Road guideline scriber

A marking machine and marking technology are applied in the field of marking equipment for road marking, which can solve the problems of affecting quality, time lag, and inability to draw marking lines, and achieve the effect of ensuring construction quality and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

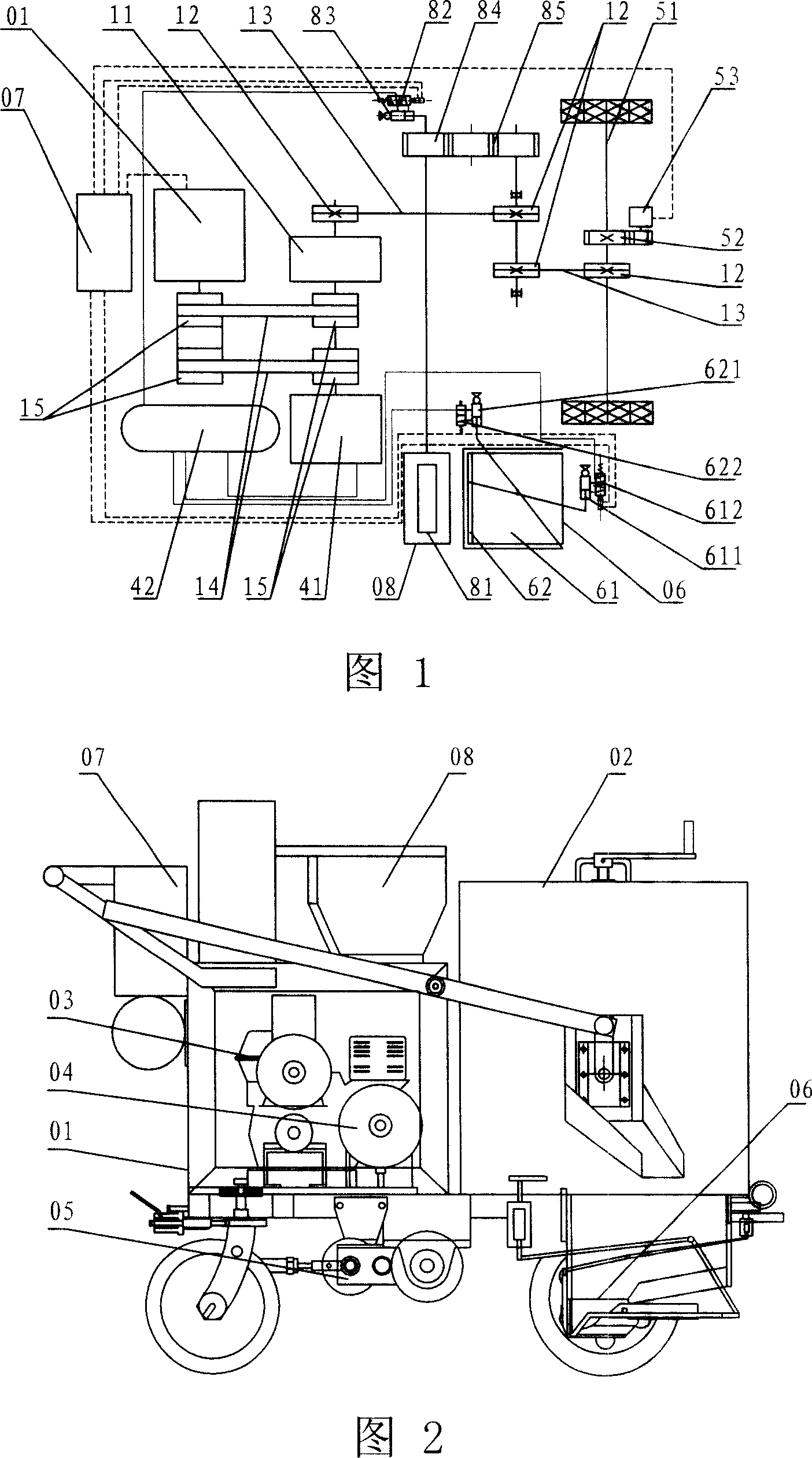

[0011] As shown in Figure 1 and Figure 2, it is the road concave-convex marking machine of the present invention, the road concave-convex marking machine includes a vehicle frame 01, and the vehicle frame 01 is provided with a paint bucket 02, an engine 03, and an air pressure system 04. Walking system 05, marking system 06 and control system 07. The engine drives the air pressure system and the walking system. A continuously variable transmission 11 is provided between the engine 03 and the walking system 05. The marking system and the air pressure system Connection, the control system manipulates the air pressure system to control the action of the marking system, and the signal of the control system to control the action of the marking system is sent by the walking system. The sensor 53 of the trigger signal, the sensor 53 is connected with the control system 07, the gear one 52 on the wheel shaft 51 is linked with the engine 03, 12 in the figure is a linked gear, 13 is a ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com