Grip for a handgun

a technology for handguns and grips, applied in the direction of breech mechanisms, weapon components, weapon assembly/disassembly, etc., can solve the problem of not being able to adapt the grip to the different specifications of weapons straight away, and achieve the effect of simple and cost-effective adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

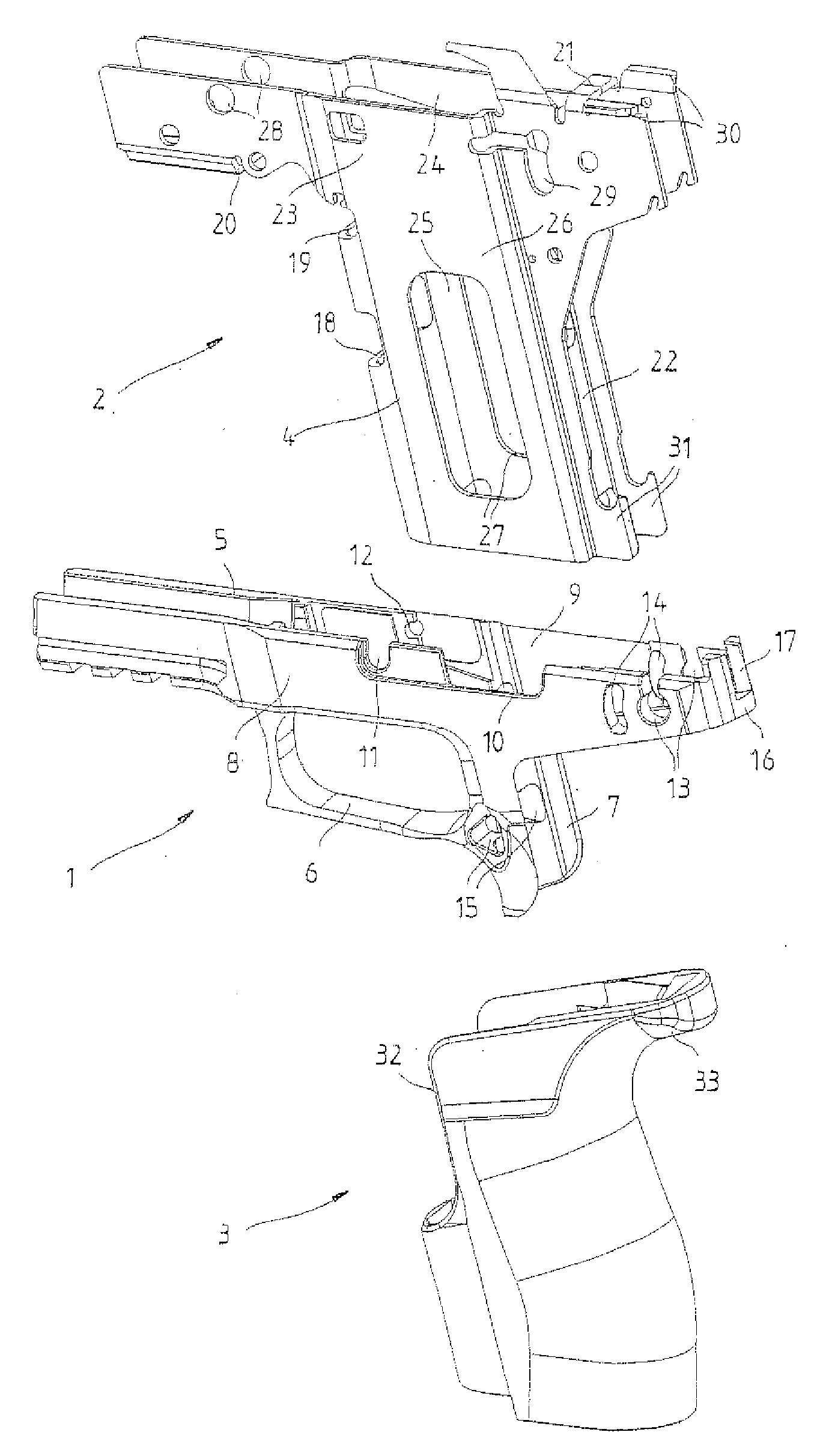

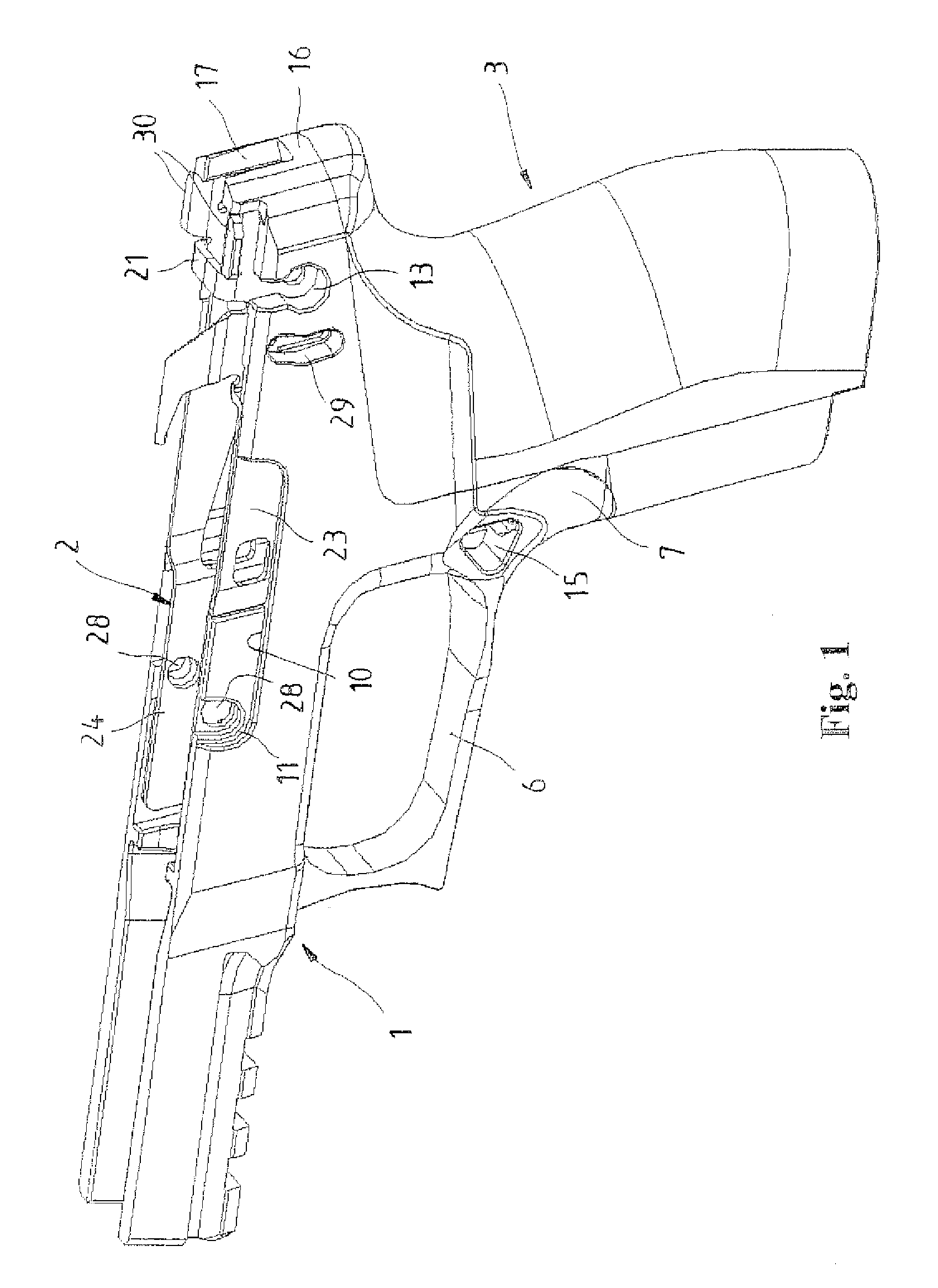

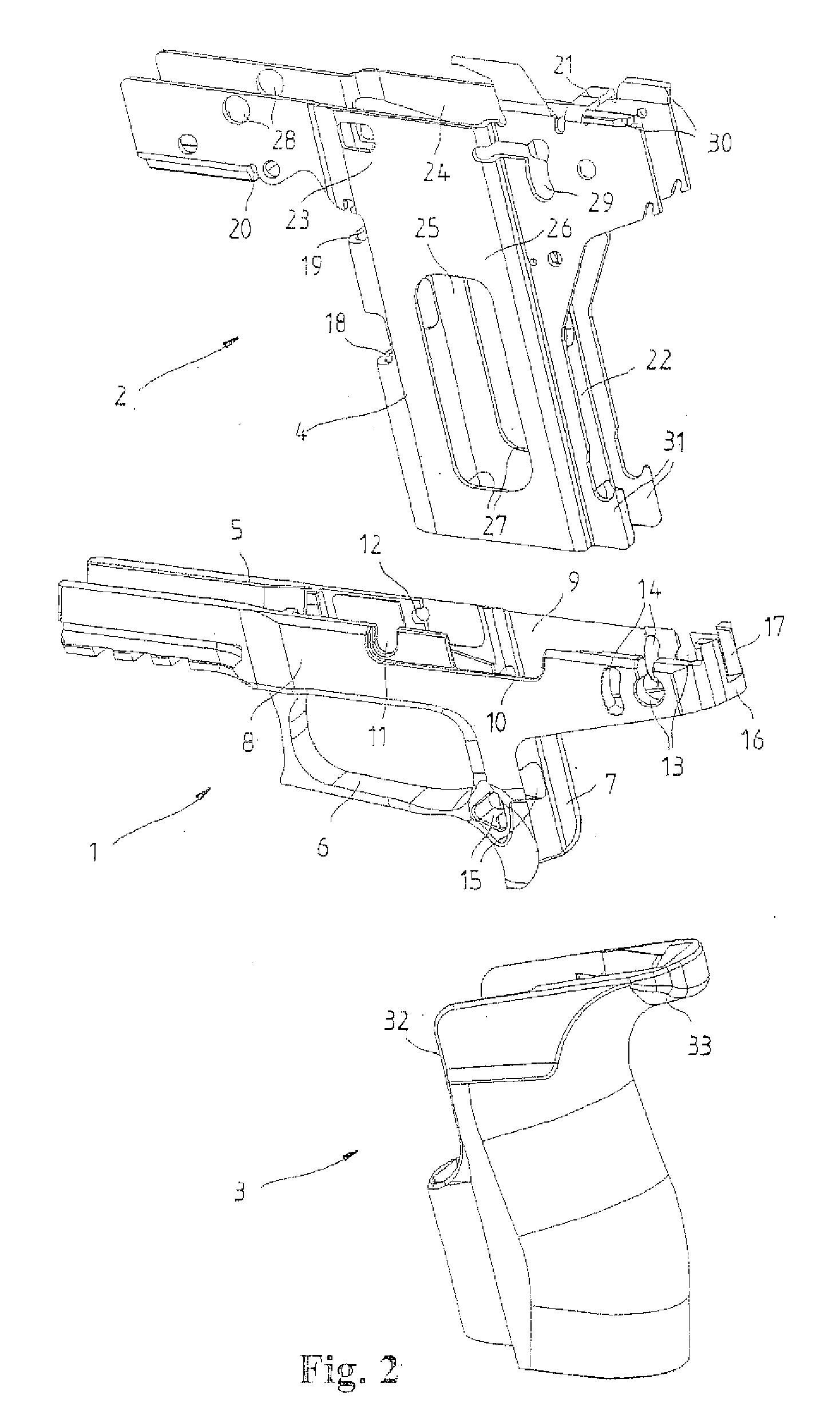

[0014] The grip of a pistol depicted diagrammatically in FIGS. 1 and 2 is composed of a grip module (1), a carrier element (2) insertable in said grip module (1), and a grip shell module (3) capable of being slipped onto the carrier element (2). As emerges from FIG. 2 in particular, a downward extending magazine shaft (4) is formed on the carrier element (2) that is insertable in the grip module (1).

[0015] The grip module (1), preferably manufactured as an injection-molded part of plastic, comprises simply an upper retainer part (5) in the form of a frame, on the underside of which is molded a trigger guard (6) and a front cover (7) in the shape of a half shell for the upper part of the magazine shaft (4). The action or slide of the handgun, not represented here, is slidably arranged on the retainer part (5). Various openings or recesses or hollows for different control elements or functional elements are provided in the two sidewalls (8, 9) of the upper retainer part (5). Thus a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com