Road line marker with energy saving function

A technology for marking machine and road, applied in the field of road marking machine with energy-saving function, can solve the problems of uneven distribution of line paint, unsteady paint sticking, and impact on the appearance of marking lines, so as to ensure clean and not easy to peel off problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

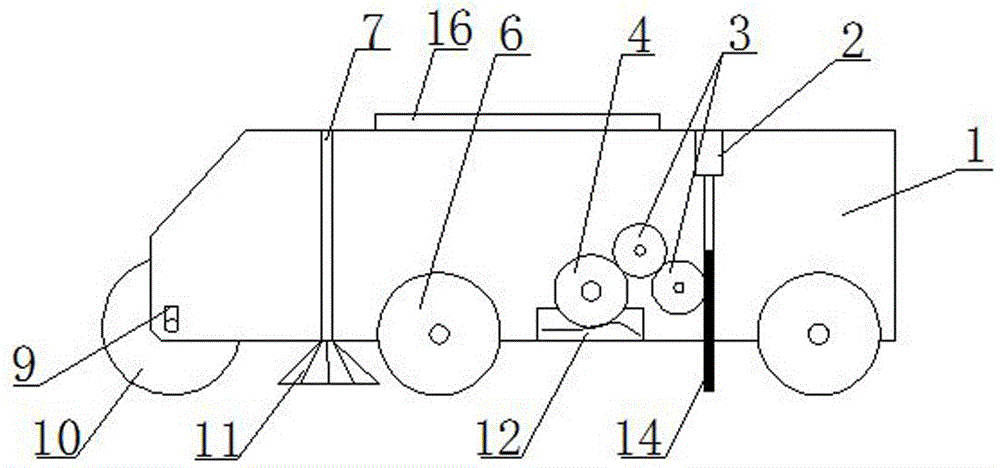

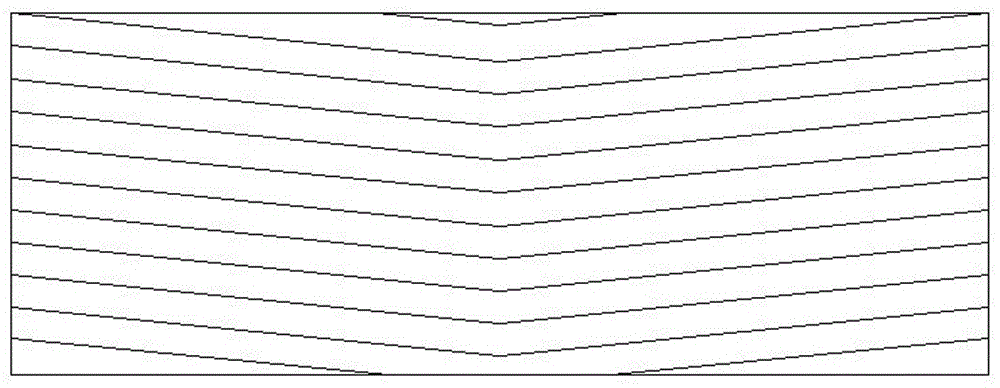

[0018] Figure 1-2 The road marking machine with energy-saving function provided by the present invention is shown, including car body 1, cylinder 2, equalizing roller group 3, feeding roller 4, wheels 6, pipe 7, dust collection cover 11, U-shaped groove 9. Hair brush 14, solar power supply device, paint box 12 and thread cleaning roller 10. The front of the car body 1 is equipped with a thread cleaning cylinder 10, and the threads on the thread cleaning cylinder 10 are left-right symmetrical. When the thread cleaning cylinder 10 rotates, the threads move from the center of the thread cleaning cylinder 10 to both sides; The car body 1 is provided with a paint tank 12; the car body 1 is provided with a feeding drum 4 above the paint tank 12, and the lower end of the feeding drum 4 extends into the paint tank 12; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com