Method for pouring and molding large scale disposal wallboard and mould carriage thereof

An infusion molding, one-time technology, applied in ceramic molding workshops, ceramic molding machines, molds, etc., can solve problems such as unstable product quality, insufficient product precision, and inability to meet mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for large-scale disposable wallboard perfusion molding is:

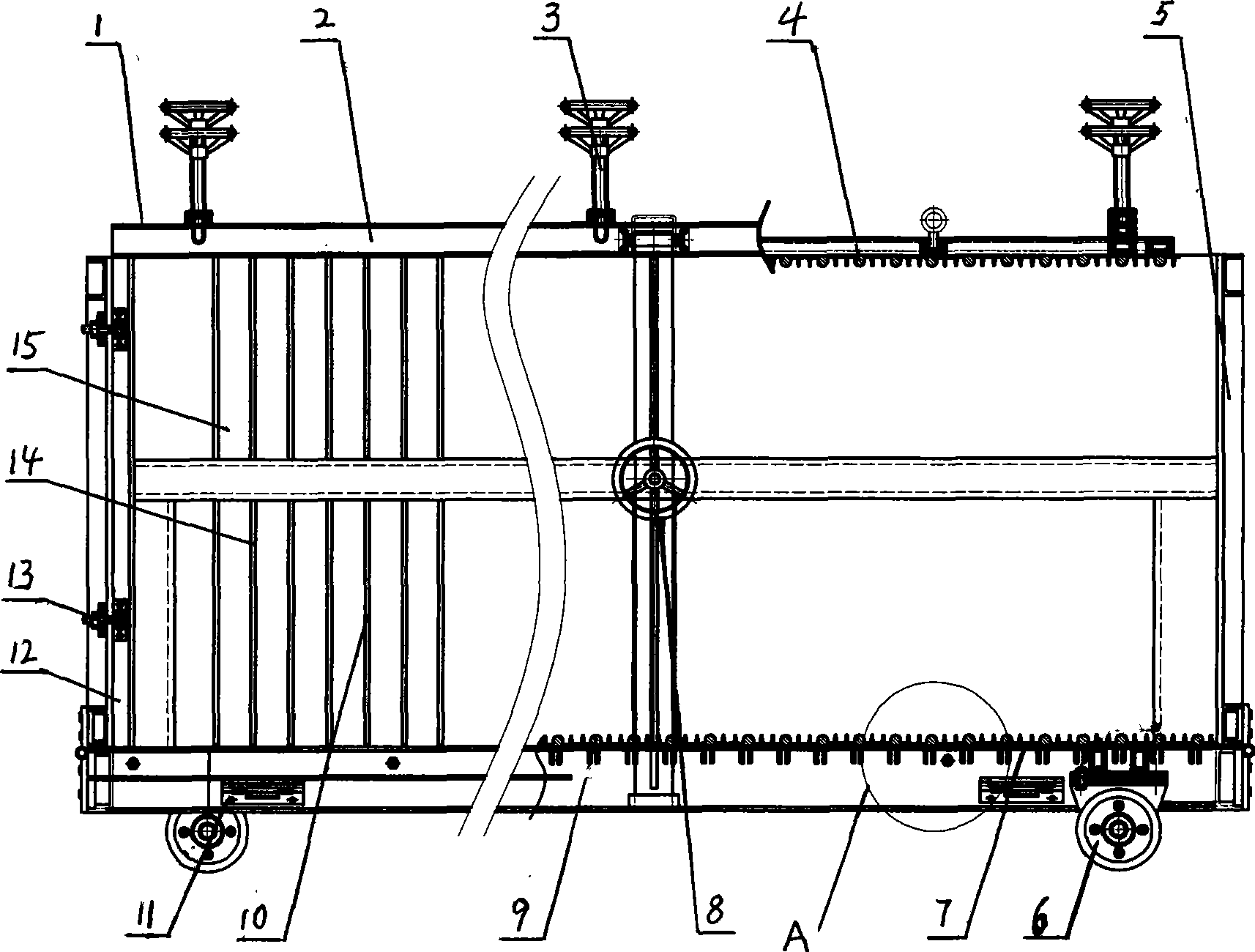

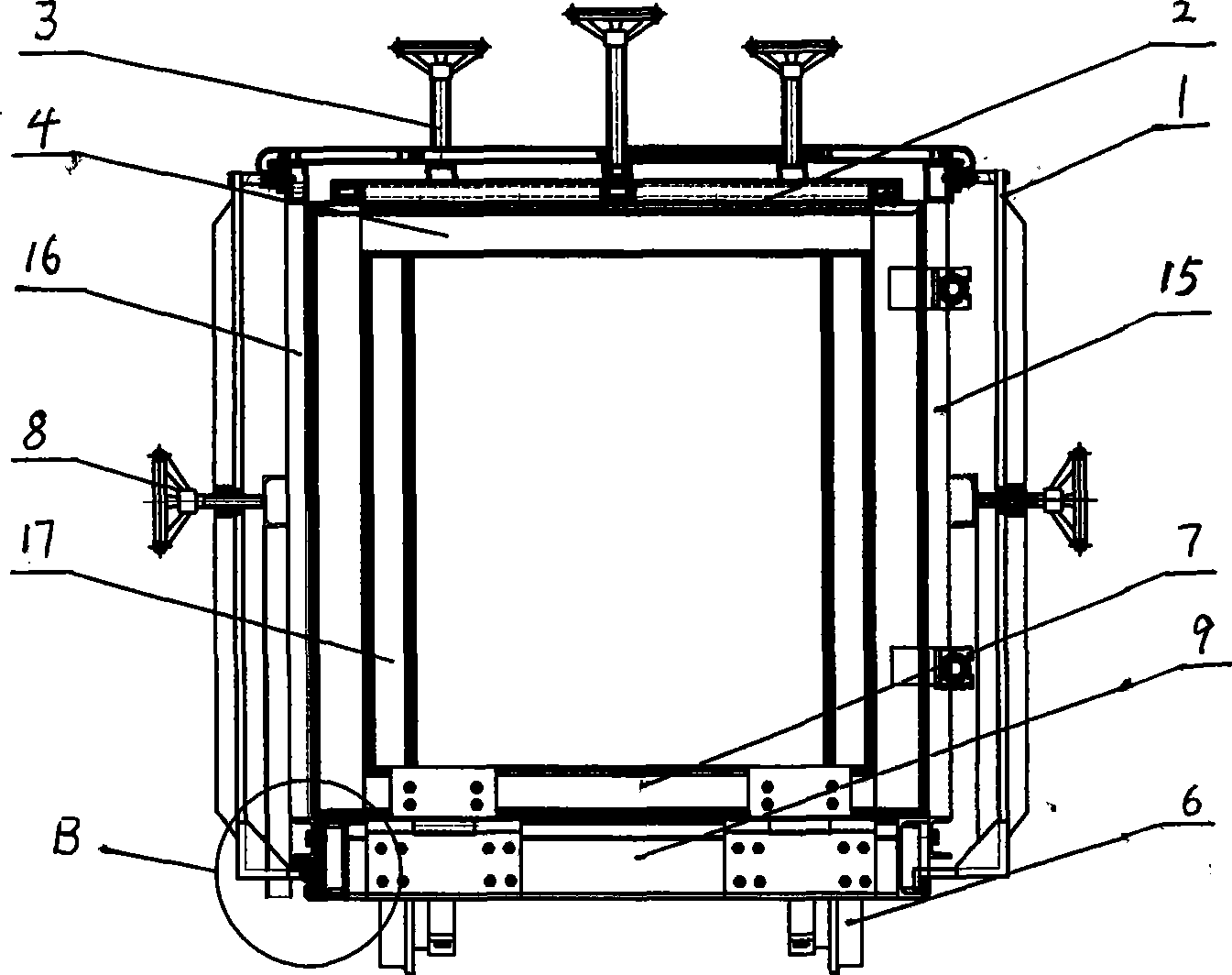

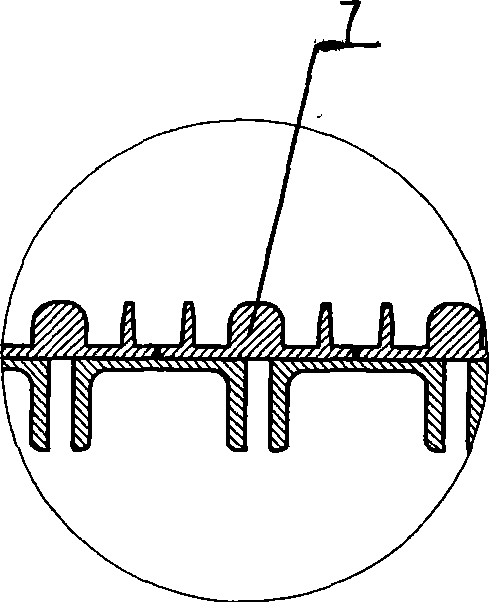

[0056] A, install the mould: on the bottom plate 9 of the mold car 1, the wall panel bottom plate mold 7 of the elongated shape is fixed equidistantly inward, on the front side plate 15 and the rear side plate 16 of the mold car 1, equidistant inward A strip-shaped wallboard side wall mold 17 that is in the same plane as the wallboard bottom plate mold 7 is respectively fixed, and a strip-shaped wallboard top plate mold 4 is fixed on the inside of each top plate 2;

[0057] B, mold car grouping: first the front side plate 15, the left side plate 12, the rear side plate 16 and the right side plate 5 that are hinged with the bottom plate 9 are erected upwards, and then through the front side plate 15, the left side plate 12, The switch gear 13 on the rear side panel 16 and the right side panel 5 locks the adjacent side panels so that they are fixed together, because between the adjacent wallboard side w...

Embodiment 2

[0070] A method for large-scale disposable wallboard perfusion molding is:

[0071] A, install the mould: on the bottom plate 9 of the mold car 1, the wall panel bottom plate mold 7 of the elongated shape is fixed equidistantly inward, on the front side plate 15 and the rear side plate 16 of the mold car 1, equidistant inward Wallboard side wall molds 17 that are elongated and in the same plane as the wallboard bottom plate mold 7 are respectively fixed;

[0072] B, model car assembly model: first erect the front side plate 15, left side plate 12, rear side plate 16 and right side plate 5 hinged with the bottom plate 9, then pass through the front side plate 15, left side plate 12 1. The switch device 13 on the rear side plate 16 and the right side plate 5 locks the adjacent side plates so that they are fixed together, and the partition plate 31 with the slurry flow hole 36 opened is placed on the bottom plate 9 in the mold car box, Between the adjacent wallboard bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com