Patents

Literature

45results about How to "Safe and cost-effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

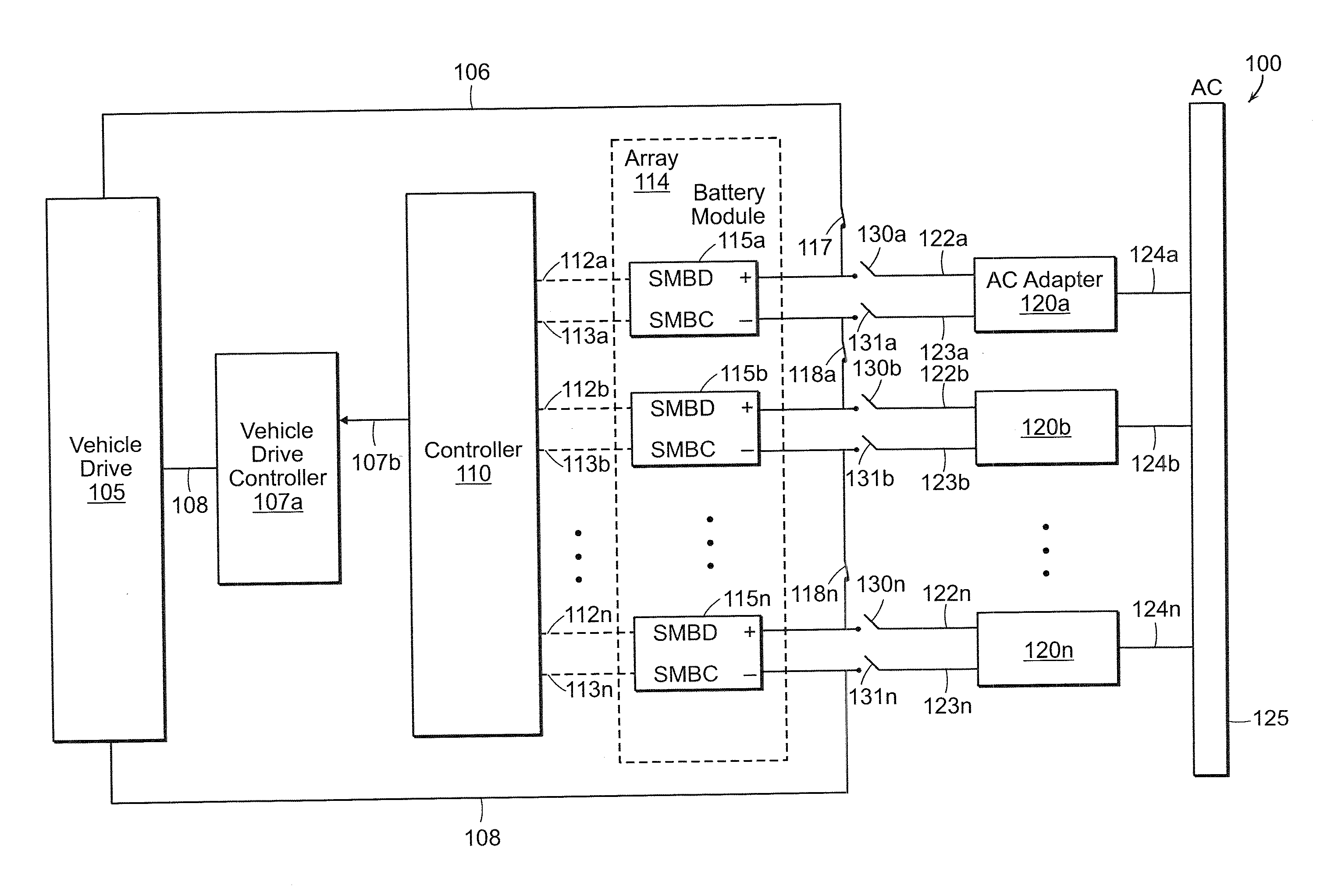

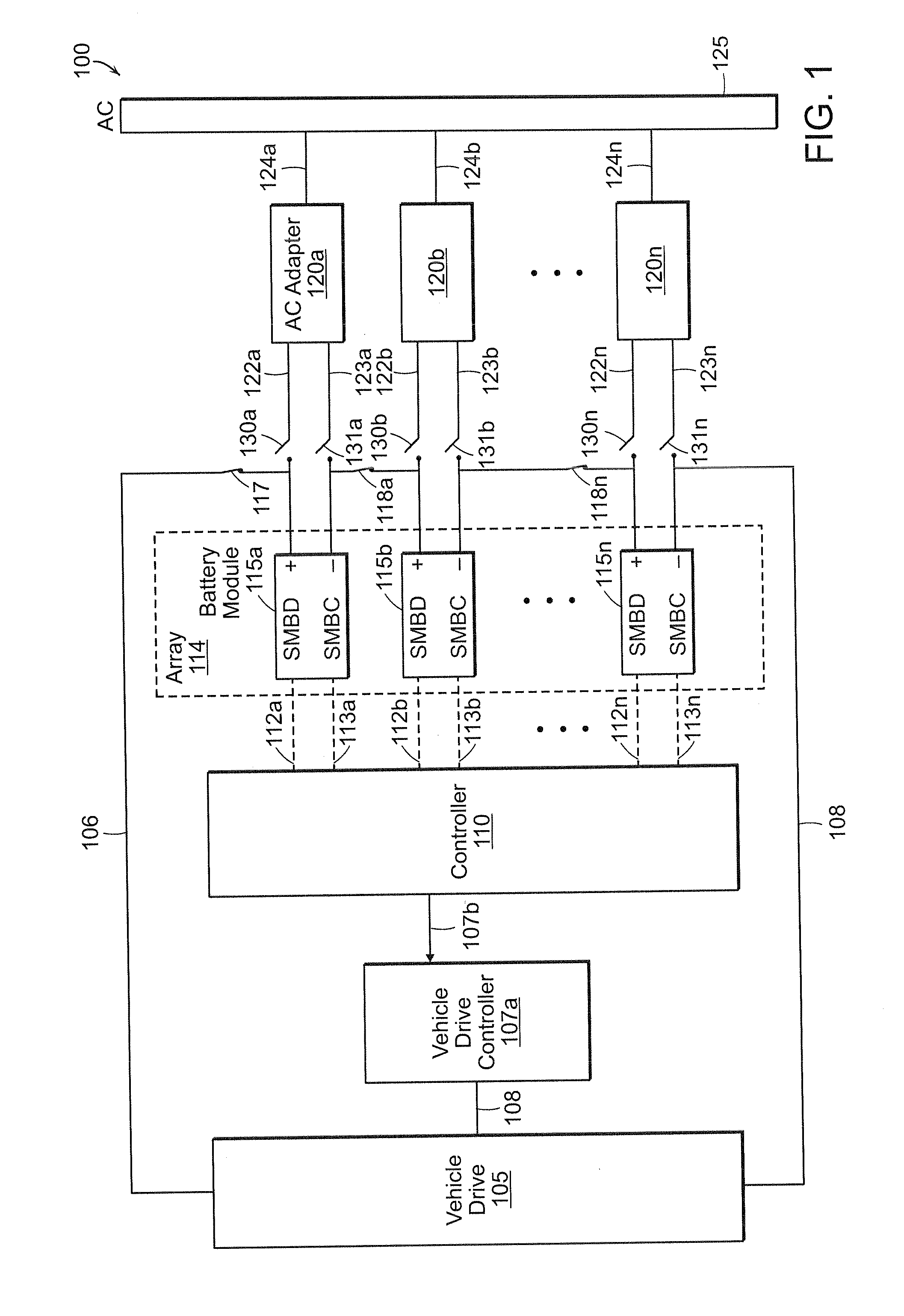

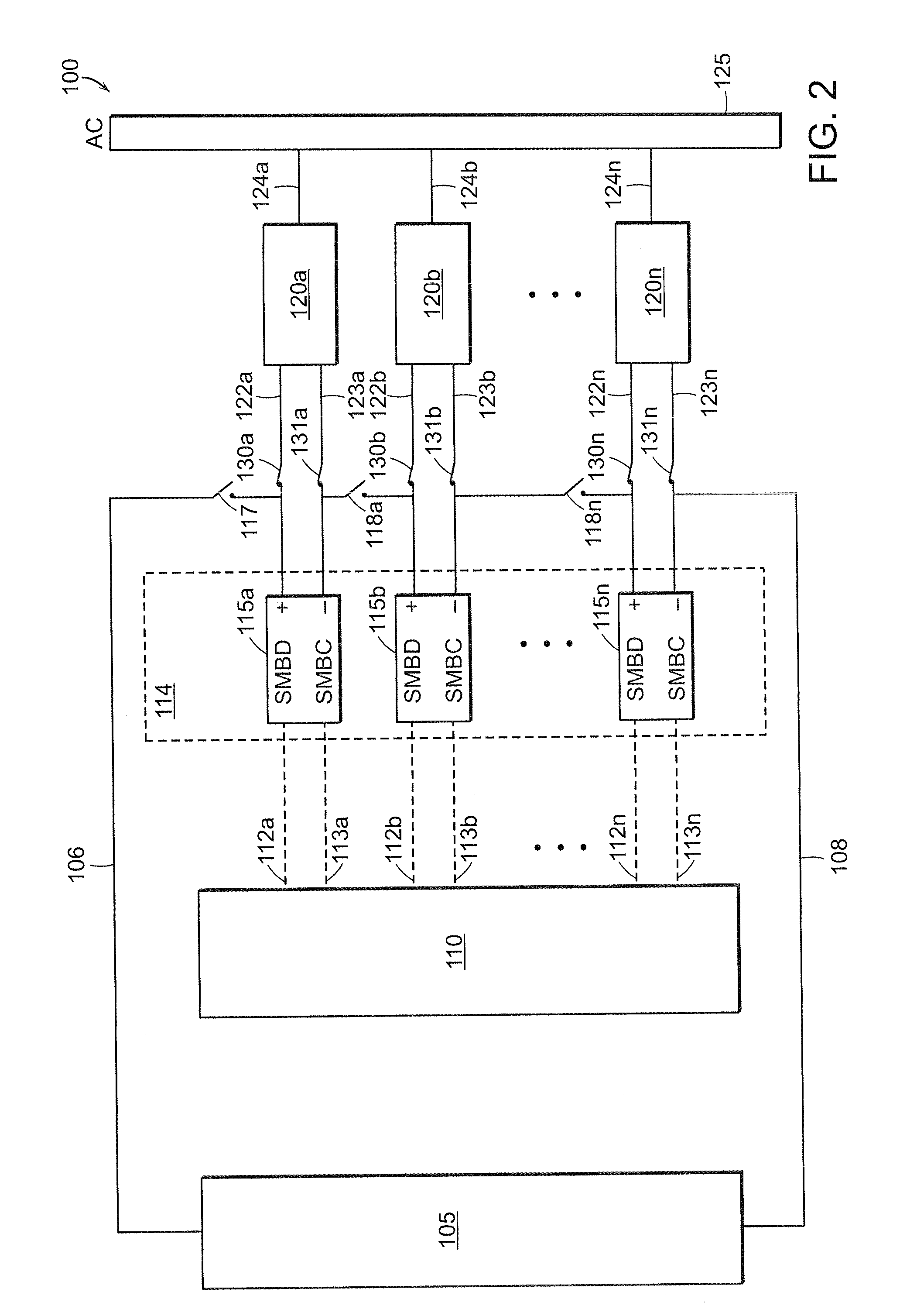

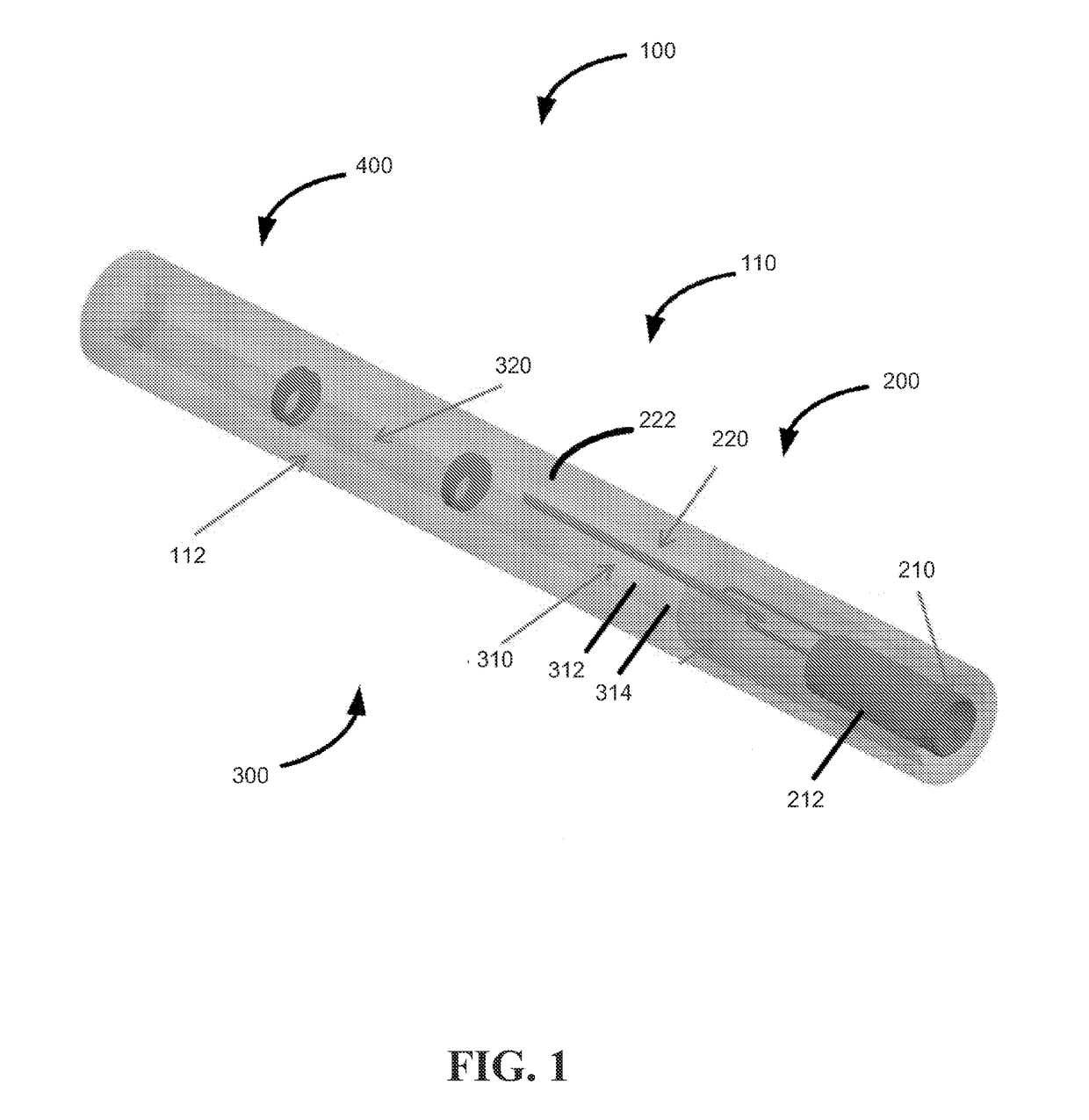

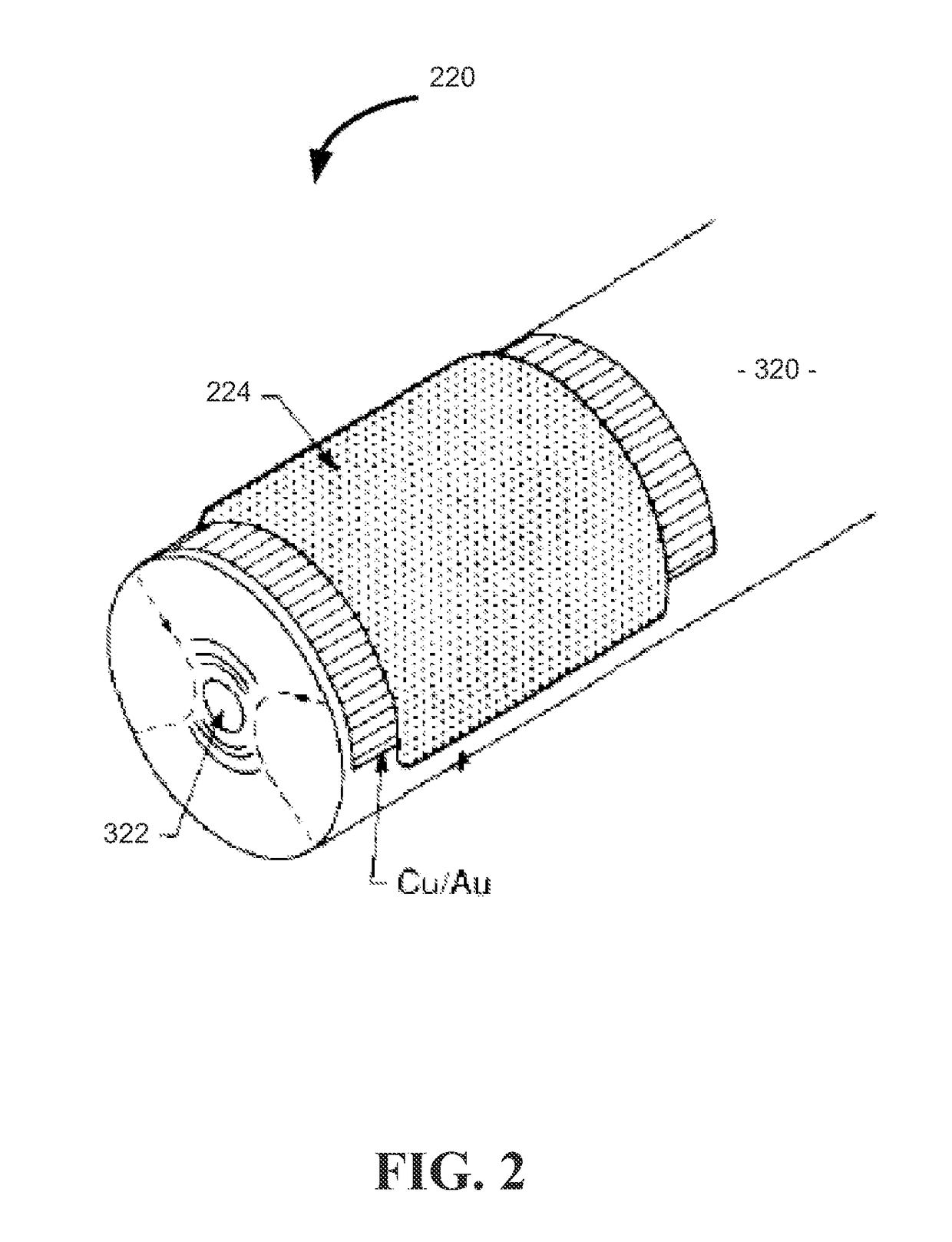

Li-ion battery array for vehicle and other large capacity applications

InactiveUS20100121511A1Improve reliabilityMinimize timeCharge equalisation circuitDigital data processing detailsElectrical batteryComputer module

A large battery array, particularly for use in an electric vehicle, is formed of multiple modules, each containing plural battery cells and module management electronics. Each battery module has a nominal output voltage in the range of about 5 volts to about 17 volts. A controller communicates with individual battery modules in the array and controls switching to connect the modules in drive and charging configurations. The module management electronics monitor conditions of each battery module, including the cells it contains, and communicates these conditions to the controller. The module management electronics may place the modules in protective modes based upon the performance of each module in comparison to known or configurable specifications. The modules may be pluggable devices so that each module may be replaced if the module is in a permanent shutdown protective mode or if a non-optimal serviceable fault is detected.

Owner:BOSTON POWER INC

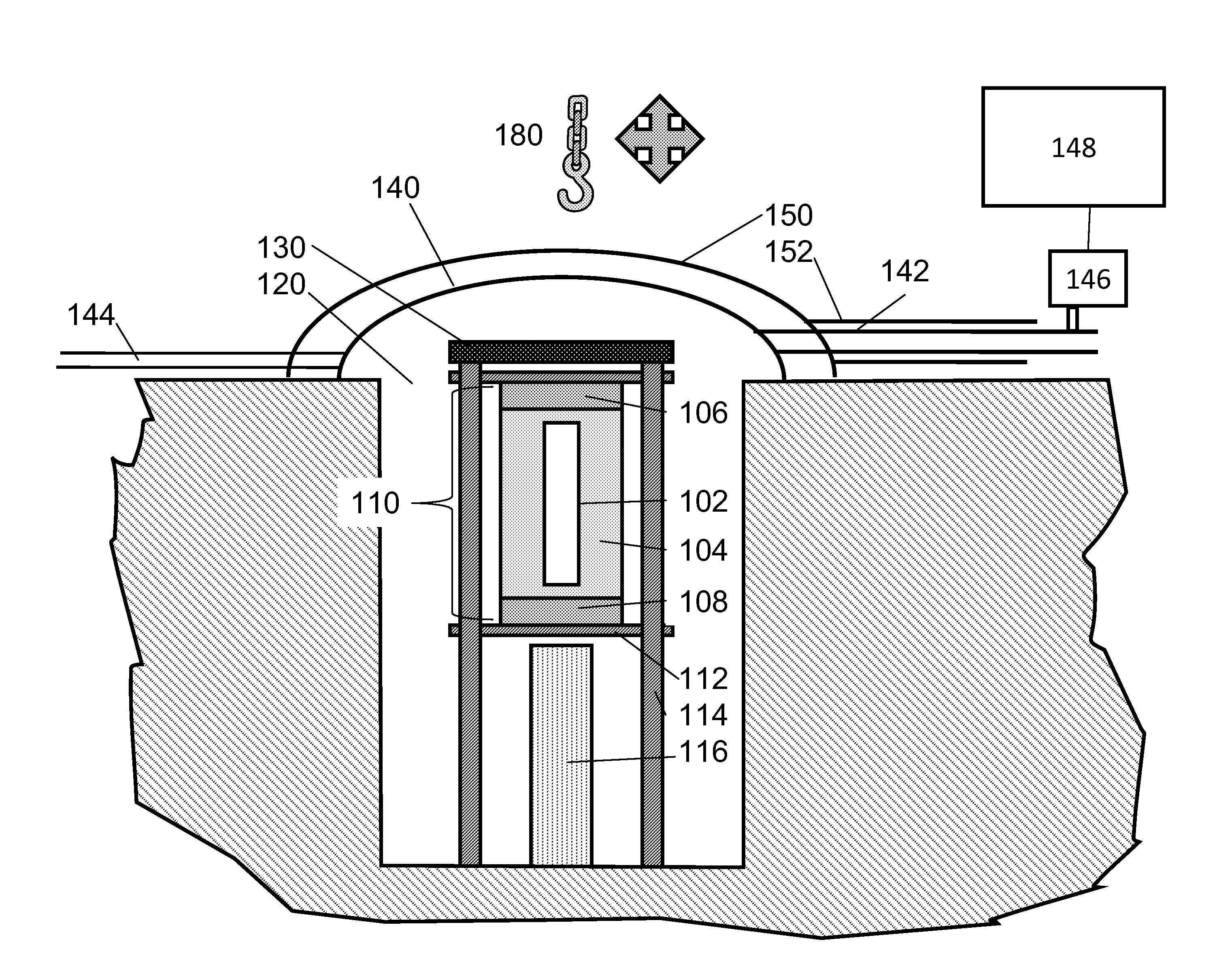

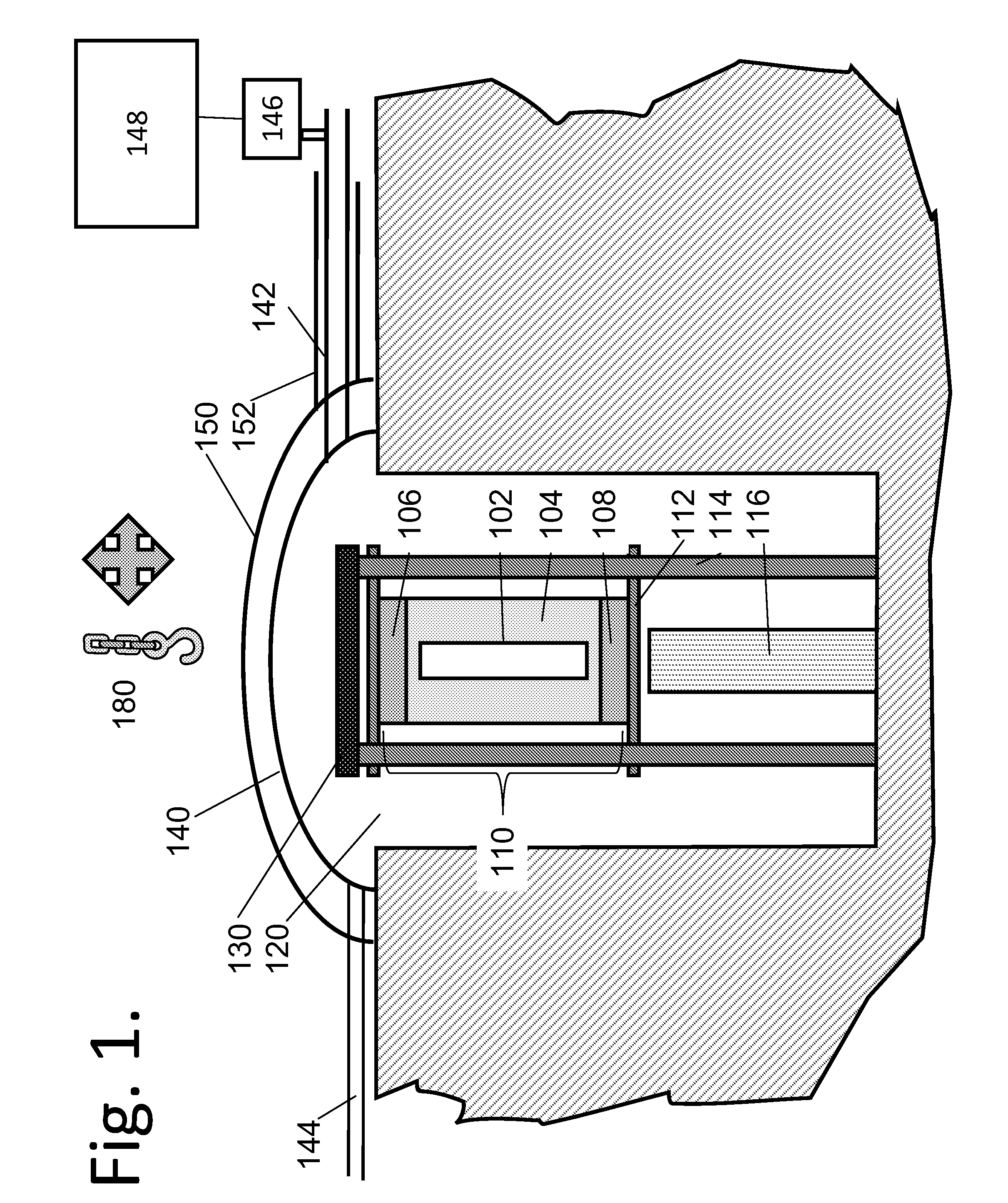

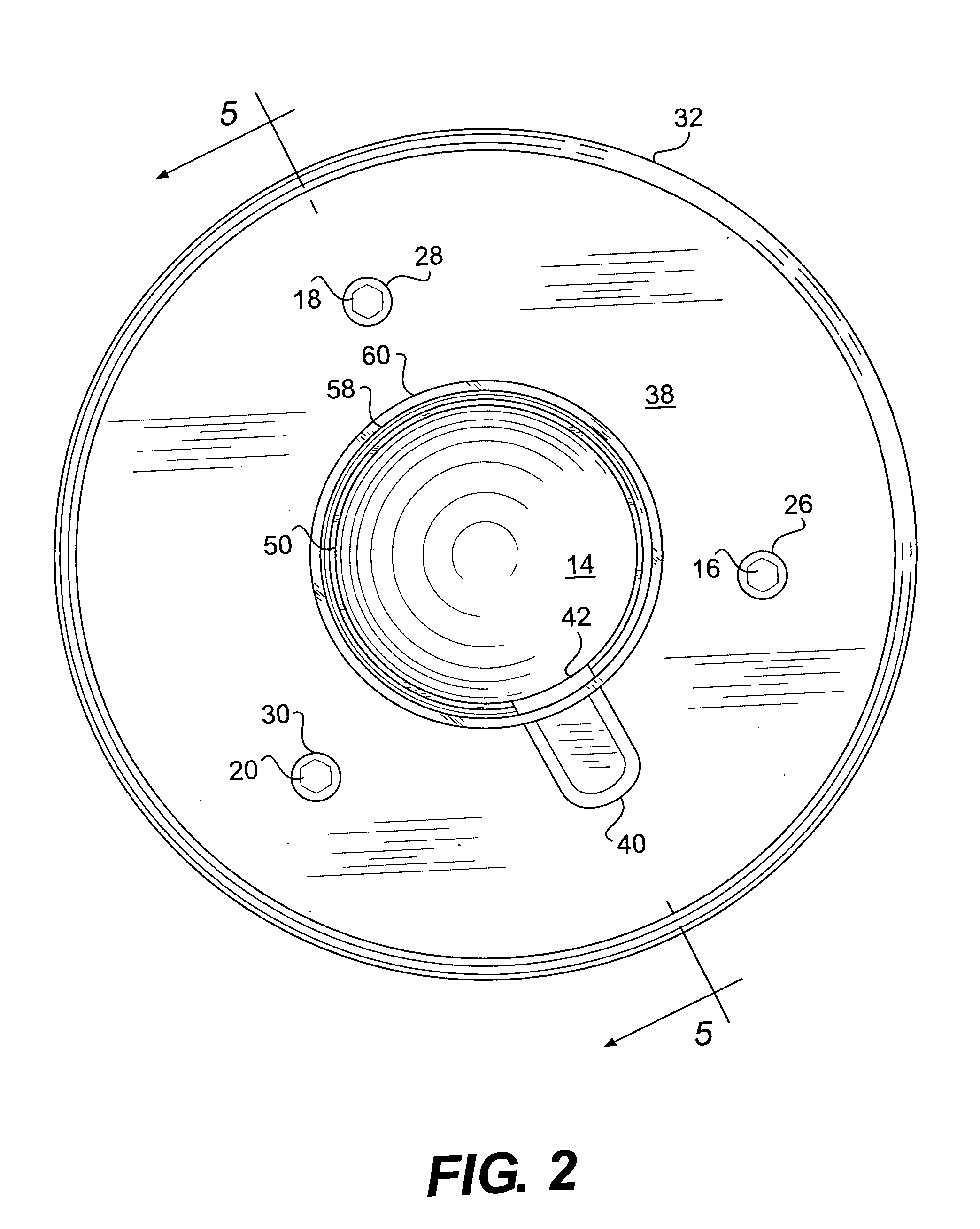

Plant and method for large-scale ammonothermal manufacturing of gallium nitride boules

InactiveUS20110100291A1Simple and cost-effective to manufactureSafe and cost-effectivePolycrystalline material growthFrom normal temperature solutionsNuclear engineeringGallium nitride

A method of operating a high pressure system for growth of gallium nitride containing materials. The method comprises providing a high pressure apparatus comprising a growth region and feedstock region. The high pressure reactor comprises a high pressure enclosure and is configured within a primary containment structure. The method includes operating an exhaust system coupled to the primary containment structure. The exhaust system is configured to remove ammonia gas derived from at least 0.3 liters of ammonia liquid.

Owner:SORAA

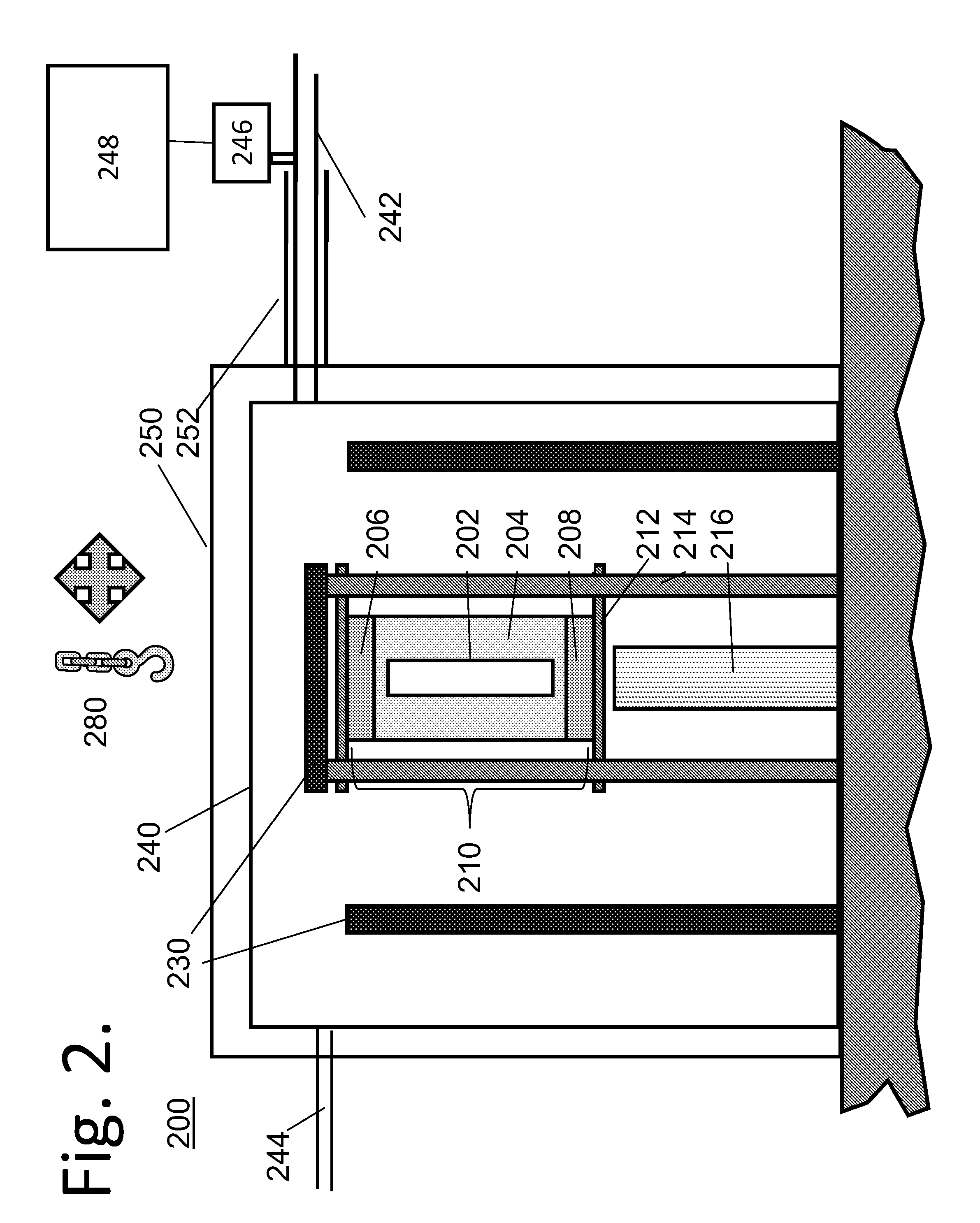

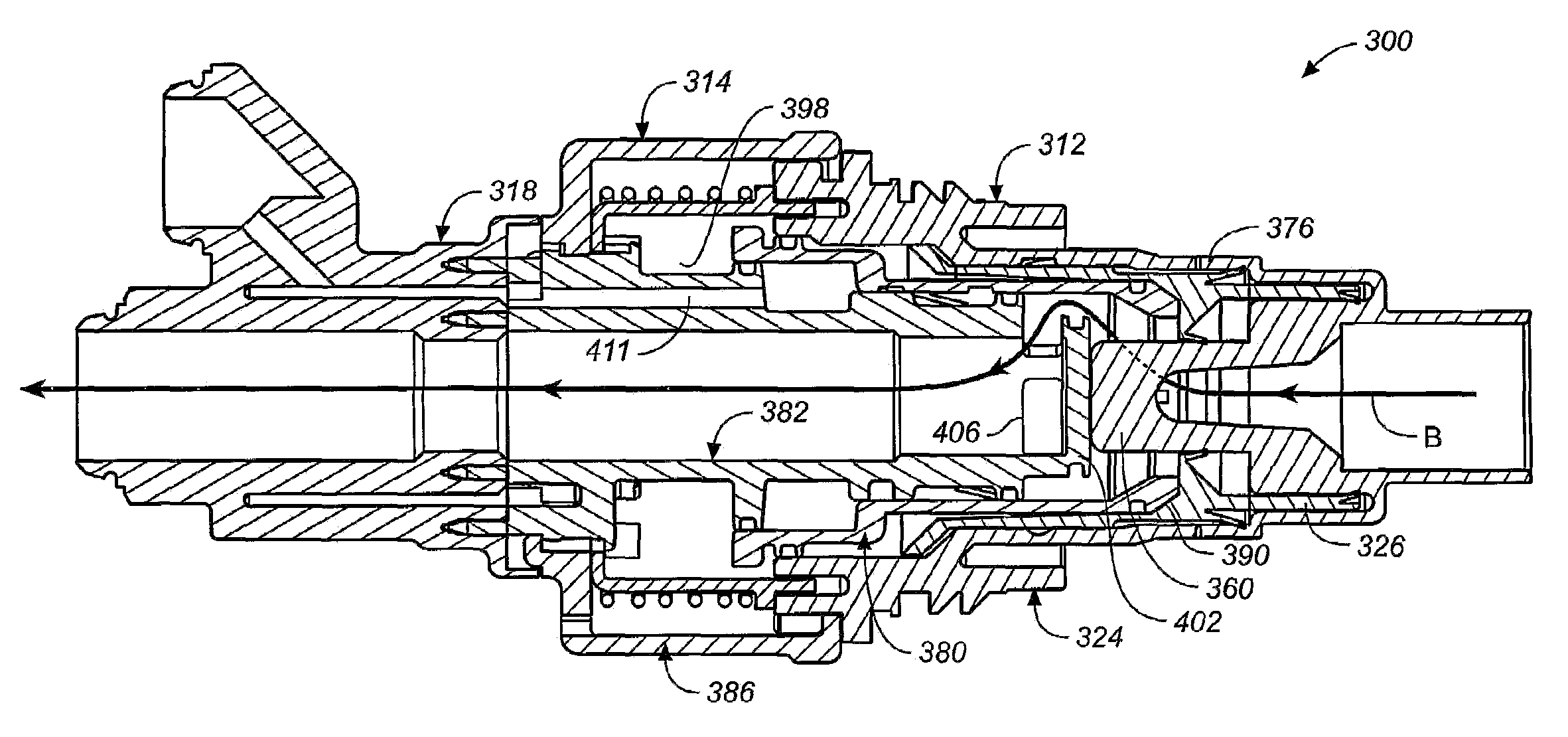

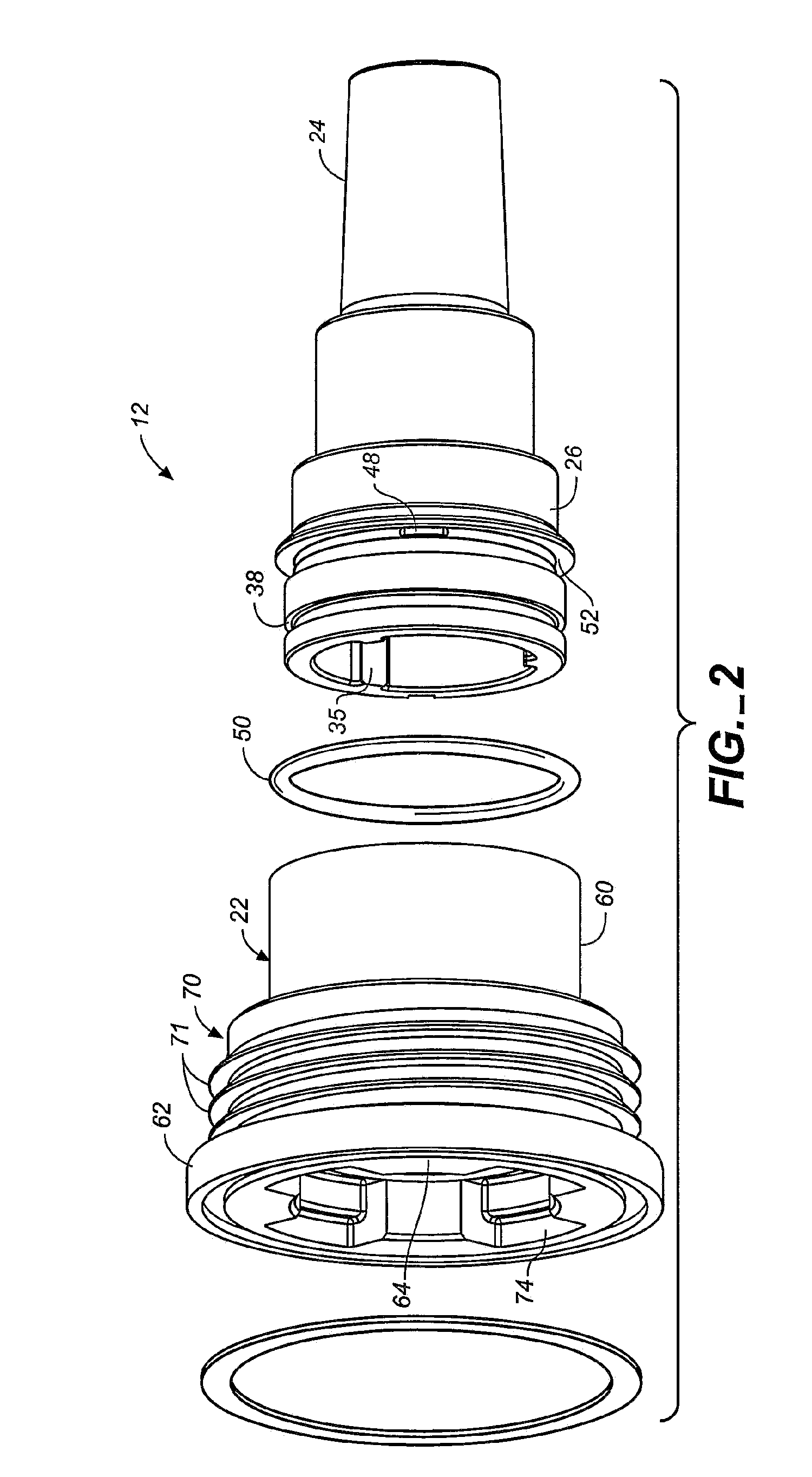

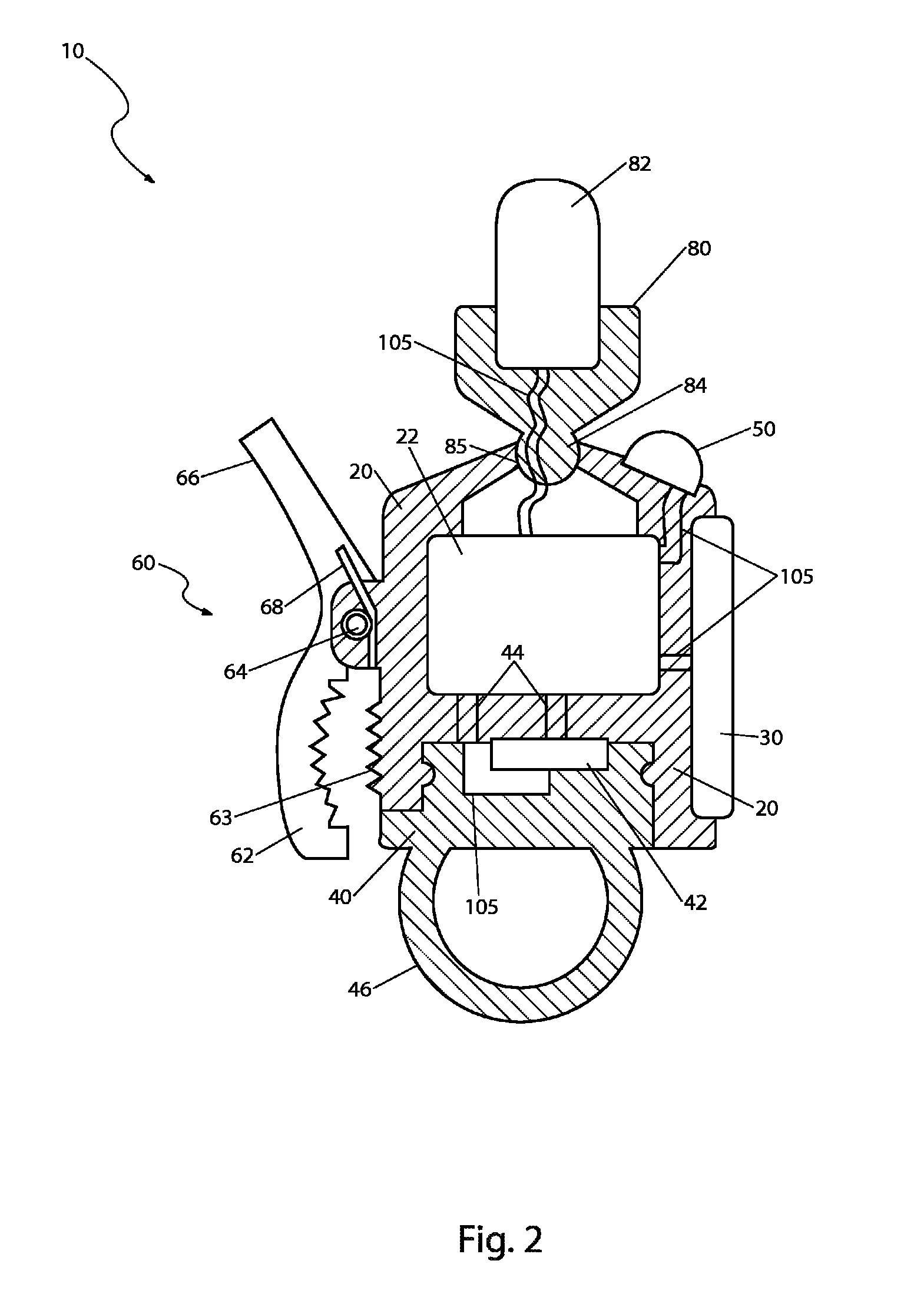

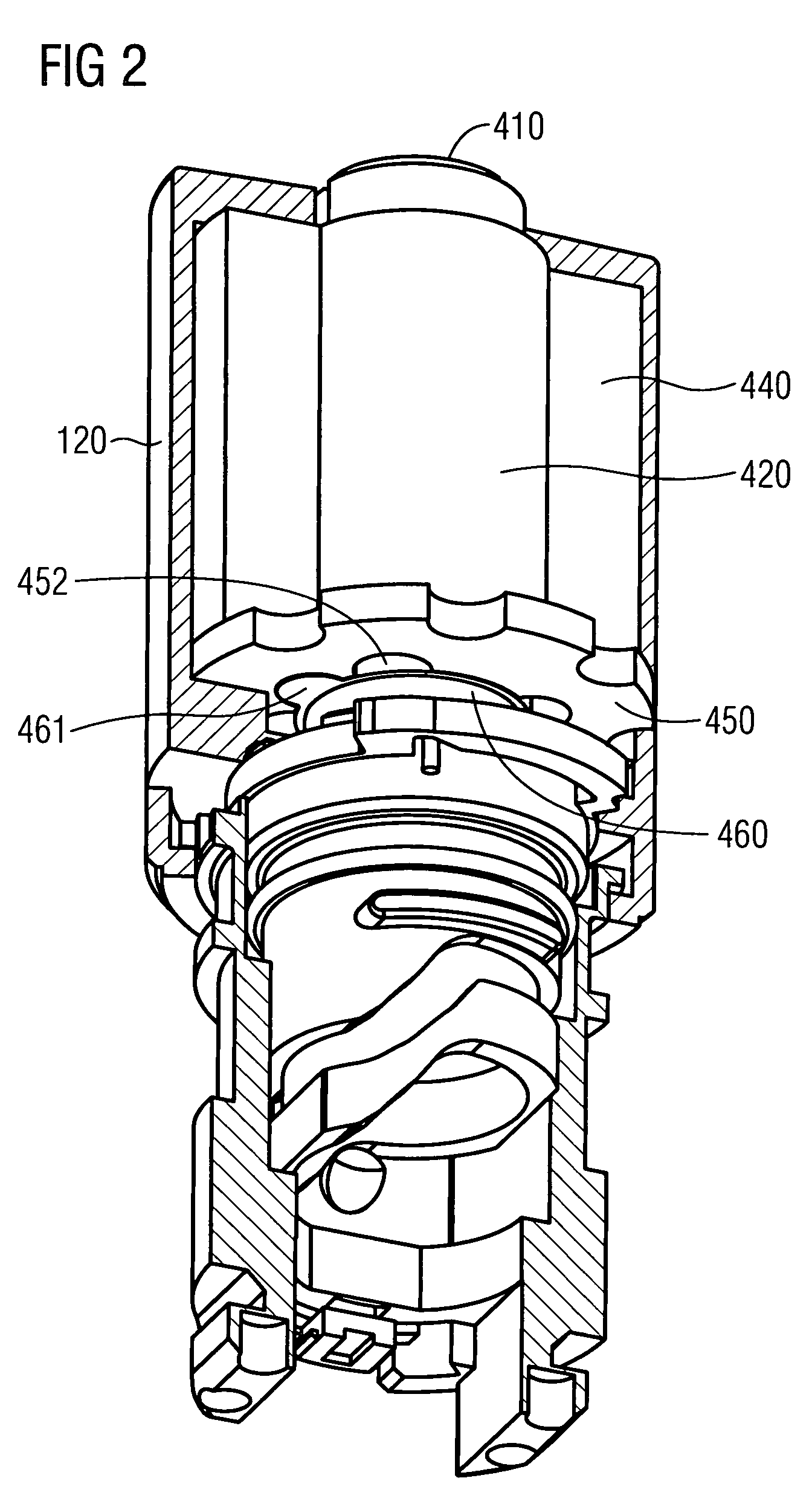

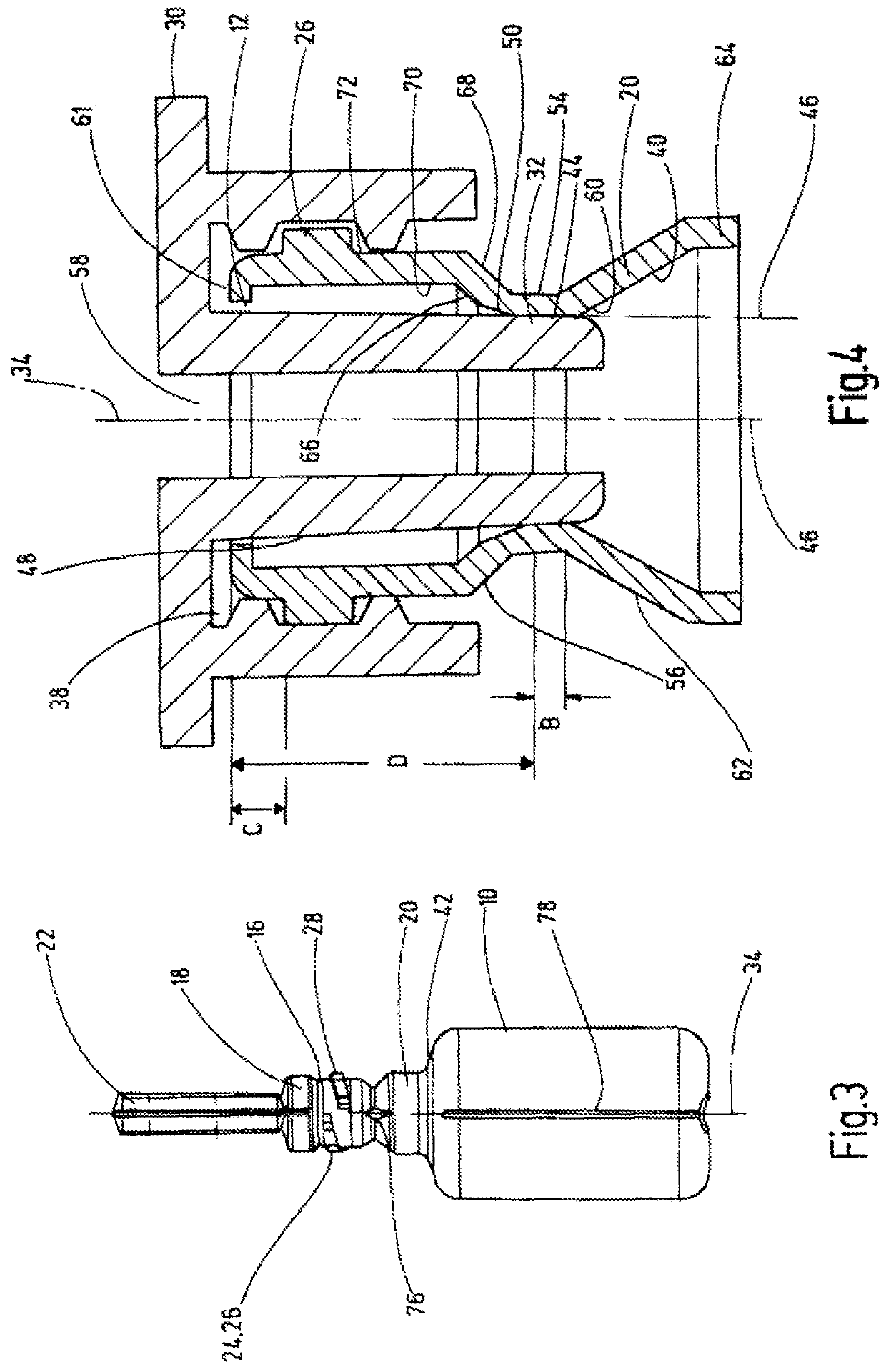

Connect/disconnect coupling for a container

ActiveUS7546857B2Safe and cost-effectiveQuick functionValve arrangementsLiquid transferring devicesCouplingEngineering

A container insert having at least two primary pieces, wherein one of the pieces includes keying features that may be replaceable with other pieces having different keying features. A related single piece container insert includes multiple keying features formed on the interior and exterior surfaces of the container insert. A related coupling assembly includes a venting system that vents a fluid into the container after a valve in the coupling assembly, which is positioned in the container contents flow path, has been opened.

Owner:COLDER PRODS

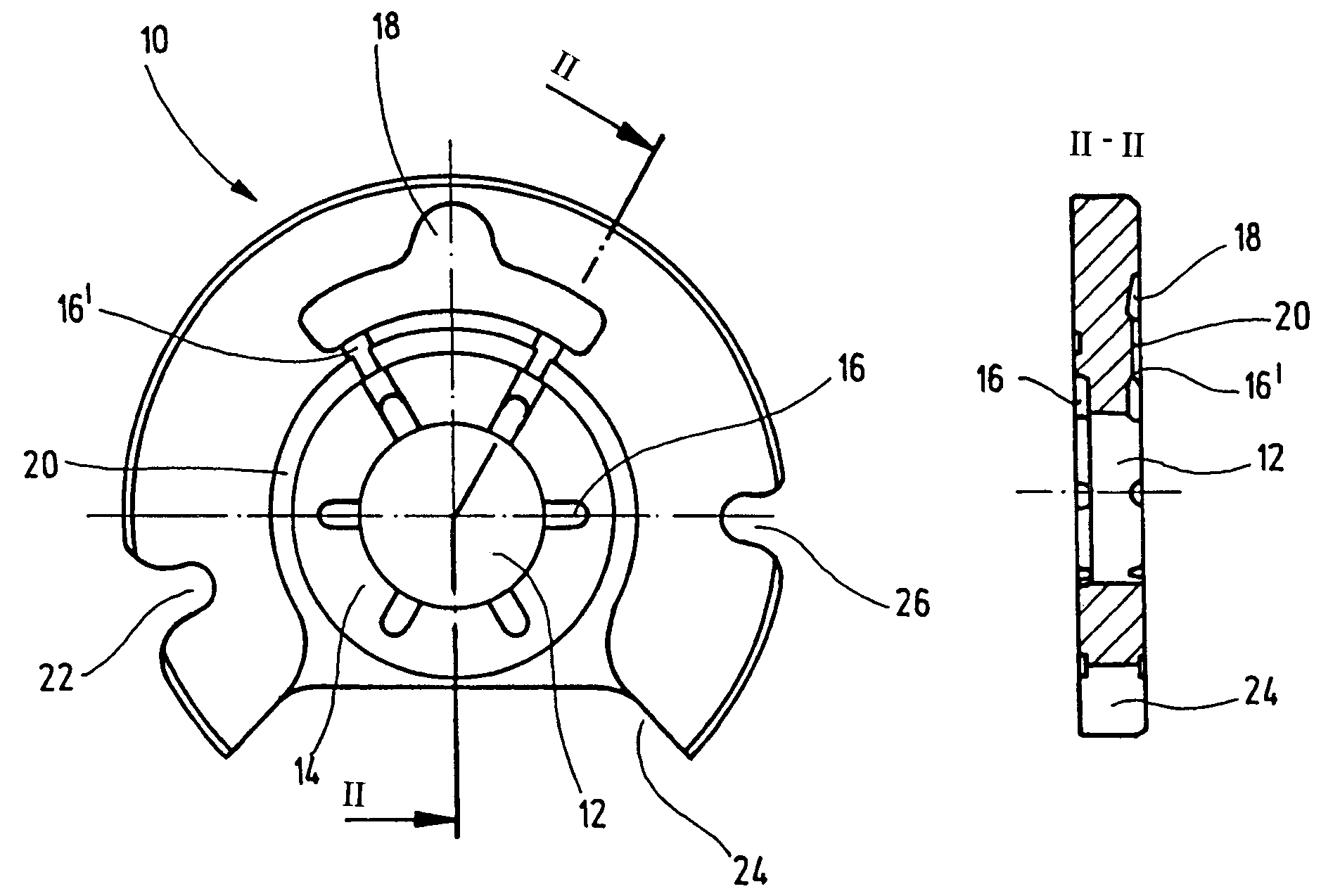

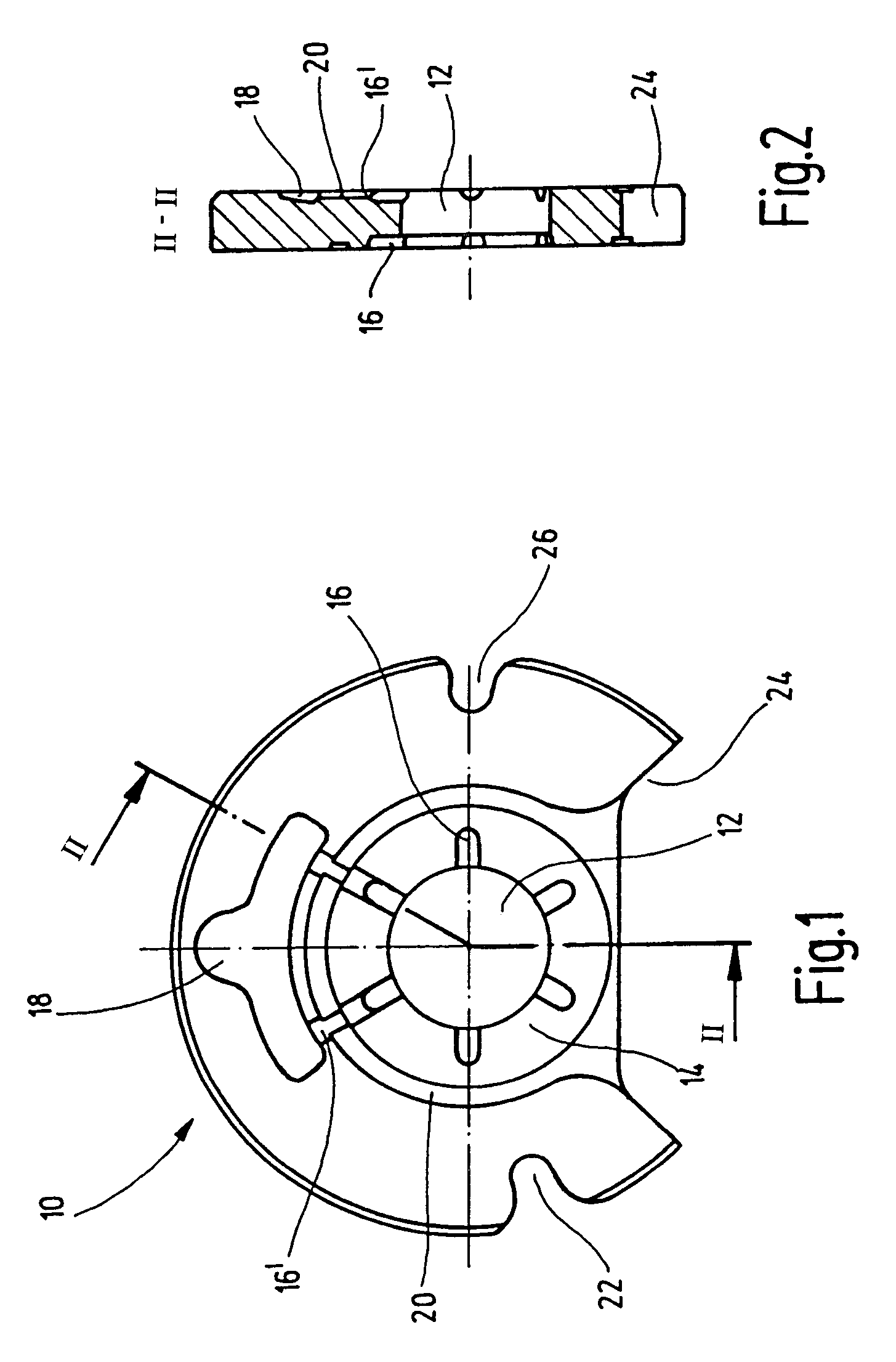

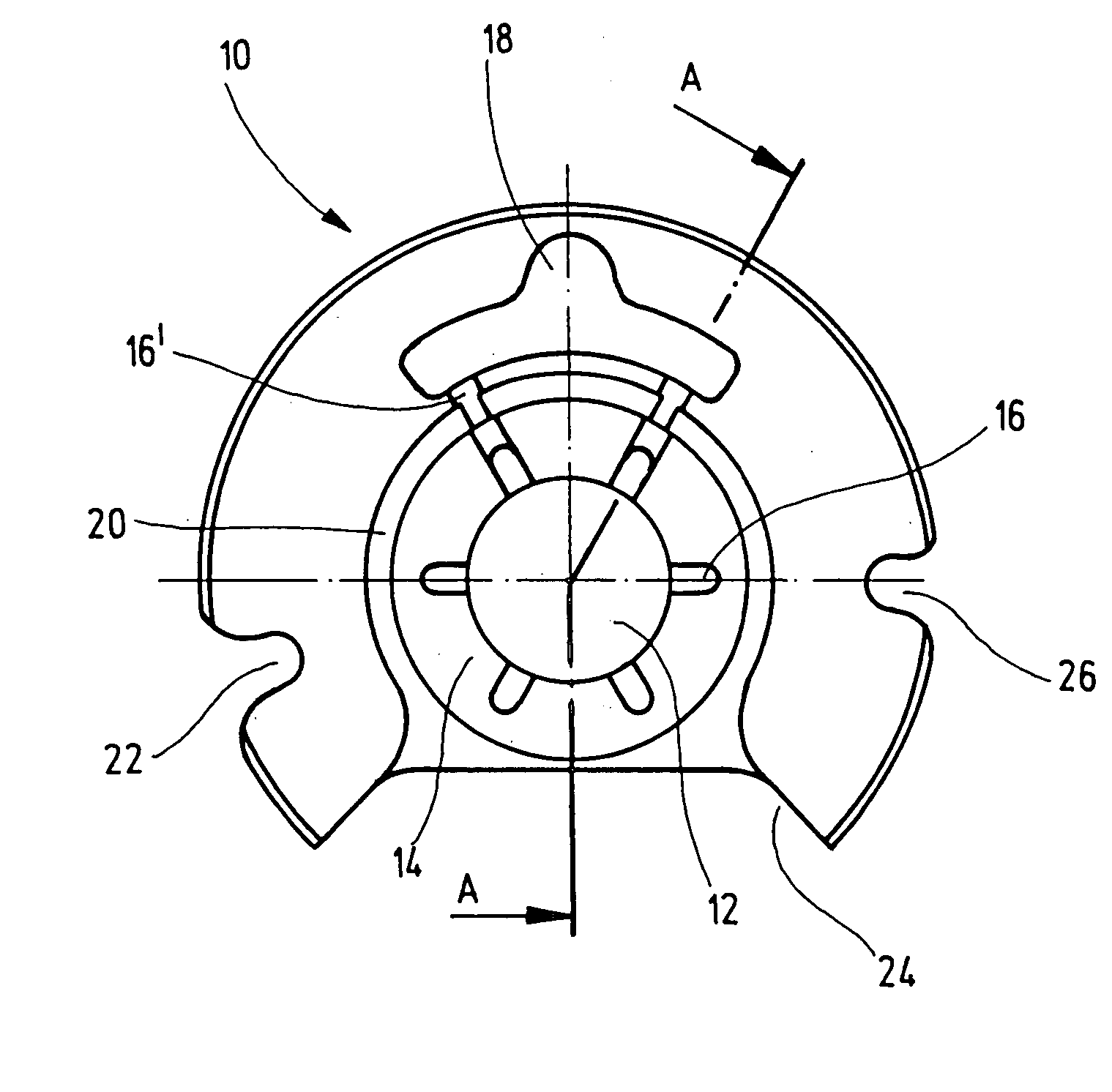

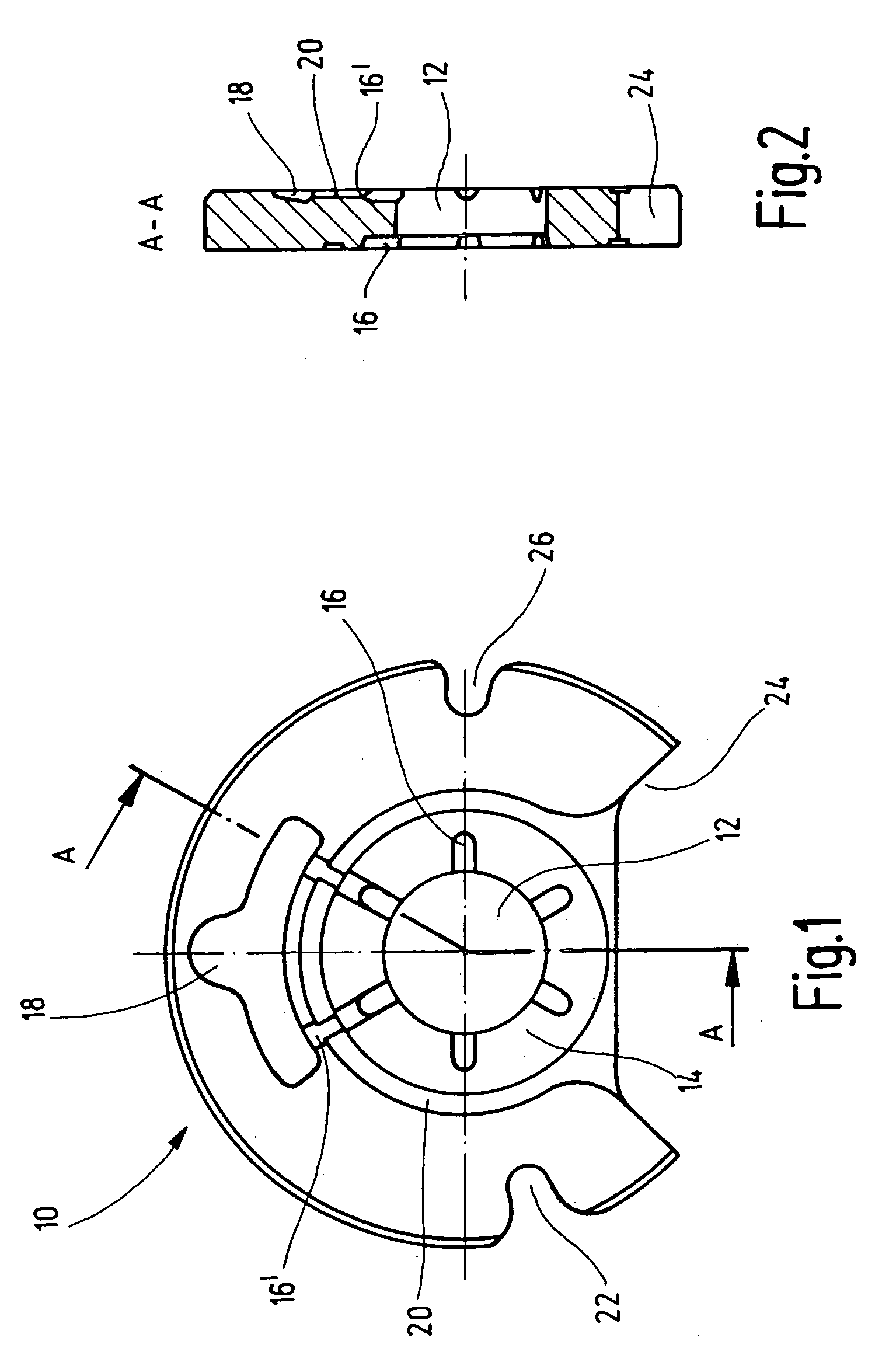

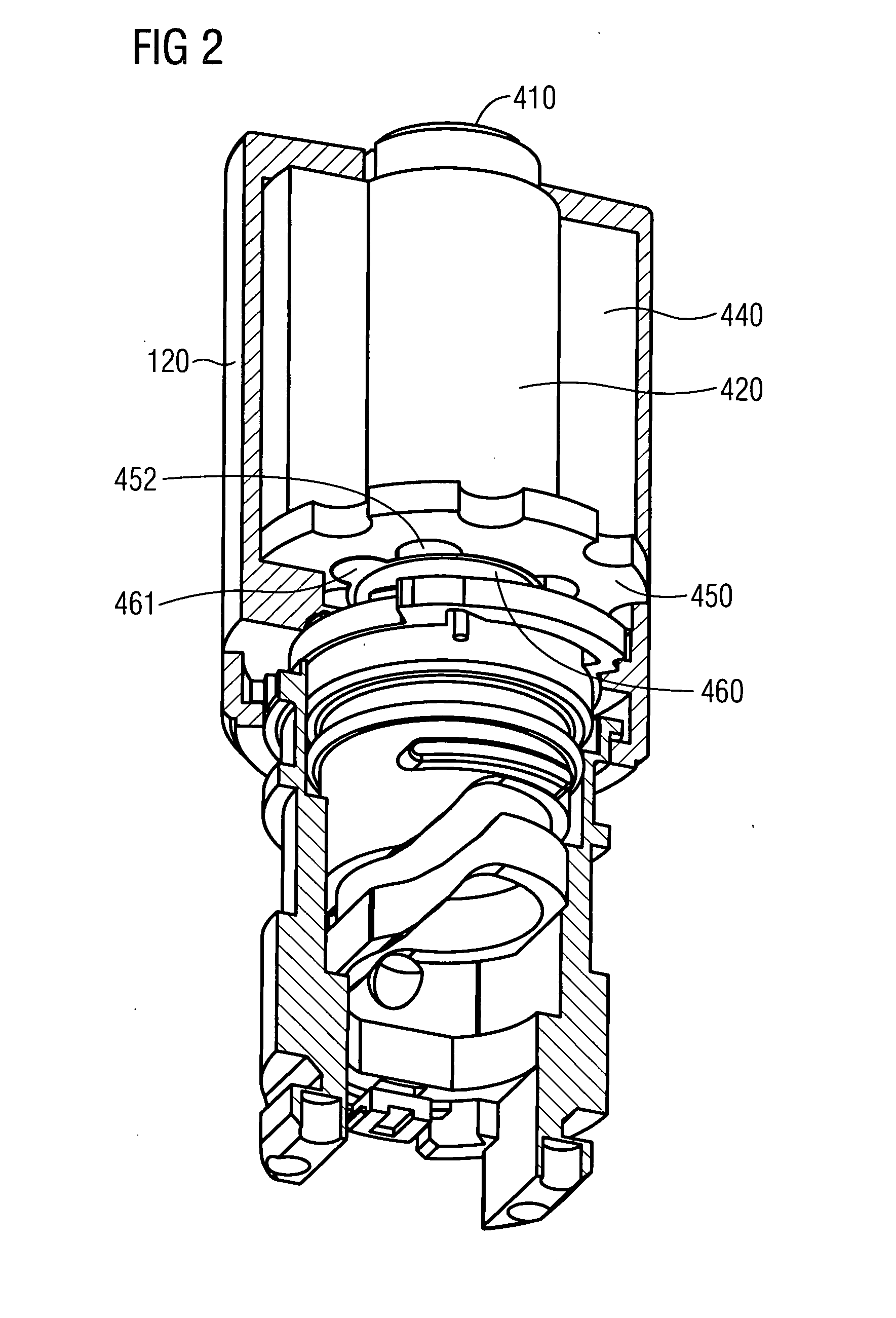

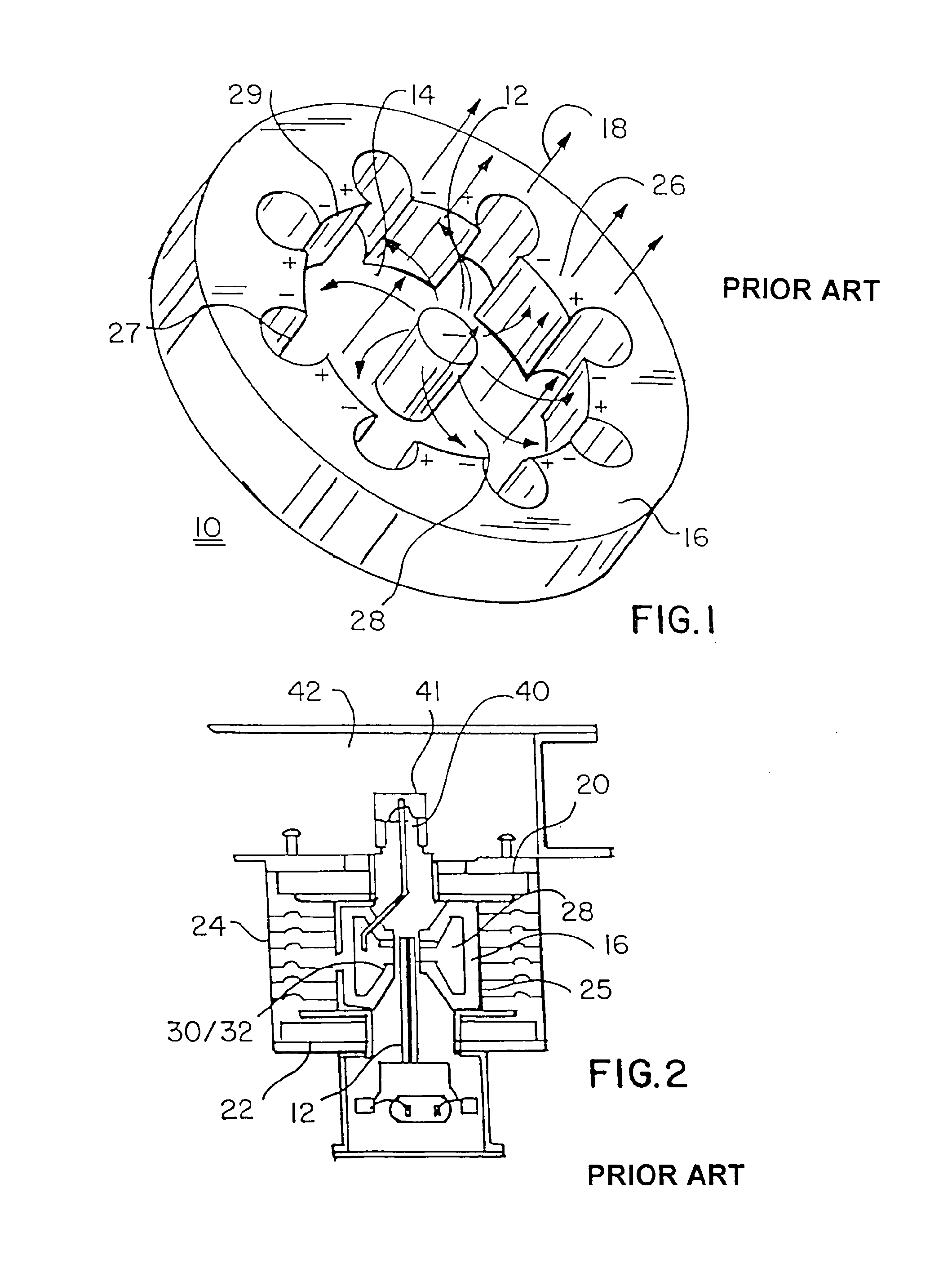

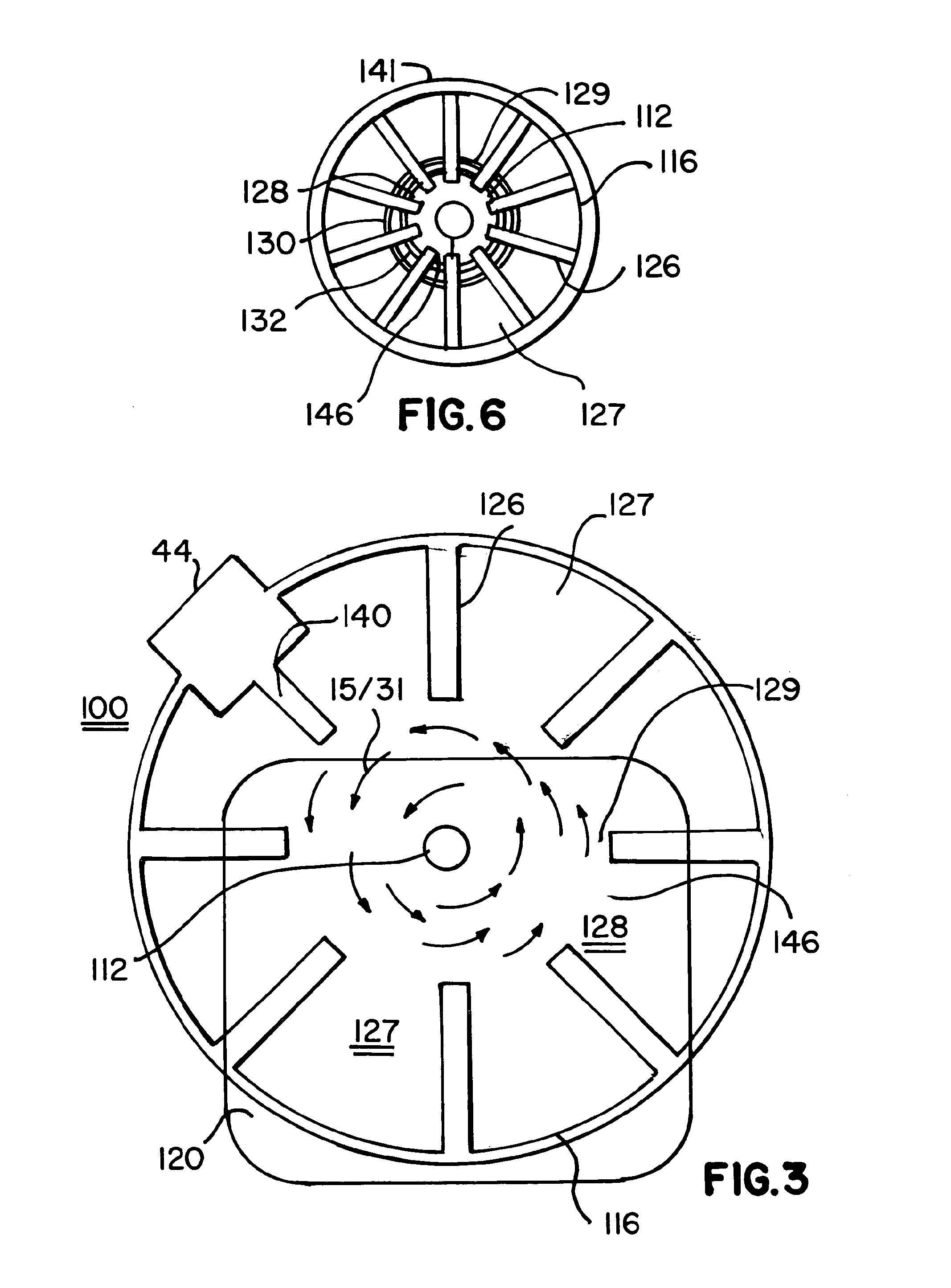

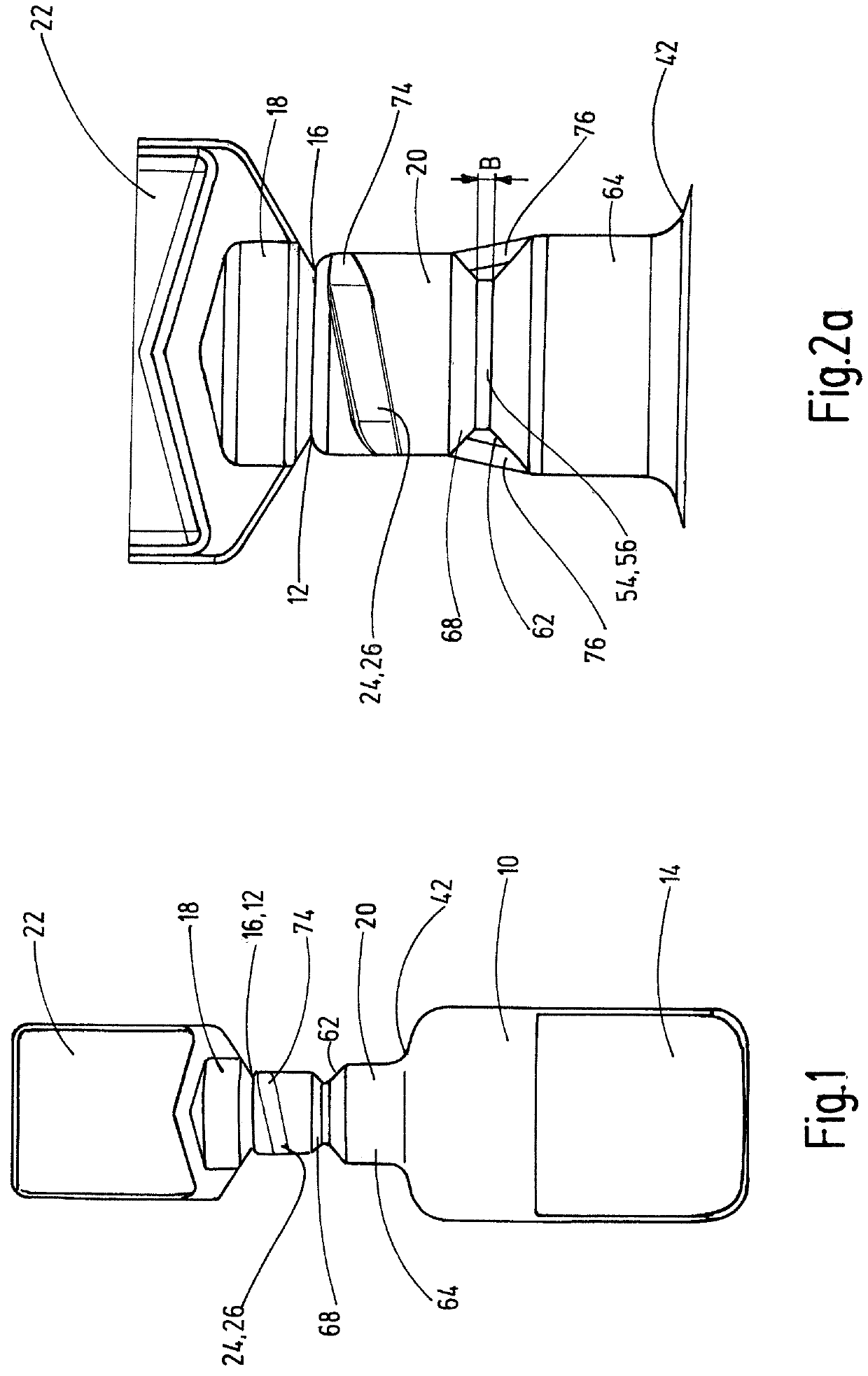

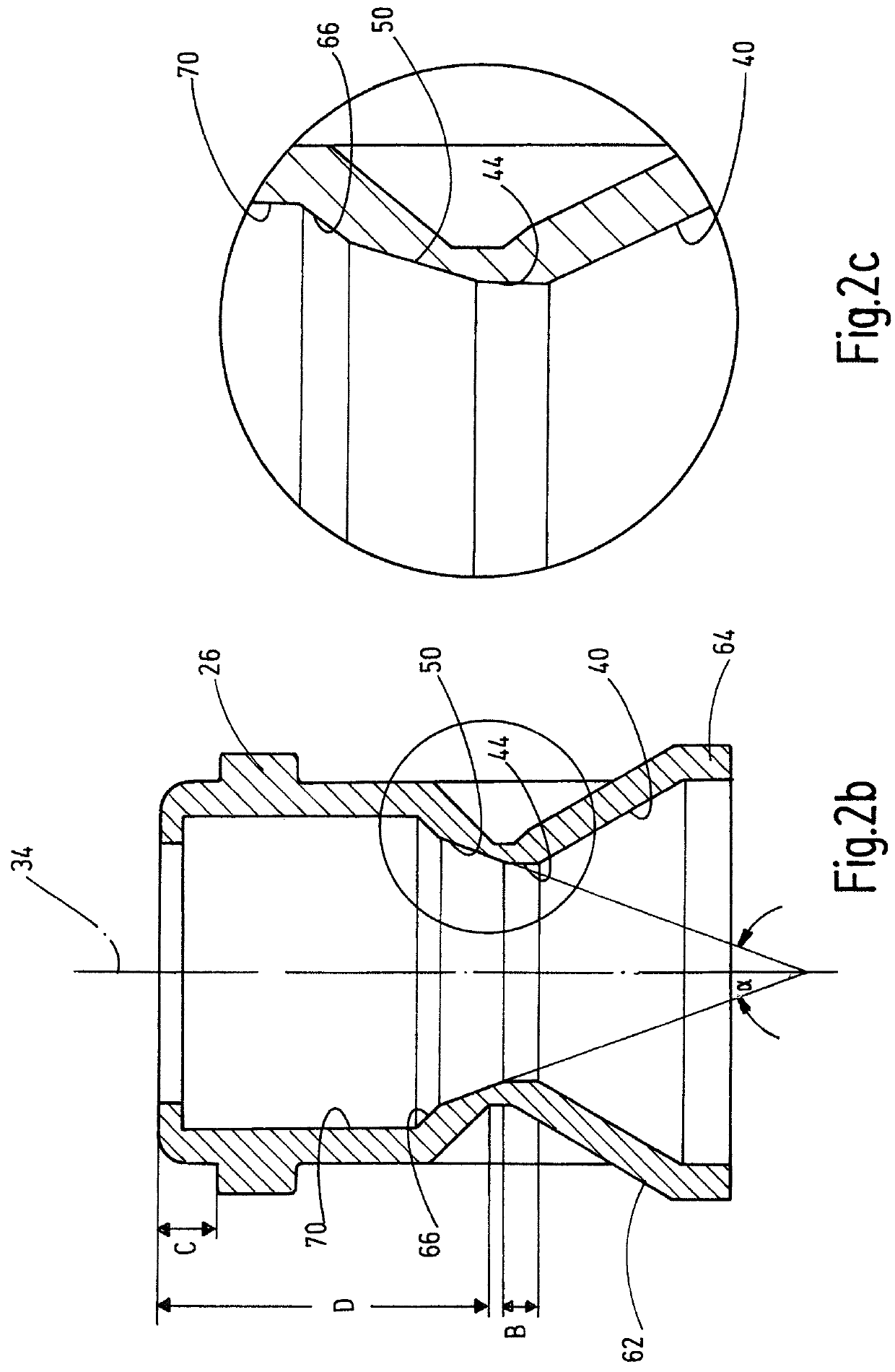

Axial bearing

ActiveUS7401980B2Safe and cost-effectiveReduce manufacturing costCrankshaftsCrossheadsTurbochargerThrust bearing

A thrust bearing, in particular for a turbo charger, has an essentially disc shaped bearing body (10) with a central through opening (12) for a shaft, at least one bearing surface (14) surrounding the through opening (12) for a collar which is placed on the shaft, and at least one oil supply channel which leads from a radially outer region of the bearing body to the through opening (12). In order to realize a cost effective manufacture of the thrust bearing it is proposed according to the invention that the at least one oil supply channel is designed to be a groove (16′).

Owner:BORGWARNER INC

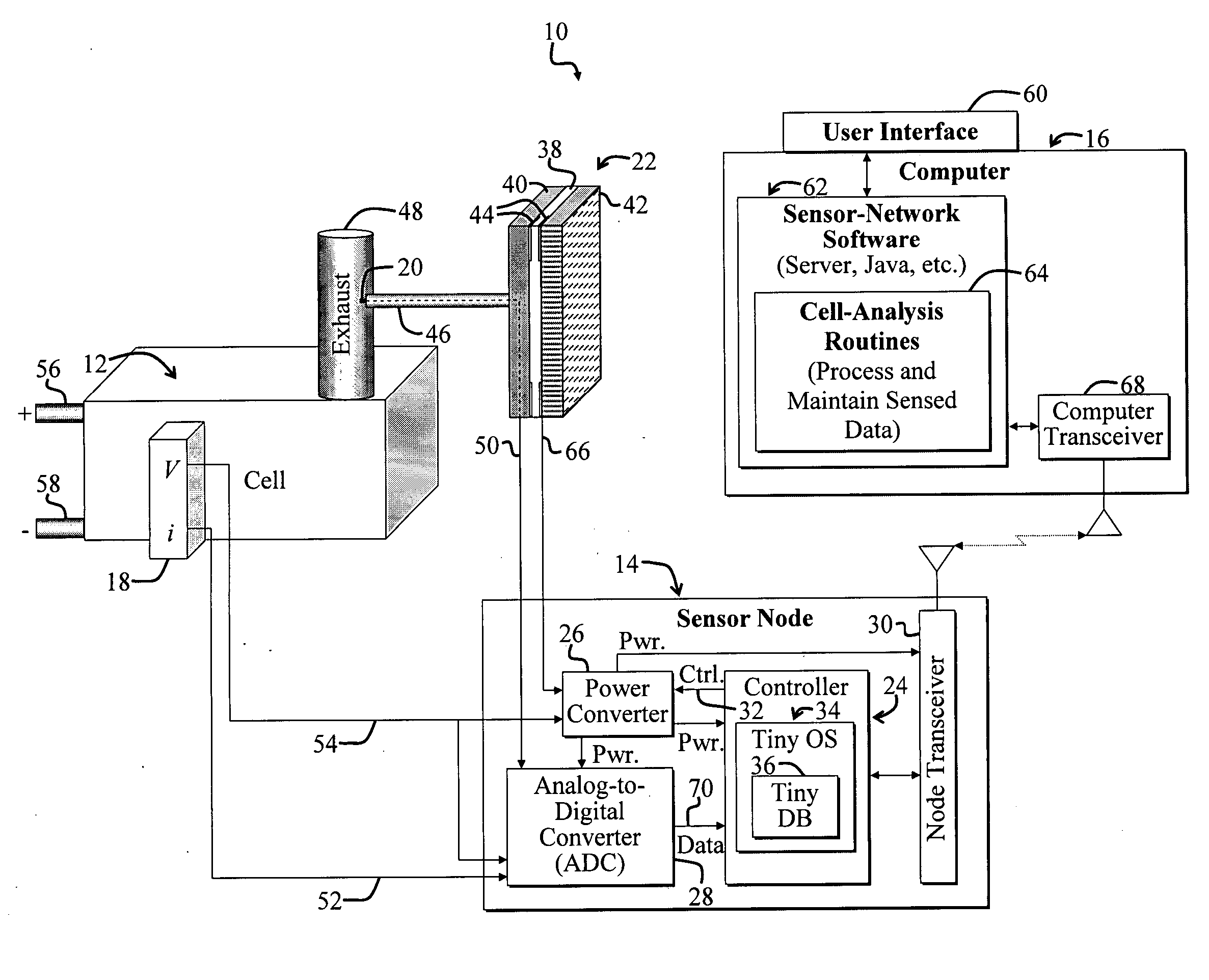

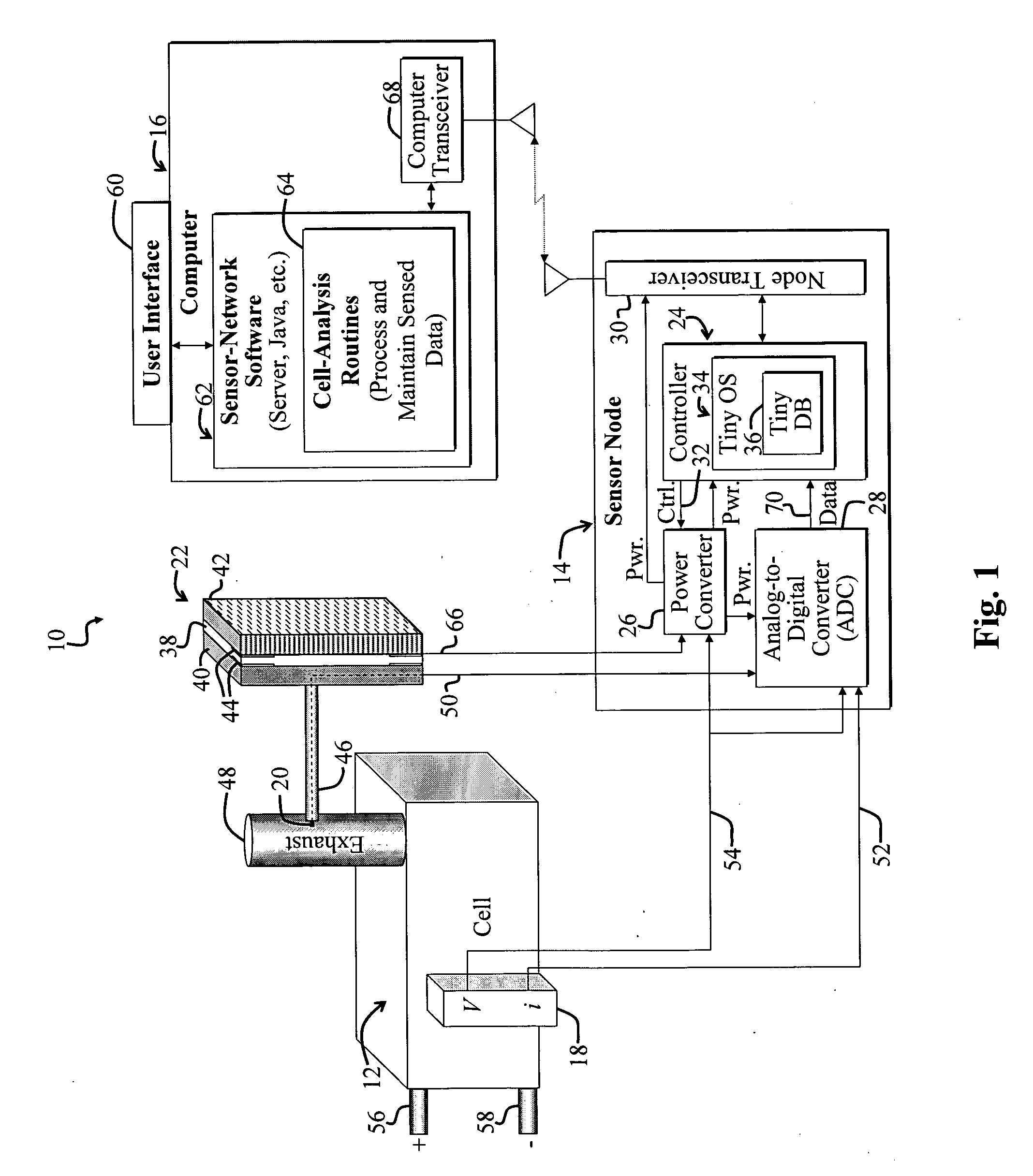

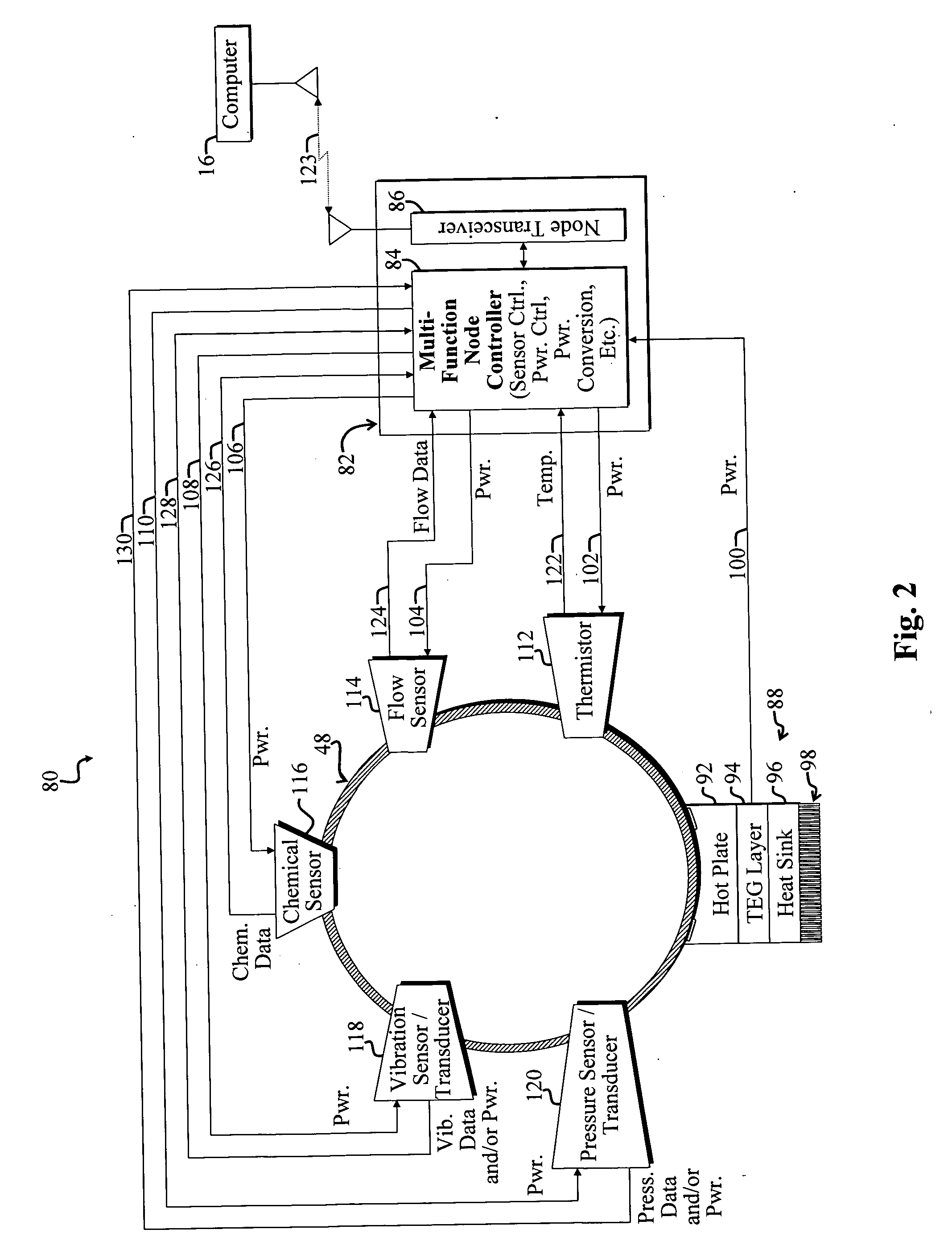

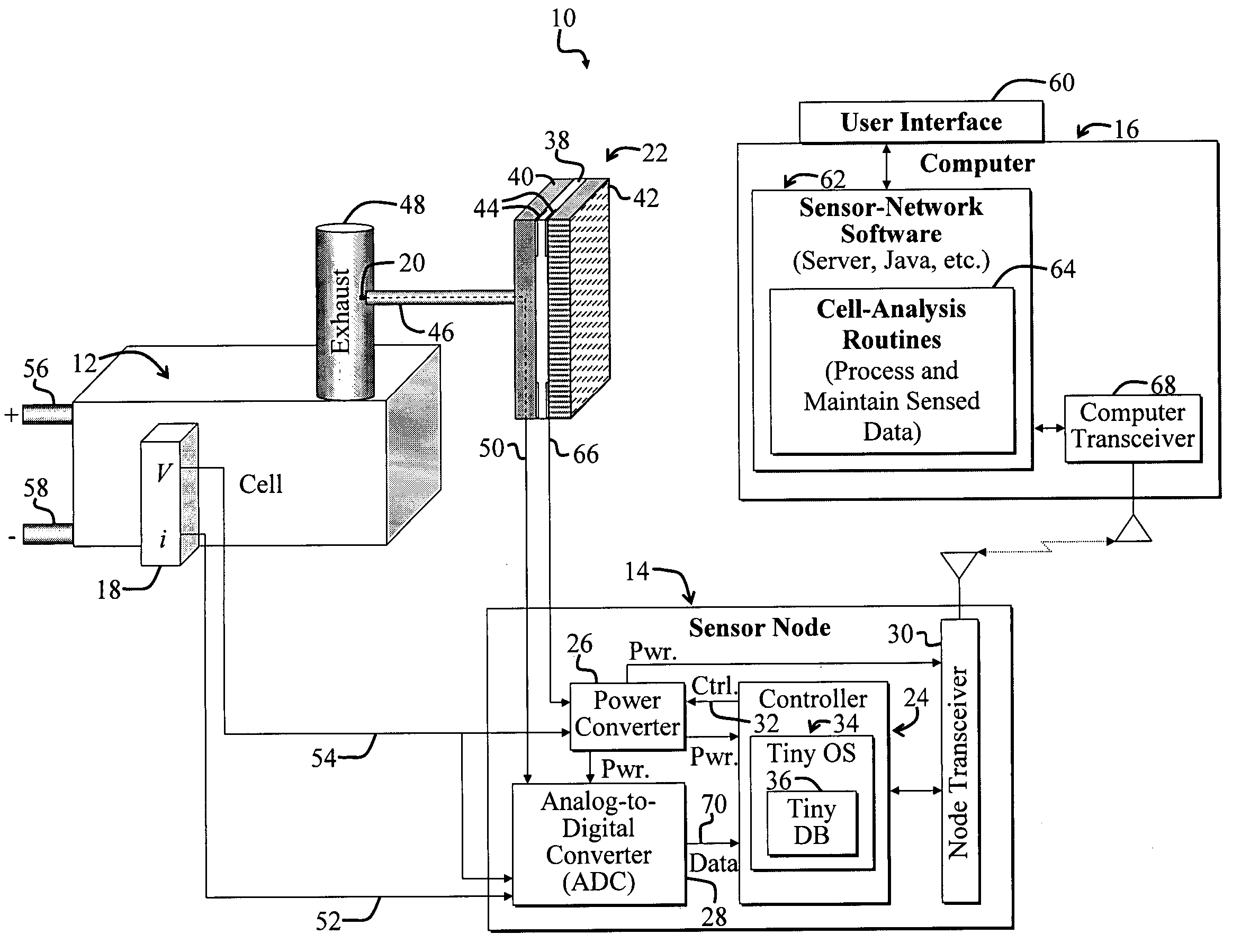

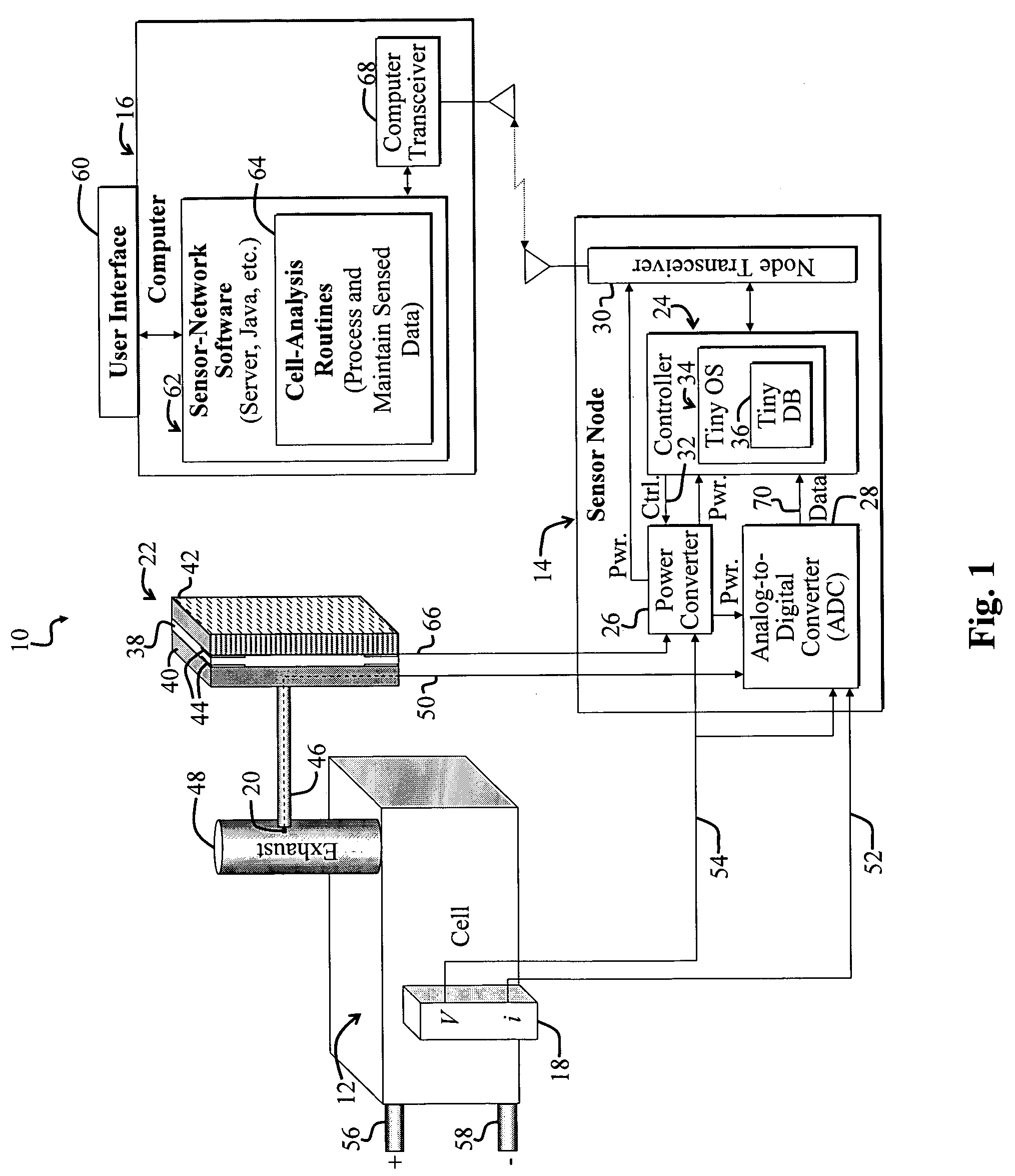

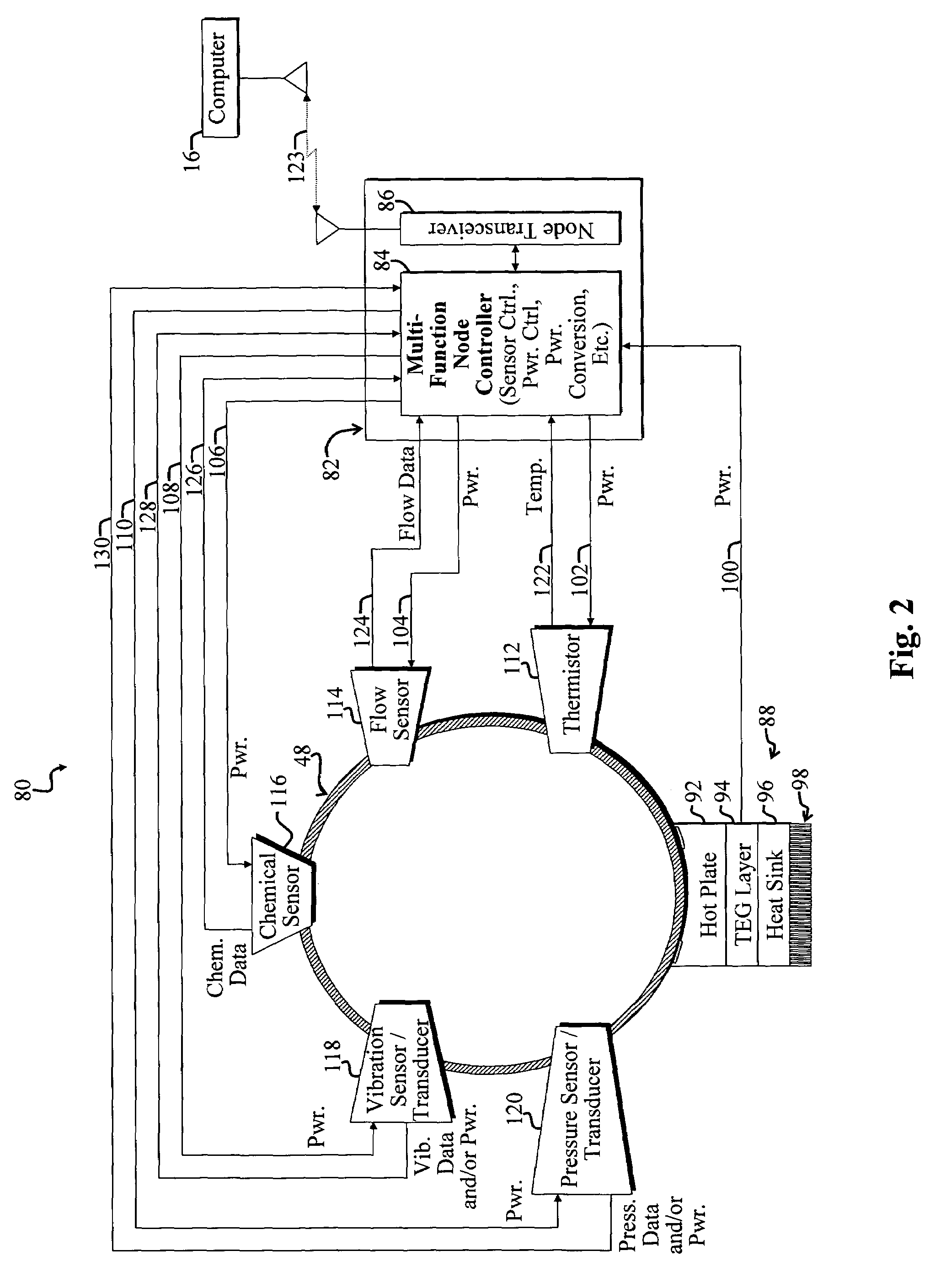

Wireless sensing node powered by energy conversion from sensed system

ActiveUS20060176175A1Efficient powerLow costElectric signal transmission systemsThermoelectric device with peltier/seeback effectRemote computerProcess information

A sensing system for sensing conditions or characteristics associated with a process or thing. The sensing system includes one or more energy converters and a sensor, which are coupled to the process or thing. A node is coupled to the sensor and the energy-converter, and the node is powered by output from the energy converter. In a more specific embodiment, the node includes a controller that implements one or more routines for selectively powering a wireless transmitter of the node based on a predetermined condition. The predetermined condition may specify that sensor output values are within a predetermined range or are below or above a predetermined threshold. Alternatively, the predetermined condition may specify that electrical energy output from the energy converter is below a predetermined threshold. A remote computer may be wirelessly connected to node and may include software and / or hardware that is adapted to process information output by the sensor and relayed to the computer via the node.

Owner:RGT UNIV OF CALIFORNIA +1

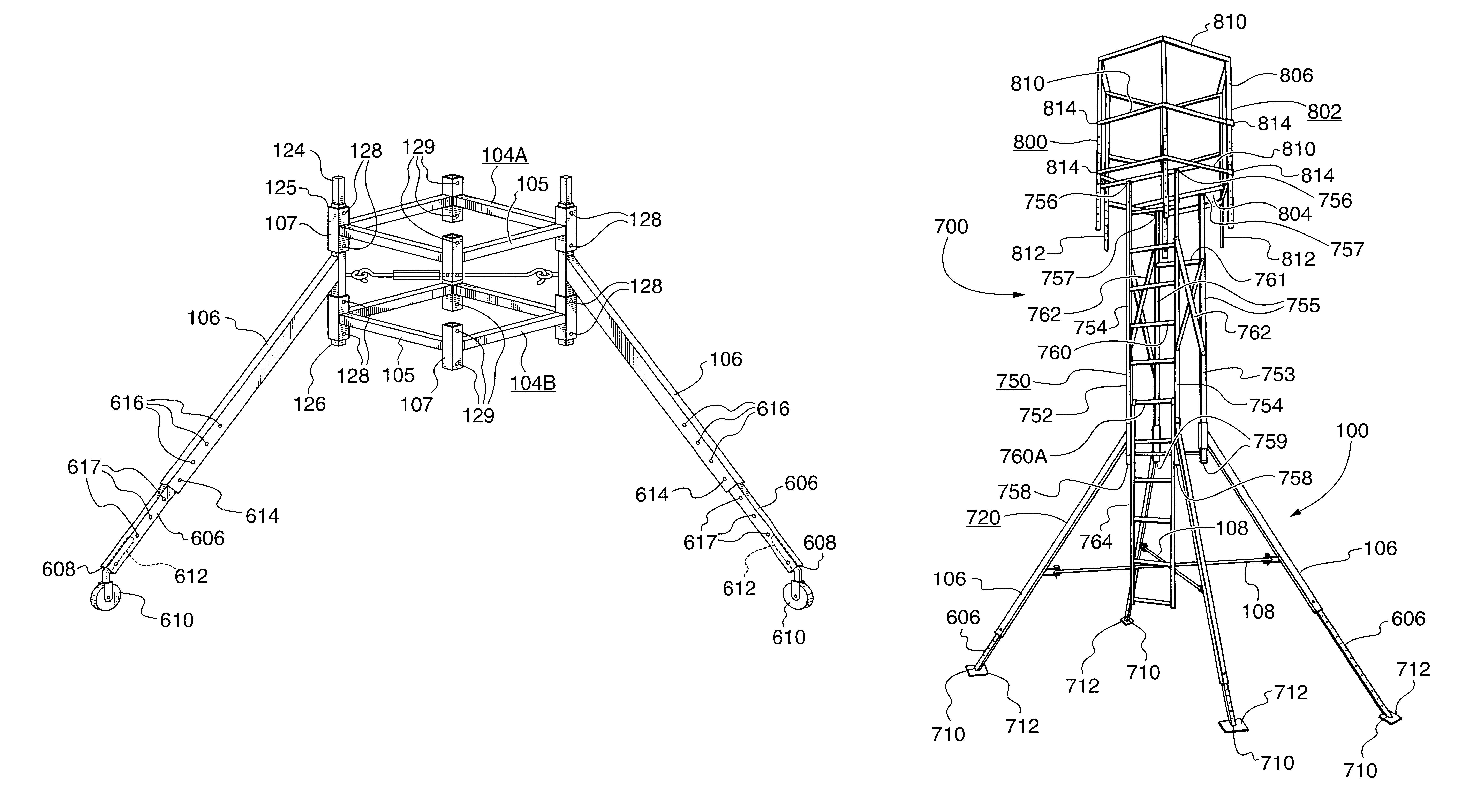

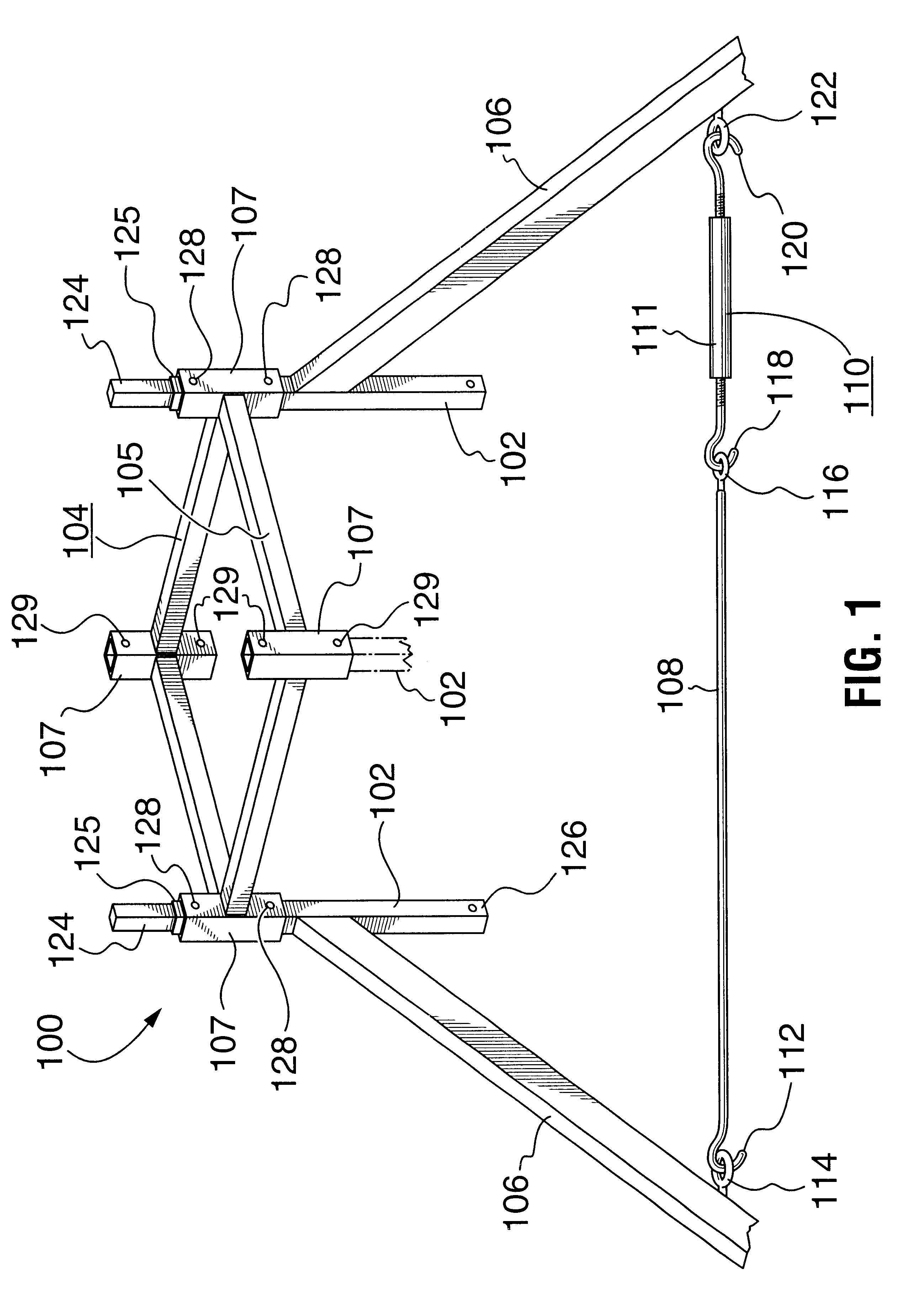

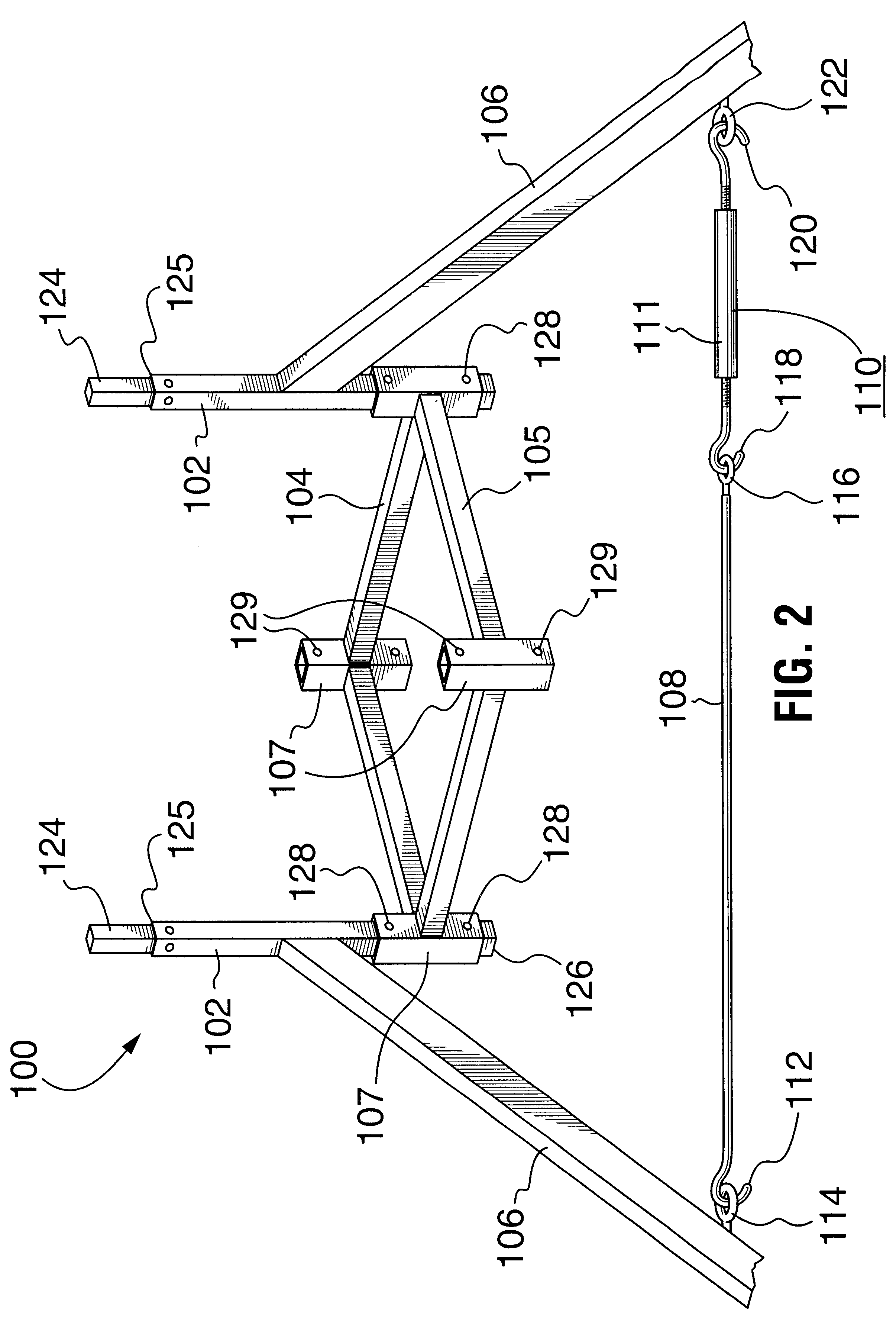

Stability alignment frame for erecting a portable multi-purpose stand

InactiveUS6725970B2Safe and cost-effectiveWeight optimizationAnimal huntingBuilding support scaffoldsEngineeringControl engineering

Owner:GAROFALO TONY

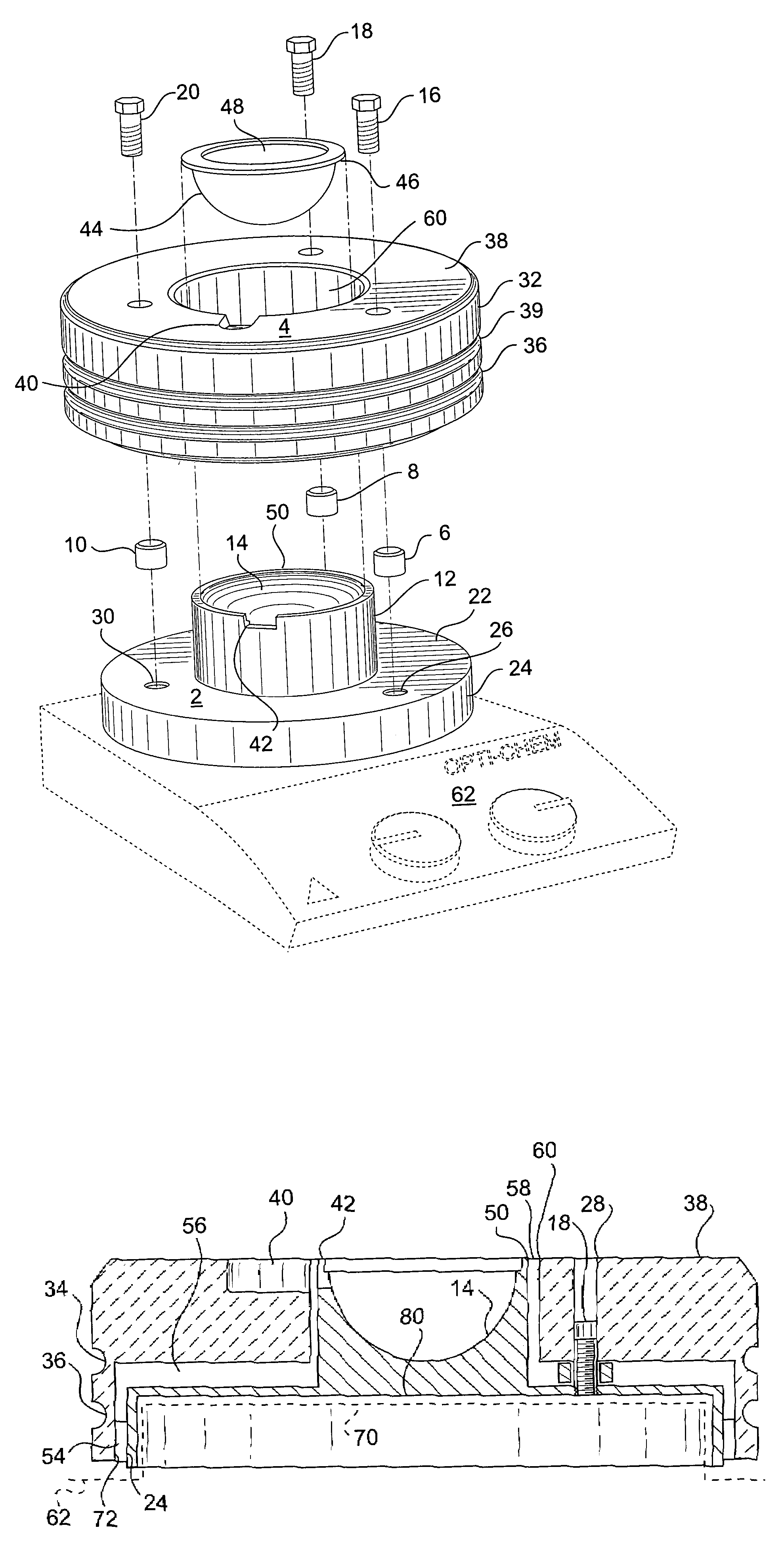

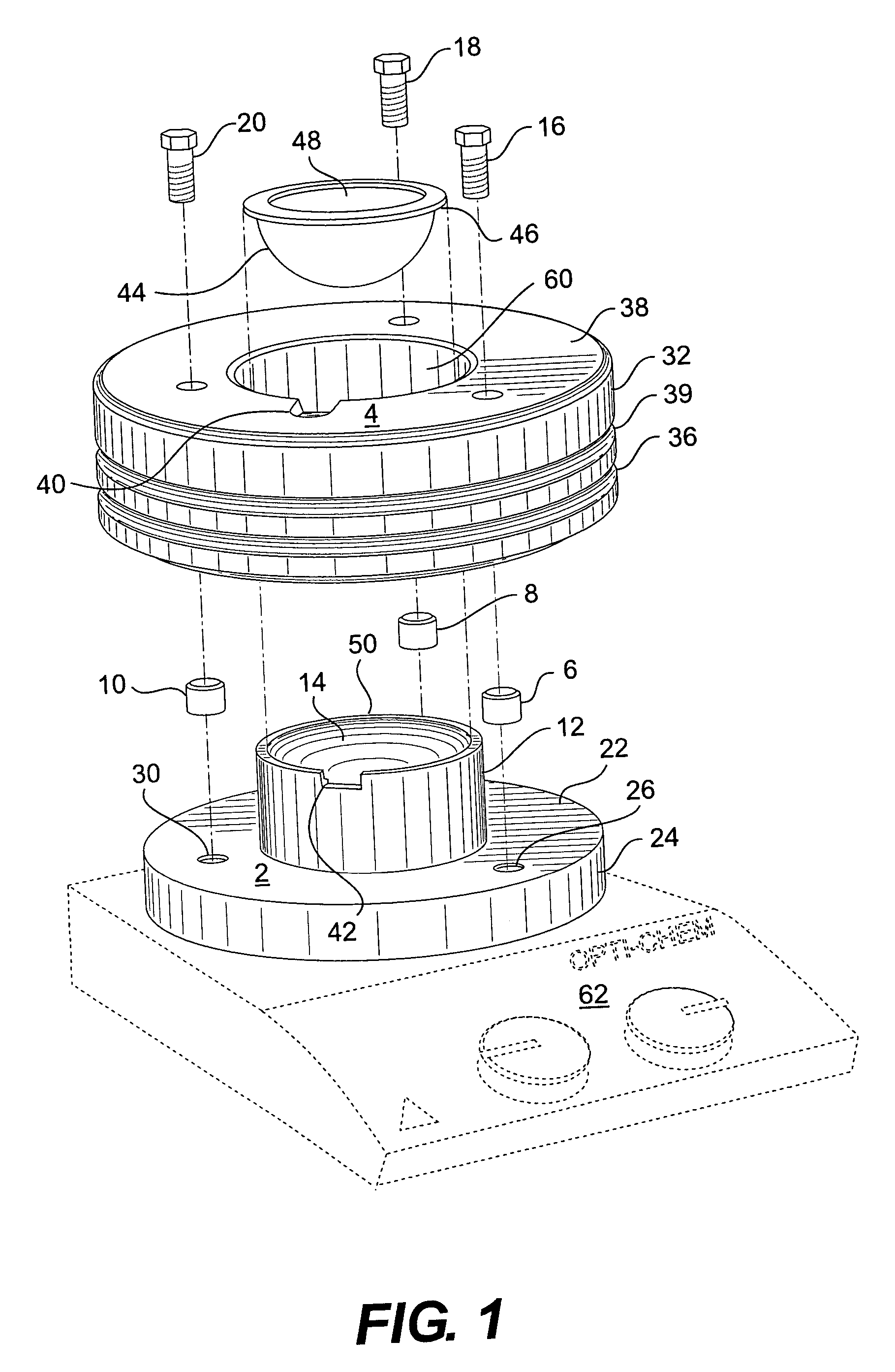

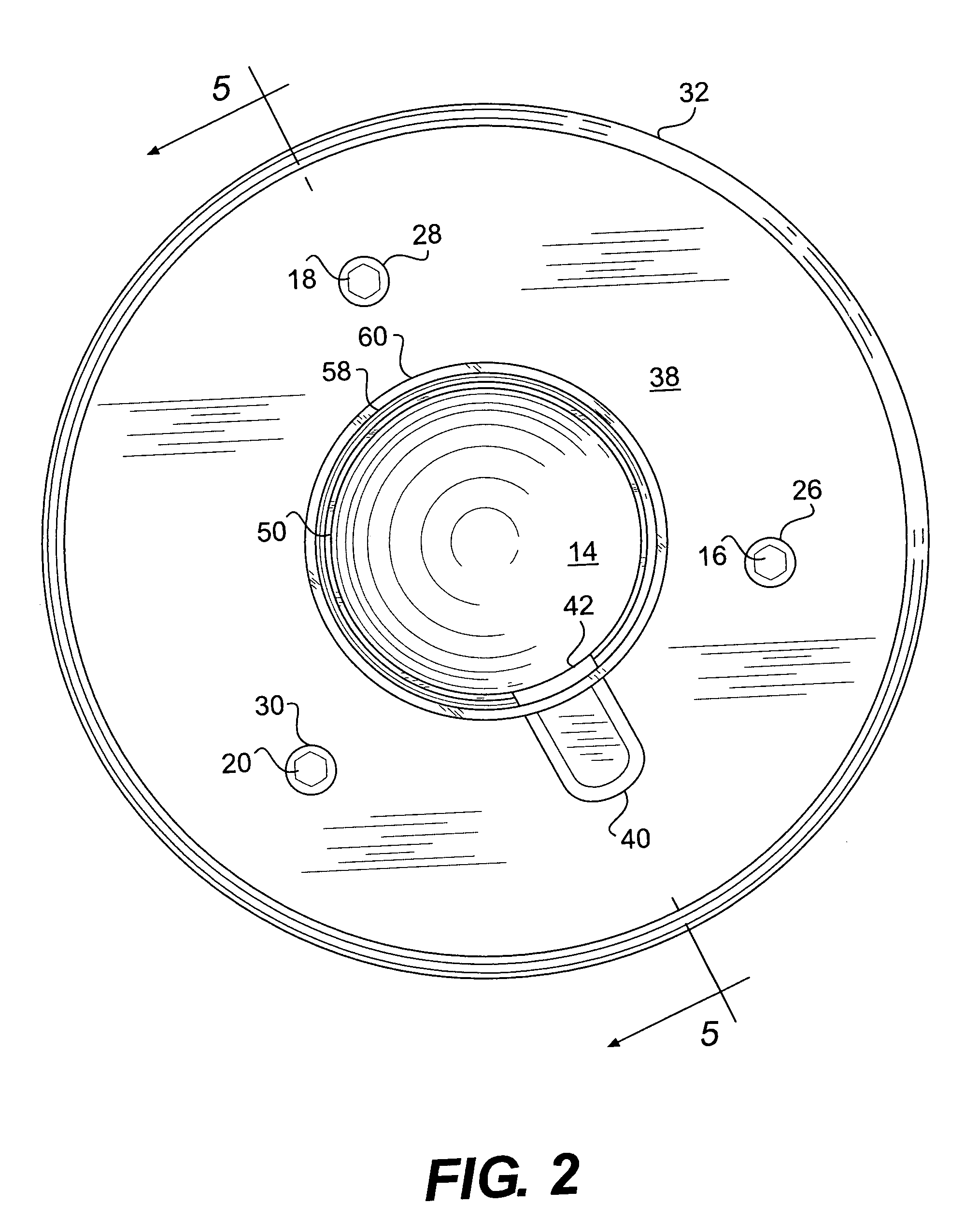

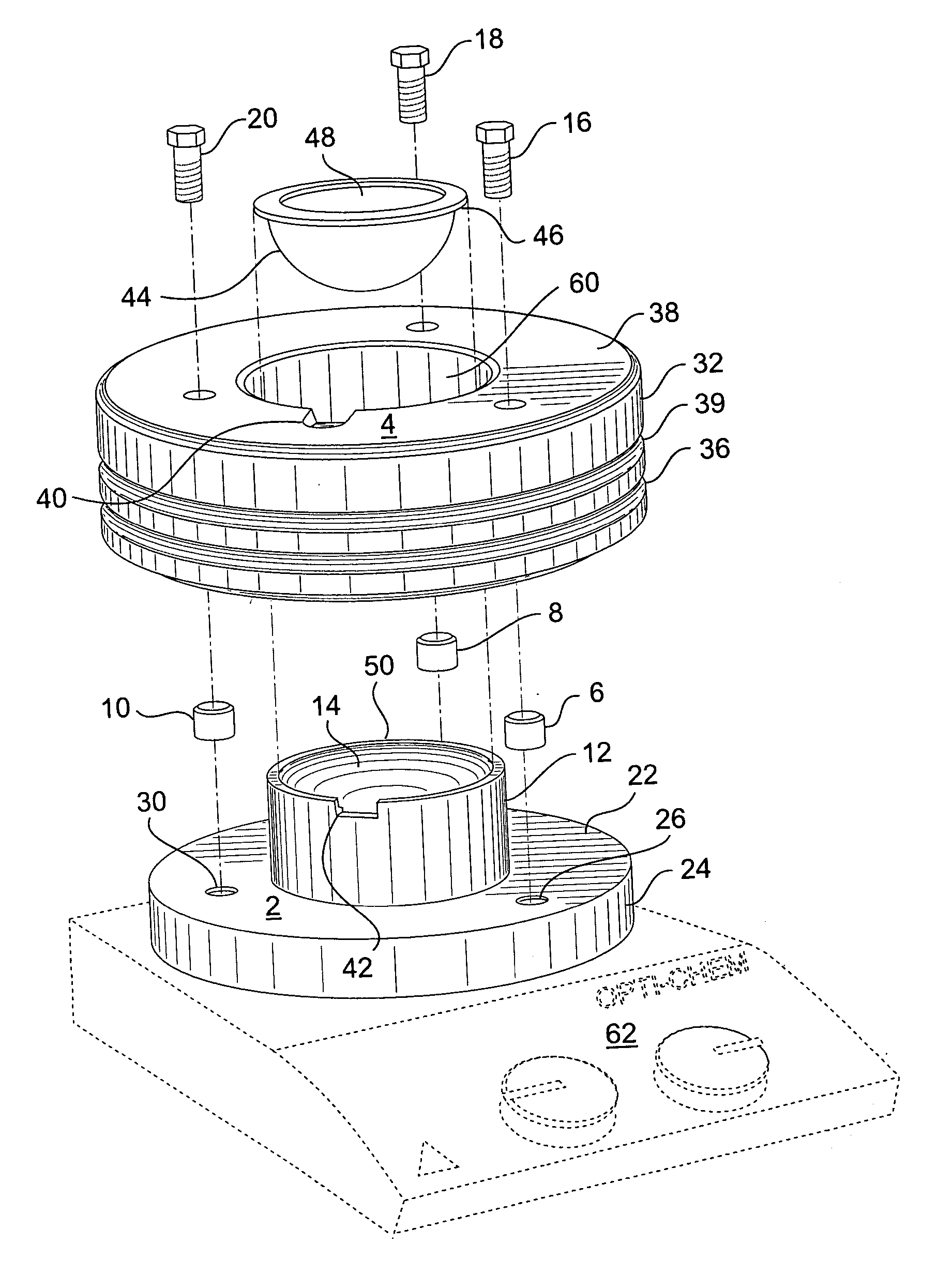

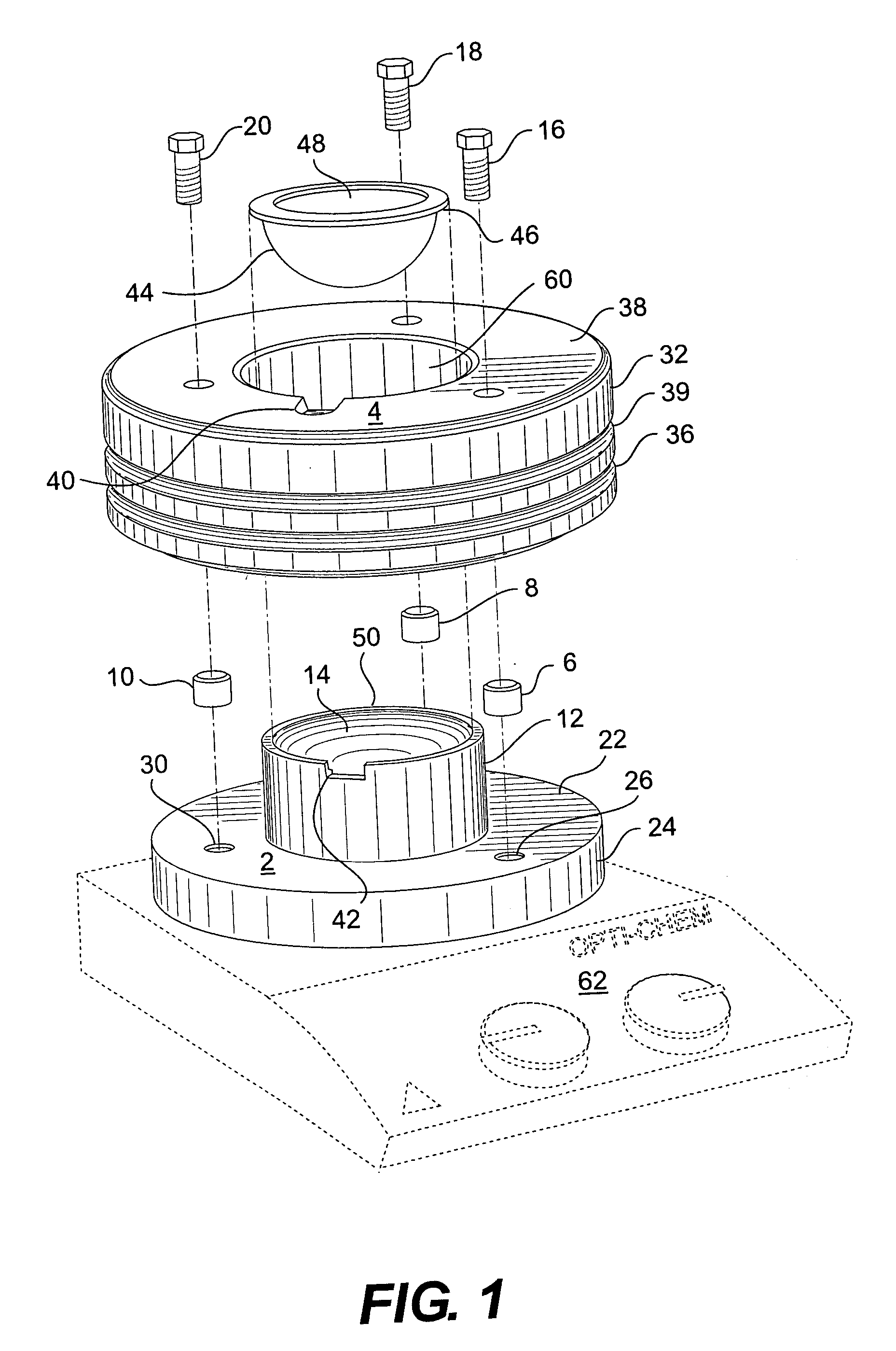

Reaction block for supporting flasks of different sizes for chemical synthesis on a hot plate stirrer

InactiveUS7494267B2Safe and cost-effectiveContinuous gripping surface regionHeating or cooling apparatusRotary stirring mixersChemical synthesisEngineering

A reaction block for mounting various round bottom flasks upon a laboratory, magnetic hot plate stirrer. An aluminum inner flask holder effectively conducts heat and does not interfere with a magnetic flux. A solid heat insulating material substantially surrounds and is spaced from the flask holder, in order to keep the reaction block at a safe temperature and provide easy gripping surface regions that extend completely around its circumference.

Owner:CHEMGLASS

Axial bearing

ActiveUS20060018578A1Safe and cost-effectiveReduce manufacturing costCrankshaftsCrossheadsTurbochargerThrust bearing

The invention relates to a thrust bearing, in particularl for a turbo charger, having an essentially disc shaped bearing body (10) with a central through opening (12) for a shaft, having at least one bearing surface (14) surrounding the through opening (12) for a collar which is placed on the shaft, and having at least one oil supply channel which leads from a radially outer region of the bearing body to the through opening (12). In order to realize a cost effective manufacture of the thrust bearing it is proposed according to the invention that the at least one oil supply channel is designed to be a groove (16′).

Owner:BORGWARNER INC

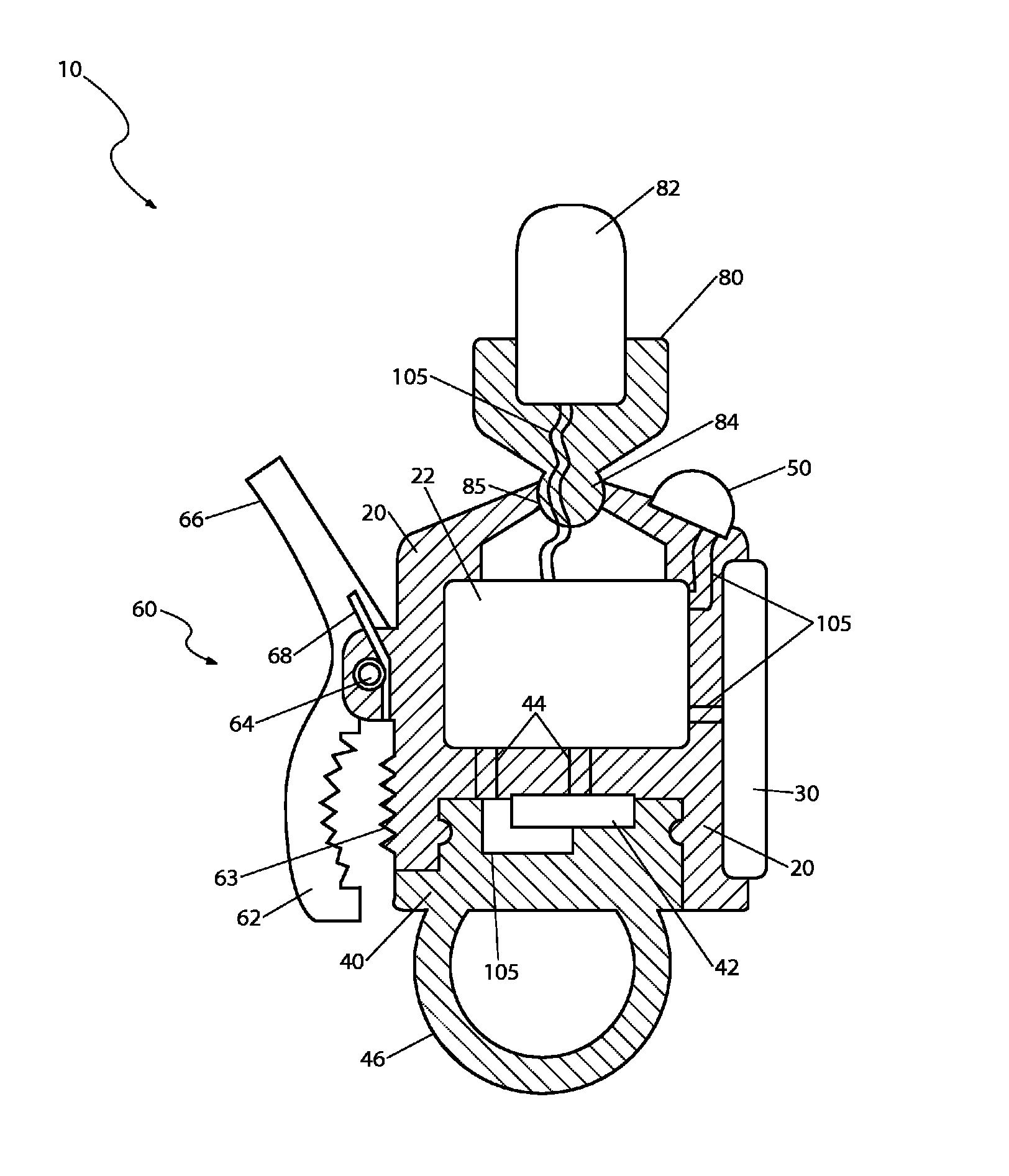

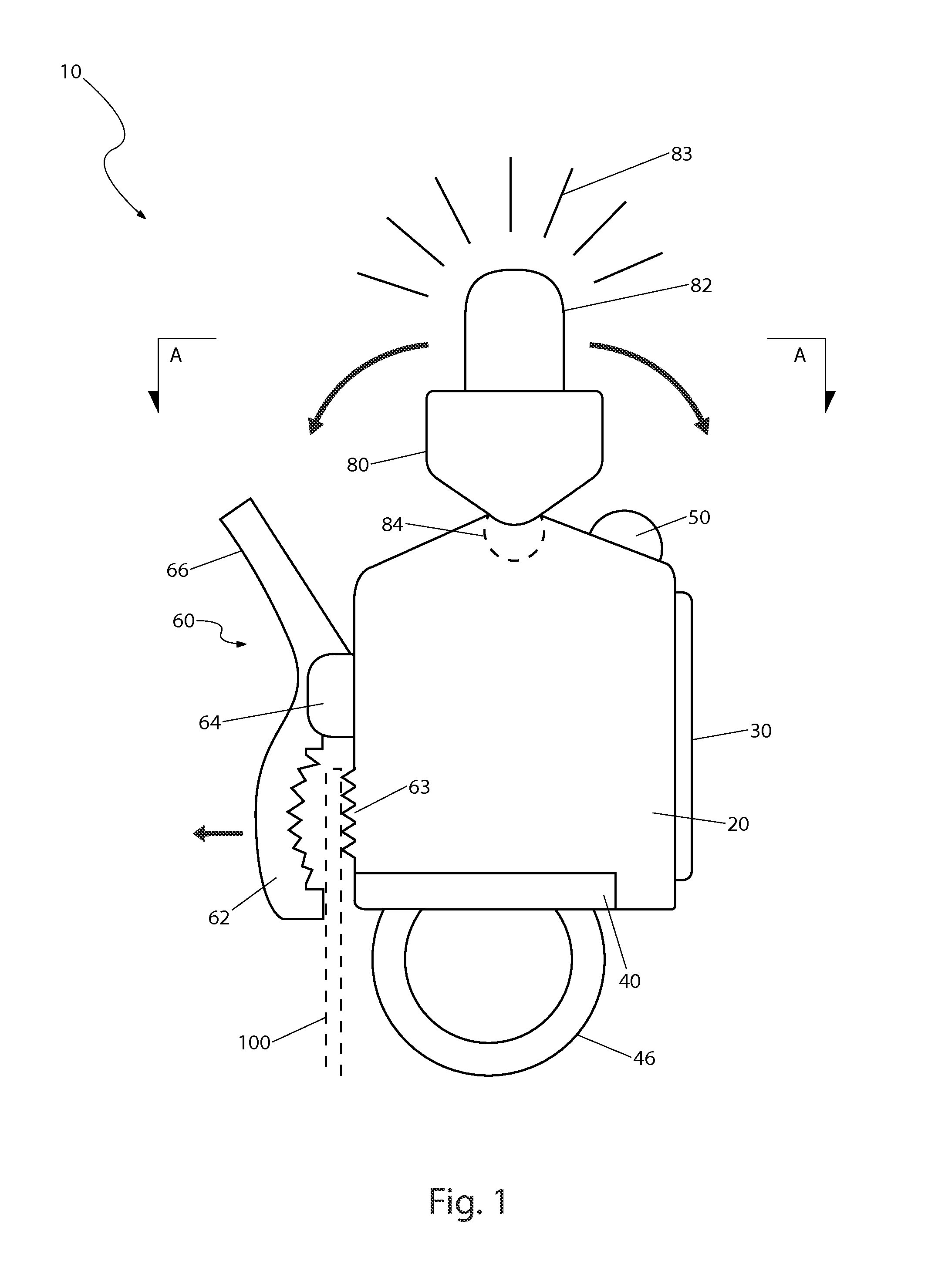

Solar powered attachable light

InactiveUS8668349B2Safe and cost-effectiveOperated particularly safely and cost-effectivelyLighting support devicesPoint-like light sourceRechargeable cellEngineering

A solar-powered attachable light is adapted for use as a holiday decoration and includes a lamp pivotably mounted to an enclosure. A solar cell charges an internal rechargeable battery during daytime hours and the rechargeable battery powers the lamp during nighttime hours. A rear of the enclosure includes a clip assembly for removable attachment of the device to various outdoor structures. The device eliminates the presence of wires and the requirement of connection to a fixed power source in a manner particularly beneficial when simultaneously arranging decorative outdoor lighting in a variety of locations.

Owner:RICHARDSON LINE C

Wireless sensing node powered by energy conversion from sensed system

ActiveUS7466240B2Efficient powerSafe and cost-effectiveElectric signal transmission systemsSurveyRemote computerEngineering

A sensing system for sensing conditions or characteristics associated with a process or thing. The sensing system includes one or more energy converters and a sensor, which are coupled to the process or thing. A node is coupled to the sensor and the energy-converter, and the node is powered by output from the energy converter. In a more specific embodiment, the node includes a controller that implements one or more routines for selectively powering a wireless transmitter of the node based on a predetermined condition. The predetermined condition may specify that sensor output values are within a predetermined range or are below or above a predetermined threshold. Alternatively, the predetermined condition may specify that electrical energy output from the energy converter is below a predetermined threshold. A remote computer may be wirelessly connected to node and may include software and / or hardware that is adapted to process information output by the sensor and relayed to the computer via the node.

Owner:RGT UNIV OF CALIFORNIA +1

Mechanical joint of a heat exchanger pipe

InactiveUS20080100058A1Safe and cost-effectiveCost benefitPipe heating/coolingPipe elementsEngineeringHigh pressure

A mechanical joint for an accumulator-internal heat exchanger (AccuIHE) module is provided. The mechanical joint includes a heat exchanger pipe and a cover plate having an internal connecting area. The internal connecting area is adapted to receive the heat exchanger pipe. The cover plate further has an external connecting area in fluid communication with the internal connecting area, the external connecting area adapted to receive a high-pressure coolant line. The mechanical joint also has a housing adapted to receive the cover plate and the heat exchanger pipe, and a sealing element. The sealing element is disposed between the heat exchanger pipe and the internal connecting area of the cover plate. The sealing element facilitates a substantially fluid tight seal therebetween. An AccuIHE module having the mechanical joint and a method for forming the mechanical joint are also provided.

Owner:VISTEON GLOBAL TECH INC

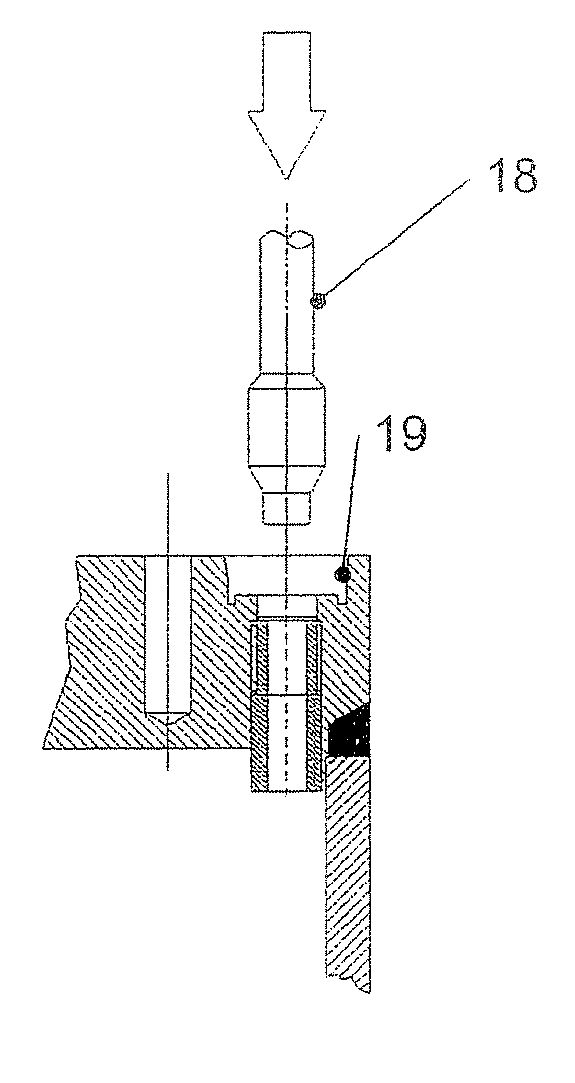

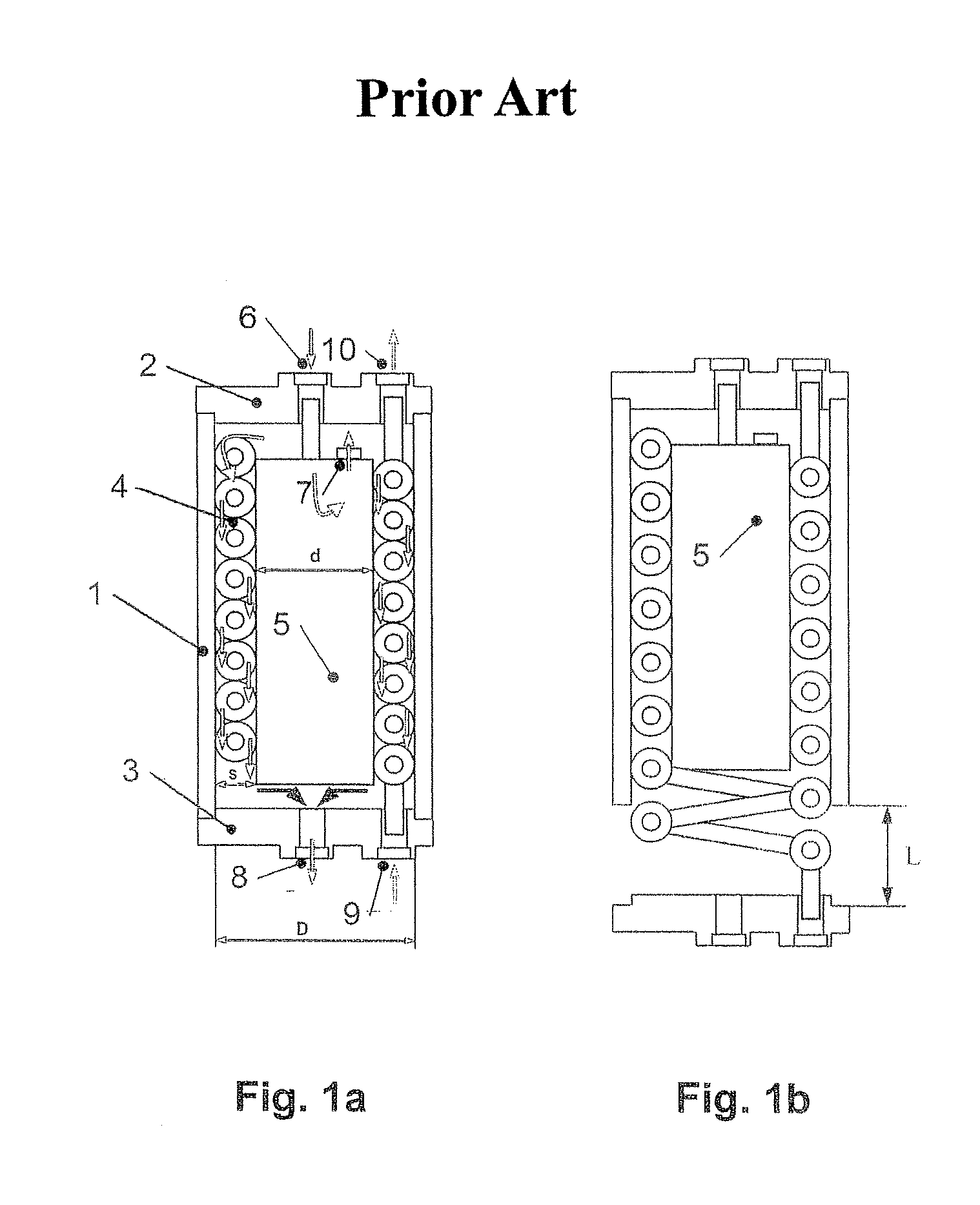

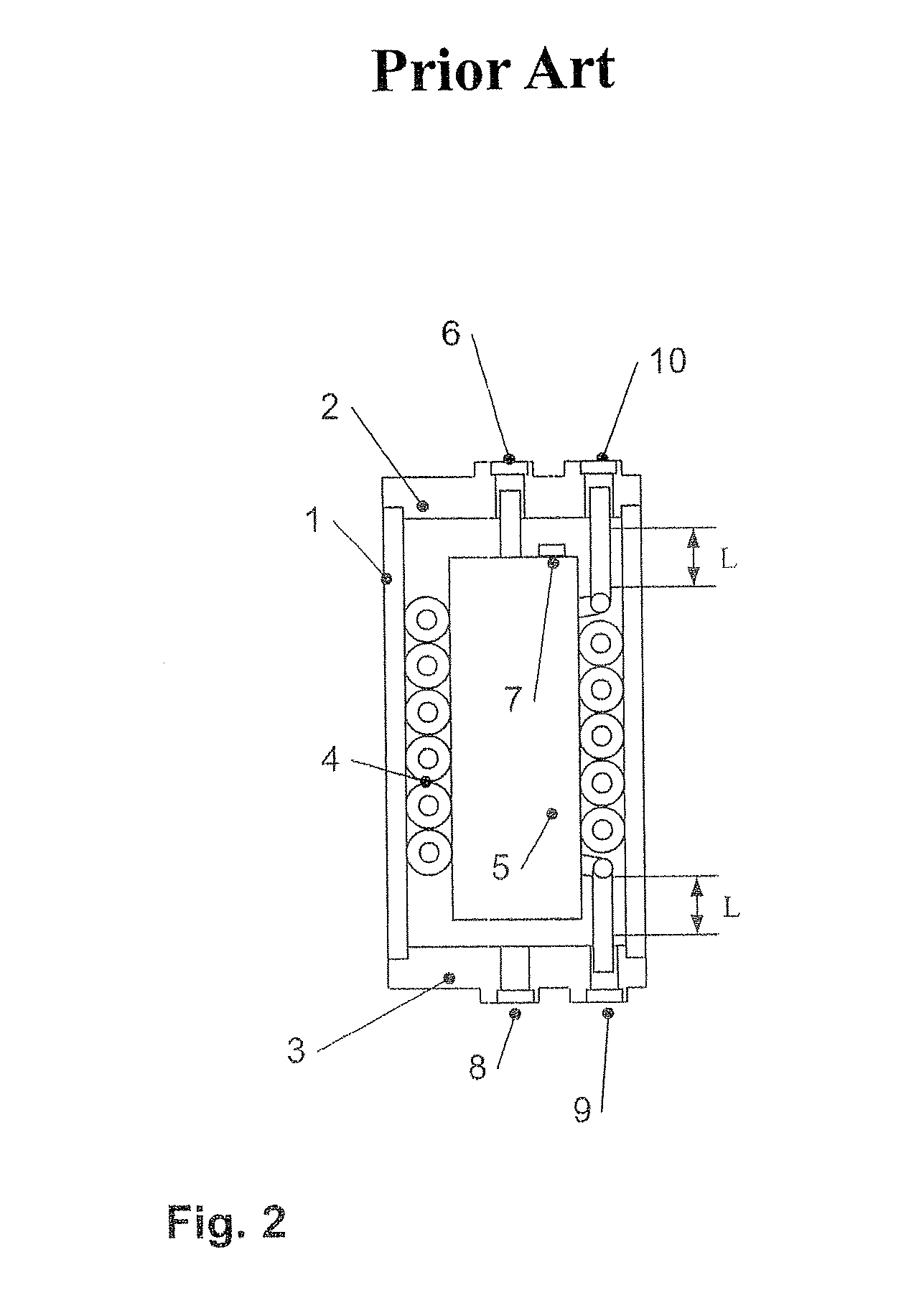

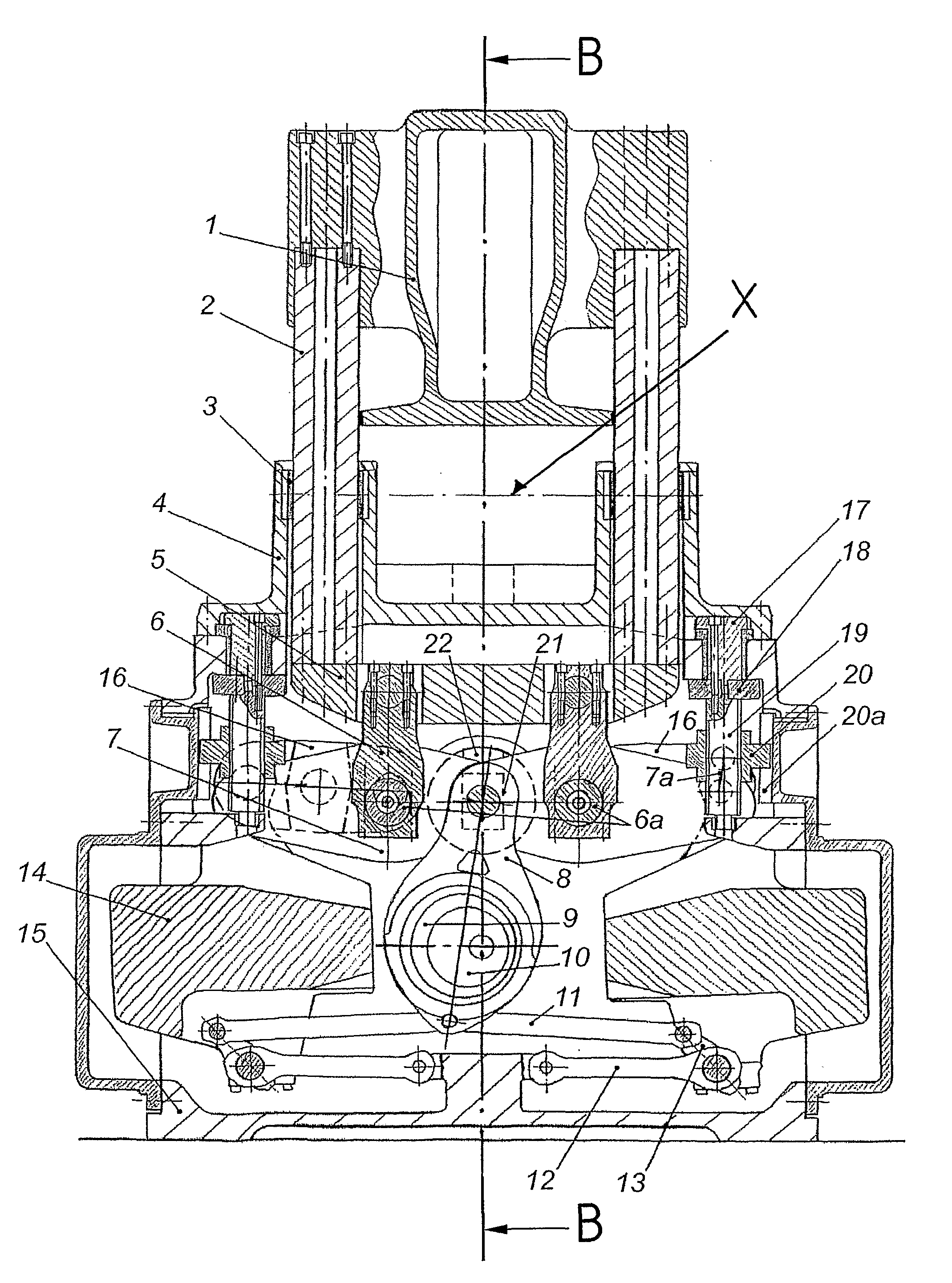

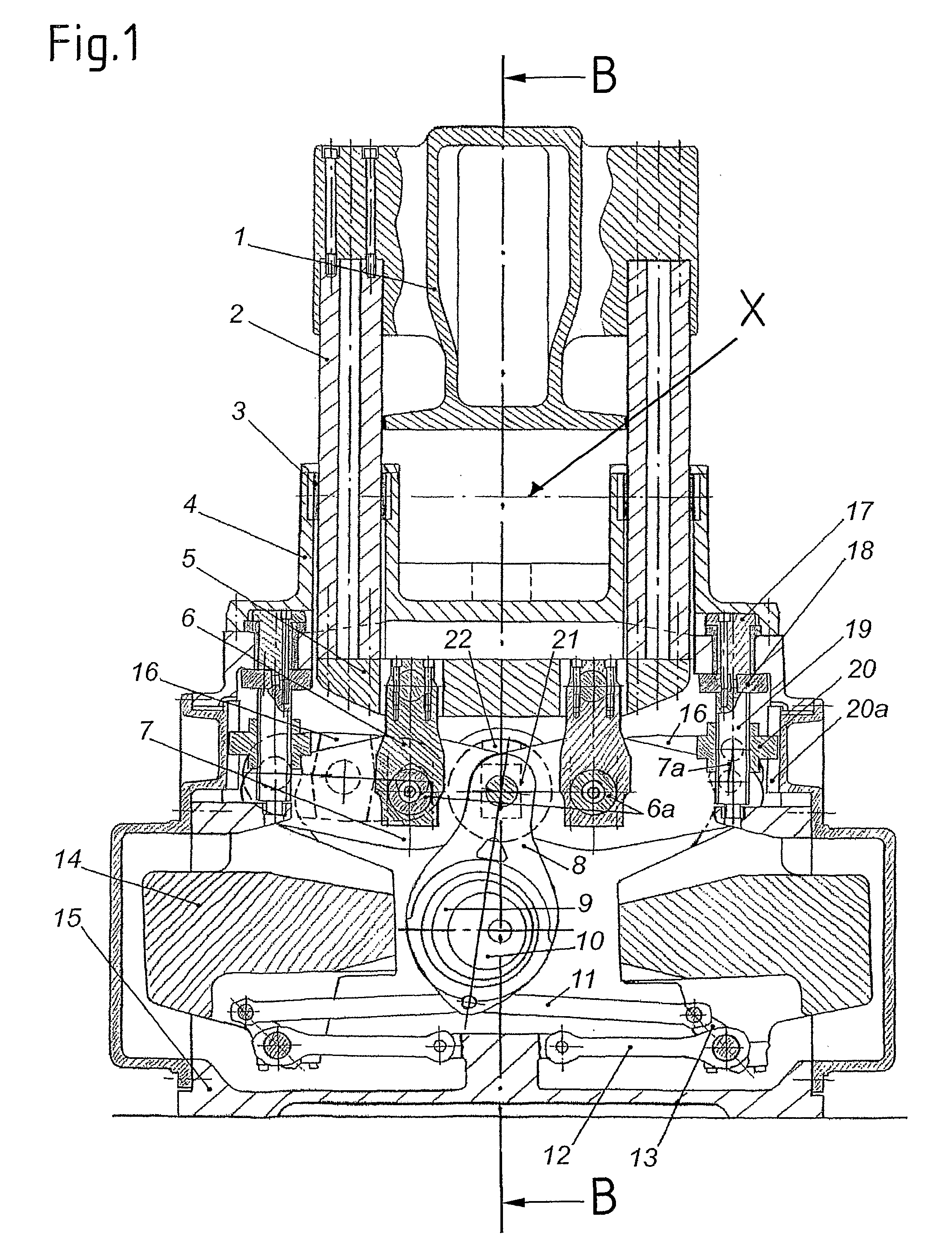

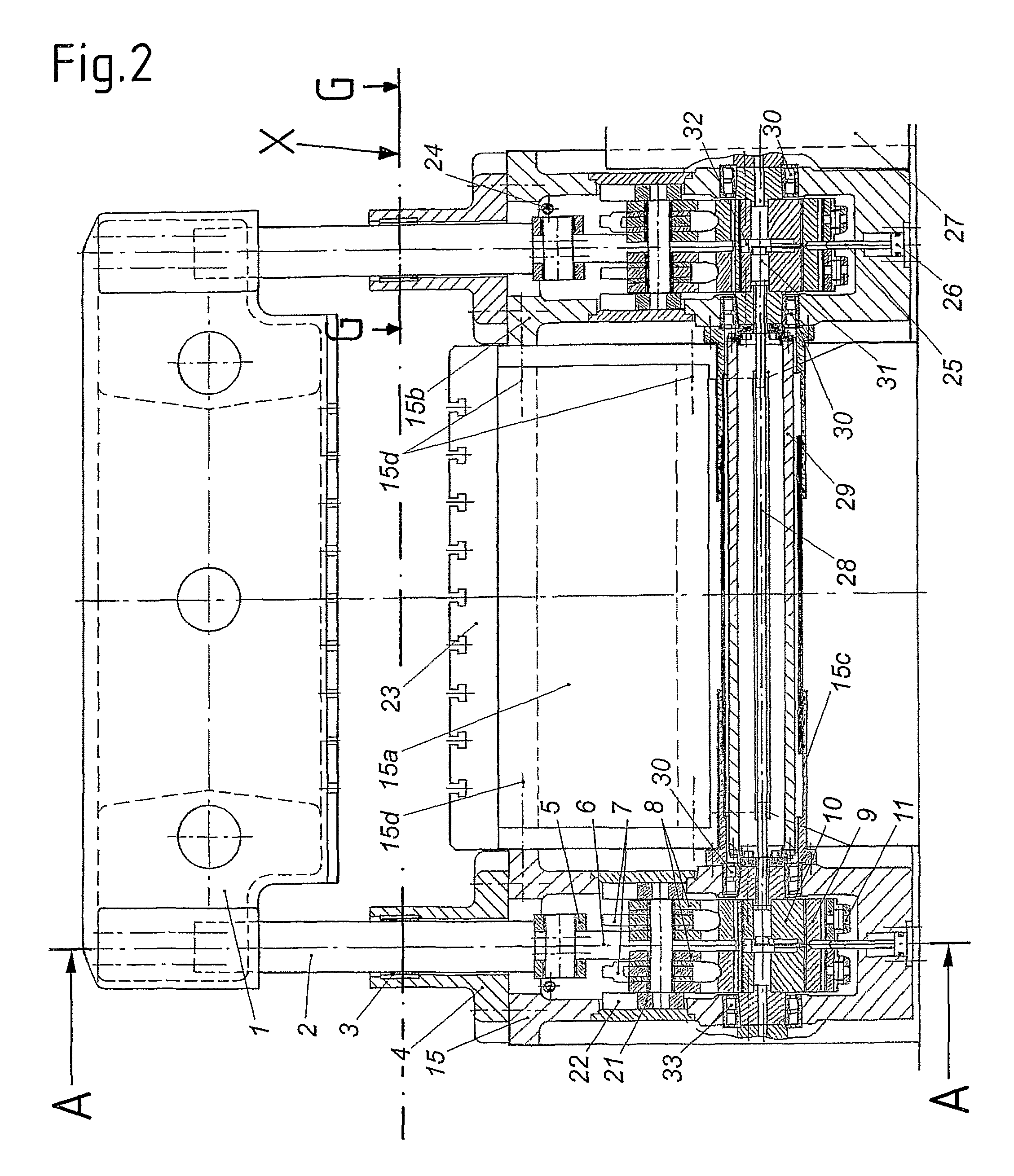

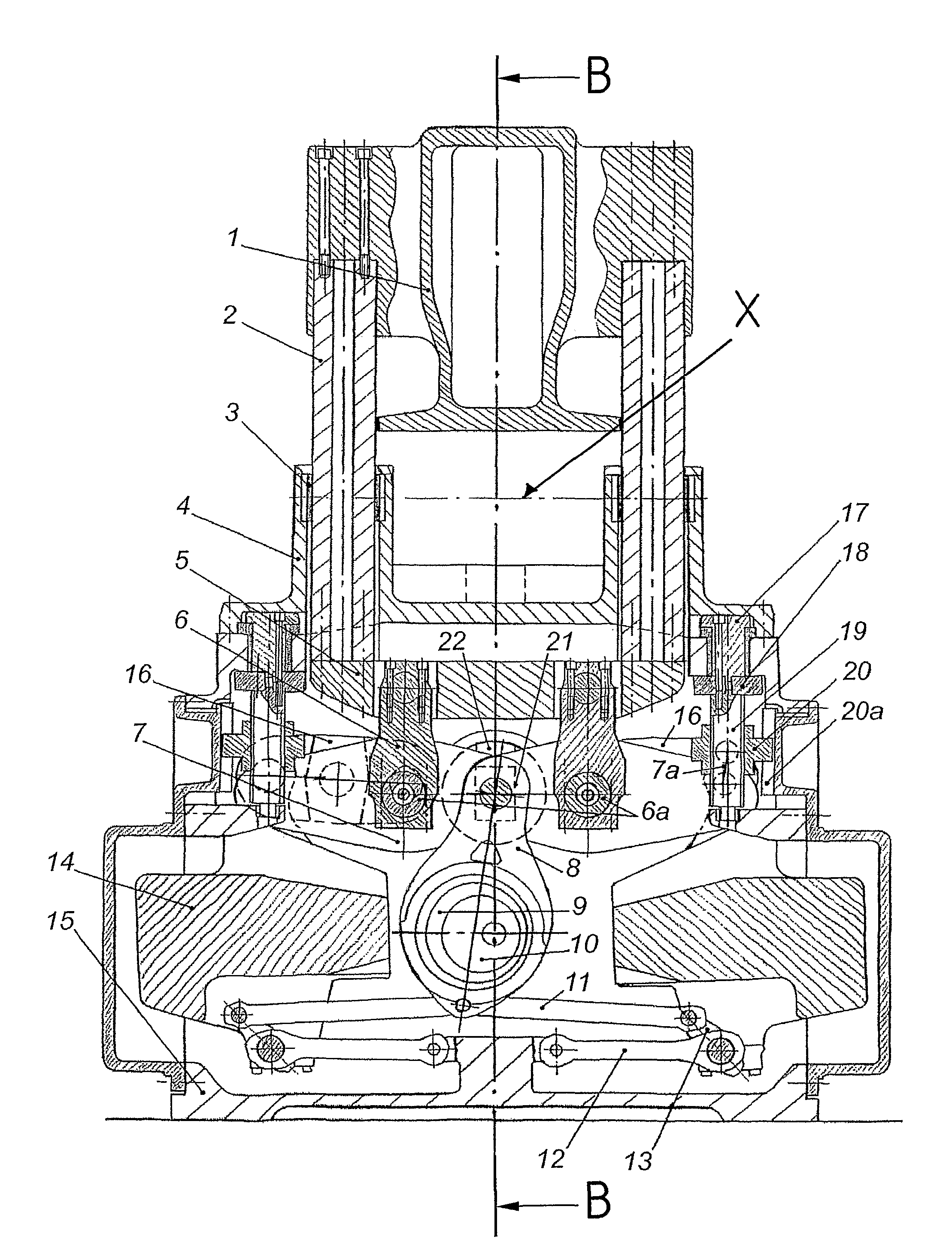

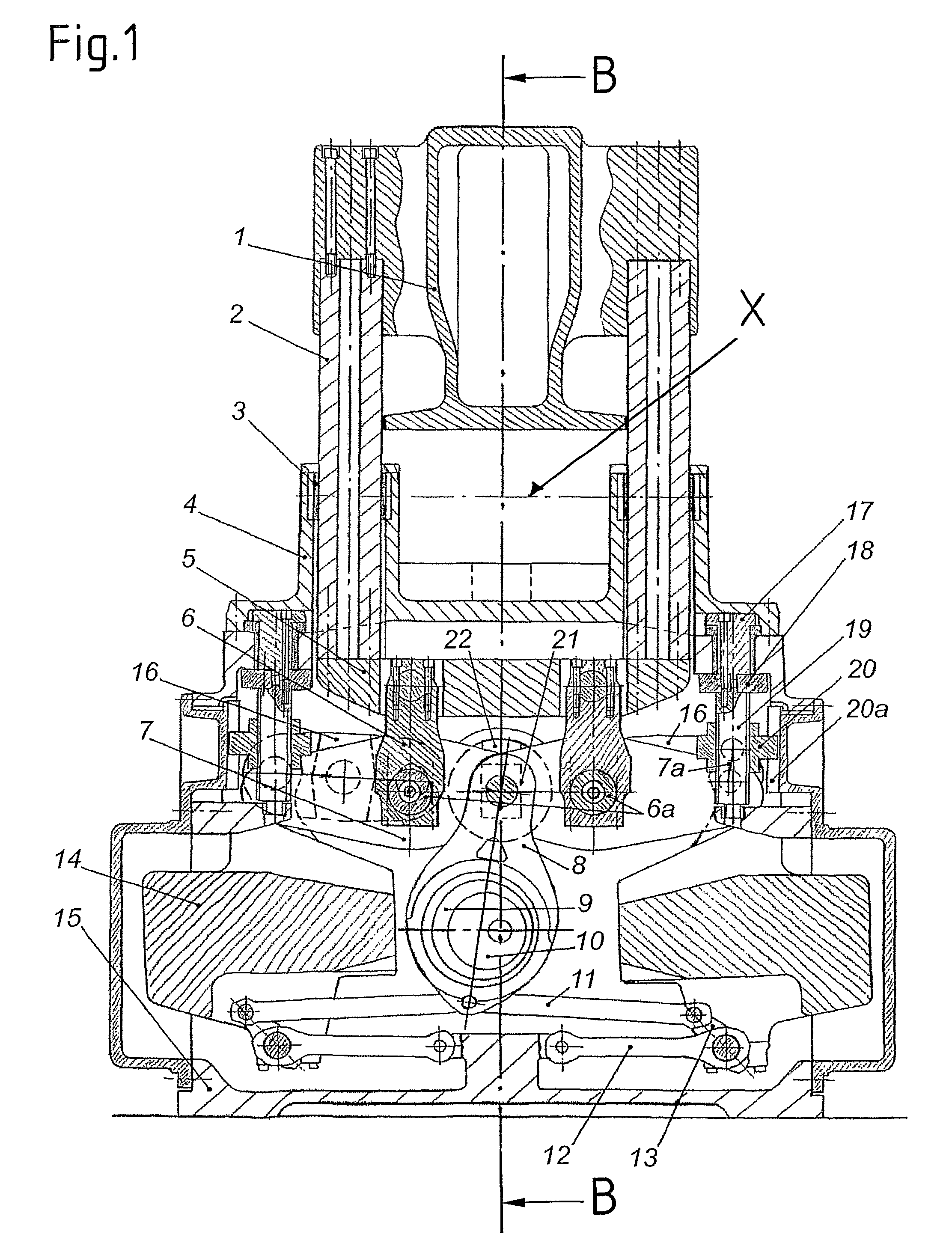

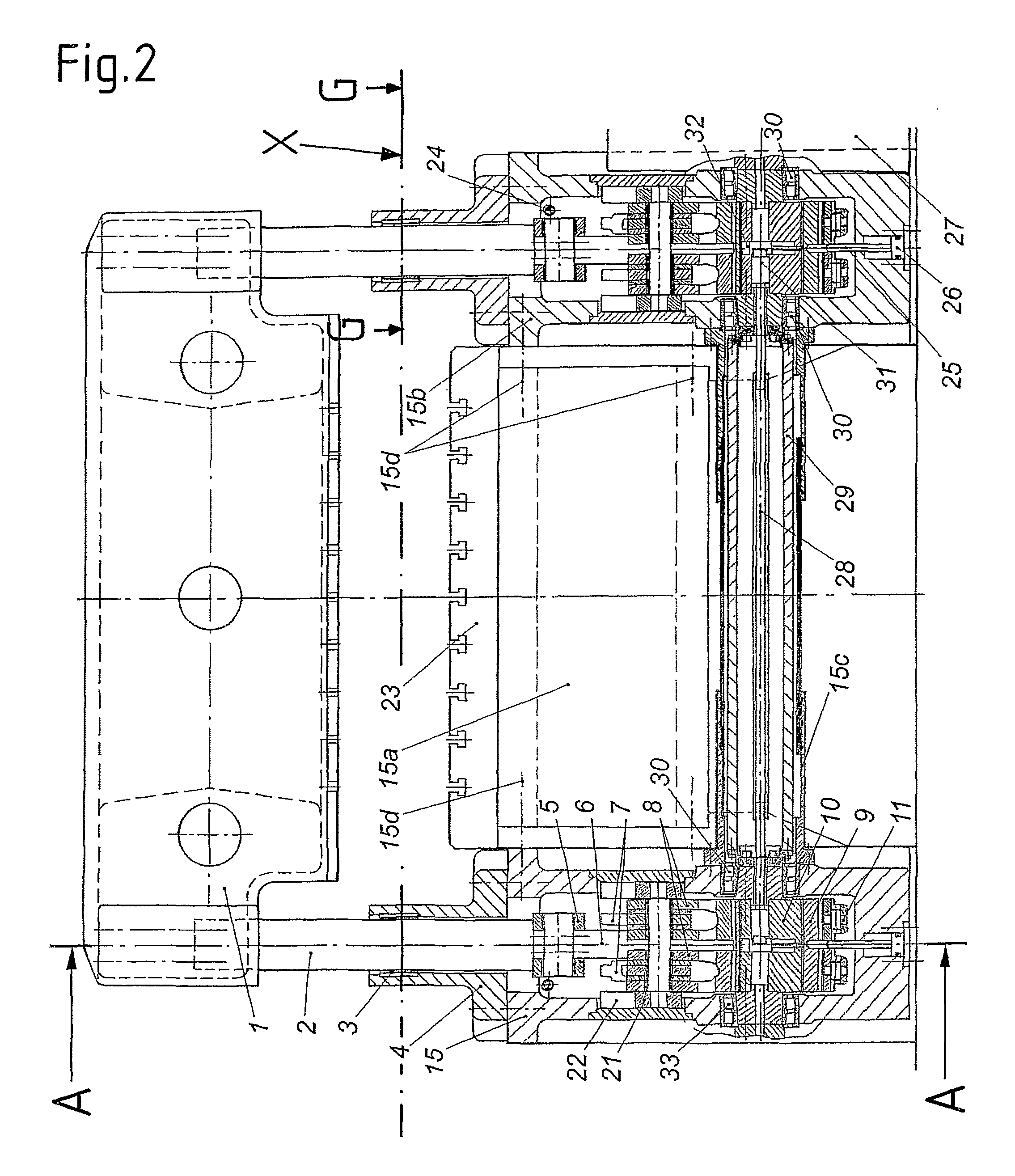

Punching press

InactiveUS20100206187A1High degree of tool wear and even in tool fractureEasy to wearPress ramDistortionMachine press

The invention relates to a punching press with a clamping plate (27) and with a press ram (1) which lies opposite the upper side of the clamping plate (27) and operates towards the clamping plate (27) and is moveable up and down via four tension columns (2) by means of a crank drive arranged below the belt movement plane (X) of the punching press. The press ram (1) is guided exclusively via the tension columns (2) which, in turn, are guided in inclination-tolerant guides (3) in the belt movement plane (X) in such a manner that the press ram (1) and the tension columns (2) can be positioned obliquely as a consequence of differing longitudinal expansion of the tension columns (2) under an eccentric load by the tension columns (2) being inclined about axes of inclination running in the region of the belt movement plane (X) of the punching press. By means of the configuration according to the invention, distortion of the punching press under an eccentric load, which would lead to uncontrollable operating conditions during the punching and a high degree of wear at the guides of the machine, is avoided, and it can be ensured that, in the event of a possible skewed position of the ram, no tool offset, which would result in a high degree of tool wear or even in tool fracture, occurs.

Owner:BRUDERER ARBON SCHWEIZ

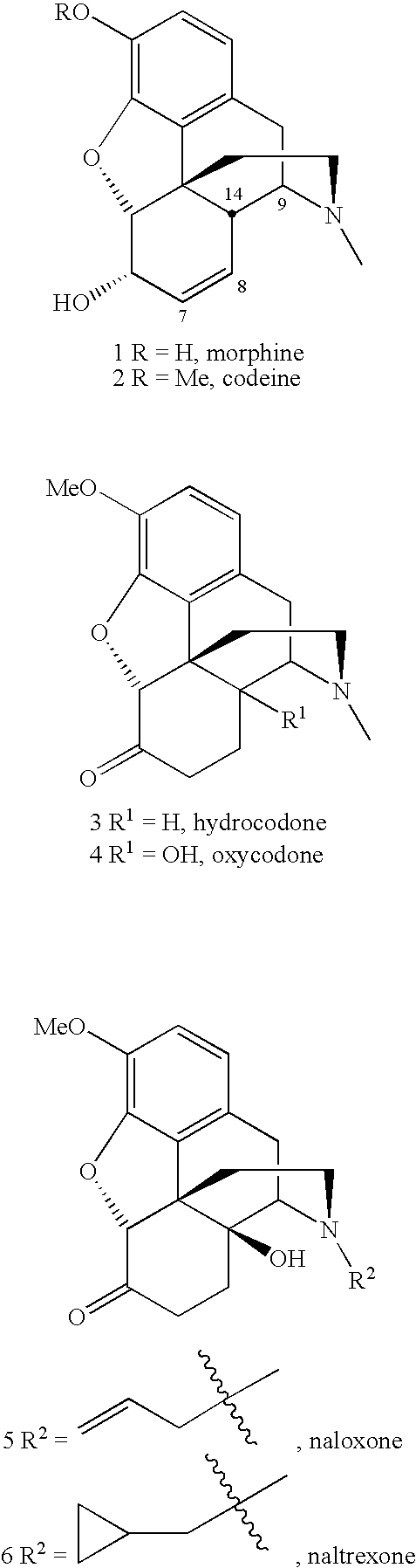

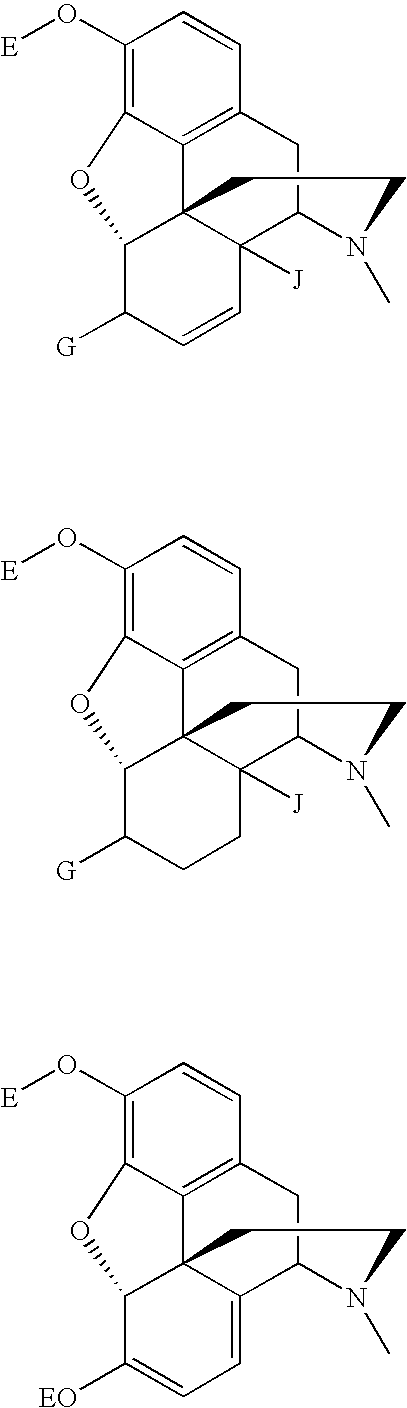

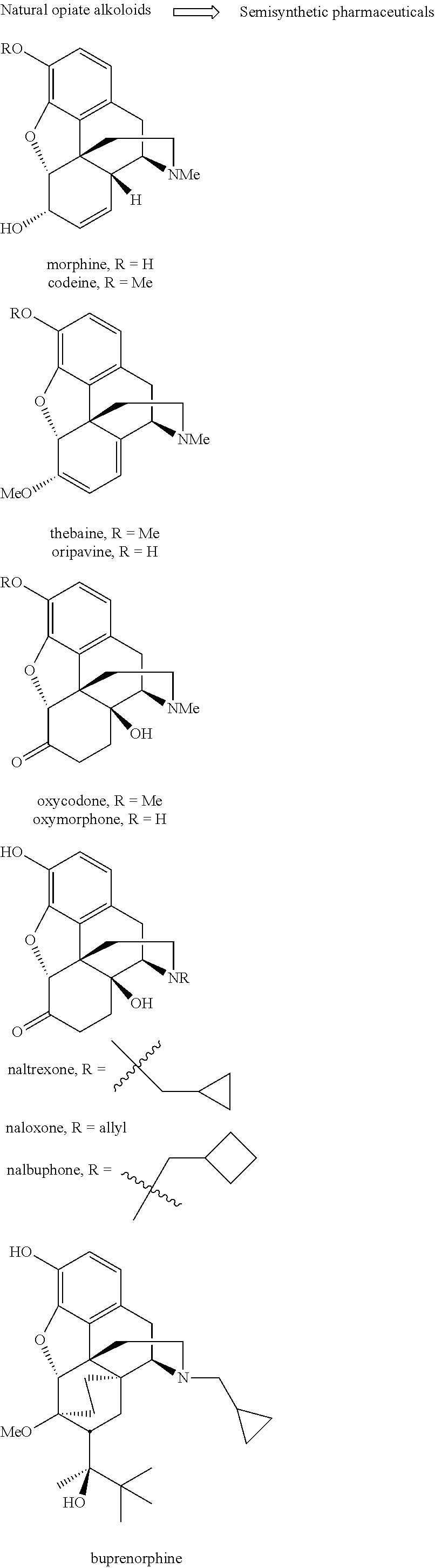

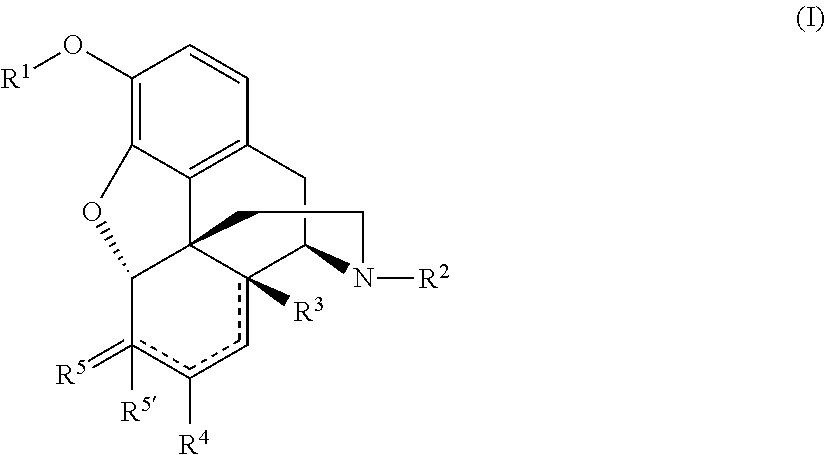

Methods for one-pot N-demethylation/N-acylation of morphine and tropane alkaloids

InactiveUS7999104B2Safe and cost-effectiveNervous disorderOrganic chemistryPtru catalystTropane alkaloid

The present invention provides a method for the N-demethylation and / or N-acylation of an N-methylated heterocycle such as morphine alkaloids or tropane alkaloids. The method comprises reacting the heterocycle with an acylating agent in the presence of a metal catalyst.

Owner:BROCK UNIVERSITY

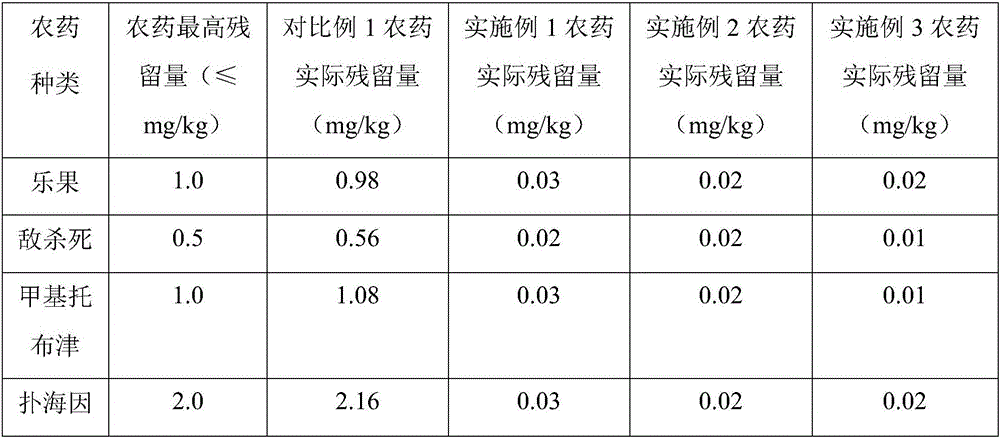

Method for planting pollution-free selenium-rich lettuce

InactiveCN106386109ASafe and cost-effectiveReduce usageSeed immunisationHorticultureFertilizerGermination

The invention discloses a method for planting pollution-free selenium-rich lettuce. The method includes: pre-treating soil : accelerating germination and raising seedlings, preparing an ozone solution, adding 2 mass %-3 mass% glass powder into the ozone solution and evenly stirring the ozone solution to acquire a soaking solution, soaking seeds, and performing germination accelerating and sowing; performing planting; performing water and fertilizer management: irrigating the lettuce with seedling-reviving water after the lettuce is planted for 3-5 days, dissolving 8-10 Kg of a mixed fertilizer and 0.8-1 Kg of the selenium-rich nutritive solution in 150 Kg water in 10-15 days to water roots of the lettuce in one mu land, dissolving 10-12 Kg of the mixed fertilizer and 1-1.2 Kg of the selenium-rich nutritive solution in 200 Kg water to water the roots of the lettuce in one mu land during a rosette stage of the lettuce, and irrigating the lettuce with water and fertilizer according to the amount of water and fertilizer of the rosette stage again when heart leaves of the lettuce curve inward; arranging a reflective curtain outside a greenhouse; and disease and pest control. The method can effectively increase the selenium content of the lettuce, improve the nutriment quality of the lettuce, and increase the income of farmers.

Owner:马山盛世生态种养专业合作社

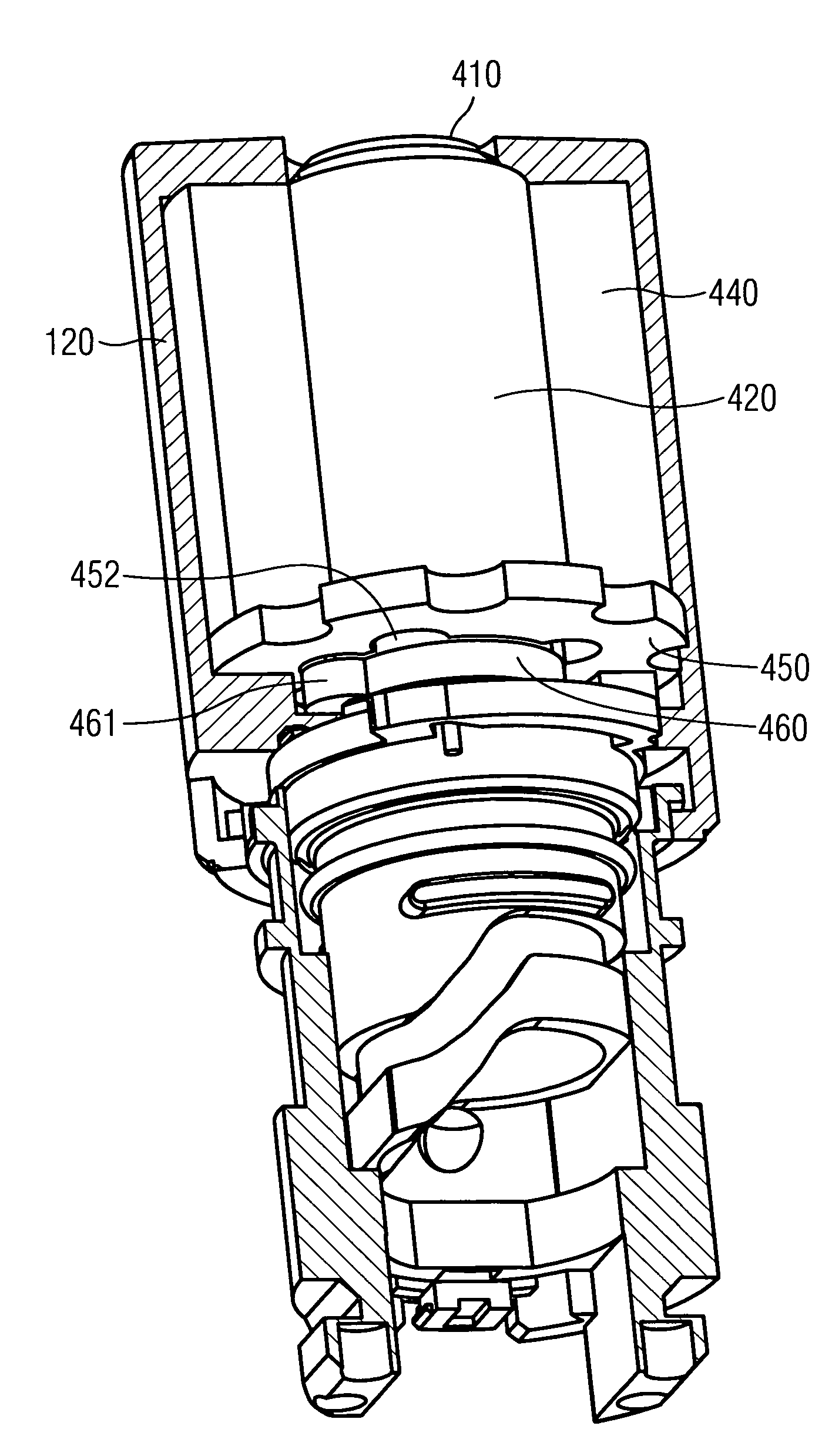

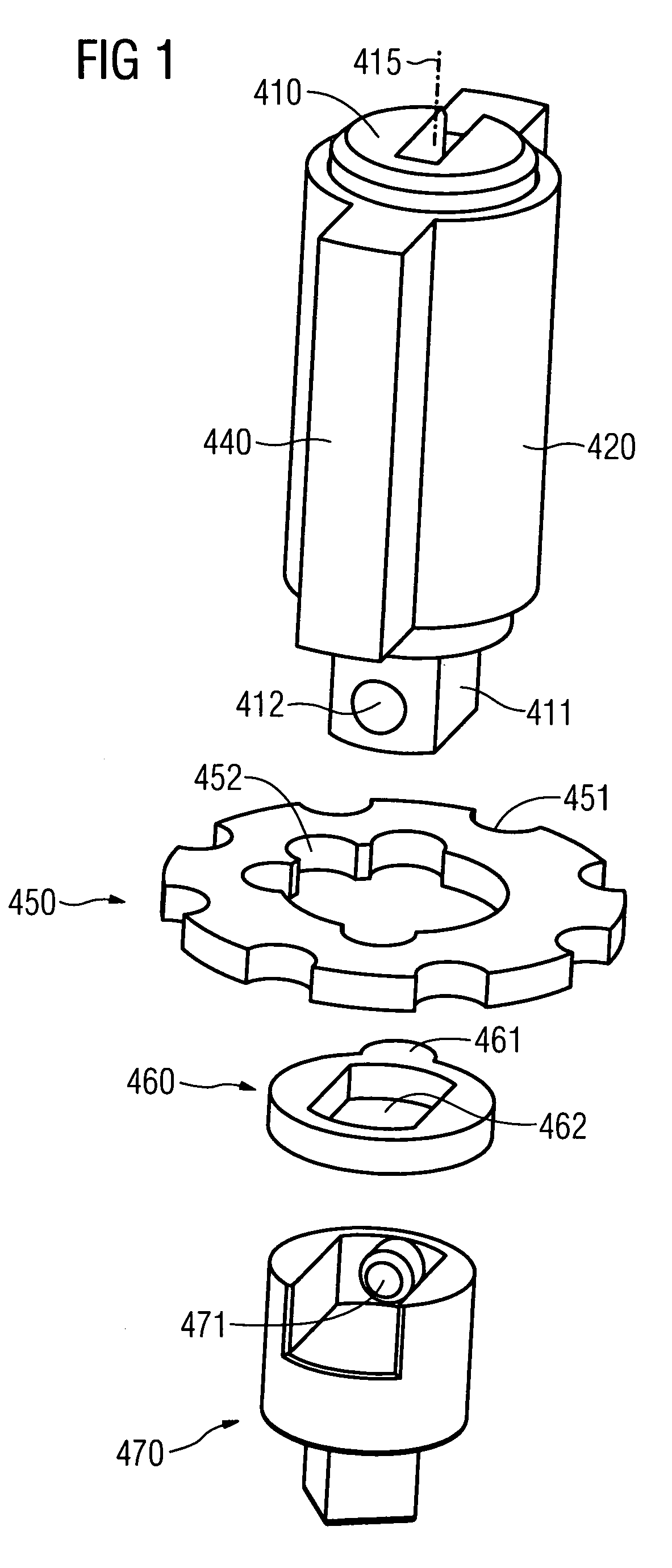

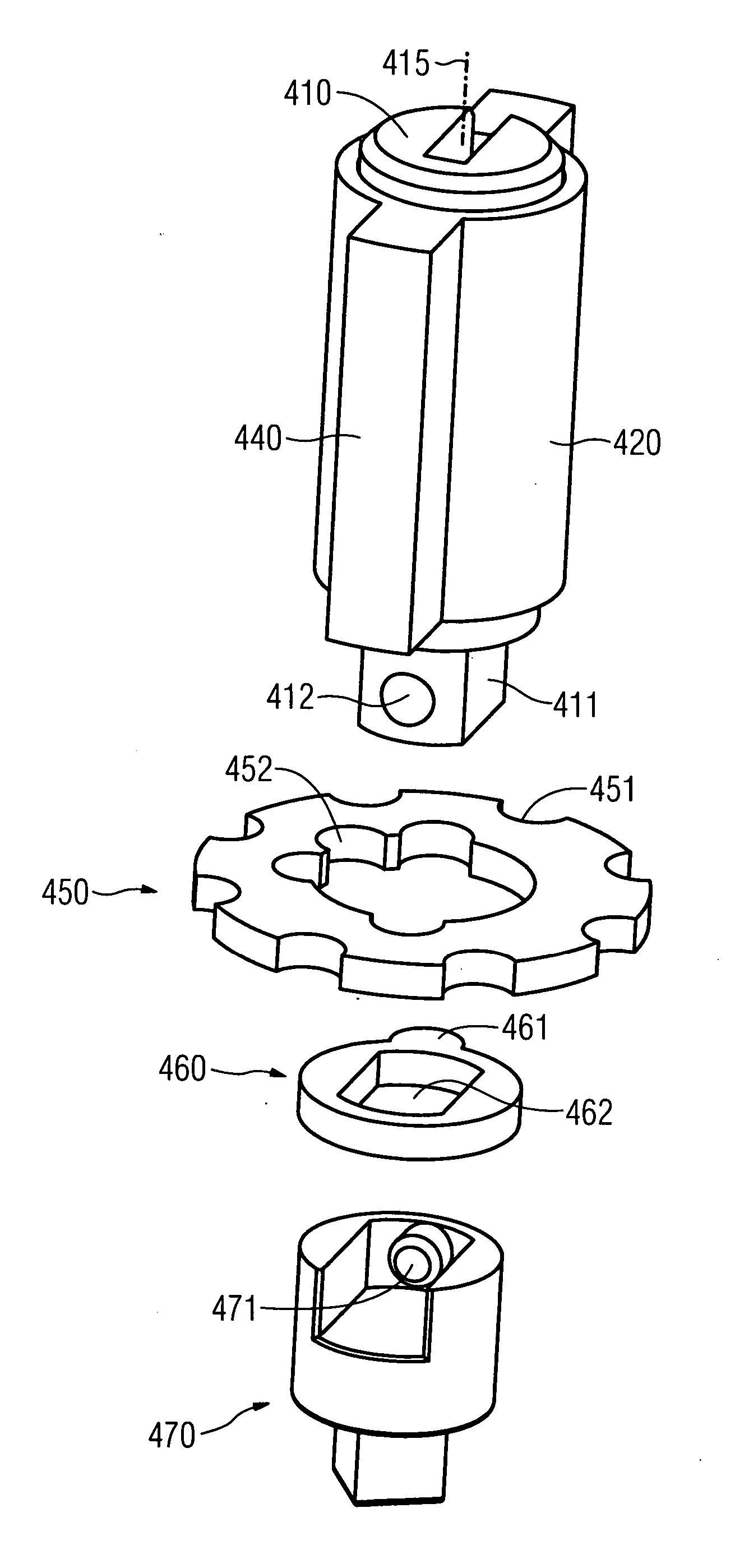

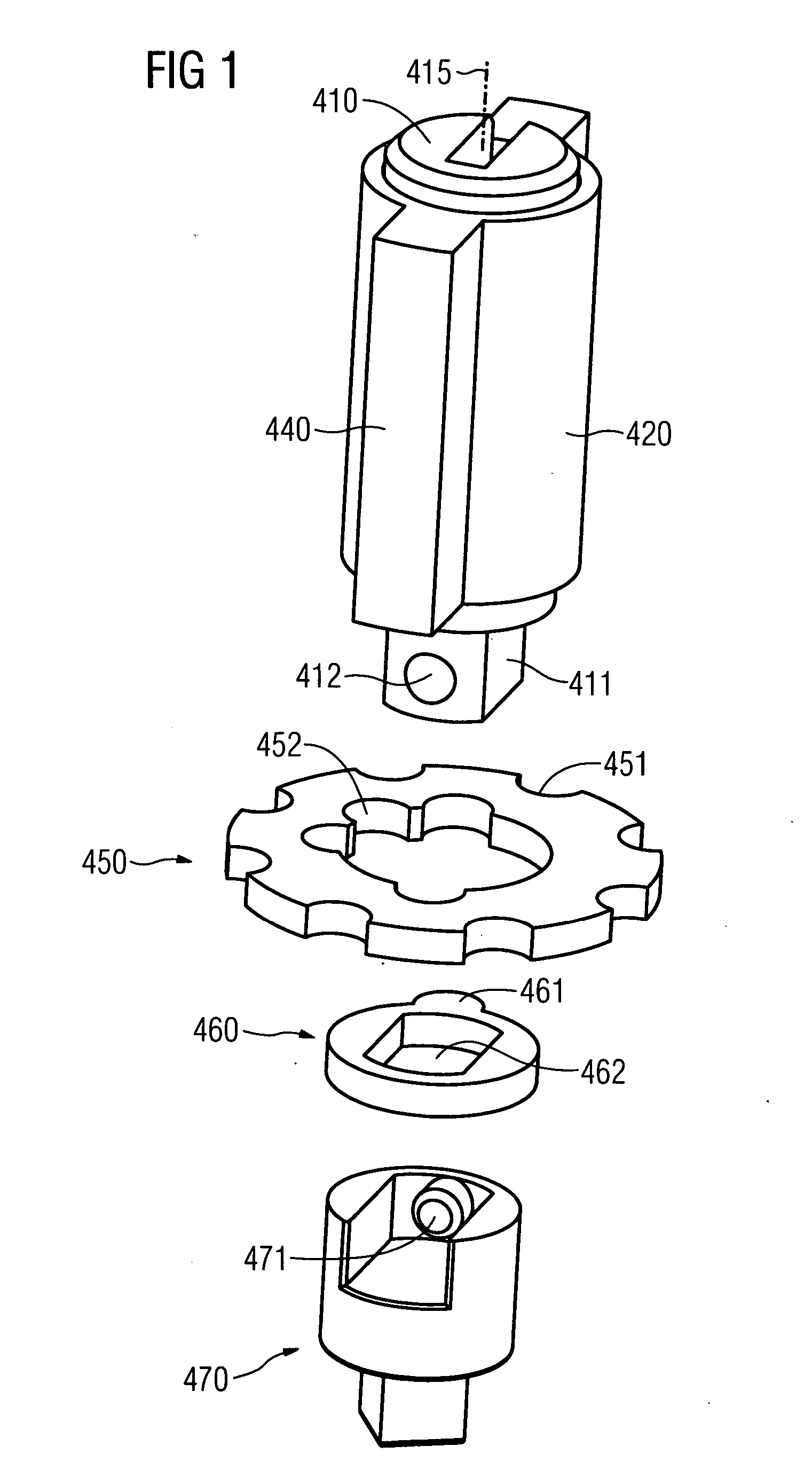

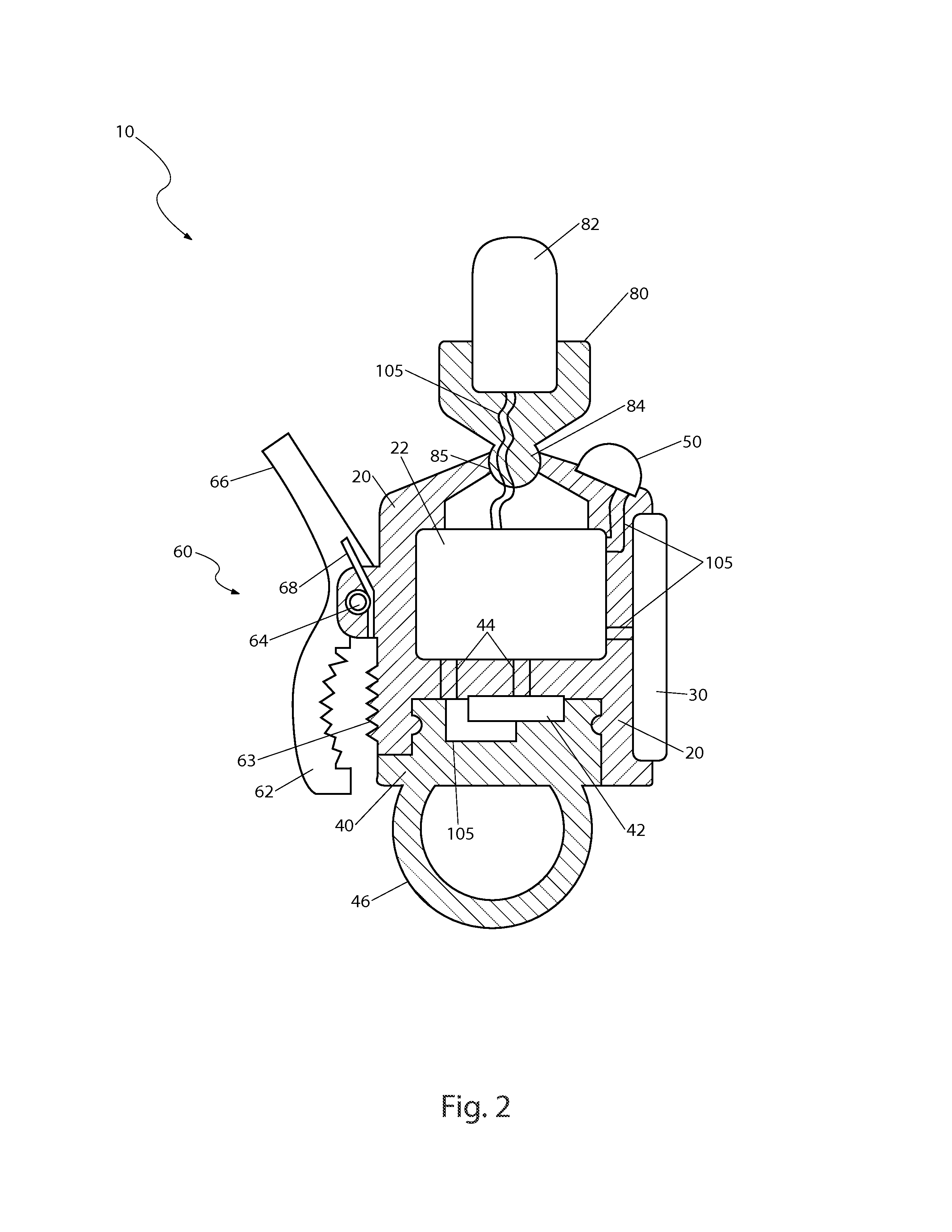

Key switch with at least one switching position

InactiveUS7275401B1Less mounting to designSaving in designElectric switchesLock casingsRotational axisAuthorization

The invention relates to a key switch with at least one turn-key switching position comprising a cylindrical lock adapted to perform a translation upon key authorization. The aim is to present a key switch being capable of allowing key hierarchies as well as the withdrawal of the key in particular switching positions. For this purpose the key switch also comprises a lock holder adapted to host the translation of a cylindrical lock in respect to the lock holder along a common rotational axis and the cylindrical lock being form-locking with the lock holder for rotations around the rotational axis. The user is able to employ the turning key movement for the selection of a switching position and an outward and inward linear translation of the key to lock or unlock a switching position.

Owner:SIEMENS AG

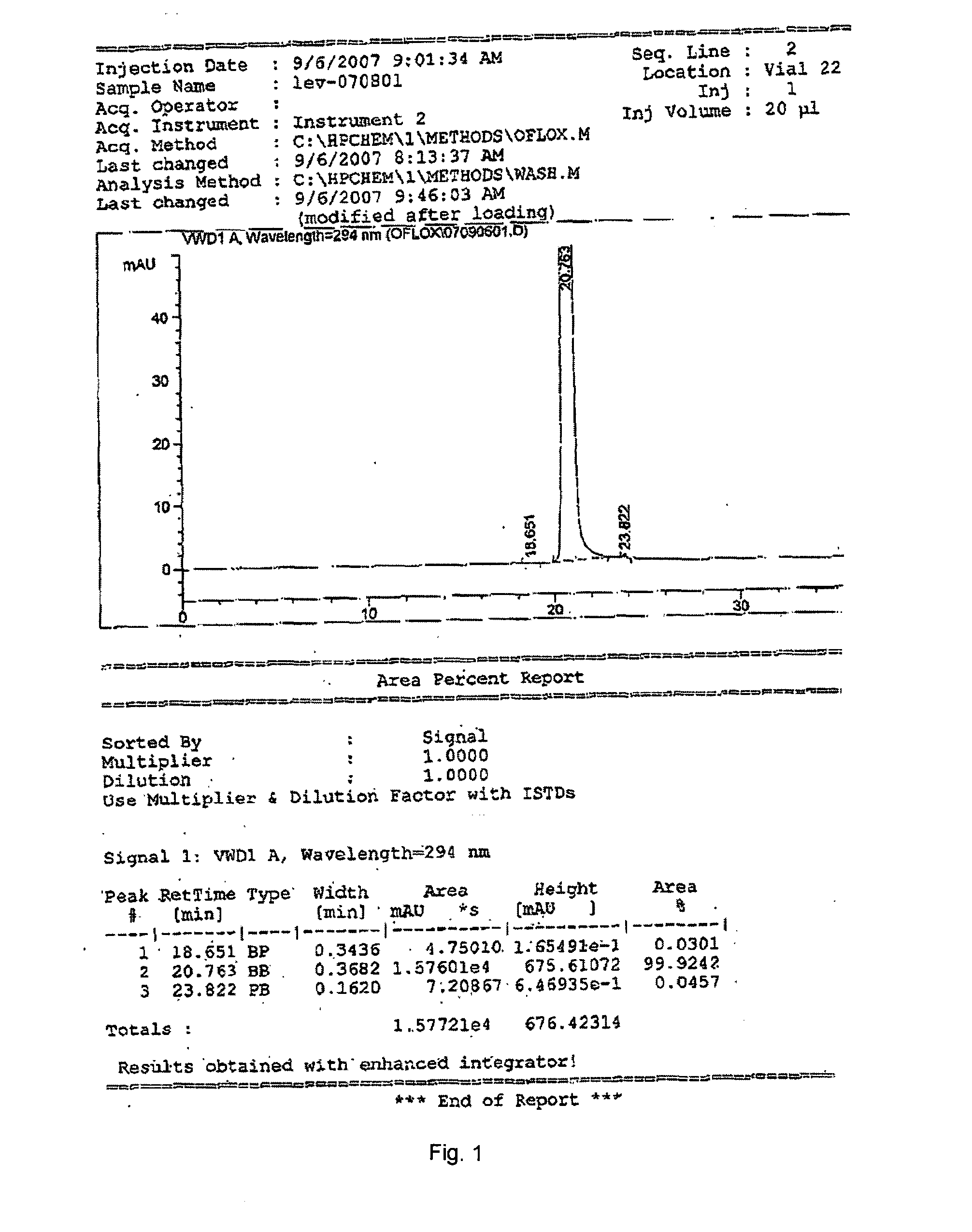

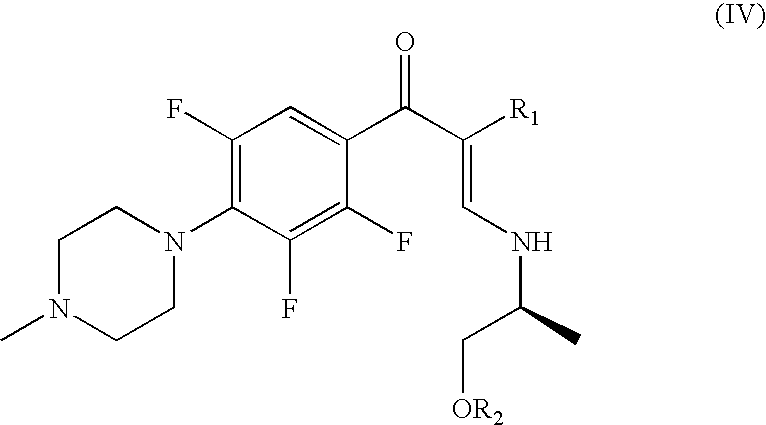

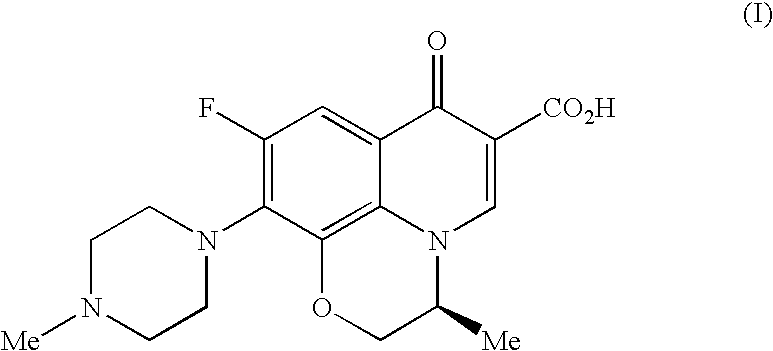

Process for the preparation of an antibacterial quinolone compound

InactiveUS20100029938A1Safe and cost-effectiveEffective alternativeOrganic chemistryQuinoloneAlcohol

It comprises a process for the preparation of levofloxacin based on a cyclisation reaction of a compound of formula (IV), which has the alcohol group protected, followed by a deprotection reaction and the conversion of the compound obtained to levofloxacin by a process comprising a hydrolysis reaction and a second cyclisation reaction. It also comprises new intermediates compounds.

Owner:FARMAPROJECTS

Reaction block for supporting flasks of different sizes for chemical synthesis on a hot plates stirrer

InactiveUS20070047387A1Safe and cost-effectiveContinuous gripping surface regionHeating or cooling apparatusTransportation and packagingChemical synthesisMagnetic tension force

A reaction block for mounting various round bottom flasks upon a laboratory, magnetic hot plate stirrer. An aluminum inner flask holder effectively conducts heat and does not interfere with a magnetic flux. A solid heat insulating material substantially surrounds and is spaced from the flask holder, in order to keep the reaction block at a safe temperature and provide easy gripping surface regions that extend completely around its circumference.

Owner:CHEMGLASS

Interventional MRI Compatible Medical Device, System, and Method

InactiveUS20170143234A1Safe and visible catheterSafe and cost-effectiveCatheterDiagnostic recording/measuringTemperature measurementTransmission line

An active catheter design incorporating a distal loop coil that is electrically connected to an ultrasonic transducer having a comparable profile. The ultrasonic transducer induces ultrasonic waves at the Larmor frequency at the distal end of a dielectric optical fiber that runs along the active catheter shaft. The optical fiber serves as the transmission line instead of a convention conductor, eliminating the RF induced heating. The dynamic strain generated by the ultrasonic transducer can be measured using optical interferometry by coupling a laser at the proximal end of the optical fiber using the acousto-optical effect. A fiber embedded Bragg reflector grating, for example, can be used for this purpose. The device can also be used for simultaneous temperature measurements among other parameters.

Owner:GEORGIA TECH RES CORP +1

Methods for one-pot N-demethylation/N-functionalization of morphine and tropane alkaloids

The present invention provides a method for the N-demethylation and N-functionalization of an N-methylated heterocycle such as a morphine alkaloid or tropane alkaloid. The method comprises reacting the heterocycle with an functionalization agent in the presence of a transition metal catalyst in air or in the presence of an oxidant.

Owner:BROCK UNIVERSITY

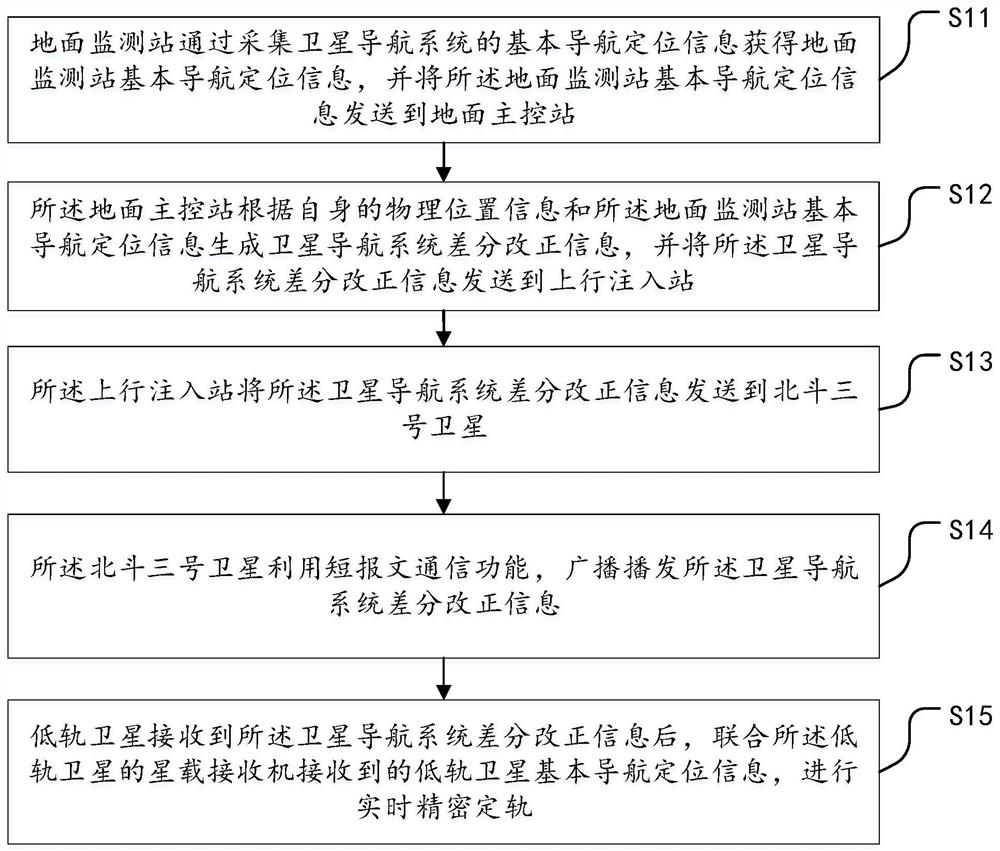

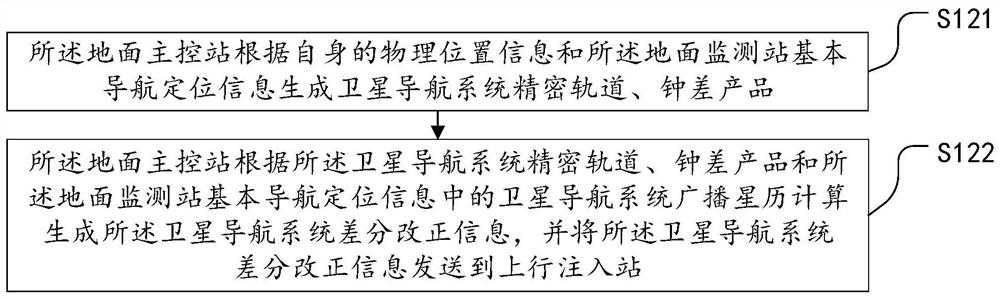

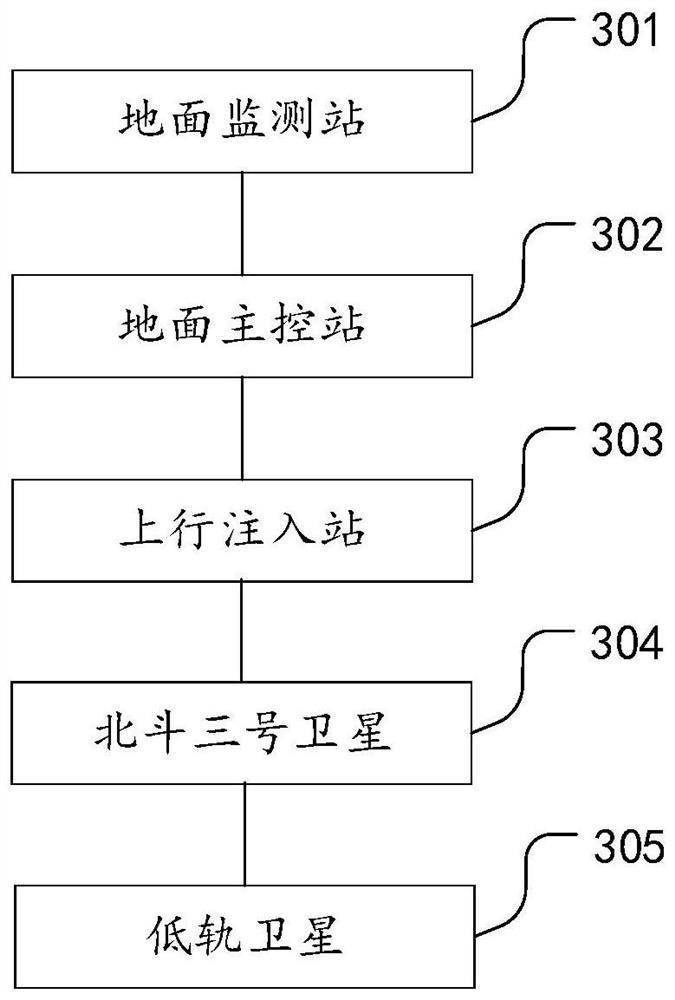

Low-orbit satellite real-time precision orbit determination method and system based on Beidou short messages

PendingCN112415550AWide coverageSafe and cost-effectiveRadio transmissionSatellite radio beaconingPhysicsDifferential correction

The invention belongs to the technical field of communication and positioning, and discloses a low-orbit satellite real-time precision orbit determination method and system, and the method comprises the steps that a ground monitoring station obtains the basic navigation positioning information of the ground monitoring station through collecting the basic navigation positioning information of a satellite navigation system, and transmits the basic navigation positioning information to a ground master control station; the ground master control station generates satellite navigation system differential correction information according to the physical position information of the ground master control station and the basic navigation positioning information of the ground monitoring station, andsends the satellite navigation system differential correction information to an uplink injection station; the uplink injection station sends the differential correction information of the satellite navigation system to a Beidou-3 satellite; the Beidou-3 satellite broadcasts satellite navigation system differential correction information by using a short message communication function; and after receiving the satellite navigation system differential correction information, the low-orbit satellite performs real-time precise orbit determination in combination with the low-orbit satellite basic navigation positioning information received by the satellite-borne receiver of the low-orbit satellite. The method and the system have the advantages that the method and the system do not depend on an external communication link, are completely independent and are high in safety and cost performance.

Owner:WUHAN UNIV

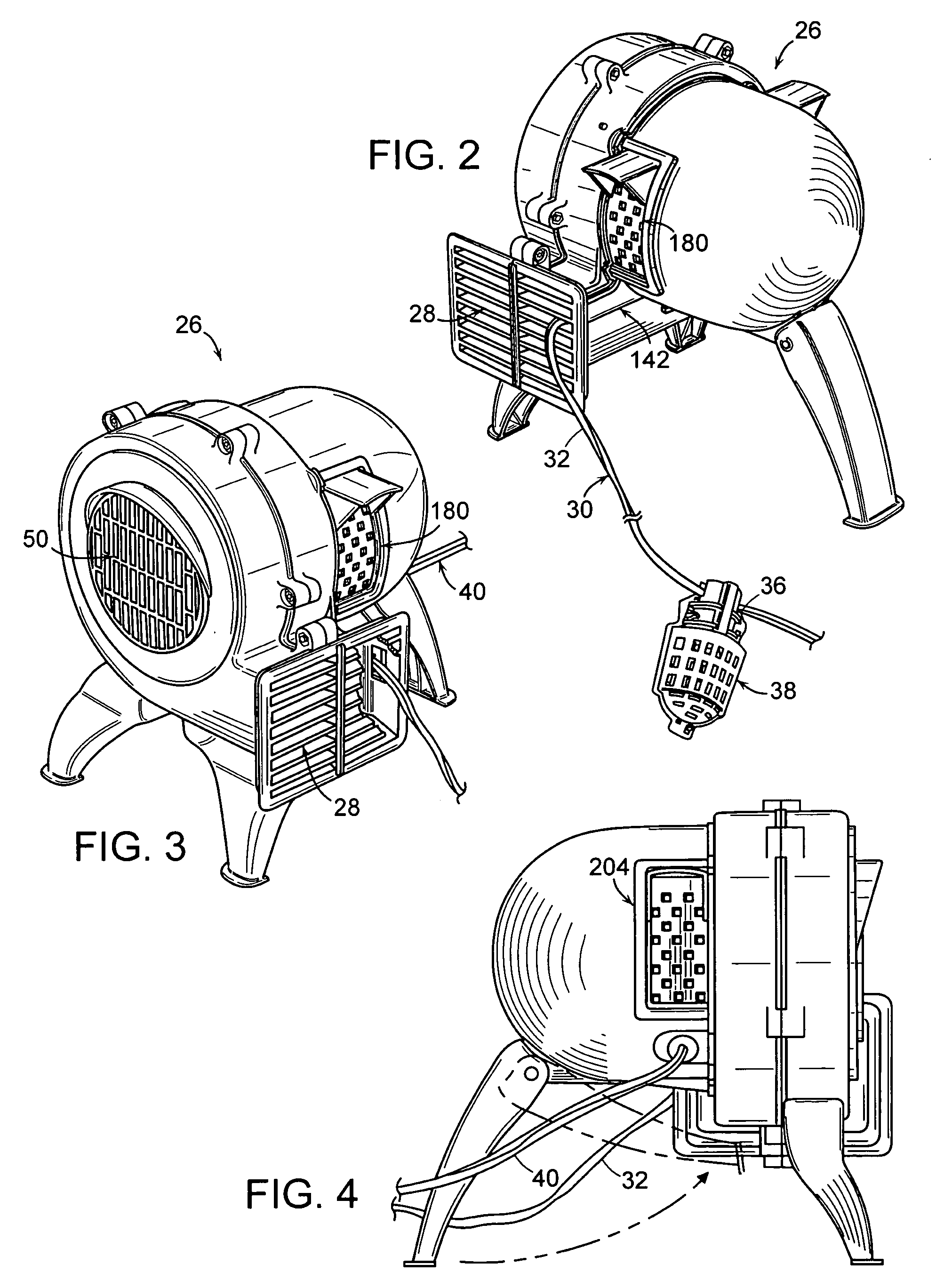

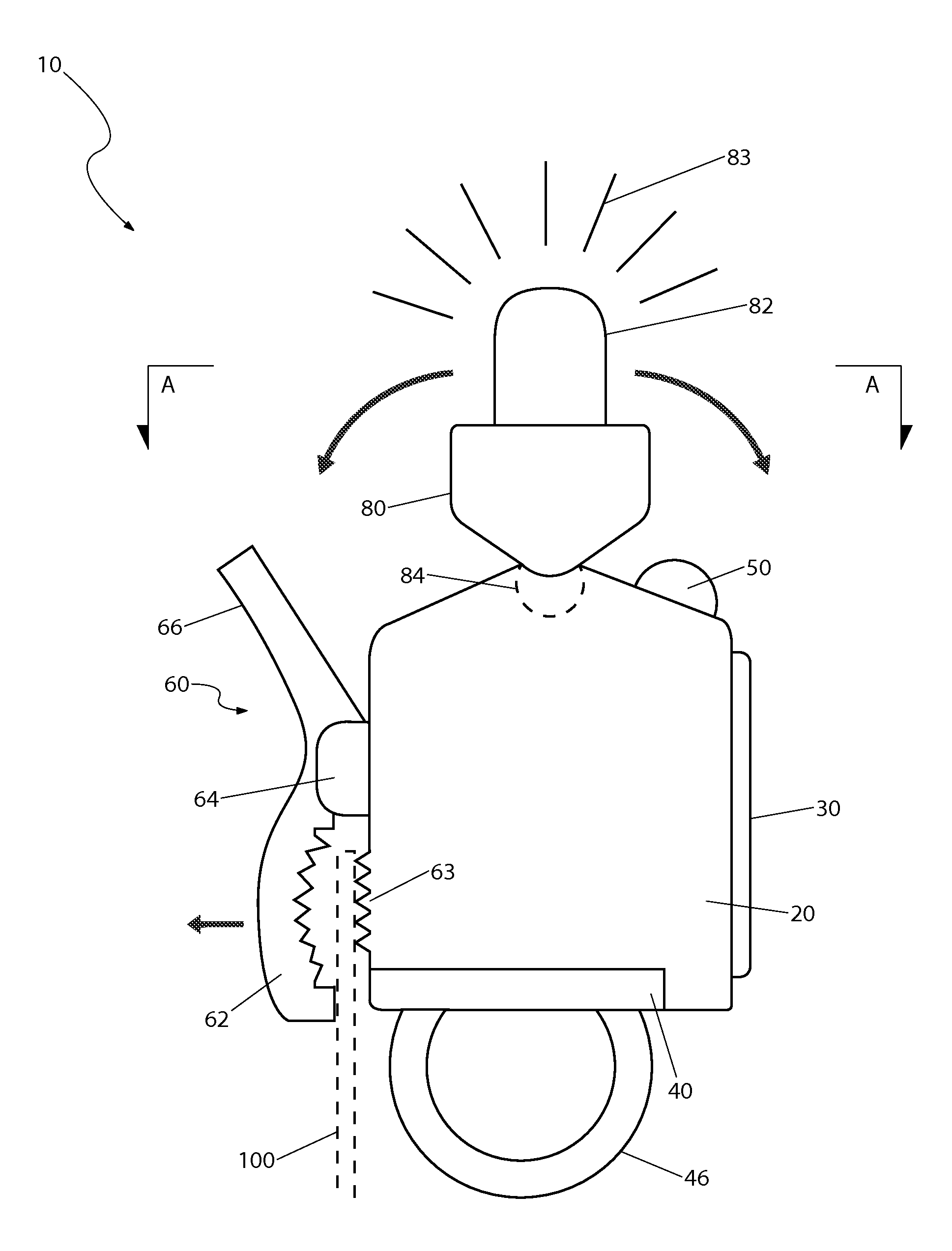

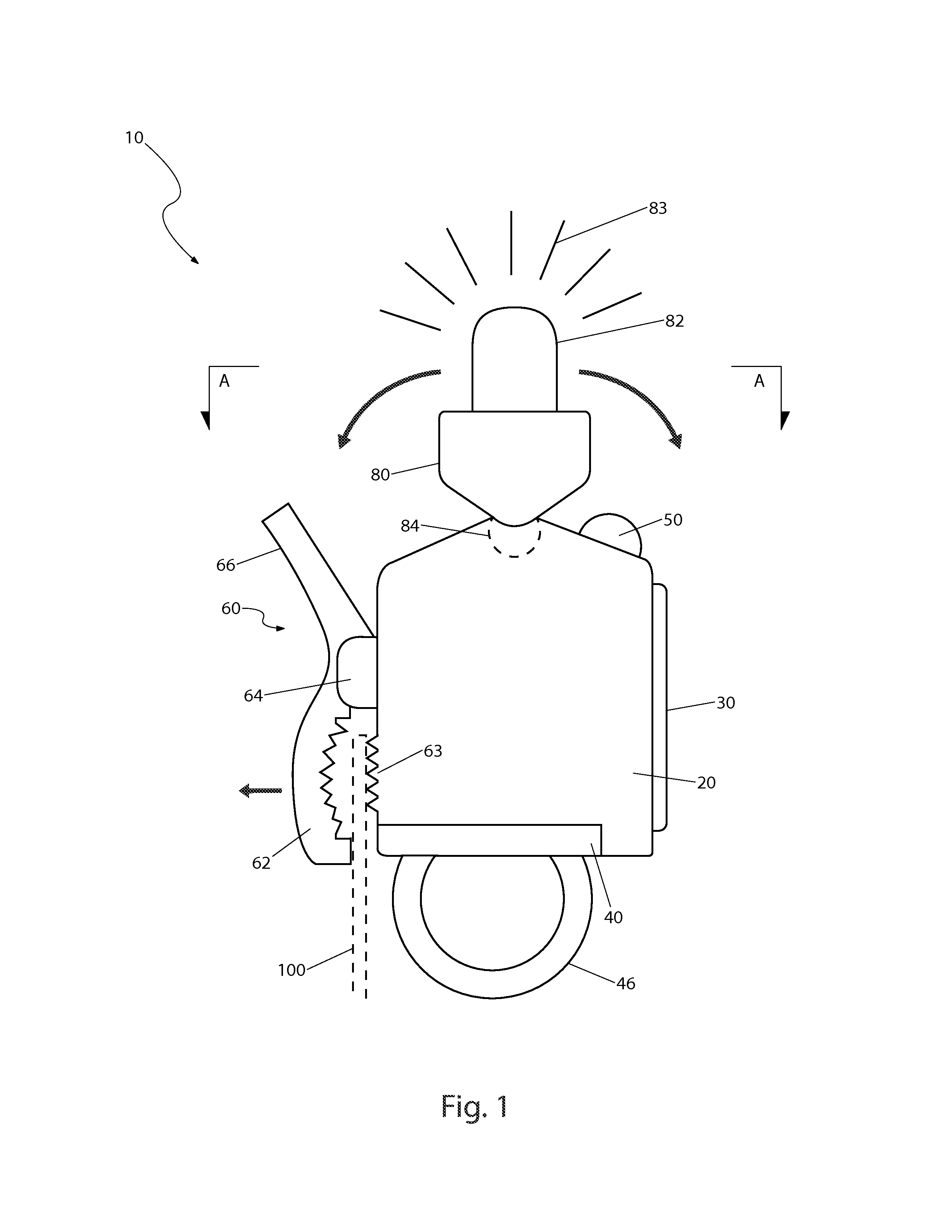

Air blower unit for inflatable body

InactiveUS20060098421A1Cost of securitySafe and cost-effectivePump componentsAmusementsElectrical wiringElectric wire

The present invention is directed to an air blower unit for inflating an air permeable body. The air permeable body has an inlet sleeve with a distal end and a light unit located within the body. The air blower unit comprises an exhaust port engageable with the distal end of the inlet sleeve for delivering air to the body thru the inlet sleeve. The air blower unit further comprises an electrical cord passing into and out of the exhaust port and thru the inlet sleeve of the body for connection with a light unit. The air blower unit may further comprise a protective cover to enclose the electrical cord as it passes into and within the exhaust port.

Owner:FIREMAN BARRY +1

Method for applying adhesive in a controlled and precise manner

InactiveUS20060175002A1Great control over shape and sizeSafe and cost-effectivePiezo electricEngineering

A method for manufacturing a multilayer hose having reduced permeation of hydrocarbon fuel vapor, wherein the multilayer hose is useful as a hydrocarbon fuel transport hose, comprises the steps of: extruding a first fluoroelastomeric tubular structure having an inner surface and an outer surface; applying an adhesive on the outer surface of the first fluoroelastomeric tubular structure, wherein the adhesive is applied to the outer surface of the first fluoroelastomeric tubular structure using piezo electric technology comprising a piezo element disposed in an adhesive reservoir positioned at an exit end of an extruder for extruding the first fluoroelastomeric tubular structure. The adhesive reservoir comprising a plurality of nozzles equally spaced apart around the exit end of the extruder through which adhesive is discharged onto the surface of the first fluoroelastomeric tubular structure in a precise and uniform manner as the first fluoroelastomeric tubular structure exits the end of the extruder, the discharge of the adhesive being activated by application of an electric current applied to the piezo element causing the piezo element to rapidly oscillate in a precise and uniform manner causing the adhesive to be repeatedly discharged through the plurality of nozzles in a pulsating manner, whereby the adhesive is uniformly applied to the outer surface of the first fluoroelastomeric tubular structure; and extruding a second fluoroplastic tubular structure onto the first fluoroelastomeric tubular structure such that the adhesive is disposed between the first fluoroelastomeric tubular structure and the second fluoroplastic tubular structure.

Owner:FLUID ROUTING SOLUTIONS

Key switch with at least one switching position

InactiveUS20070240466A1Less mounting to designSaving in designElectric switchesLock casingsRotational axisEngineering

The invention relates to a key switch with at least one turn-key switching position comprising a cylindrical lock adapted to perform a translation upon key authorization. The aim is to present a key switch being capable of allowing key hierarchies as well as the withdrawal of the key in particular switching positions. For this purpose the key switch also comprises a lock holder adapted to host the translation of a cylindrical lock in respect to the lock holder along a common rotational axis and the cylindrical lock being form—locking with the lock holder for rotations around the rotational axis. The user is able to employ the turning key movement for the selection of a switching position and an outward and inward linear translation of the key to lock or unlock a switching position.

Owner:SIEMENS AG

Punching press

InactiveUS8739595B2High degree of tool wear and even in tool fractureEasy to wearForging/hammering/pressing machinesForging press detailsPunch pressEngineering

The invention relates to a punching press with a clamping plate (27) and with a press ram (1) which lies opposite the upper side of the clamping plate (27) and operates towards the clamping plate (27) and is moveable up and down via four tension columns (2) by means of a crank drive arranged below the belt movement plane (X) of the punching press. The press ram (1) is guided exclusively via the tension columns (2) which, in turn, are guided in inclination-tolerant guides (3) in the belt movement plane (X) in such a manner that the press ram (1) and the tension columns (2) can be positioned obliquely as a consequence of differing longitudinal expansion of the tension columns (2) under an eccentric load by the tension columns (2) being inclined about axes of inclination running in the region of the belt movement plane (X) of the punching press. By means of the configuration according to the invention, distortion of the punching press under an eccentric load, which would lead to uncontrollable operating conditions during the punching and a high degree of wear at the guides of the machine, is avoided, and it can be ensured that, in the event of a possible skewed position of the ram, no tool offset, which would result in a high degree of tool wear or even in tool fracture, occurs.

Owner:BRUDERER ARBON SCHWEIZ

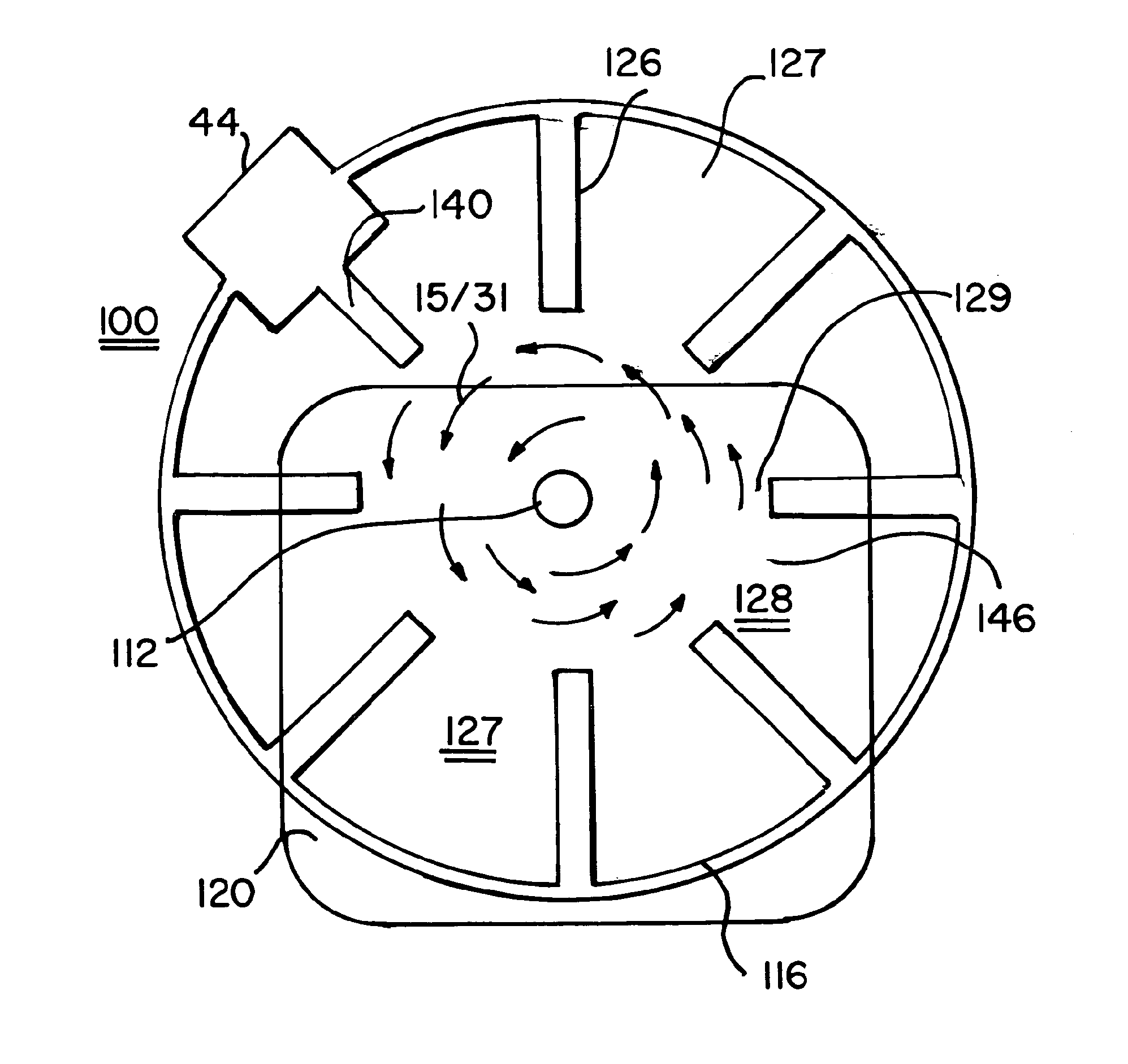

System For Generation Of Useful Electrical Power From Isotopic Emissions

ActiveUS20140035435A1Safe and cost-effectiveTransit-tube cathodesGenerators/motorsElectricityHigh energy

Particles emitted by radio-isotopic by-products of nuclear fission are used as a power source at the cathode of a magnetron system. Particles include high energy electrons having a large associated EMF. In the system a radial electrical vector E, between the cathode and anode, interacts with an axial magnetic vector B vector to produce an E×B force that rotates the particles about the system axis. These emissions are within a set range of velocities. The angular velocity and geometry of a rotating field, known as a space charge wheel (SCW), may be modulated by an external RF inputs to cavities of an anode block and the use of concentric biasing grids between the cathode and anode block. The SCW induces LC values into cavities of the anode, exciting them and producing electrons resonance which may be used to generate power.

Owner:WEBER DAVID

Solar Powered Attachable Light

InactiveUS20130182420A1Safe and cost-effectiveOperated particularly safely and cost-effectivelyLighting support devicesPoint-like light sourceSolar powerSolar cell

A solar-powered attachable light is adapted for use as a holiday decoration and includes a lamp pivotably mounted to an enclosure. A solar cell charges an internal rechargeable battery during daytime hours and the rechargeable battery powers the lamp during nighttime hours. A rear of the enclosure includes a clip assembly for removable attachment of the device to various outdoor structures. The device eliminates the presence of wires and the requirement of connection to a fixed power source in a manner particularly beneficial when simultaneously arranging decorative outdoor lighting in a variety of locations.

Owner:RICHARDSON LINE C

Carotenoid and other anti-oxidants extraction

InactiveCN1300190AHigh yieldSimple methodAnimal feeding stuffAccessory food factorsSludgeProtein-protein complex

A carotenoid-containing plant extract in the form of a lipid-protein complex particularly enriched in carotenoids and other anti-oxidants and process for preparing it, wherein a crushed carotenoid-containing plant material is incubated, then a juice recovered after separation of plant solids is subjected to a heat treatment, a precipitate is then recovered from the heated liquid phase after a second separation to obtain a coloured sludge extract.

Owner:SOC DES PROD NESTLE SA

Container, connection and production device

ActiveUS11324660B2Reduce wall thicknessSufficient axial stiffnessPharmaceutical containersMedical packagingPlastic materialsNeck parts

Owner:KOCHER PLASTIK MASCHBAUU

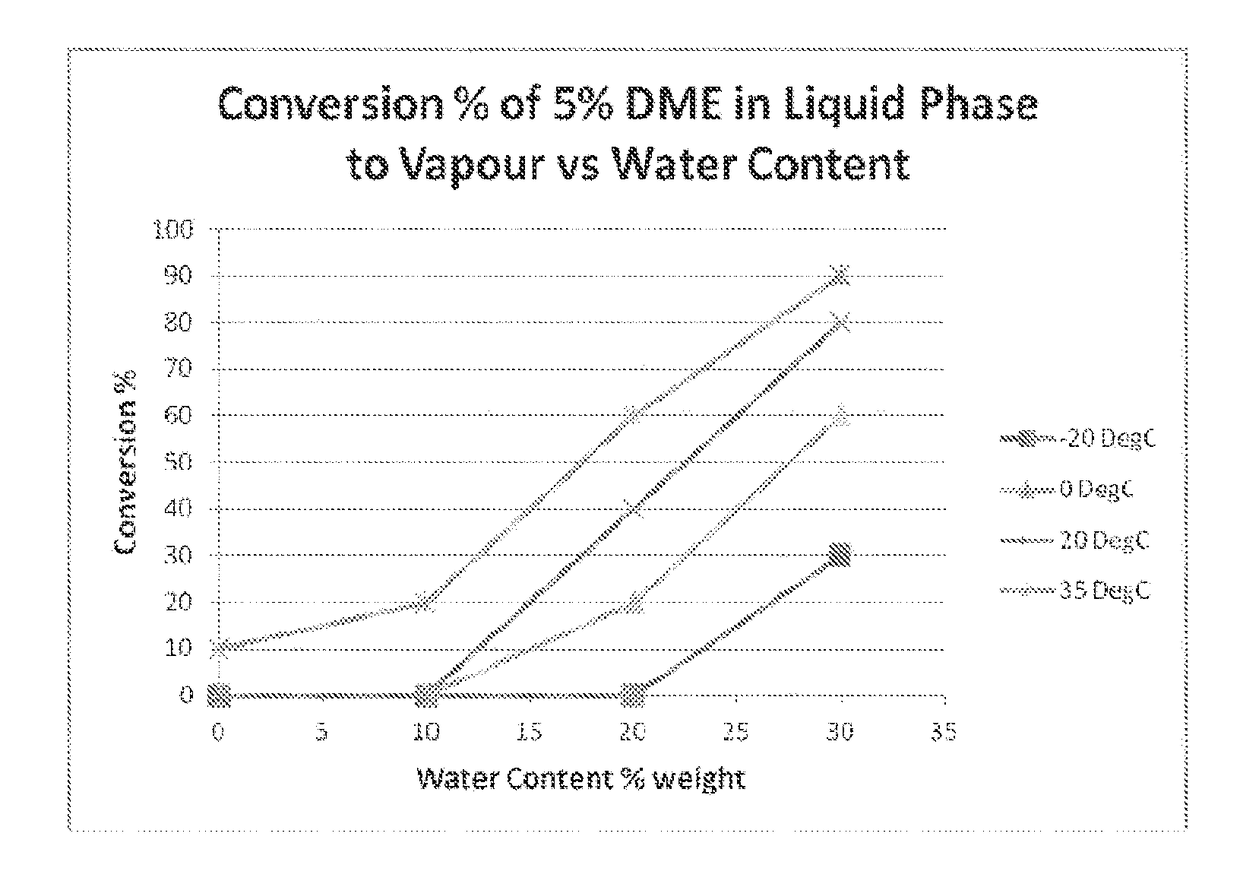

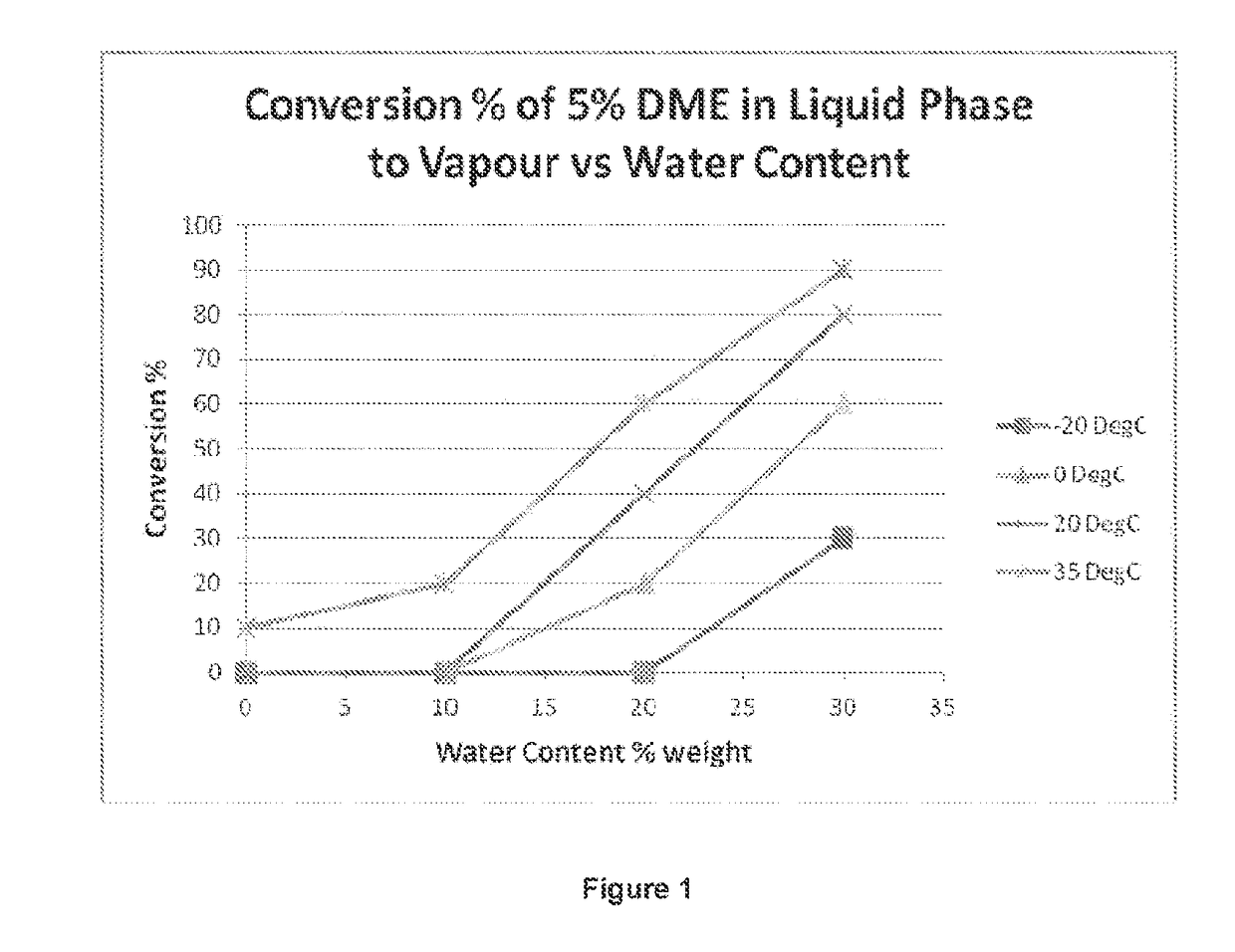

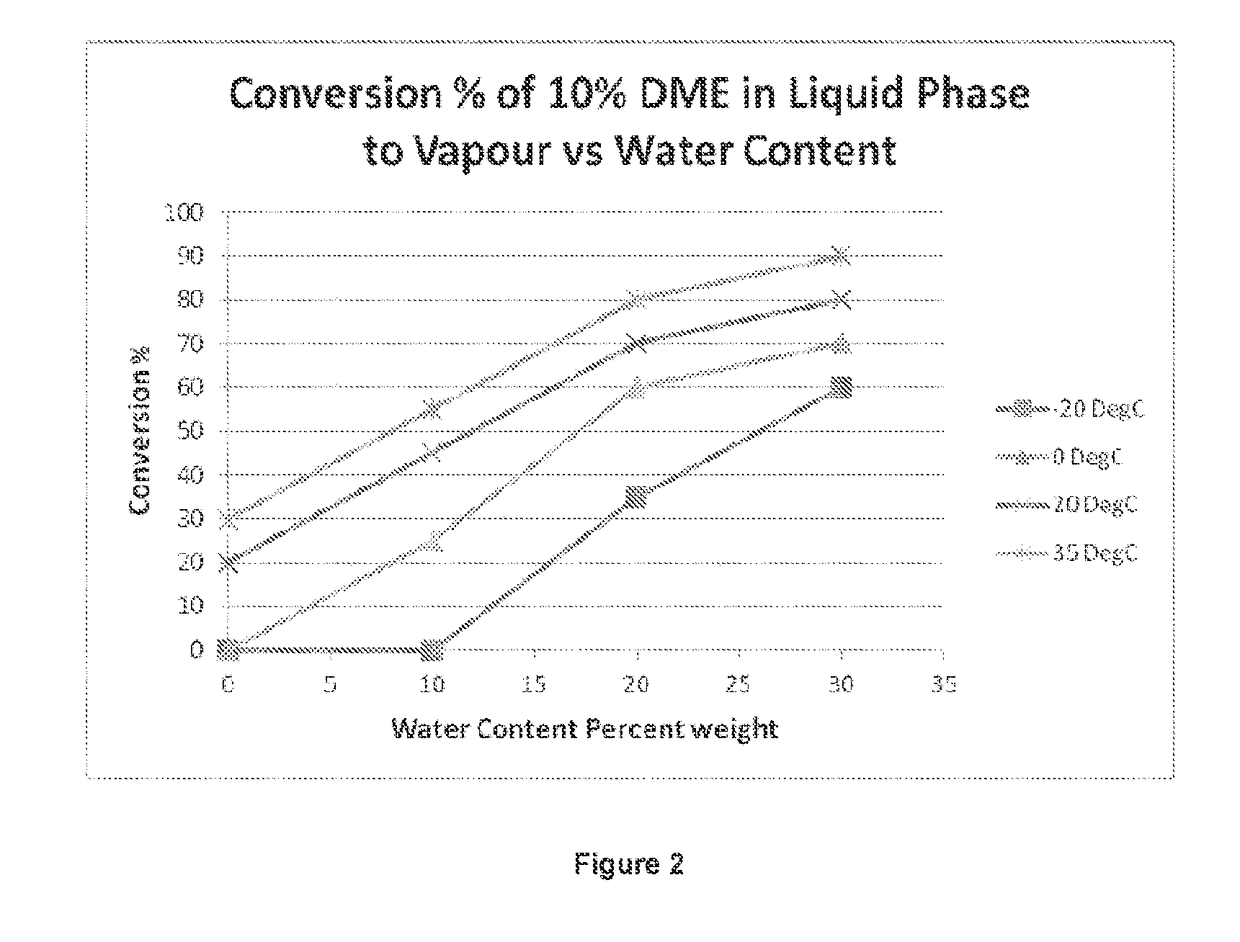

Methods for the preparation and delivery of fuel compositions

ActiveUS9593284B2Easy to useSafe and cost-effectiveNon-fuel substance addition to fuelInternal combustion piston enginesEvaporationDimethyl ether

Owner:GANE ENERGY & RESOURCES

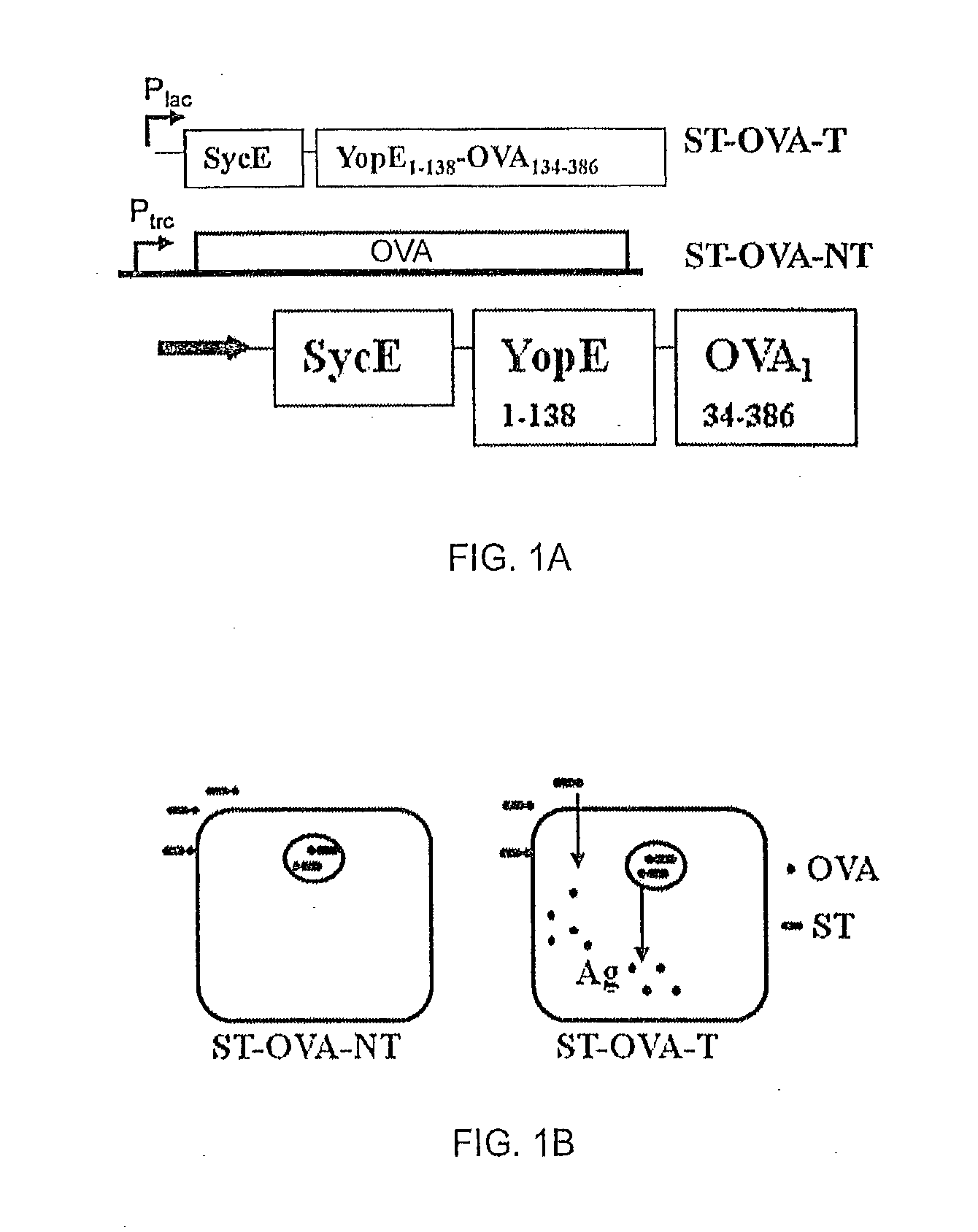

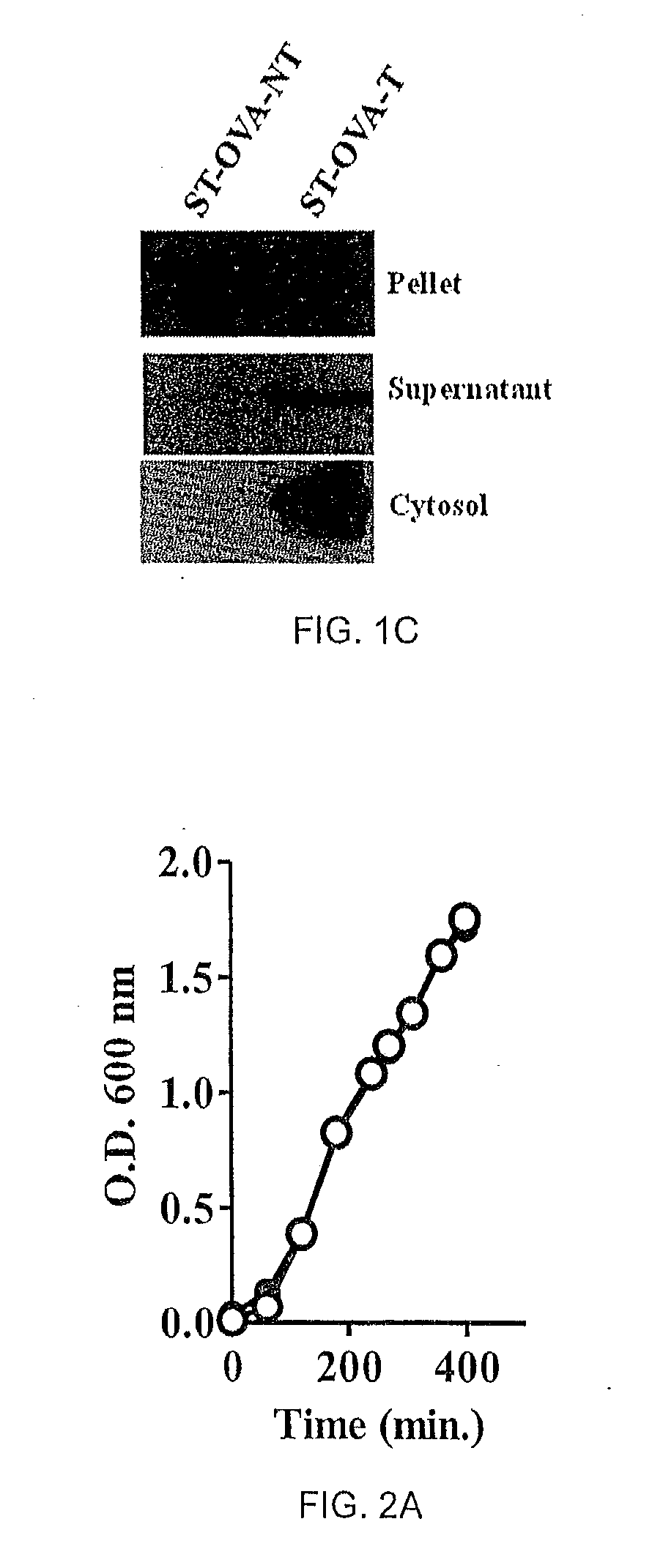

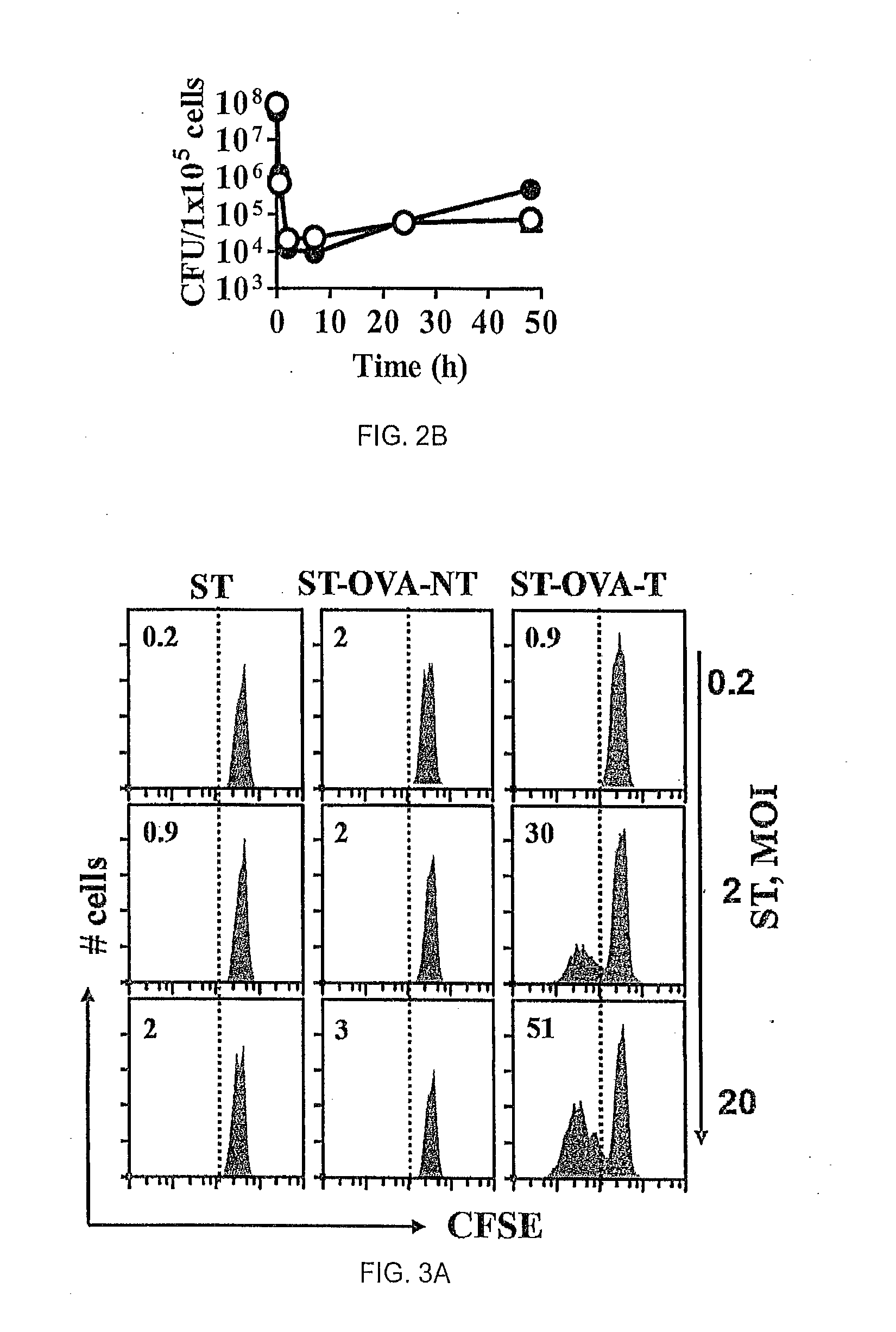

Recombinant Bacterium and Uses Thereof

ActiveUS20150140028A1Effective controlQuick responseAntibacterial agentsSsRNA viruses negative-senseBacteroidesType three secretion system

The present invention relates to a recombinant bacterium expressing an antigen that is translocated to the cytosol of a host organism, and uses thereof. To this end, the present invention provides a recombinant bacterium comprising a nucleic acid encoding an antigen that is translocated to the cytosol of a host cell utilizing Type III secretion system. The recombinant bacterium is generally chosen from intracellular pathogens that reside in the phagosome and fail to induce rapid T cell activation. The translocated antigen may be a viral antigen, a bacterial antigen, or a tumour antigen. Methods of imparting immunity using the recombinant bacterium are also provided.

Owner:NAT RES COUNCIL OF CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com