Dual-durometer divided bar

a technology of divided bars and durometers, applied in the field of prefabricated construction elements, can solve the problems of detracting from the aesthetic appearance of decorative divider bars, painting or tinted surfaces exposed to air, and the conventional divider bars are quite functional in appearance, and achieve good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

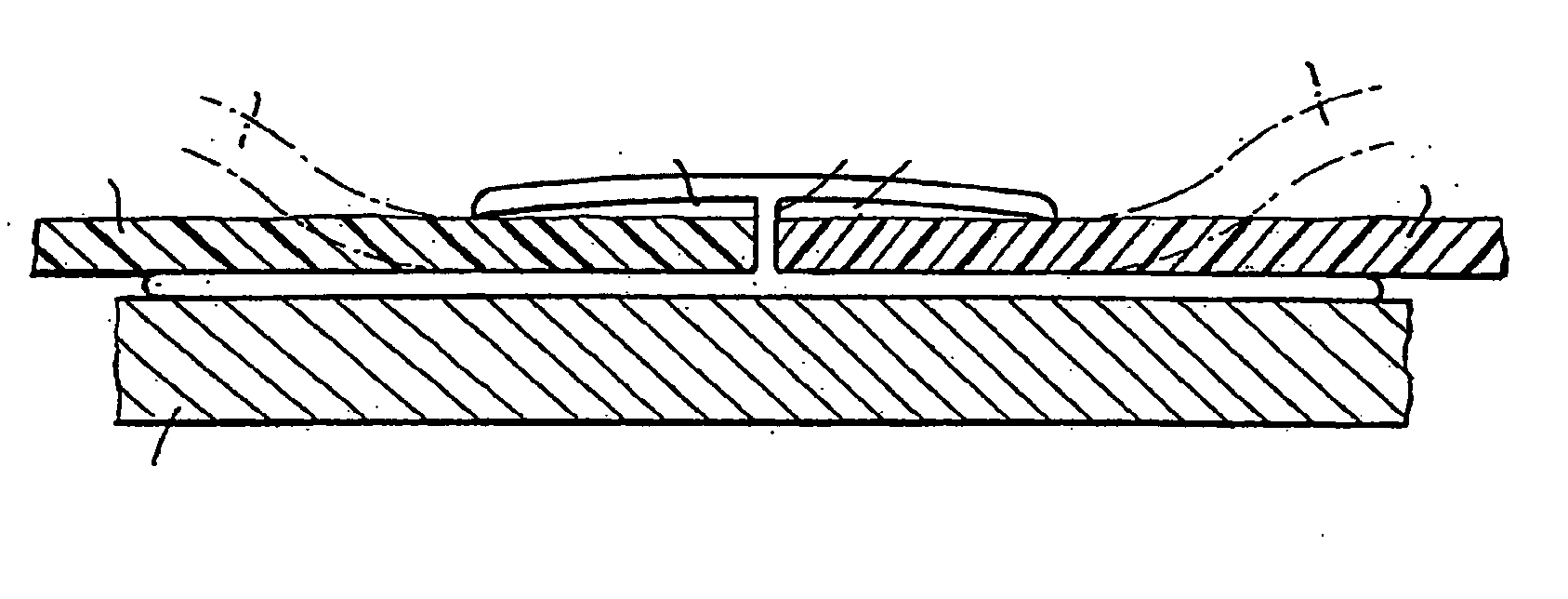

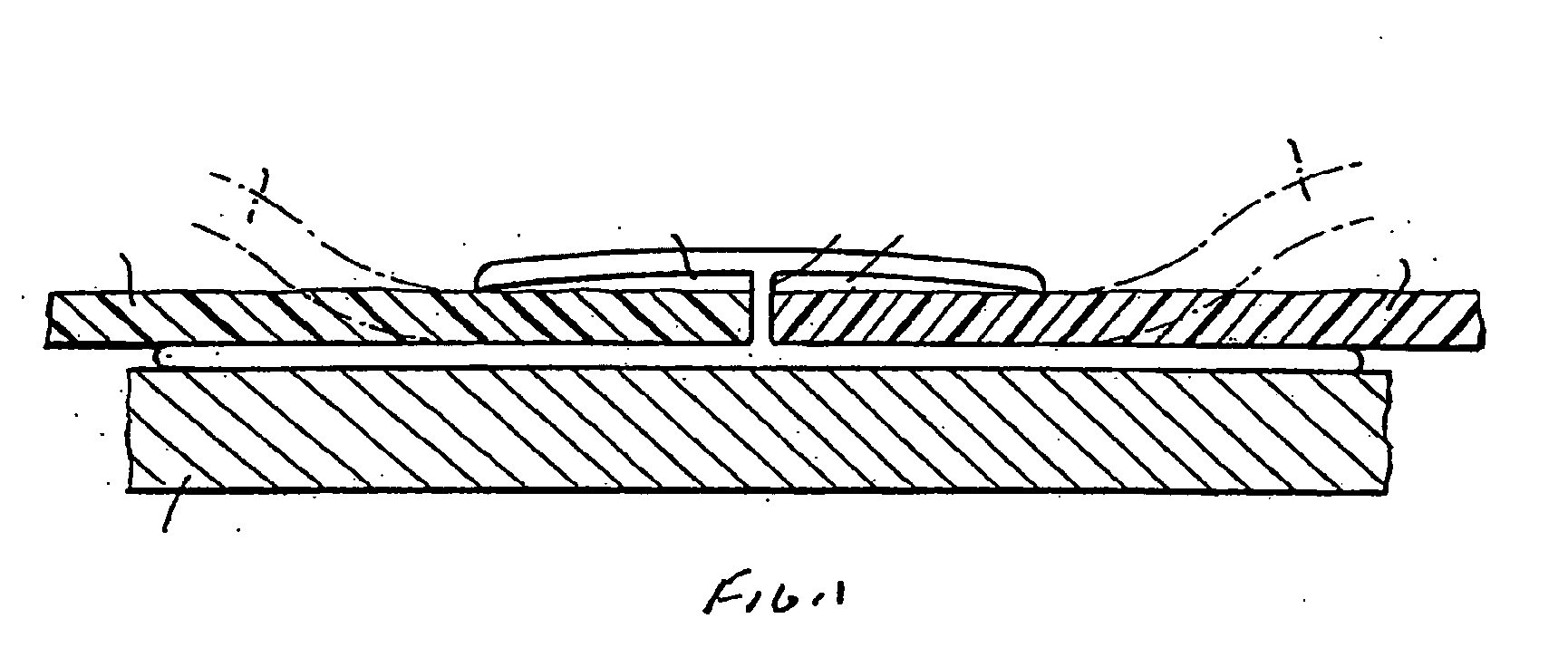

[0018] As is well known, divider bars are conventionally used to provide a seal between adjacent FRP panels. Part of the divider bar extends from the backing surface, and has two channels formed in it, to receive the edges of two panels. Conventionally, adhesive or caulk is laid down in the channels, or on the edge of the panels, and the panel edges are then placed in the channel portions of the divider bars. A portion of the divider bar remains visible after installation. As will be appreciated from the following, the preferred embodiment of the present invention is a divider bar that can be used with no need for any caulk or sealant. An example is shown in FIG. 1, illustrating the engagement of the divider bar with two sheets of paneling (all shown in section).

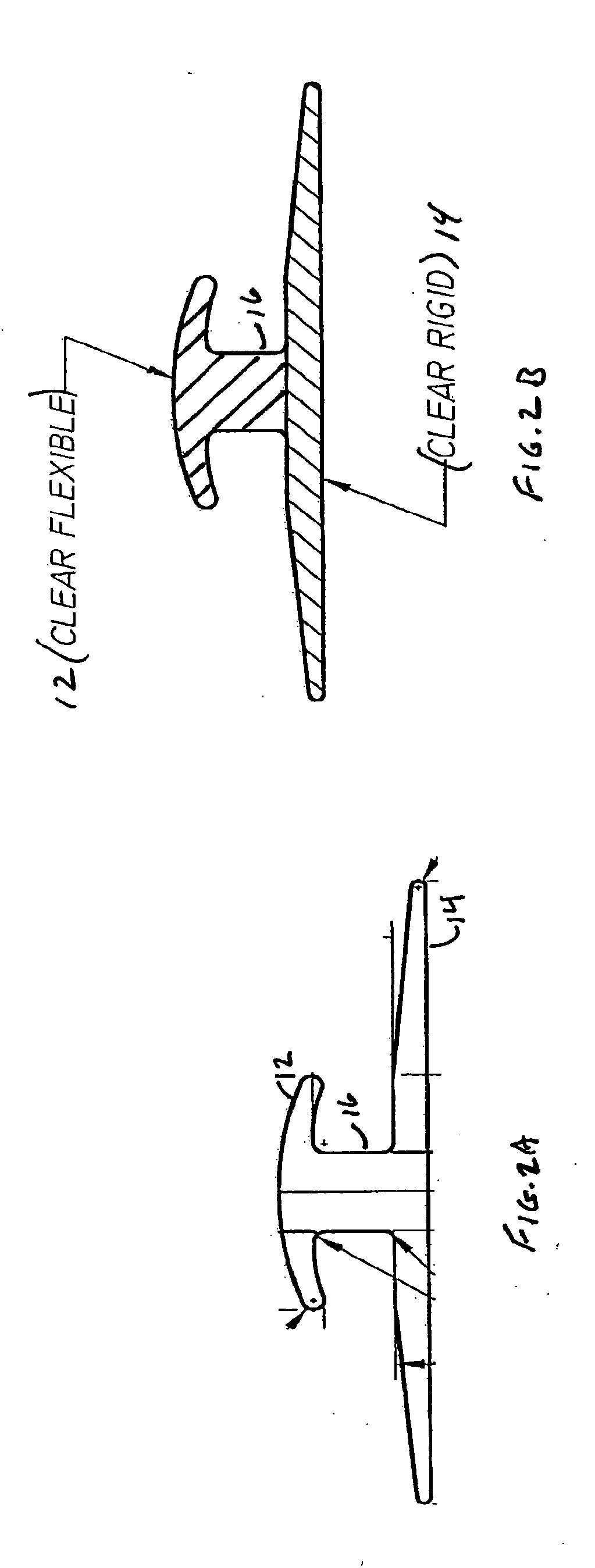

[0019] According to the preferred embodiment of the present invention, the divider bar has a first portion 12, which remains visible after installation, and a second portion 14 that floats behind the panels. The first and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com