Passive and inactive integrated water stop middle buried type water stop belt structure for construction joint

A technology of active and passive construction joints, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve problems affecting the normal operation of tunnels and underground engineering, endangering structural durability, and detailed waterproof defects, etc., to achieve engineering quality Easier to control, save construction cost, simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

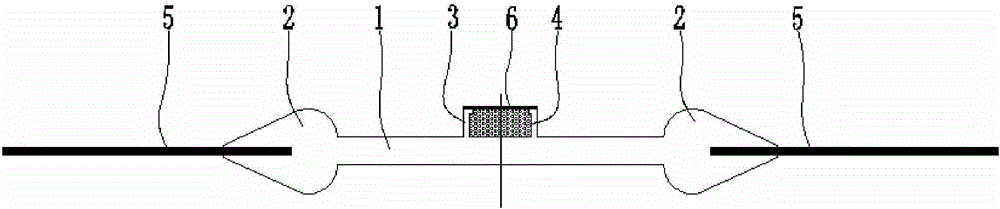

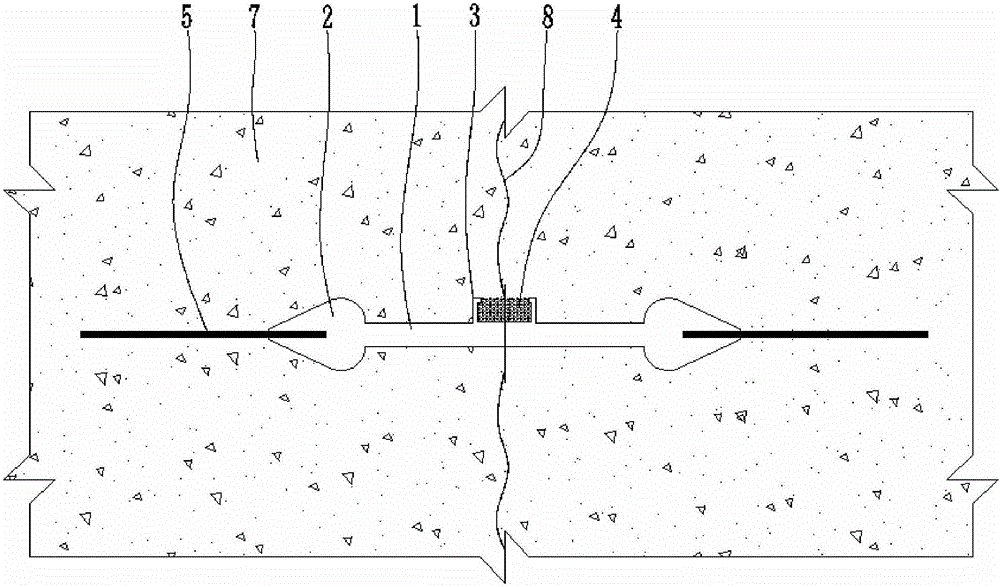

[0020] Such as figure 1 , figure 2 As shown, it is defined that the left-right direction shown in the figure is the width direction of the main belt body 1, and the direction perpendicular to the paper surface is the length direction of the main belt body 1. The main belt body 1 is preferably formed by extrusion molding, and an upwardly protruding middle convex bag 3 is integrally formed in the middle part of the main belt body 1 top surface. The middle part convex bag 3 extends along the length direction of the main belt body 1. The middle convex bag 3 The front and rear ends are flush with the corresponding end faces of the main belt body 1 . The top of the middle convex bag 3 is provided with an opening or a water inlet hole. In the present embodiment, the middle convex bag 3 is preferably a rectangular through groove with a notch on the top, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com