Energy consumption type rolling stone protection system and energy consumption type rolling stone protection system design method

A technology of protection system and design method, applied in protection equipment, construction, etc., can solve the problems of steel column damage, failure to achieve protection, uneven load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

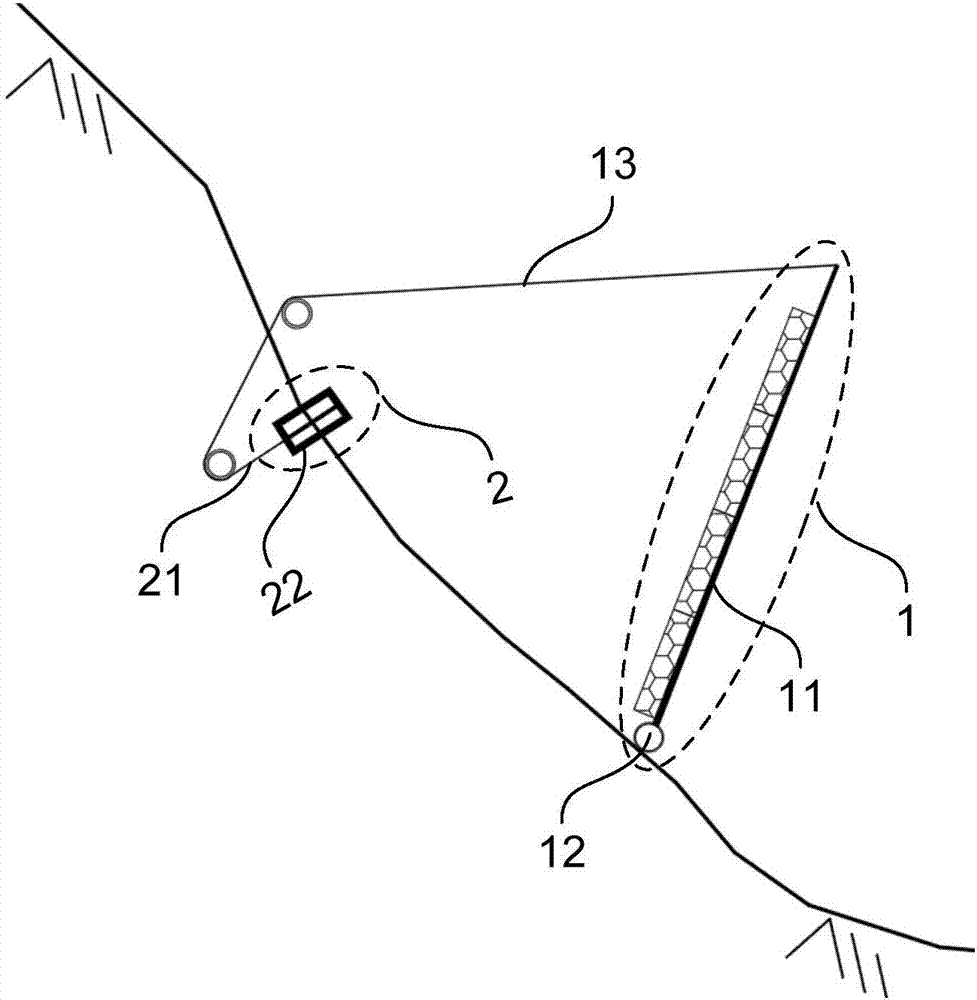

[0121] Such as figure 1 As shown, an energy-consuming rolling stone protection system is processed.

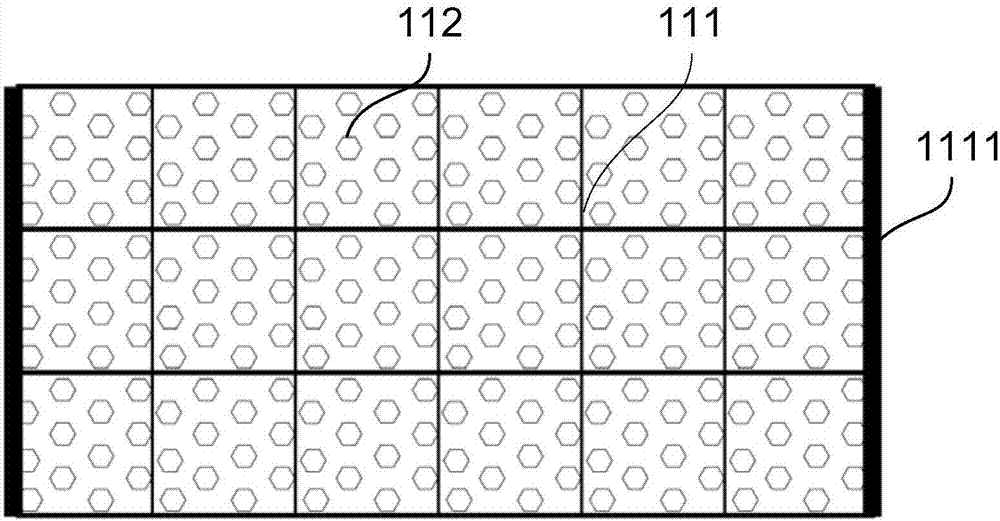

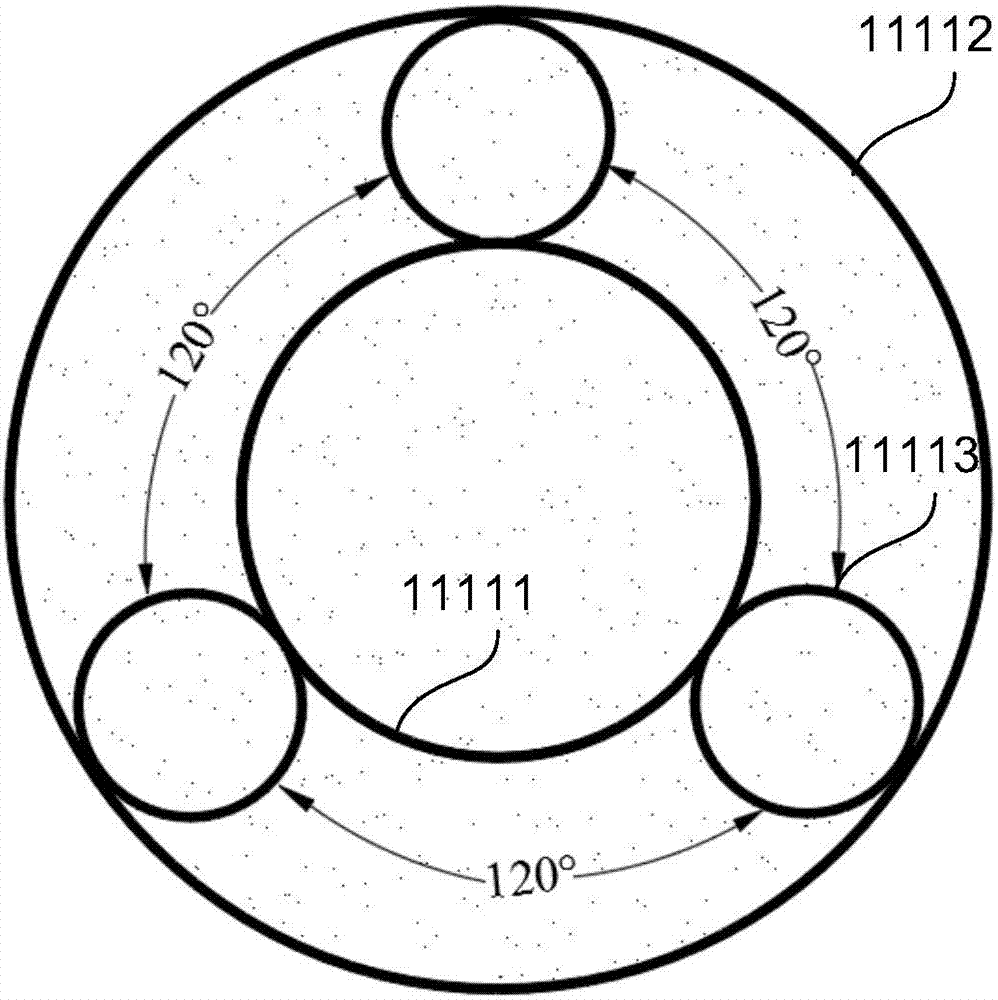

[0122] figure 1 It is a schematic diagram of the structure of the energy-consuming rolling stone protection system; figure 2 It is a schematic diagram of the structure of the energy dissipation panel. The energy-dissipative rolling stone protection system is arranged with a mountain slope where rolling stones occur, and includes two-stage energy-dissipating structures, the first-stage energy-dissipating structure is an energy-dissipating plate device 1, and the second-stage energy-dissipating structure is an energy-dissipating piston device 2; The energy-dissipating panel device 1 includes an energy-dissipating panel 11 arranged facing the slope. The energy-dissipating panel 11 is fixed in the rolling stone impact area through a hinged frame 12. The energy-dissipating panel 11 is a metal grid frame 111 filled with an energy-dissipating material block monomer. 112; the ener...

Embodiment 2

[0128] Using the design method of the present invention, the design of the specifications of the energy-dissipating panel 11 in Embodiment 1 is completed.

[0129] The energy-dissipating material block unit 112 adopts a quadrangular prism structure, the bottom surface is a square with a side length B, and a thickness Z.

[0130] Step S1. Obtain basic data

[0131] Investigate the site of the disaster site, collect data on kinematic parameters such as the diameter, speed, and direction of the rolling stone, and determine the characteristic diameter D of the rolling stone after data analysis 85 = 4m, characteristic impact velocity v 85 =12m / s. The rolling stone density ρ = 2500kg / m is determined by field sampling and laboratory tests 3 .

[0132] The energy-dissipating material block is made of foamed aluminum, and it is determined by the uniaxial compression test: the yield platform stress of the energy-dissipating material block is σ y =960kPa, Yield platform strain ε of ...

Embodiment 3

[0139] Adopt the design method of the present invention, continue to complete the piston cylinder 22 length 1 in the embodiment one on the basis of the embodiment two 0 the design of.

[0140] Supplementary completion of the determination of the following parameters: In this embodiment, according to the occurrence of disasters in this area and the protection range of each single body, it is determined that the energy-consuming material block monomer 112 filled in the metal grid frame 111 is based on a single layer of 3× 4 ways to arrange, a total of n = 12. Determine the number N=10 of the piston and cylinder 22 in the energy-consuming piston device 2 according to the topographical conditions of the disaster site, and the bottom area S of the piston and cylinder 22 0 =7m 2 . Measure to determine the maximum diameter D of the rolling stone in the limit max =10m, maximum impact velocity v max =24m / s. Determine the tensile strength σ of the piston and cylinder according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com