Face rockfill dam toe board structure constructed on completely weathered bed rock and construction method thereof

A face rockfill dam and full weathering technology, which is applied in the direction of dams, barrages, barrages, etc., can solve the problems of no engineering examples, etc., and achieve the effects of reducing project investment, ensuring bearing capacity, and reducing excavation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

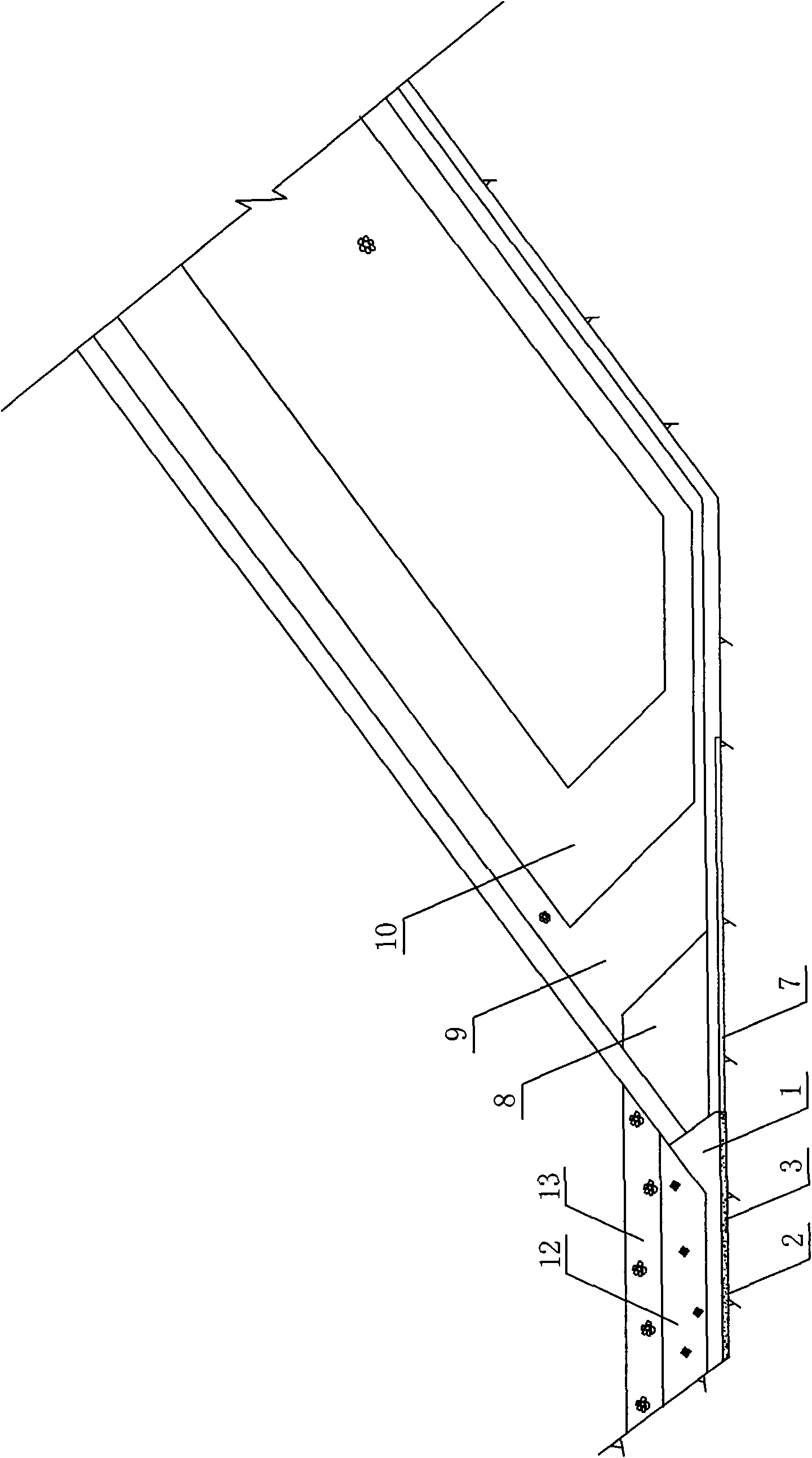

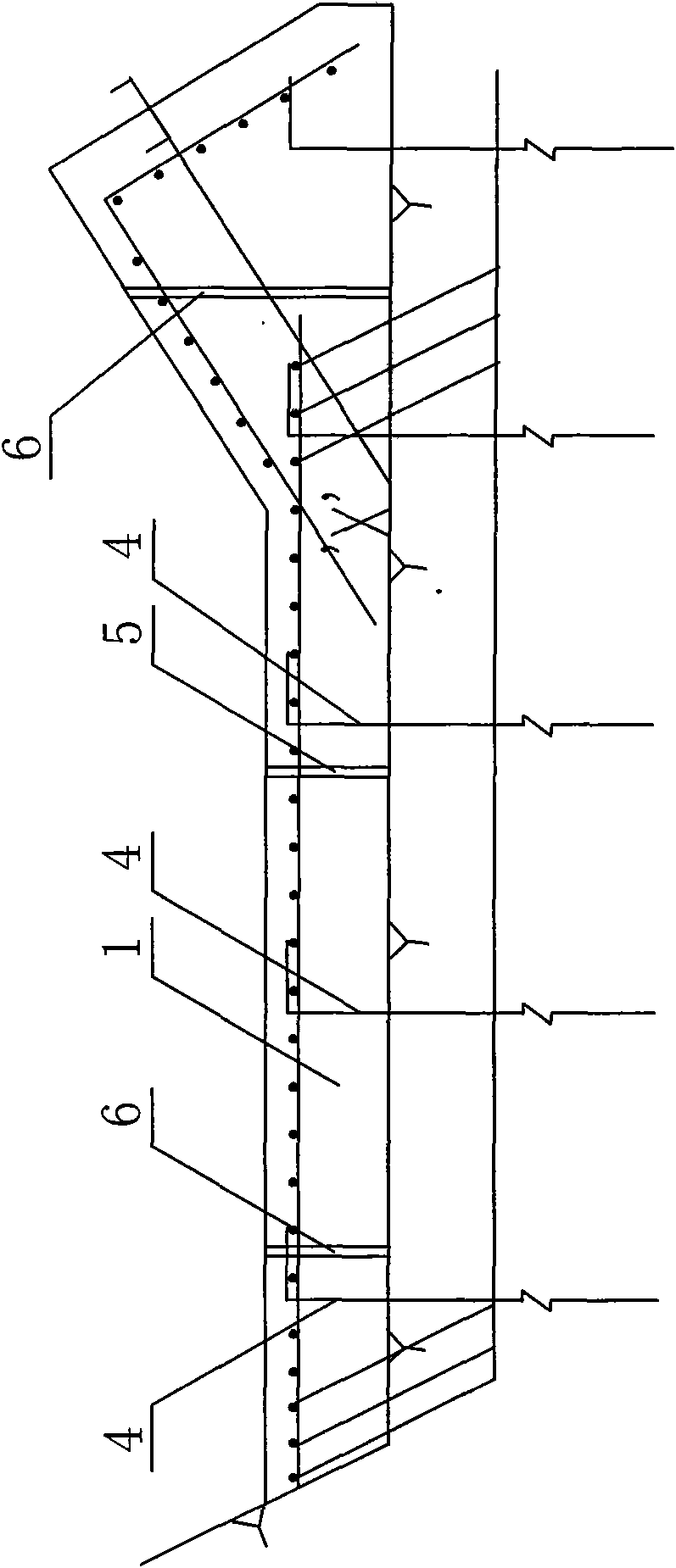

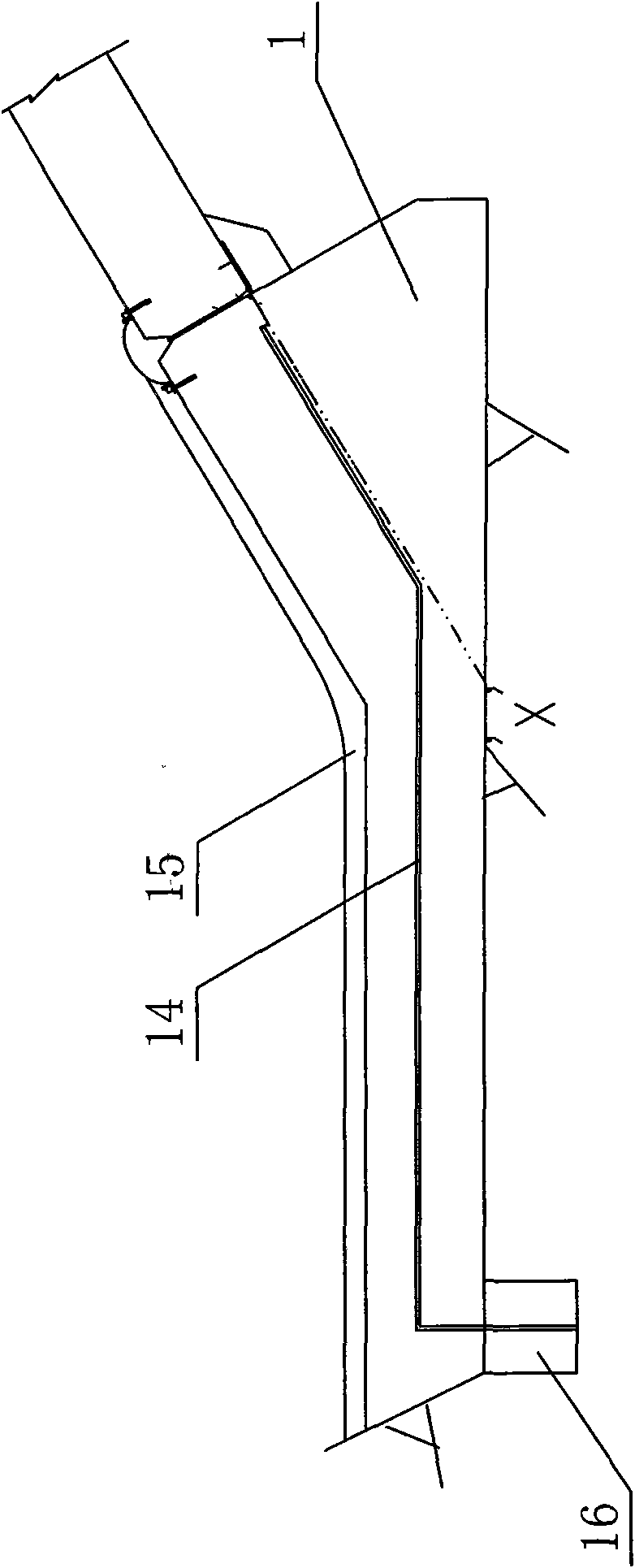

[0025] Such as Figure 1 to Figure 5 As shown, this embodiment includes a concrete plinth 1 built on the fully weathered bedrock 2, and a concrete anti-seepage connecting plate 7 is arranged downstream of the plinth 1, and its length is half of the upstream water head, so that the concrete anti-seepage connecting plate 7 The downstream hydraulic gradient is less than 2, and the anti-seepage connecting plate 7 is laid on the top and downstream of the anti-filter material extending to the downstream dam foot. In this example, the anti-filter material includes small area material 8, cushion material 9 and transition Material 10; in general, when the dam height is higher than 70m, it is necessary to lay the anti-seepage bedding 12 on the toe slab 1 of the riverbed section (clay or silt is selected as the anti-seepage bedding material in this example), because the toe slab 1 of this example It is built on fully weathered bedrock, so in addition to laying anti-seepage bedding 12 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com