Early strength micro expansion steel fiber road concrete

A steel fiber and micro-expansion technology, applied in the field of concrete, can solve the problems of concrete cracking and setting a large number of expansion joints, restricting large-scale application, long-term maintenance and other problems, so as to shorten the maintenance period and improve the traffic environment , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments are provided in conjunction with the contents of the present invention:

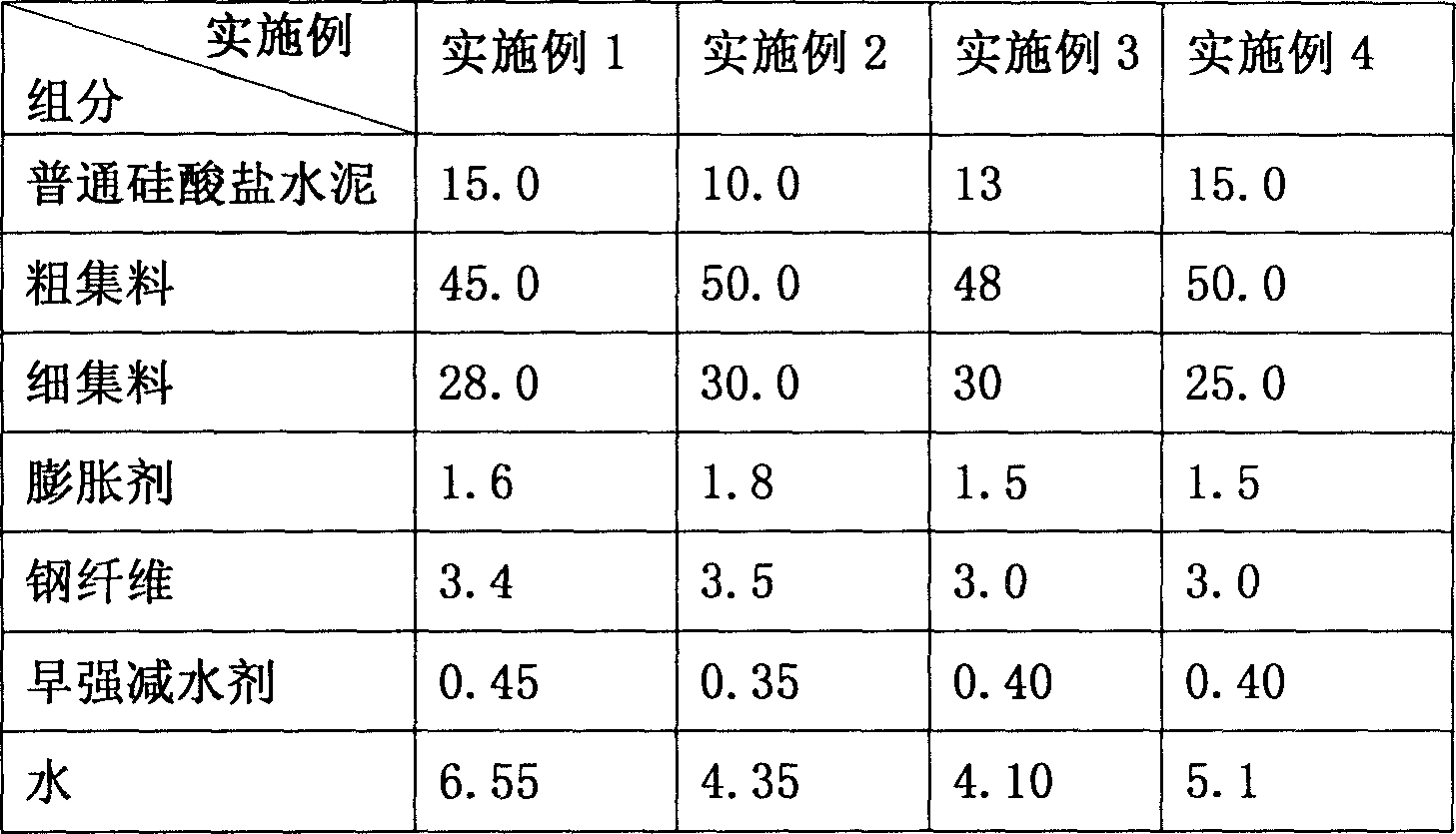

[0019] The early-strength micro-expansion steel fiber concrete material is made of ordinary Portland cement, coarse aggregate, fine aggregate, expansion agent, steel fiber, early-strength water reducer and water in a certain proportion, and is completed by the following process: first The cement, expansion agent powder and early-strength superplasticizer powder required by the mix ratio design are dry-mixed for 30 seconds, then coarse aggregate and fine aggregate are added, and the mixing time is 15 seconds to 1 minute, then steel fiber is added and stirred for 30 seconds ; Finally, add water and stir to form a concrete mixture. The mixing time is 2-3 minutes. Pave the pavement with the well-mixed concrete mixture, and vibrate properly, and the vibrating time should not exceed 2 minutes. Carry out proper maintenance after pouring and molding, and open the road after 3 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com