A kind of preparation method of graphene-based lightweight heat-insulating wave-absorbing material

A technology of light-weight thermal insulation and wave-absorbing materials, applied in chemical instruments and methods, sustainable manufacturing/processing, other chemical processes, etc. and other problems, to achieve long-term stability and reliability of thermal insulation performance and wave absorbing performance, avoid shedding failure, and stabilize chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]A method for preparing a graphene-based lightweight heat-insulating wave-absorbing material, comprising the following steps:

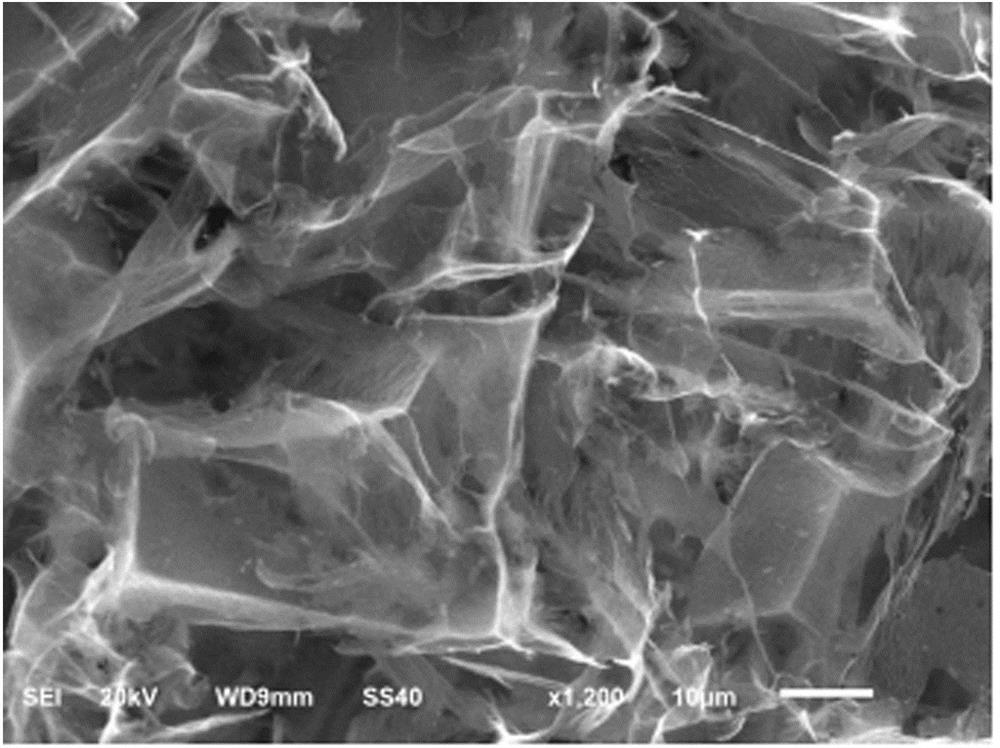

[0035] S1. Pretreatment of raw materials: Graphene oxide and carbonylated iron nanoparticles are respectively pretreated. The pretreatment method is as follows: heating and drying at 120°C-160°C for 1 to 2 hours, followed by acetone and ethanol cleaning. Drying treatment; wherein the graphene oxide is a common commercial grade product, and the carbonylation nano-iron particles are analytically pure, with a particle size of 50-200 nm.

[0036] S2. Surface modification of graphene oxide: The pretreated graphene oxide powder in step S1 is uniformly dispersed in N-methylpyrrolidone to obtain a brown-black graphene oxide solution, and the graphene oxide concentration is less than or equal to 0.01g / mL ; Graphene oxide solution is added the N-methylpyrrolidone solution that dissolves ferric amino acid under the continuous stirring of 80 ℃ of nitrogen en...

Embodiment 1

[0044] 1. Raw material pretreatment: take 5 g of carbonylated nano iron powder and 1 g of graphene oxide, and place them in a vacuum oven at 120 ° C for 1 hour to remove the catalyst and residual organic impurities on the powder surface, and then ultrasonically clean the raw material powder with acetone and ethanol successively. Filter and dry under ambient conditions.

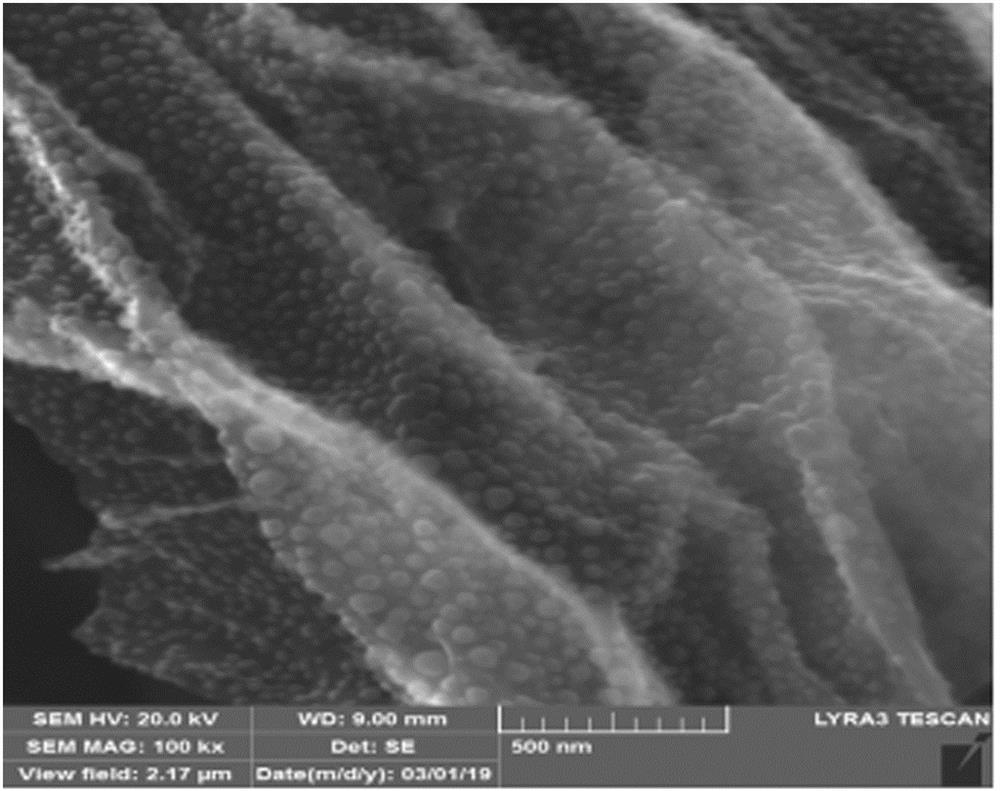

[0045] 2. Evenly disperse the pretreated graphene oxide powder in 100 mL of N-methylpyrrolidone to obtain a brown-black solution. Then, the graphene oxide solution was put into a three-necked flask, and the N-methylpyrrolidone solution (the amino iron concentration: 0.01 g / mL) was added to dissolve the amino iron under continuous stirring in a nitrogen environment at 80 °C to make the reaction proceed, and then the obtained reaction mixture was transferred. The mixture was subjected to suction filtration in a hydrothermal kettle for 16 hours in a drying oven at 80°C. During the suction filtration process, eth...

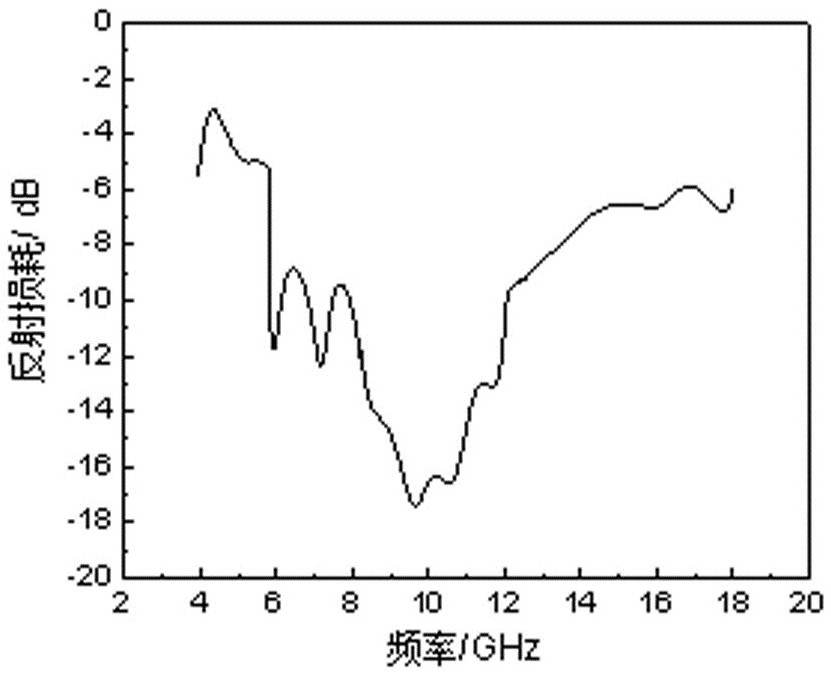

Embodiment 2

[0053] 1. Raw material pretreatment. Take 10 g of carbonylated nano iron powder and 1 g of graphene oxide, and place them in a vacuum oven at 160 ° C for 1.5 hours to remove the catalyst and residual organic impurities on the powder surface, then ultrasonically clean the raw material powder with acetone and ethanol in turn, and filter and dry at room temperature. deal with.

[0054] 2. Evenly disperse the pretreated graphene oxide powder in 100 mL of N-methylpyrrolidone to obtain a brown-black solution. Then, the graphene oxide solution was put into a three-necked flask, and the N-methylpyrrolidone solution (the amino iron concentration: 0.01 g / mL) was added to dissolve the amino iron under continuous stirring in a nitrogen environment at 80 °C to make the reaction proceed, and then the obtained reaction mixture was transferred. The mixture was subjected to suction filtration in a hydrothermal kettle for 24 hours in a drying oven at 80°C. During the suction filtration proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com