Active and passive integrated water-stopping middle-buried type water-stopping strip structure for deformation joint

An active and passive, deformation joint technology, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve problems affecting the normal operation of tunnels and underground engineering, jeopardizing structural durability, detail waterproofing defects, etc., to achieve engineering quality It is easier to control, slow down water leakage, and implement simple and feasible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

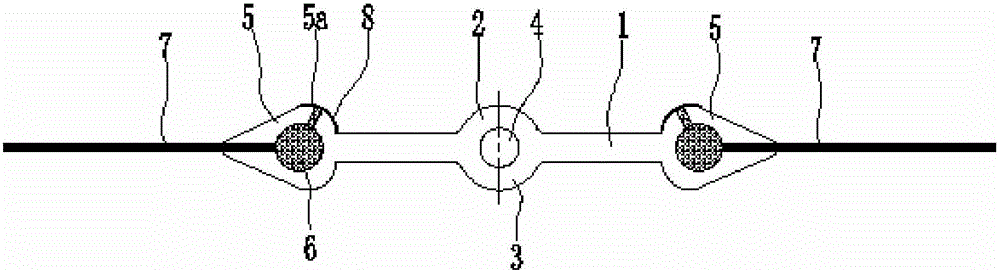

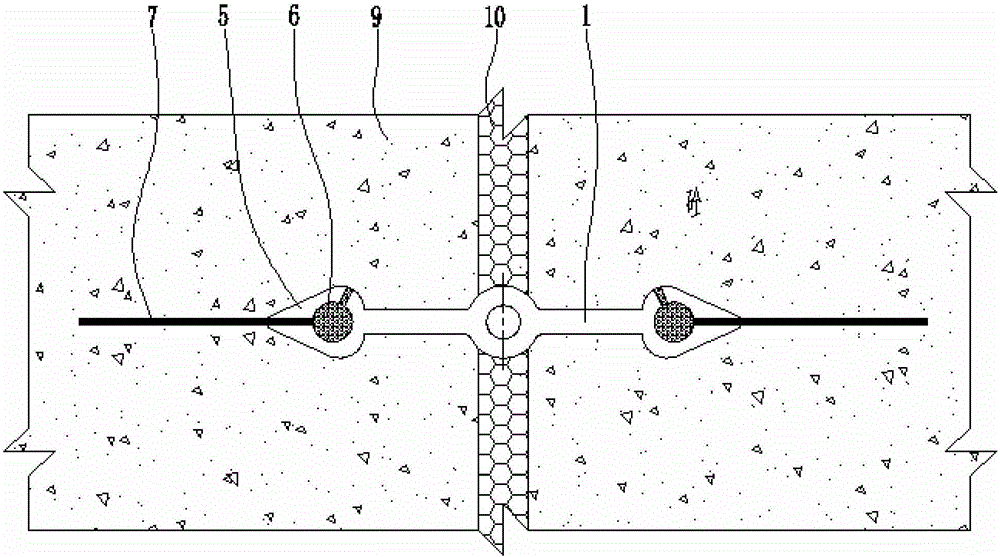

[0023] Such as figure 1 , figure 2 As shown, it is defined that the left-right direction shown in the figure is the width direction of the main belt body 1, and the direction perpendicular to the paper surface is the length direction of the main belt body 1. The main belt body 1 is preferably formed by extrusion molding, and an upper boss 2 and a lower boss 3 are integrally formed in the middle of the main belt body 1. The upper boss 2 protrudes from the top surface of the main belt body 1, and the lower boss 3 protrudes from the top surface of the main belt body 1. The bottom surface of the main belt body 1 and the upper and lower bosses all extend along the length direction of the main belt body 1 . Preferably, the upper boss 2 and the lower boss 3 are circular arcs arranged symmetrically, and a cavity 4 is formed between the upper boss 2 and the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com