Waterproof processing method and structure for roof stretching seam

A technology of waterproof treatment and expansion joints, applied in the direction of roof, roof covering, building roof, etc., can solve the problems of weak waterproof ability, hidden danger of water leakage, hidden danger of water leakage, etc., to enhance waterproof ability, prevent water leakage, and improve roof waterproof ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

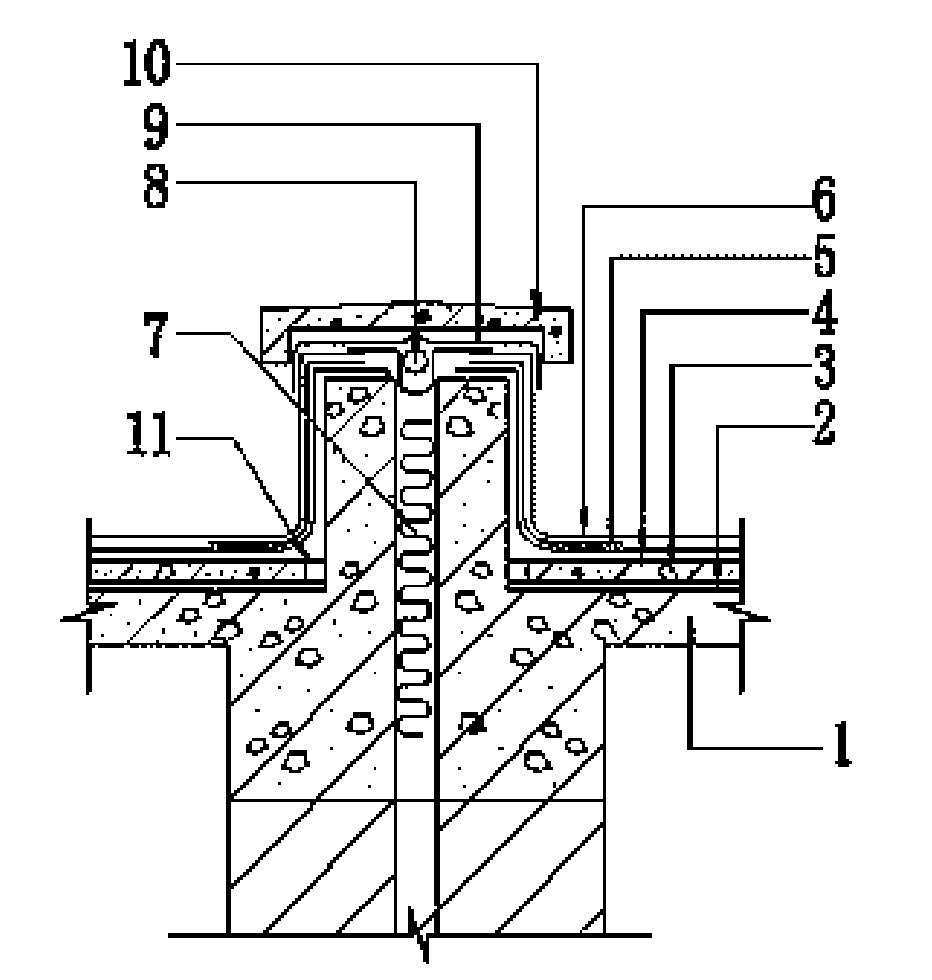

[0013] Example: such as figure 1 First, pour the roof slab and the waterproof block at the expansion joint of the roof into a whole 1. After the concrete roof is initially set, the mold is removed, and cleaned, a layer of asphalt linoleum is dryly laid as the isolation layer 2, and fine stone concrete is laid on it in turn Waterproof layer 3, 1:2 cement mortar leveling layer 4, polymer coiled material additional layer 5, polymer coiled material waterproof layer 6, and the expansion joint is filled with foam 7 and cushioning material 8 is filled on it. The rubber foam rod that adapts to the expansion and contraction of the base layer is covered with a coil 9 and a concrete cover plate 10 is buckled on the top. The buckled concrete cover plate is C20 concrete with φ6 longitudinal ribs with a spacing of 100.

[0014] Leave a gap 11 with a width of 30mm at the junction of the fine stone concrete waterproof layer 3 and the walls on both sides of the roof expansion joint, and use the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com