Upper differential feeding mechanism with contraction joint function of sewing machine and upper feeding wrinkling mechanism using same

A technology of feeding mechanism and sewing machine, which is applied in the direction of feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problems of inability to sew differential effect sewn products, wrinkling, and inability to achieve sewing material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

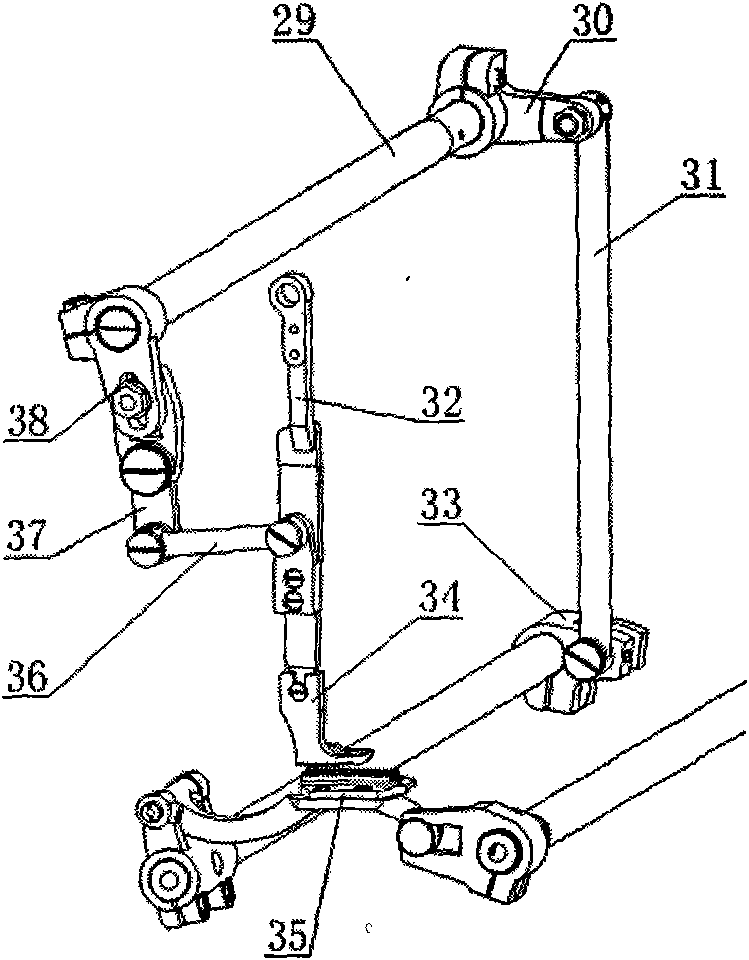

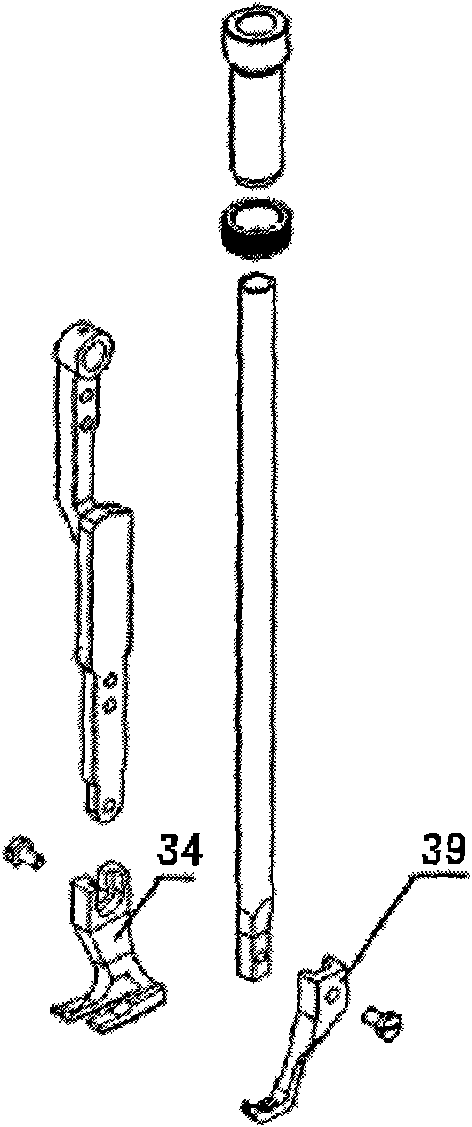

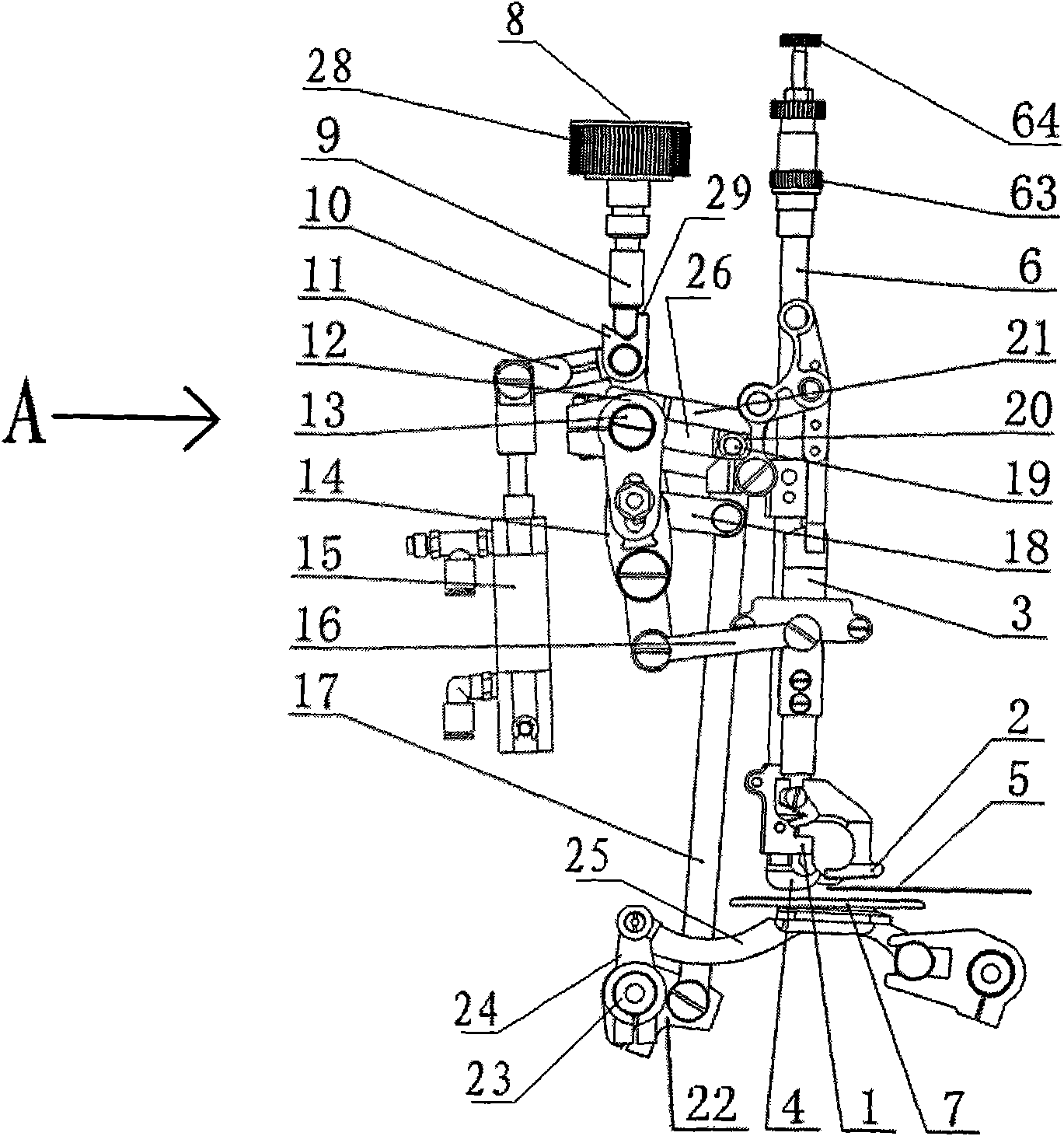

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the structure of the present invention will be further elaborated below in conjunction with specific diagrams.

[0039] see Figure 3 to Figure 7 , The upper differential feeding mechanism with the shrinkage function of the medium-heavy material sewing machine is installed in the left side window of the casing. The two ends of the presser foot swing shaft 13 of the upper differential feeding mechanism are fixedly equipped with a crank 21 and a presser foot swing crank 12 by screws, and the presser foot swing shaft 13 synchronously drives the crank 21 and the presser foot swing crank 12 to swing.

[0040] The cloth feed crank 22 and the needle plate crank 24 are fixedly installed on the cloth feed shaft 23 by screws. The plate 7 moves back and forth, and the feeding teeth on the needle plate 7 realize the feeding of the lower layer sewing mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com