Electromagnetic induction coil panel and manufacturing process thereof

An electromagnetic induction coil and manufacturing process technology, applied in coil manufacturing, coil device, induction heating, etc., can solve problems such as potential safety hazards, deformation of coil windings and magnetic strips, complex dispensing process, etc., and achieve cleanliness and sanitation. The effect of production process and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

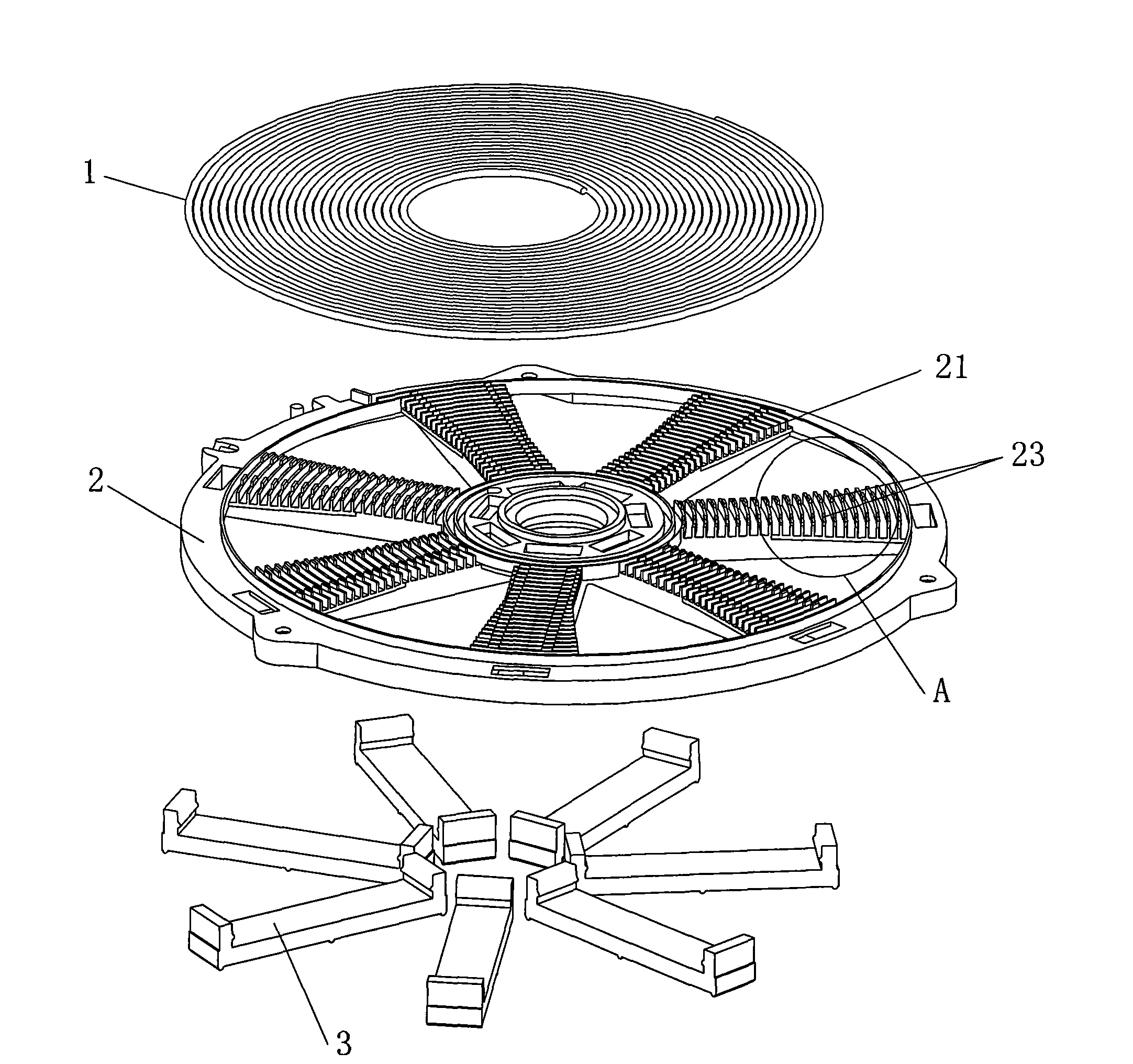

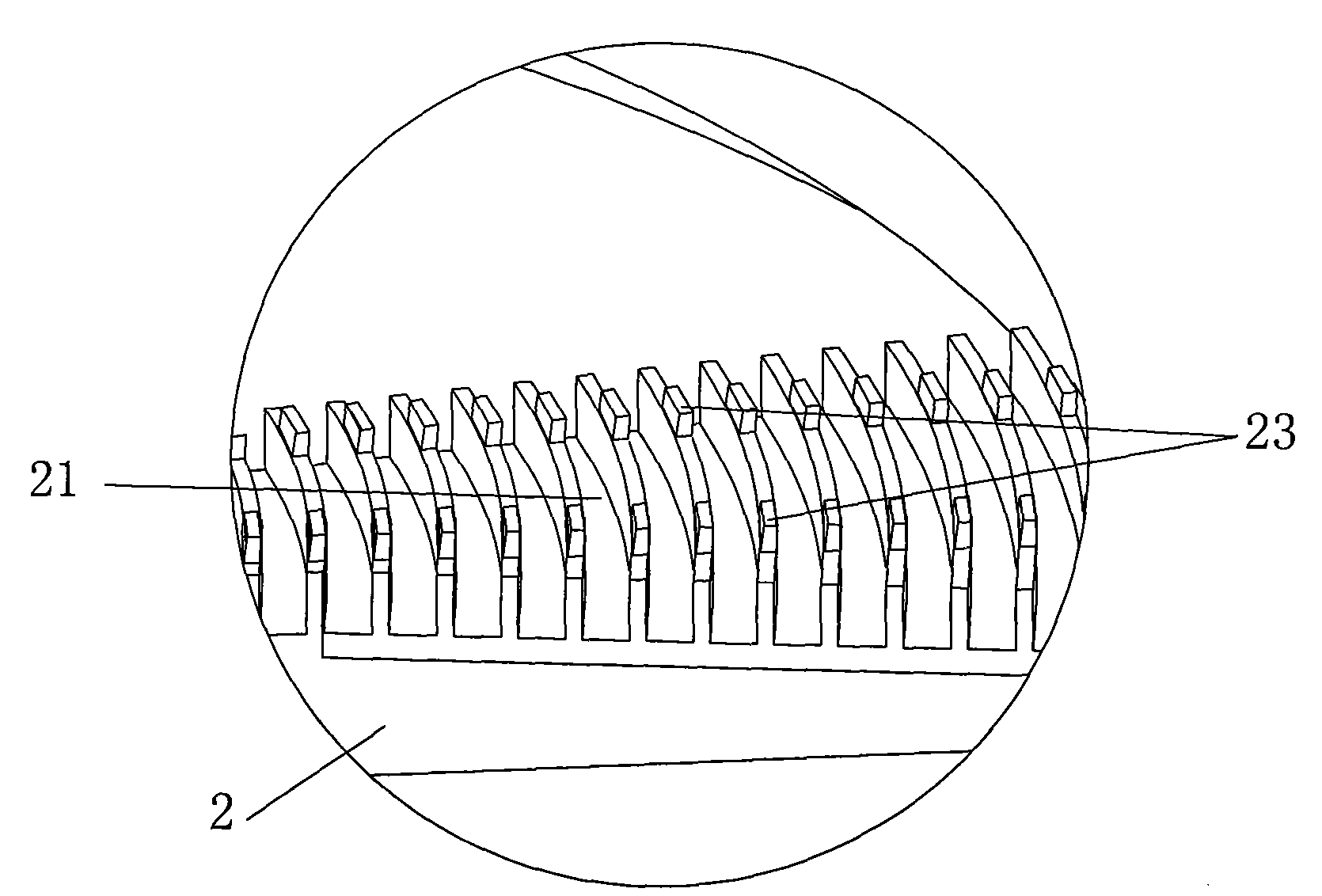

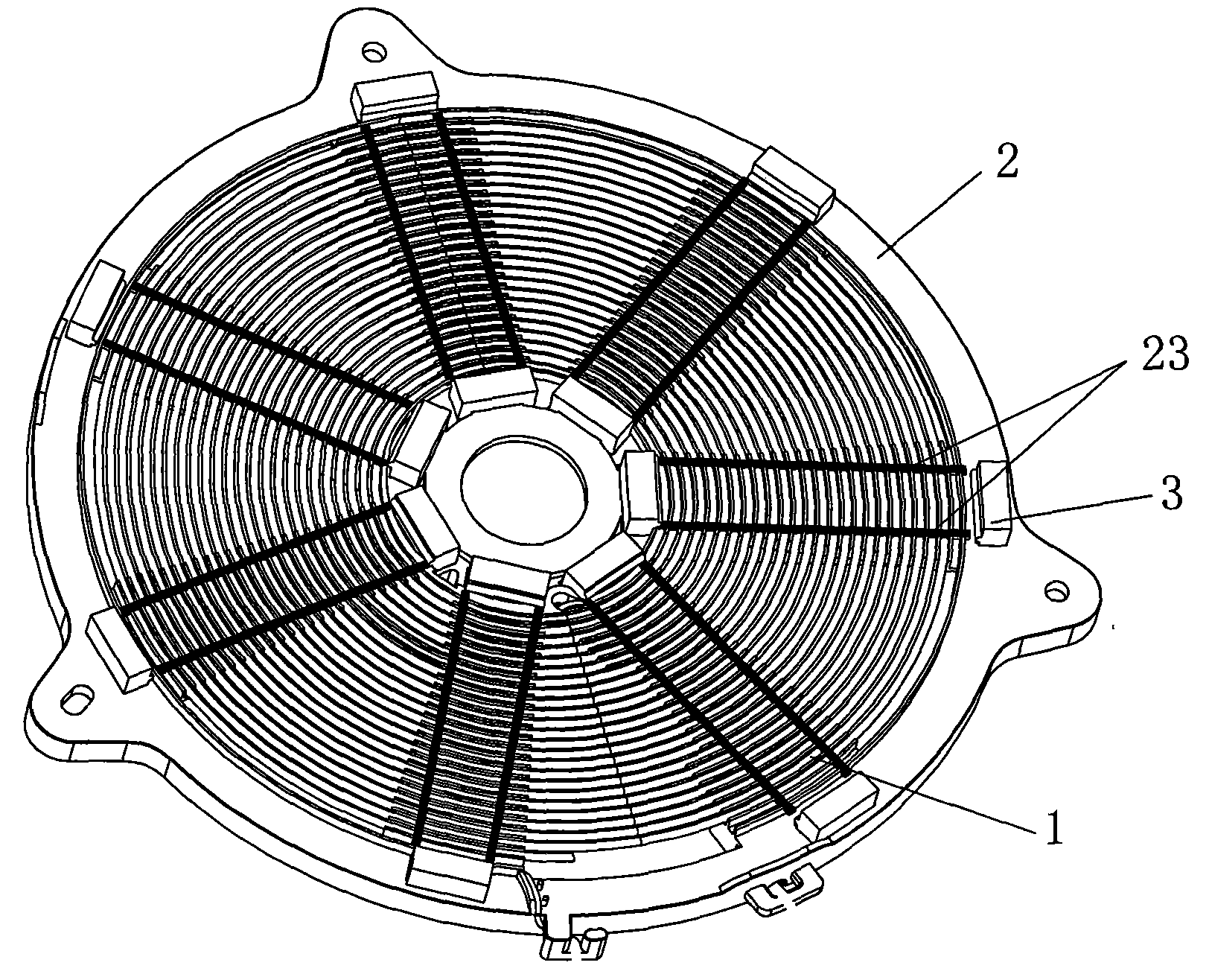

[0022] The structure diagram of the electromagnetic induction coil disk of the present invention is as follows: figure 1 , 2 , 3, 4, 5, 6, including coil winding 1, plastic bracket 2 and several magnetic strips 3, wherein the coil winding 1 is wound in the wire groove 21 on the upper surface of the plastic bracket, and several magnetic strips 3 are respectively installed on the plastic In a plurality of accommodating grooves 22 provided on the lower surface of the bracket 2, one or more positioning bosses 23 are respectively provided on both sides of the wire groove 21 and the accommodating groove 22, and the hot-pressing positioning bosses 23 make the coil winding 1 embedded Into the wire slot 21 and integrated with the wire slot, the positioning boss 23 is hot-pressed so that it partially wraps the magnetic strip 3 . In this embodiment, there are 7 accommodating slots 22 , and 7 corresponding magnetic strips 3 are also provided. Two po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com