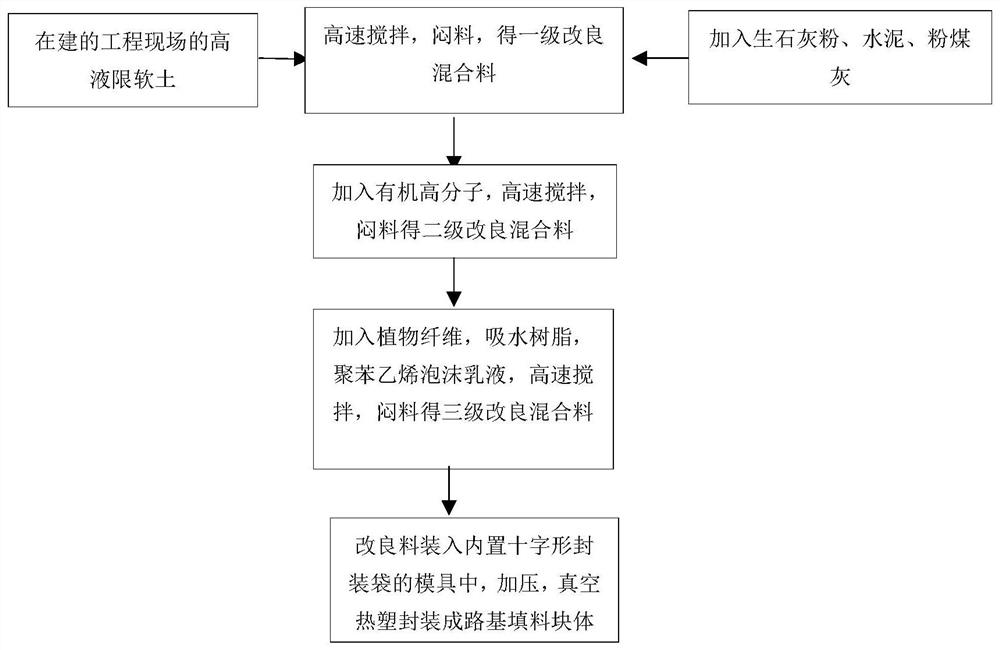

[0035] In the present embodiment, the high liquid limit soft soil of soil sample 1 is directly used in the improvement method of prefabricated roadbed filling material, comprises the following steps:

[0036] a. To the high liquid limit soft soil of soil sample 1, add quicklime powder, low-grade cement, and fly ash powder in sequence, and then stir at high speed in turn according to the adding order to obtain the first-stage initial mixture; the amount of quicklime powder added Add and stir for 2 minutes according to the mass ratio of 14:100 to the high liquid limit soft soil; add the low-grade cement according to the mass ratio of 4:100 to the high liquid limit soft soil and stir for 2 minutes; And the addition of fly ash powder according to the mass ratio of high liquid limit soft soil is the ratio of 6:100 after adding and stirring for 1min;

[0037] b. The first-stage initial...

Embodiment 2

[0050] The soil sample 2 of the present embodiment is taken near Xinyang Port, Yancheng;

[0051] In the present embodiment, the high liquid limit soft soil of soil sample 2 is directly used in the improvement method of prefabricated roadbed filling material, comprises the following steps:

[0052] a. To the high liquid limit soft soil of soil sample 2, add quicklime powder, low-grade cement, and fly ash powder in sequence, and then stir at high speed in turn according to the order of addition to obtain the first-stage initial mixture; the amount of quicklime powder added Add and stir for 5 minutes according to the mass ratio of 20:100 to the high liquid limit soft soil; add the low-grade cement according to the mass ratio of 8:100 to the high liquid limit soft soil and stir for 3 minutes; And the addition of fly ash powder according to the mass ratio of high liquid limit soft soil is 15:100 after adding and stirring for 2min;

[0053] B, the first-stage initial mixture obtai...

Embodiment 3

[0065] The soil sample 3 of the present embodiment is taken from the road construction site in Wuai Town, 329 National Road, Ningbo City;

[0066] The high liquid limit soft soil in the soil sample 3 of the present embodiment is directly used in the improvement method of prefabricated roadbed filling material, comprises the following steps:

[0067] a. To the high liquid limit soft soil of soil sample 3, add quicklime powder, low-grade cement, and fly ash powder in sequence, and then stir them at high speed in turn according to the order of addition to obtain the first-stage initial mixture; the amount of quicklime powder added Add and stir for 3 minutes according to the mass ratio of 16:100 to the high liquid limit soft soil; add the low-grade cement according to the mass ratio of 6:100 to the high liquid limit soft soil and stir for 4 minutes; And the addition amount of fly ash powder according to the mass ratio of high liquid limit soft soil is 10:100 after adding and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com