Tunnel Reinforcing Method of Spraying Steel Fiber Concrete Tunnel with Tunnel Mesh

A steel fiber and tunnel technology, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problems of poor compression resistance, bending resistance and shear resistance, weak bearing capacity of lining structure, poor safety, etc., and achieves field operation. It has strong properties, prevents and inhibits the formation and development of cracks, and improves the bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

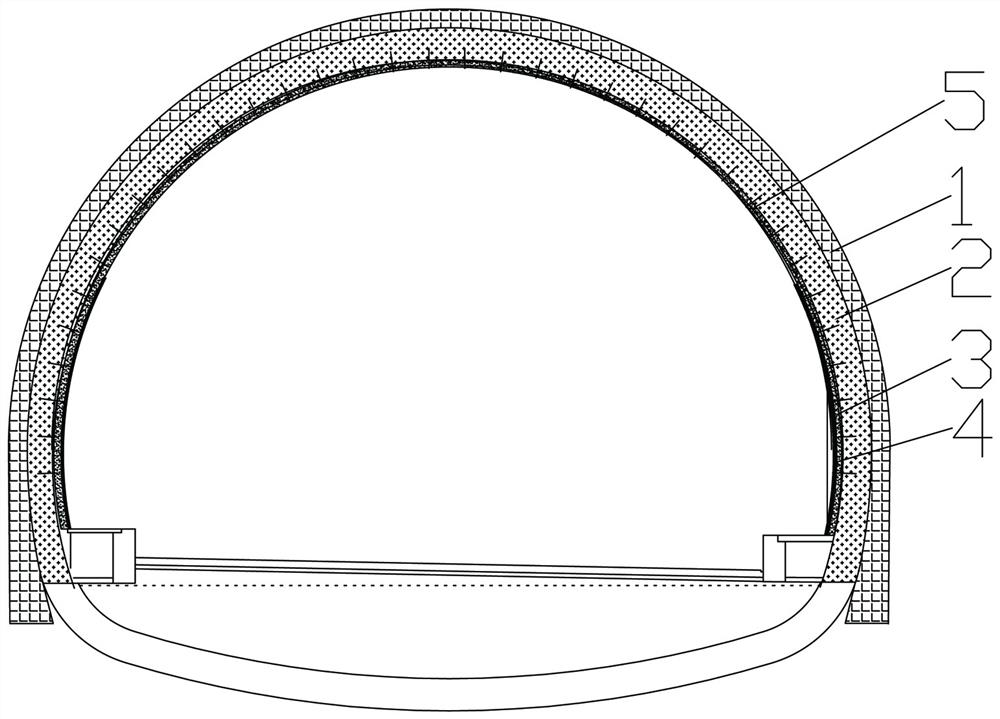

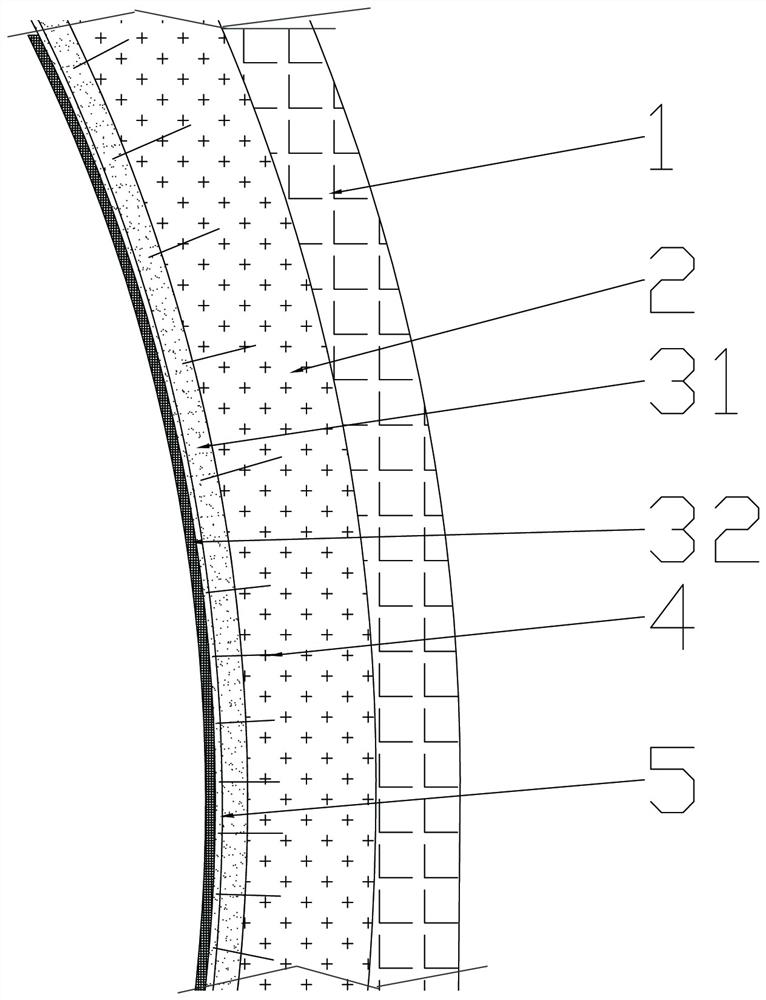

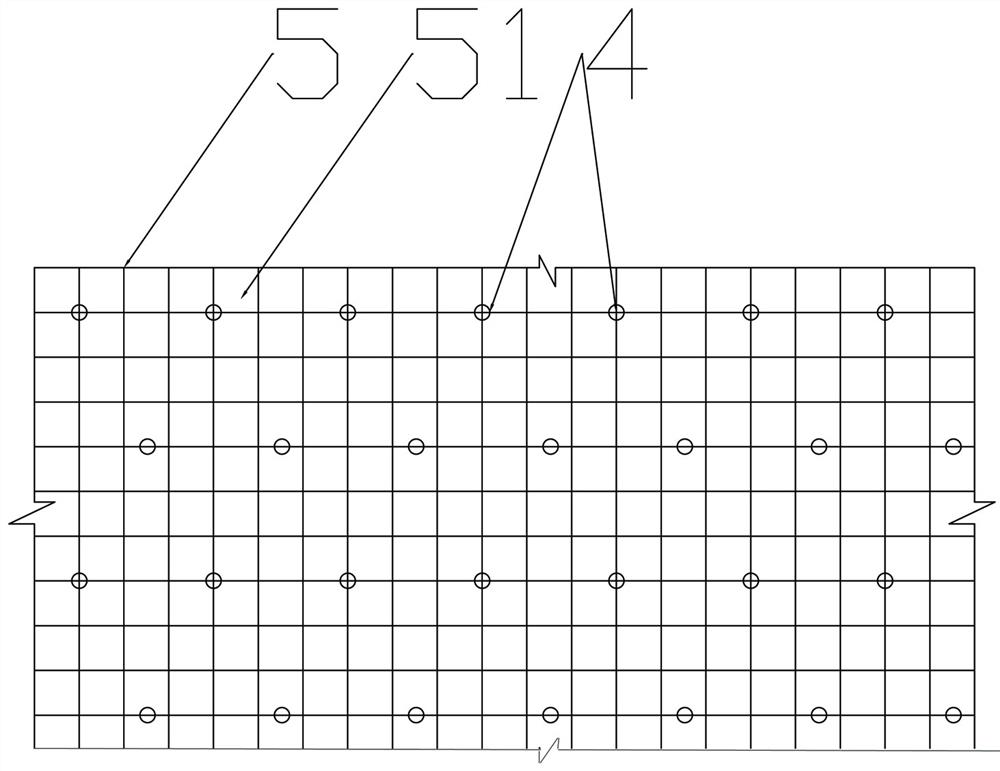

[0038] Embodiment 1: A kind of method for reinforcing the tunnel net sprayed steel fiber reinforced concrete tunnel, see Figure 1-4 , including the following steps:

[0039](1) Cross-section monitoring and re-testing: During the tunnel maintenance process, the surrounding rock and supporting structure 1 should be monitored for disease, cracks, peripheral displacement and vault subsidence, and corresponding indicators should be marked on site, and the surrounding area should be judged based on the monitoring data. The stability and working status of the rock and supporting structure 1 system, determine the selection and correction of supporting parameters and guide the construction. Before, the reinforcement section of the second lining is arranged in a section of 10-50m, and re-measurement is carried out on the inner contour construction of the section of the lining structure 2 to be reinforced at a distance of 5m, and the left and right arch waist positions of the tunnel are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com