Field emission electron gun baking device and baking method of electron gun chamber

A baking device and electron gun technology, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of unstable electron beams and vacuum degrees that cannot meet the needs of electron guns, and achieve the effect of maintaining cleanliness and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

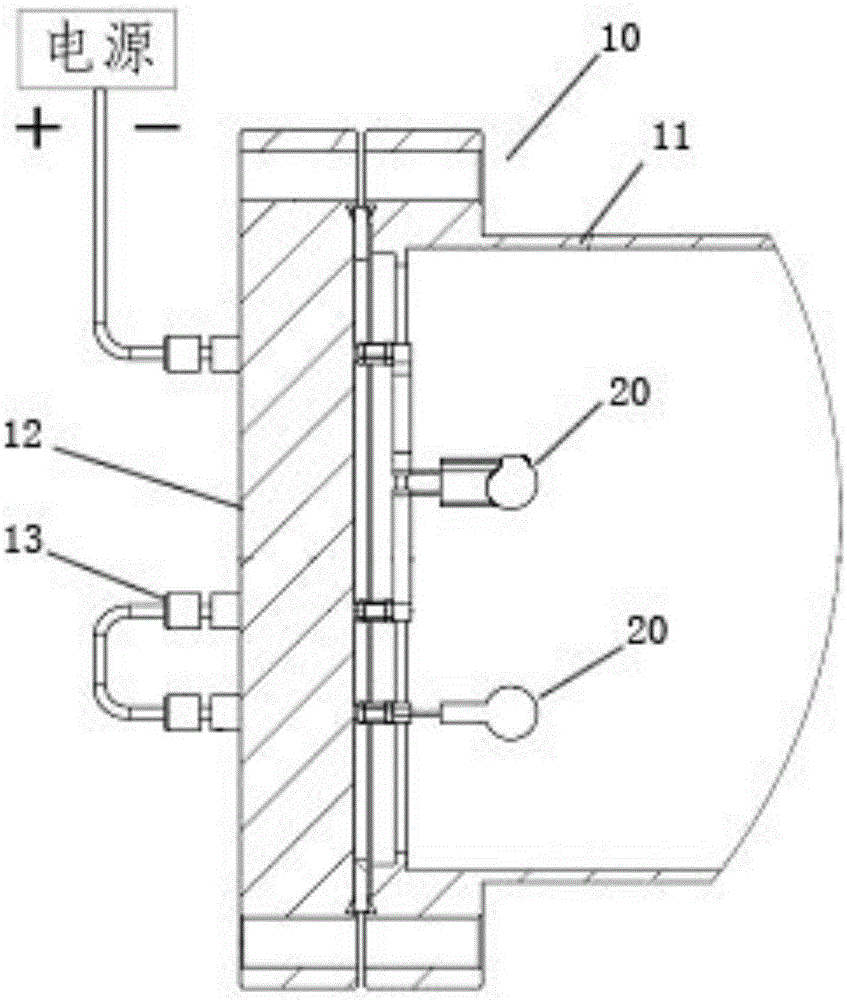

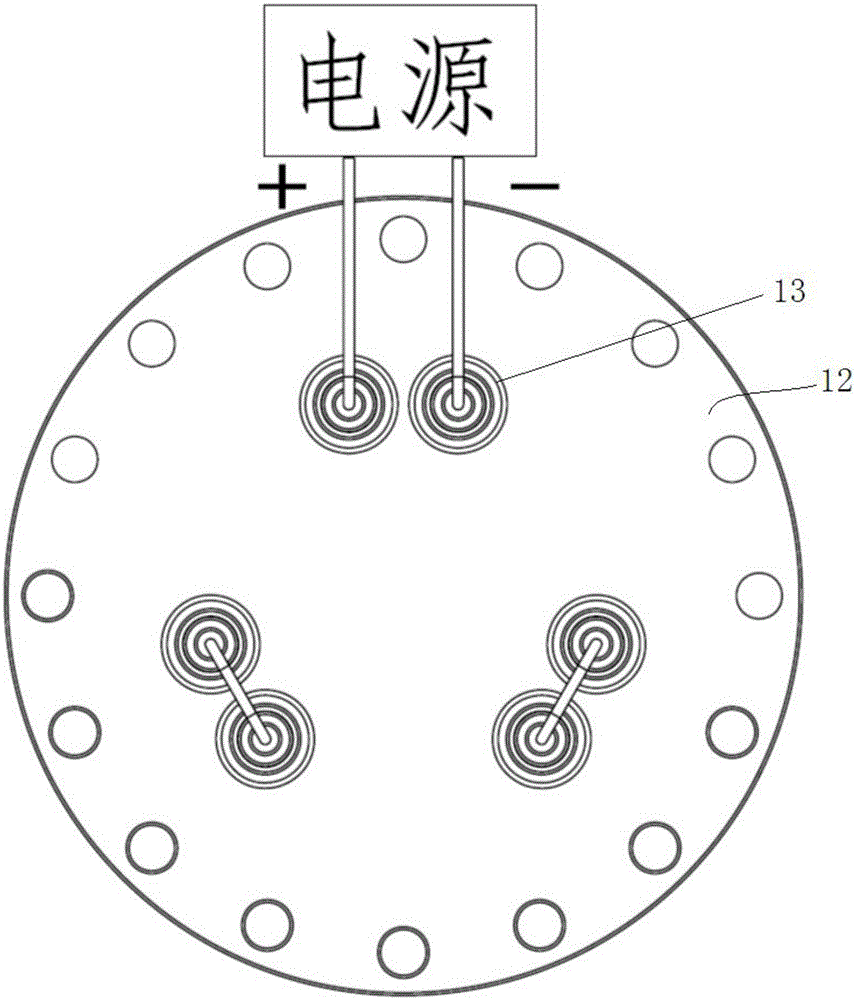

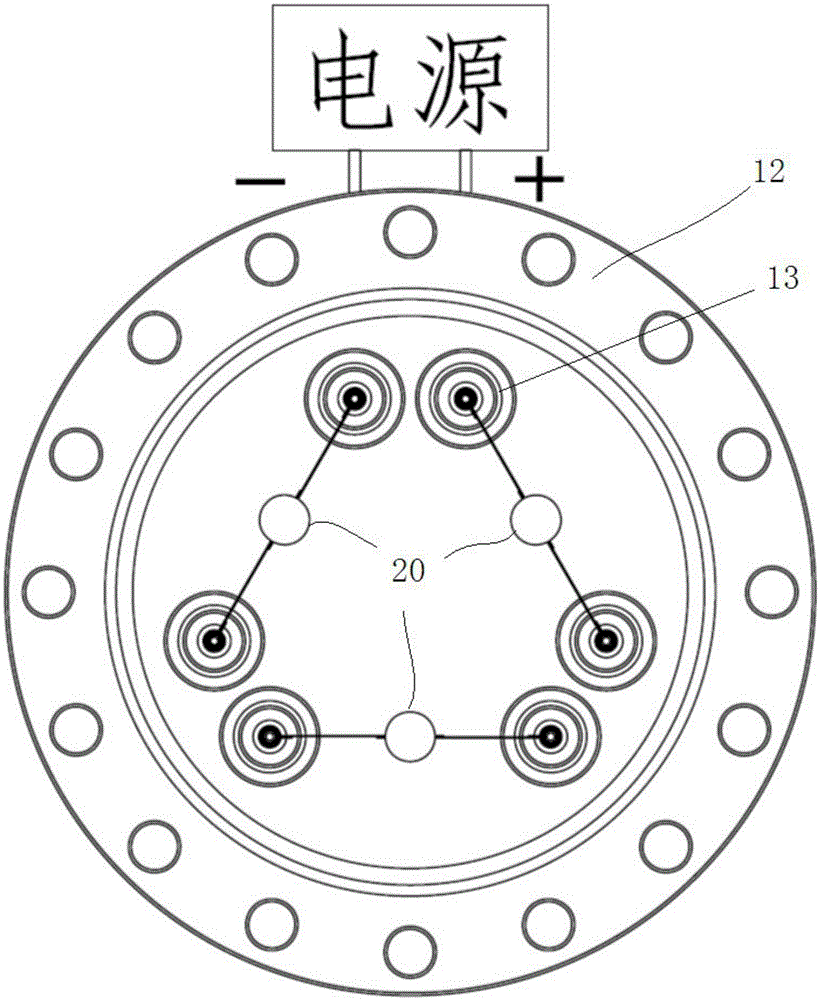

[0031] This embodiment provides a field emission electron gun baking device, which is used to bake the electron gun chamber 10 of the scanning electron microscope to increase the temperature in the electron gun chamber 10 .

[0032] refer to figure 1 , the field emission electron gun baking device of the present embodiment comprises at least one heat source 20, and this heat source 20 is arranged on the inside of the electron gun chamber 10, and the vacuum pumping assembly is connected with the electron gun chamber 10, and the position connected with the electron gun chamber 10 forms the pumping of the vacuum pumping assembly. breath. In the prior art, the heating of the electron gun chamber 10 generally adopts the method of wrapping a heating tape outside the electron gun chamber. The heating tape is made of resistance wire. After the heating tape is energized, the heat is transferred to the inside of the electron gun chamber 10 through the shell 11 of the electron gun chambe...

Embodiment 2

[0040] This embodiment provides a baking method for an electron gun chamber, which is used for baking and heating the interior of a scanning electron microscope or other vacuum containers. Specifically, the baking method includes the following steps:

[0041] Bake it inside the electron gun chamber 10 by using a heat source 20 to keep the temperature in the electron gun chamber 10 between 120°C and 180°C;

[0042] Vacuumize the electron gun chamber 10 using a vacuum assembly.

[0043] It should be noted that: the heat source 20 preferably bakes the electron gun chamber 10 under the condition that the electron gun chamber 10 is airtight, so that the vacuuming step of the vacuum assembly can be carried out synchronously with the baking of the heat source 20, so that more heat is obtained in the electron gun chamber 10. High level of vacuum.

[0044] Further, the heat selection 20 selects a halogen bulb, which utilizes the advantages of high heating efficiency of the halogen bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com