Milling machine waste collection device

A waste collection and milling machine technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problem of low efficiency of collecting iron filings, achieve the effect of reducing work intensity, improving efficiency, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

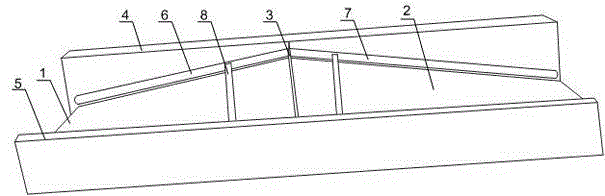

[0021] Such as figure 1 As shown, this embodiment includes a plurality of collection units connected in sequence, and the collection units are arranged at the bottom of the external milling machine. Described collecting unit comprises the left base plate 1 of inclined setting, the right base plate 2 of inclined setting, first baffle plate 4, the second baffle plate 5 and connecting plate 3, the top of left base plate 1 is connected with the top of right base plate 2, connecting plate 3. Set at the junction of the left bottom plate 1 and the right bottom plate 2. The first baffle plate 4 and the second baffle plate 5 are respectively arranged on both sides of the left bottom plate 1 and the right bottom plate 2. The first baffle plate 4 and the second baffle plate 5 pass through The connecting plates 3 are connected; the first baffle plate 4 is provided with a slideway A6 and a slideway B7, and also includes a cleaning mechanism 8 slidably arranged on the slideway A6 and the sl...

Embodiment 2

[0024] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the angle formed between the left bottom plate 1 and the right bottom plate 2 is 120° to 150°. Within the angle range of 120-150°, the operator can quickly collect iron filings and engine oil by using the inclined plane. When it is higher than the range of 120-150°, the inclination of the left bottom plate 1 and the right bottom plate 2 is not obvious, and the iron filings and engine oil slide down slowly during collection, and the collection efficiency is low; when it is lower than the range of 120-150°, the generated iron filings and Engine oil is easy to be scattered directly on the ground, which is not conducive to collection.

Embodiment 3

[0026] Such as figure 1 As shown, this embodiment is based on Embodiment 1. The cleaning mechanism 8 includes a cleaning rod and bristles arranged on the cleaning rod. The length of the cleaning rod is equal to the width of the left bottom plate 1 and the right bottom plate 2 . The cleaning rod is slidably arranged on the slideway A6 or the slideway B7. When the cleaning rod is pulled, the bristles are driven to move downward along the slope, and the bristles push down the debris on the left bottom plate 1 or the right bottom plate 2 to collect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com