Omnidirectional rotating lamp

An all-round, lighting technology, applied in the direction of electric light circuit layout, lighting device components, lighting and heating equipment, etc., can solve the problems of inconvenient operation, unsafe, complex structure, etc., to achieve convenient use, reasonable structure, and reduce occupancy. large space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

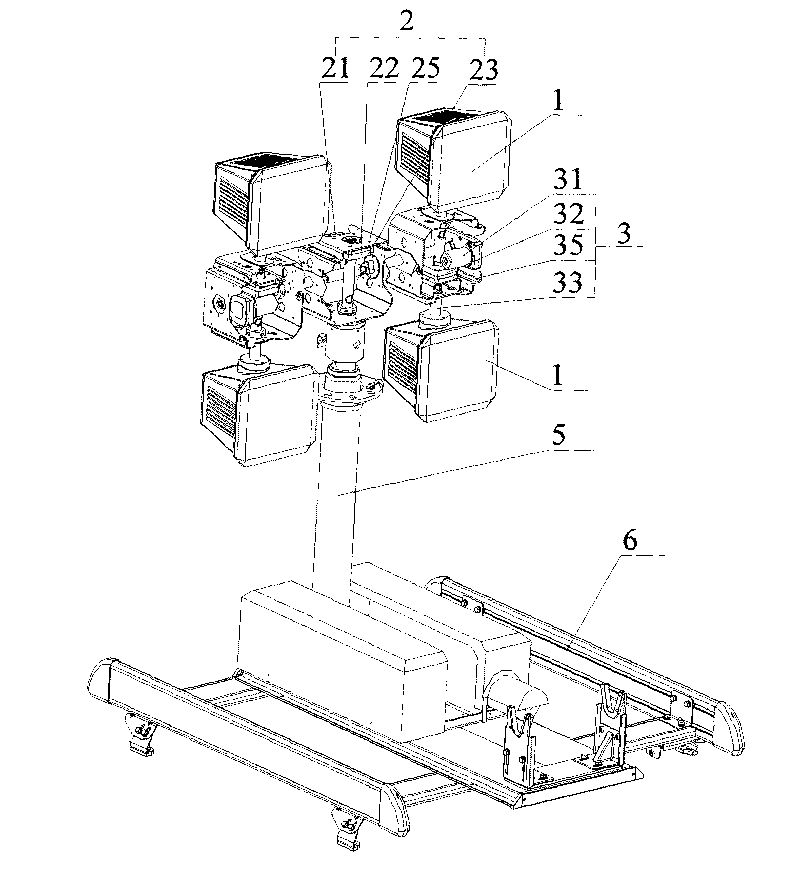

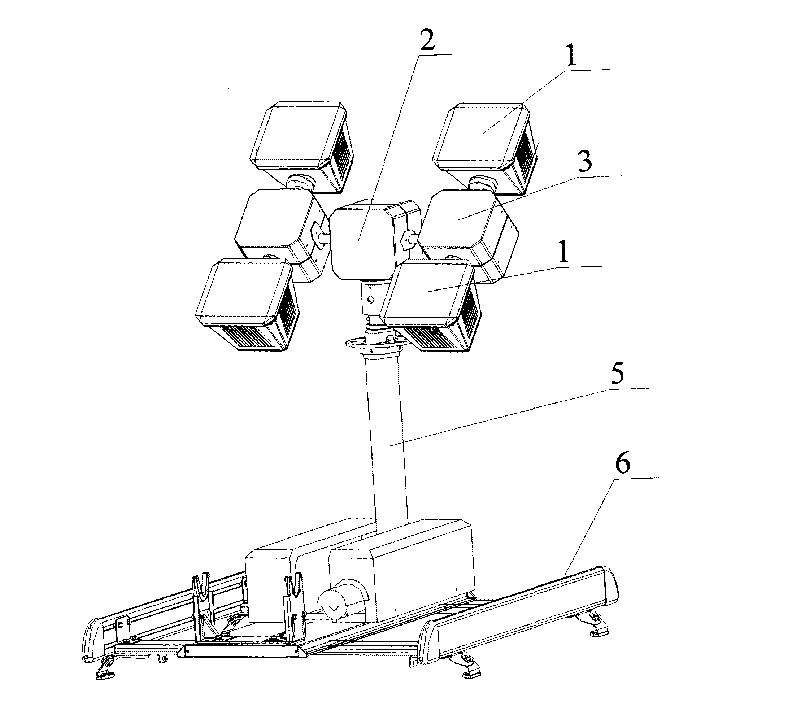

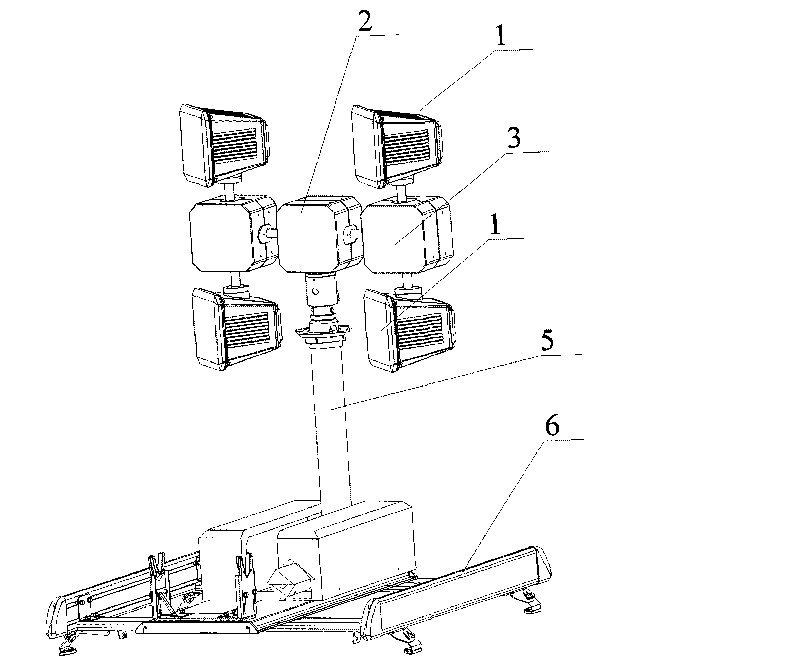

[0023] Example 1, such as figure 1 , 2 , 3, a lamp that rotates in all directions, includes a lamp body 1, and the lamp body 1 is connected with a pan-tilt mechanism that drives it to realize omni-directional rotation, and the pan-tilt mechanism includes a control device (not shown in the figure), At least two pan-tilts that are rotatably connected together, one of which is the main pan-tilt 2, and the rest of the pan-tilts are auxiliary pan-tilts 3, the auxiliary pan-tilt 3 is rotatably connected with the lamp body 1 to drive the lamp body to rotate 360°, the main The pan-tilt 2 and the auxiliary pan-tilt 3 are rotationally connected to drive the auxiliary pan-tilt 3 to rotate 360°, the main pan-tilt 2 and the auxiliary pan-tilt 3 are connected to the control device, and the main pan-tilt housing 21 is provided with a support frame 5 and a base 6 .

[0024] like figure 1 , 4 , shown in 5, main platform 2 comprises main platform housing 25, is provided with main platform m...

Embodiment 2

[0029] Embodiment 2, as Figure 6 As shown, it is a structural schematic diagram of two lamp bodies, one main pan-tilt, and one auxiliary pan-tilt. The auxiliary cloud platform rotating shaft 33 is vertically arranged, and its upper and lower ends are fixedly connected with one or more lamp bodies 1 respectively. The lamp body 1 operates synchronously. The middle part of the auxiliary cloud platform rotating shaft 33 is meshed with the gear in the auxiliary cloud platform reduction box 32 . The main cloud platform rotation shaft 23 is horizontally arranged, and one end thereof is fixedly connected with the auxiliary cloud platform housing 33, and the other end is engaged with the gear in the main cloud platform reduction box 22, and the auxiliary cloud with the gear engagement in the auxiliary cloud platform reduction box 32 The table rotating shaft 33 rotates to drive the lamp body 1 to rotate 360° in the horizontal direction, and the direction of rotation can be clockwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com