Mounting structure for light incidence end face of automobile light guide bar

A technology of light guide strips and light entrance ends, applied in optics, light guides, motor vehicles, etc., can solve the problems of reduced work efficiency, reduced production efficiency, inaccurate positioning, etc., and achieves the effects of simple structure, improved production efficiency, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

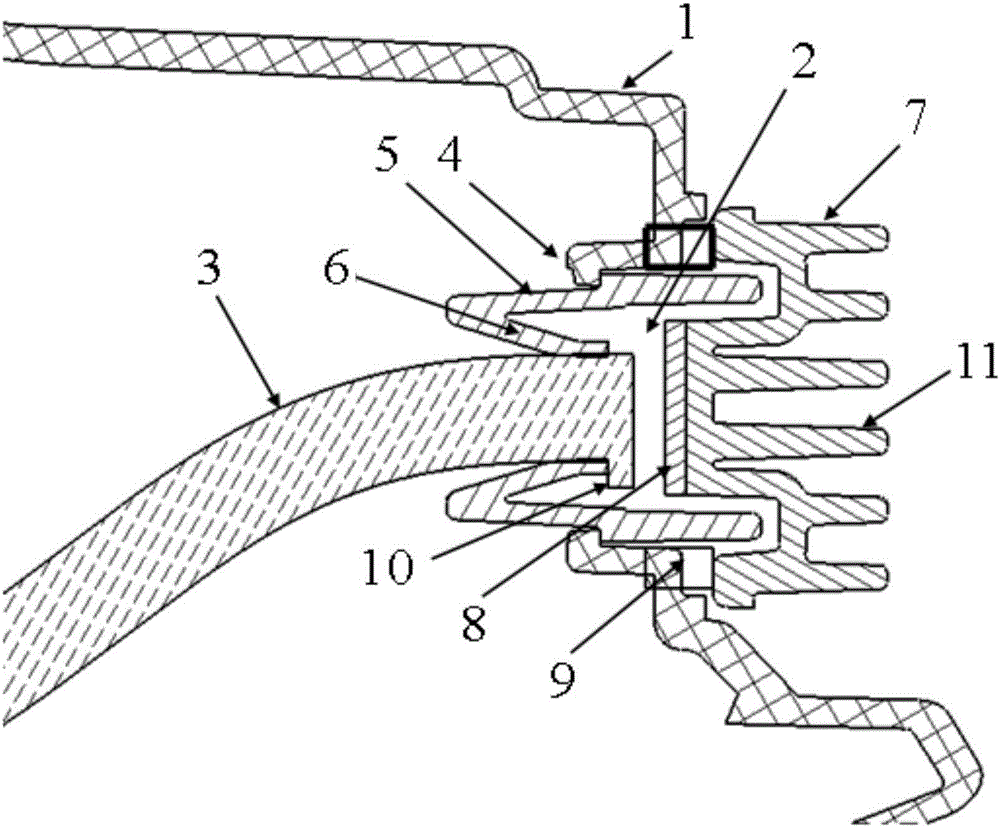

[0015] Such as figure 1 The light-incident end surface installation structure of a light guide strip for automobiles shown includes a lamp housing 1, a through hole 2 is arranged on the lamp housing 1, a light source module is arranged on one side of the through hole 2, and a light source module is arranged on the other side Install the light guide strip 3; the inner wall of the through hole 2 is provided with a fixing device for installing the light guide strip fixing part 5, and the through hole 2 is located on the side of the light guide strip 3 and is provided with a card for clamping the fixing device Point 4.

[0016] The fixing device includes a fixing part 5 that is clamped on the inner wall of the through hole 2 , and a clamping part 6 that extends inwardly from the fixing part 5 and is engaged with the end surface of the light guide strip 3 . Preferably, the fixing part 5 is in the shape of a tube, and the engaging part 6 extends from one end of the fixing part 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com