Construction method of hinged pull-type steel inner formwork and prefabricated hollow slab beam

A pull-out, hinged technology, applied in the direction of manufacturing tools, mold separation devices, ceramic molding machines, etc., can solve the problems of insufficient rigidity, difficulty, exposed ribs on the contact surface, etc., and achieves significant economic benefits, simple operation, and convenient demoulding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

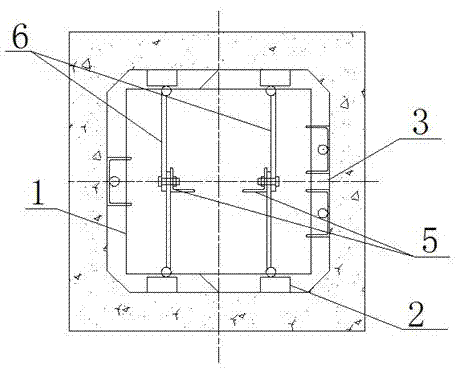

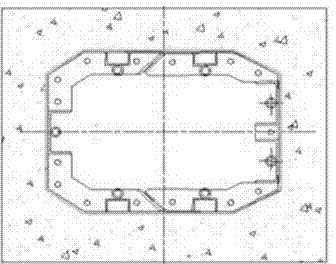

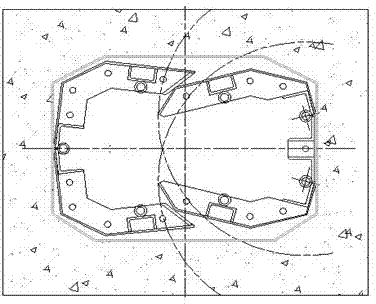

[0029] A hinged pull-type steel inner mold, such as figure 1 As shown in Figure 3, it includes: a first member 1, a second member 2, a hinged straight section 3, a pull rod 5 and an arm plate 6, wherein: the first member 1 and the second member 2 are divided into two symmetrical parts up and down. segment, the upper and lower segments of the first member 1 are hinged together through a hinge point, and the upper and lower segments of the second member 2 and the two ends of the hinged straight segment 3 are hinged together through a hinge point; the first Component 1 and second component 2 are connected by oblique wedge joints; an arm plate 6 is provided between the upper and lower segments of the first component 1 and second component 2 to support the inner mold; the arm plate 6 is divided into upper and lower sections, which are connected by pull rod 5 between the two sections. When drawing the mold outward, you only need to pull the pull rod 5, and the upper and lower secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com