Liquid level measuring device

A technology of liquid level measuring device and floating device, which is applied in the field of measurement, and can solve the problems of large adhesion, large error, aging and damage of sealing ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

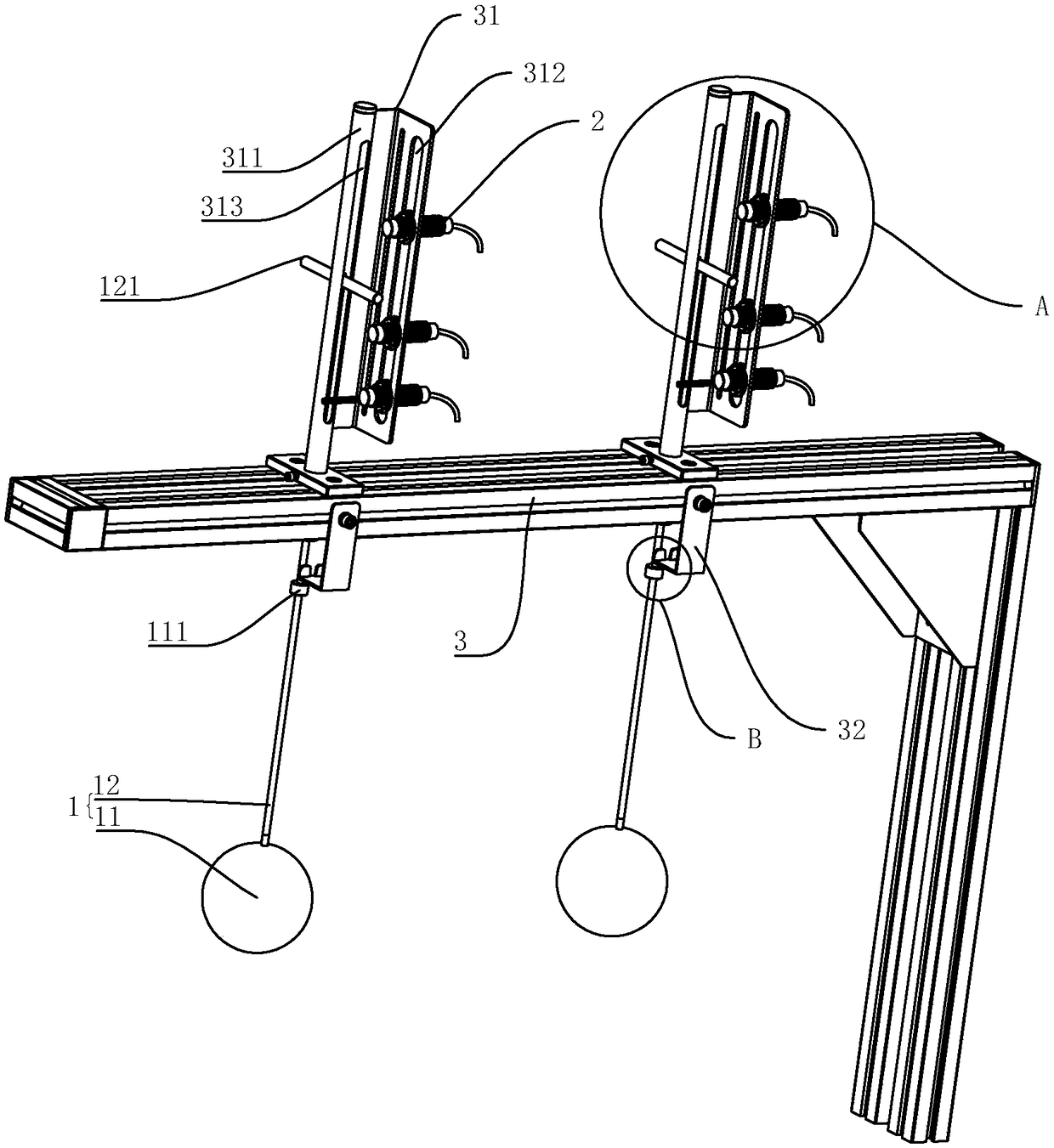

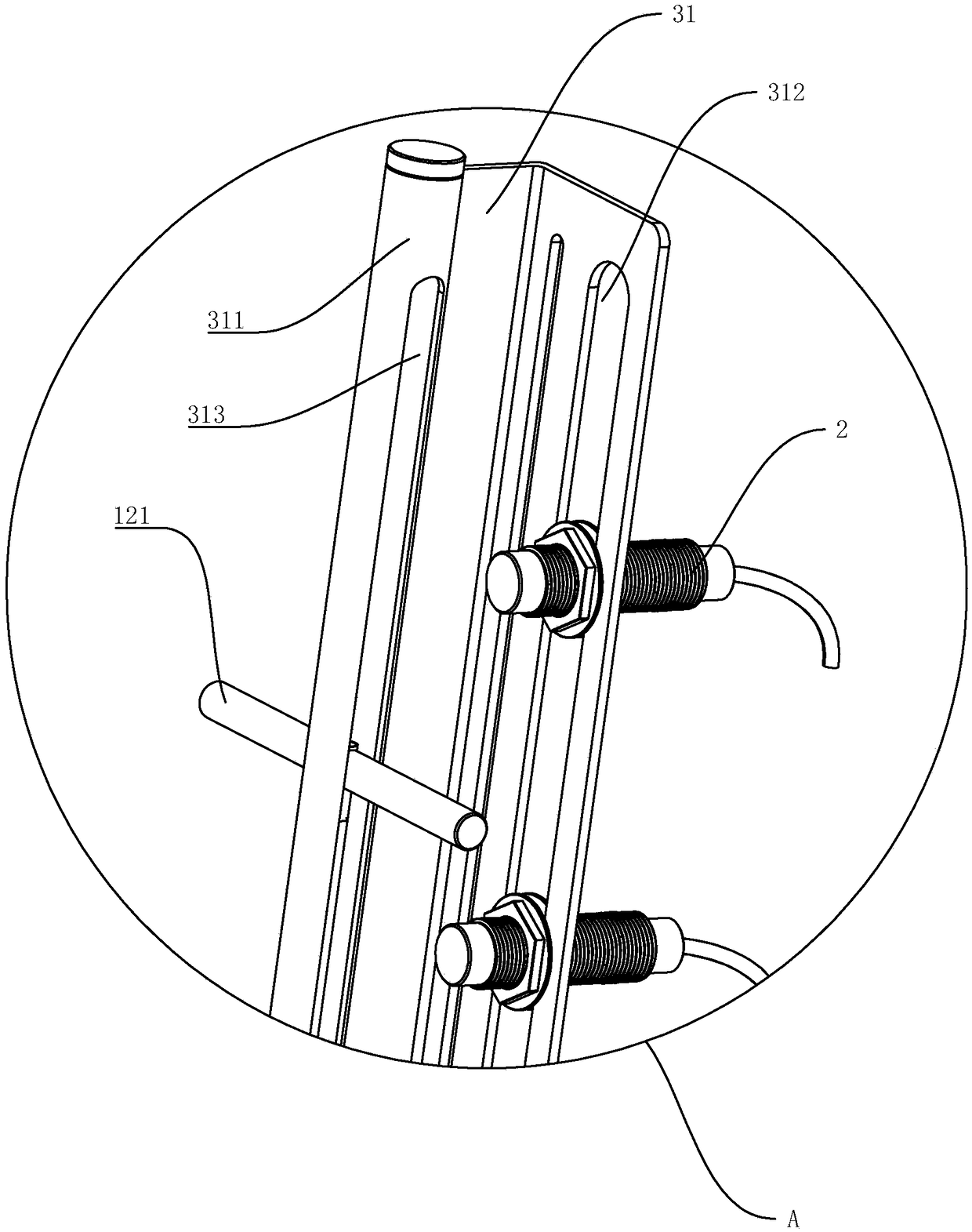

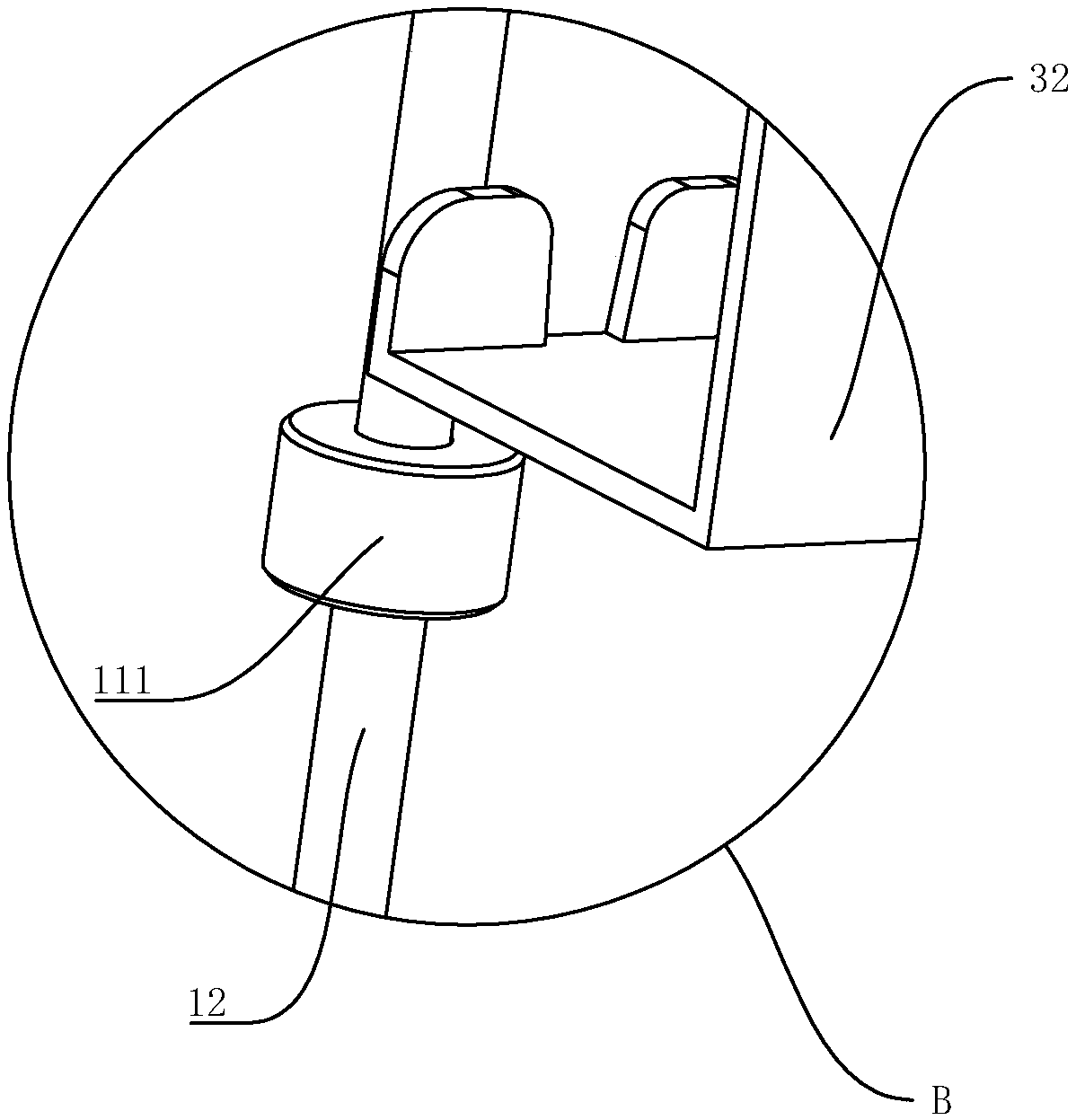

[0019] Such as figure 1 As shown, a liquid level measurement device includes a floating device 1, a detection part 2 and an installation structure 3, the installation structure 3 is installed on the facility to be tested, the floating device 1 floats on the liquid surface, and the detection part 2 is arranged on the installation structure 3 , used to detect the height of the floating device 1 to obtain liquid level information. This design obtains liquid level information by setting the detection part 2 above the liquid surface and detecting the floating device 1 as the liquid level rises or falls. This method of setting the detection part 2 above the liquid surface is limited by the liquid surface activity The impact is small, if the liquid surface boils, it will not affect the vertical movement of the floating device 1, and the device will not be affected by water vapor and scale to reduce its sensitivity, so it will not cause too much damage to the liquid level measurement....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com