Combined steel-plastic composite lacing bar

A composite tie rod and combined technology, applied in the field of building materials, can solve the problems of poor bending resistance and shear resistance, and achieve the effects of small tensile deformation, enhanced pullout resistance, and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

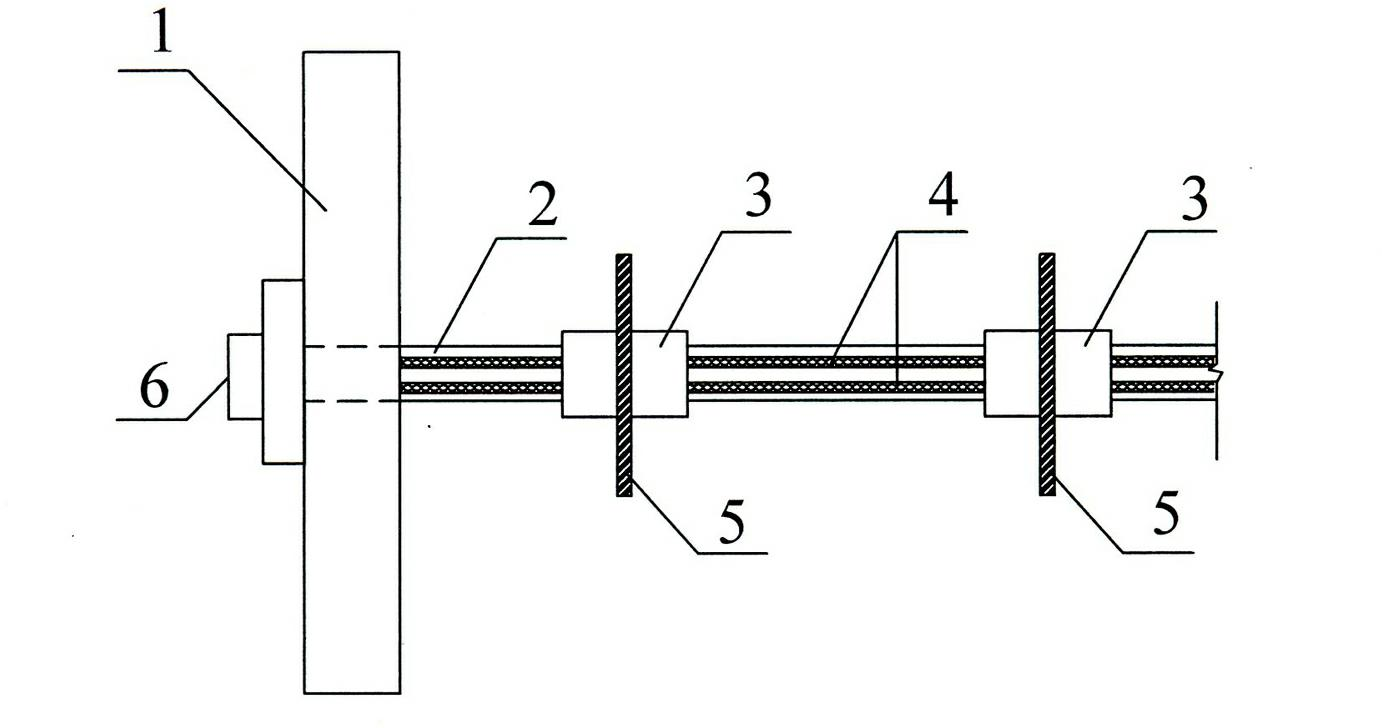

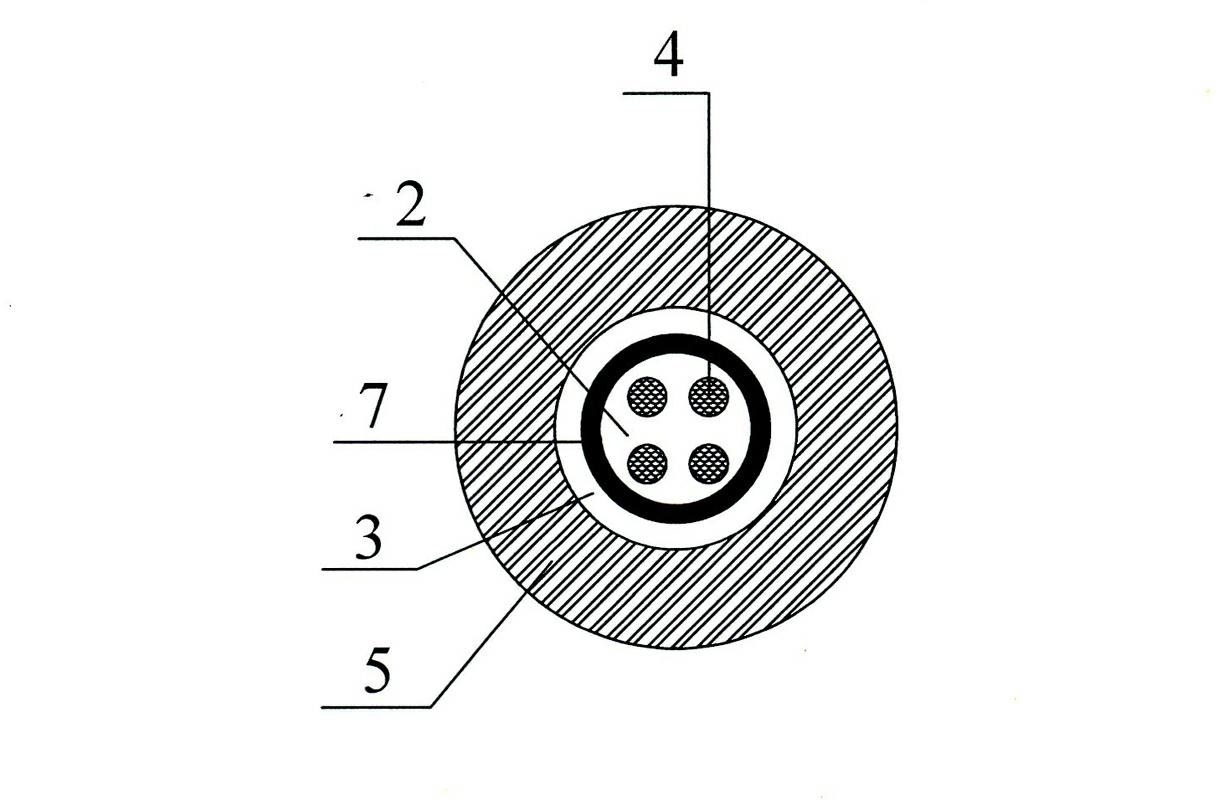

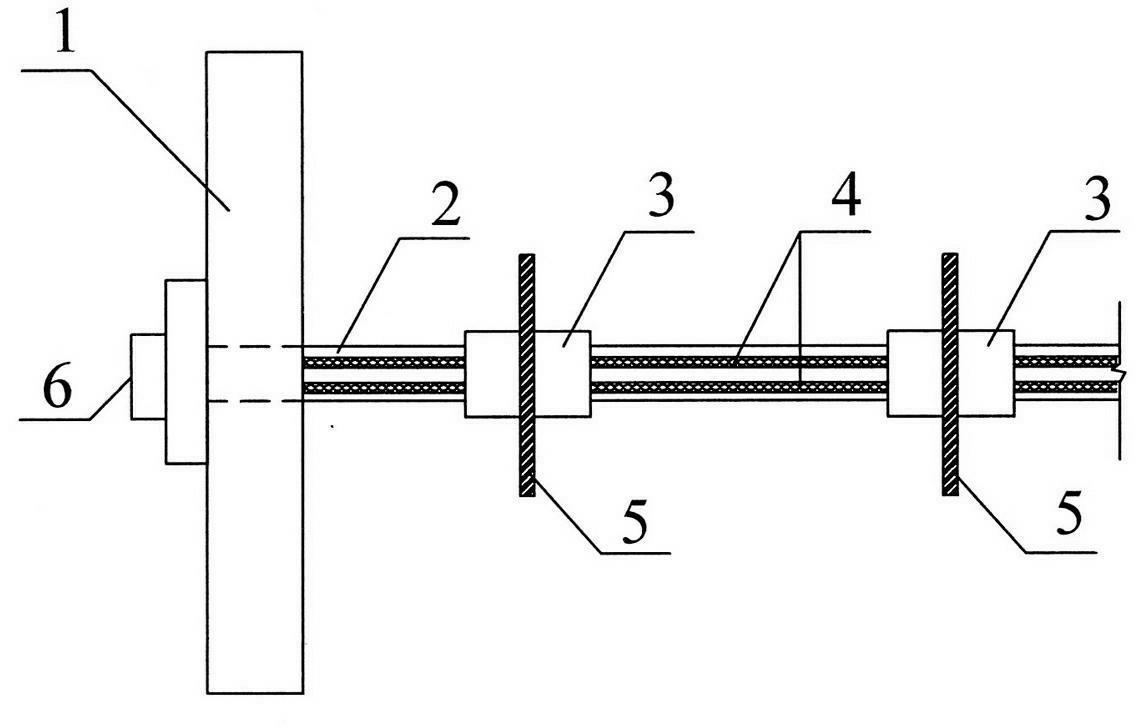

[0016] exist figure 1 and figure 2 In the schematic diagram of the cross-section of a combined steel-plastic composite lacing rod shown, four 10mm steel strands 4 are tightly wrapped with a geosynthetic casing 2 with a wall thickness of 5mm to form the main body of the lacing rod. The outer surface of the above-mentioned geosynthetic casing is engraved with concave-convex grooves, and on the above-mentioned lacing bar, a steel ring stopper 5 with an outer diameter of 90mm is provided every 1m. A steel extrusion sleeve 3 with a thickness of 10 cm and a wall thickness of 4 mm is fixed. The above-mentioned ring baffle and the extrusion sleeve pass through the geosynthetic casing, and the space between the extrusion sleeve and the above-mentioned geosynthetic casing is filled with The rubber glue 7 is used to connect one end of the lacing bar to the wall panel 1 with the anchor head 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com