Novel multifunctional bench drill

A multi-functional, bench drilling technology, used in drilling/drilling equipment, components of boring machines/drilling machines, maintenance and safety accessories, etc. Good collection of waste, ensure cleanliness, and ensure smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

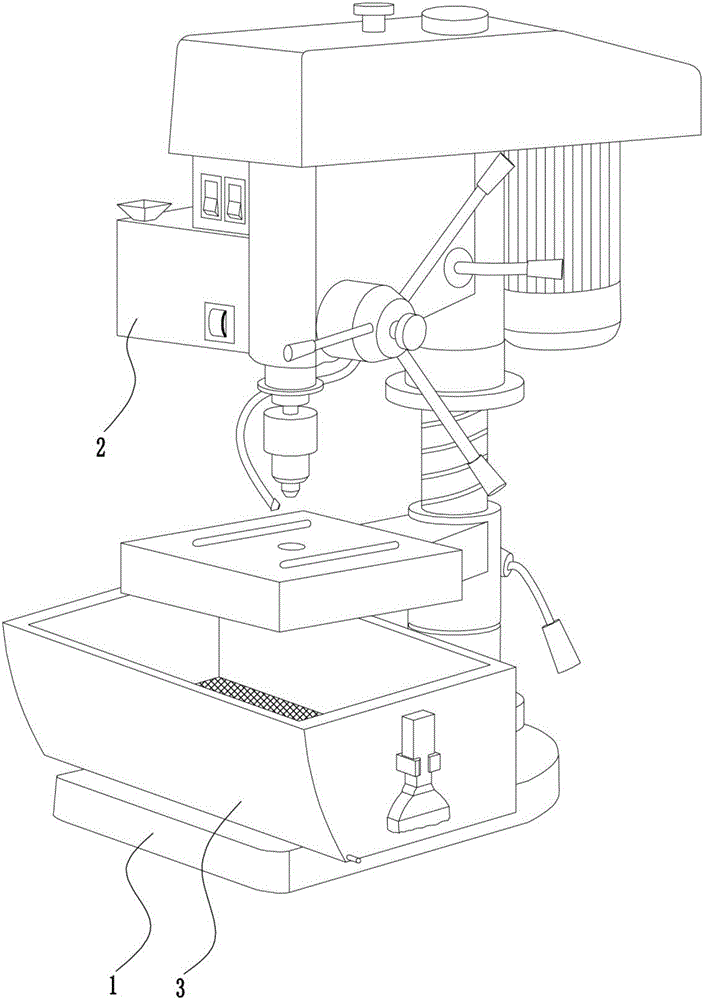

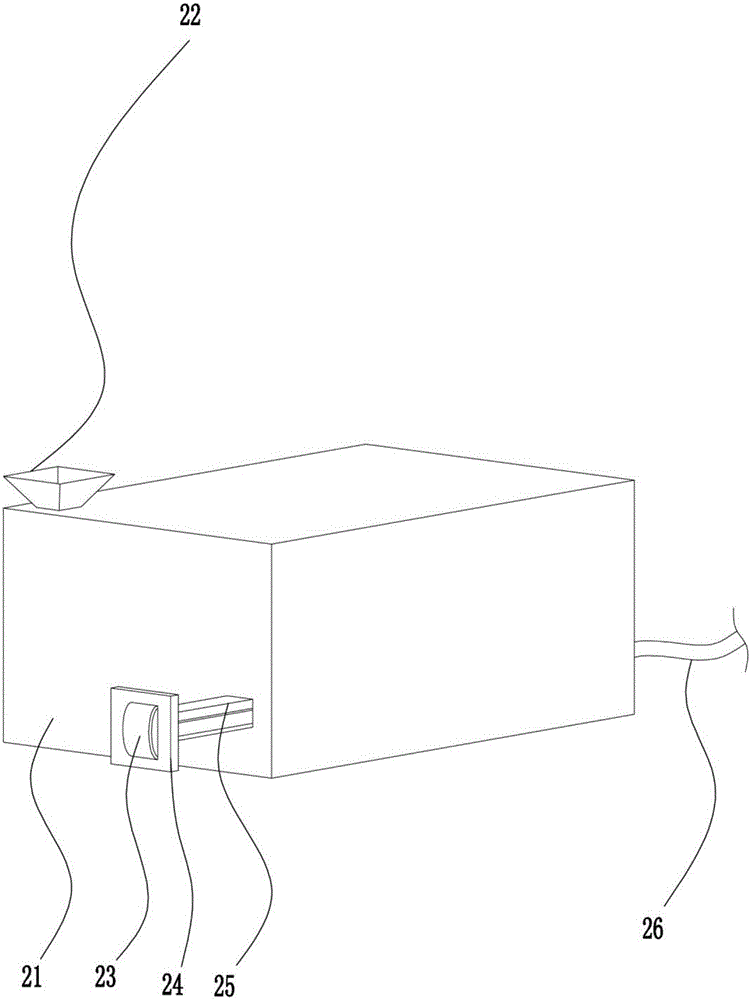

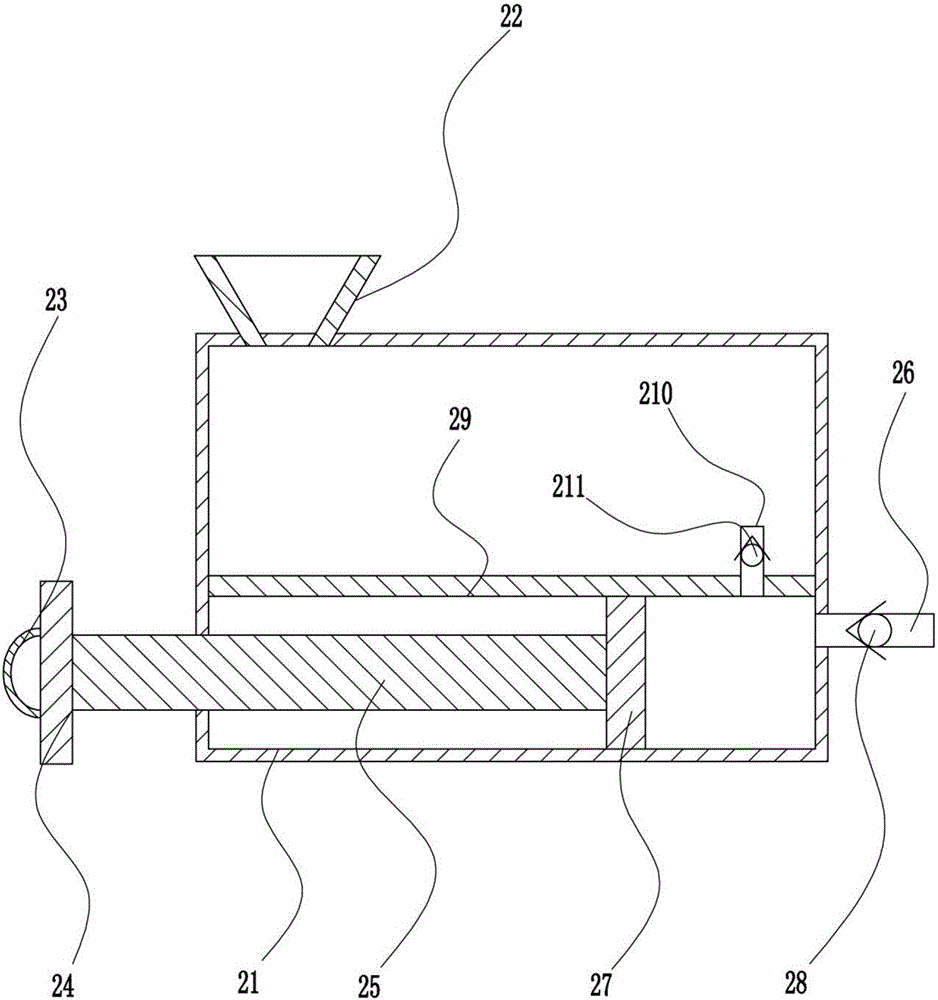

[0031] A new type of multifunctional bench drill, such as Figure 1-10 As shown, it includes a drilling machine 1, a cooling device 2 and a waste chip collecting device 3. The left side of the feeding box of the drilling machine 1 is provided with a cooling device 2, and the cooling device 2 includes a casing 21, a feed hopper 22, a handle 23, a fixed Plate 24, push rod 25, bamboo tube 26, push plate 27, the first one-way valve 28, dividing plate 29, communicating pipe 210 and the second one-way valve 211, the box body 21 is connected in the feed by the mode of screw connection On the left side of the box, the top of the box body 21 is welded with a feed hopper 22, and the right side of the box body 21 is provided with a partition 29, the partition 29 is provided with a connecting pipe 210, and the connecting pipe 210 is provided with a second one-way valve 211. A push plate 27 is arranged between the lower part of the dividing plate 29 and the box body 21, and the push plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com