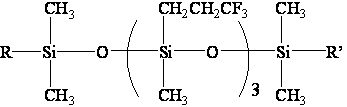

Preparation method of fluorosilicone rubber with controllable molecular weight

A technology of fluorosilicone raw rubber and molecular weight, which is applied in the field of preparation of molecular weight controllable fluorosilicone raw rubber, which can solve the problems of wide molecular weight distribution, affecting the quality and performance of fluorosilicone raw rubber, and large amount of catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

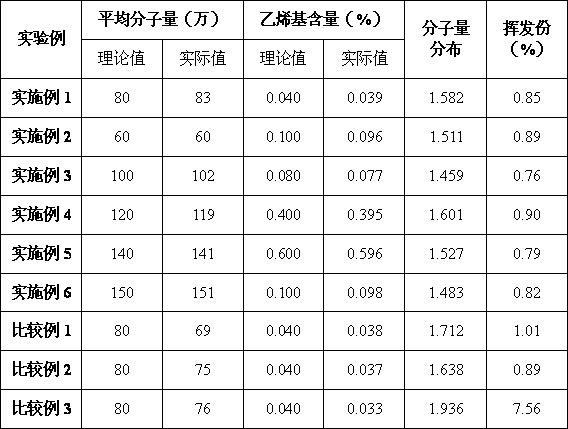

Embodiment 1

[0039] According to the above formula, calculate the feeding amount, and prepare fluorosilicone raw rubber with an average molecular weight of 800,000 and a vinyl molar content of 0.04%.

[0040] Add 100KgD to the reactor 3 F and 22.1gD 3 Vi , heated to 55~60°C, dehydrated under 130Pa pressure for 1.5h, added 46.2g sodium silanolate catalyst (3.25% sodium hydroxide content, accounting for 0.0015% of the total mass of raw materials) and 66.9g 1,1,1,3, 5,7,9,9,9-nonamethyl-3,5,7-tris(3,3,3-trifluoropropyl)pentasiloxane, with high purity N 2 Replace the air in the reactor, raise the temperature to 90°C, start the reaction, raise the temperature to 130°C at a rate of 1.5°C / min, maintain the temperature for 0.5h, reduce the system pressure to 26Pa for 1.5h, add 51.8g of fluorine-containing silicon base Phosphoric acid ester (phosphoric acid content 3.55%), neutralized under normal pressure for 2 hours, finally raised the temperature to 180~200°C, kept it under ultimate vacuum fo...

Embodiment 2

[0042] Preparation of fluorosilicone raw rubber with an average molecular weight of 600,000 and a vinyl content of 0.1%

[0043] Add 100KgD to the reactor 3 F and 55.3gD 3 Vi , heated to 55~60°C, dehydrated under 130Pa pressure for 1.5h, added 61.6g sodium silanolate catalyst (3.25% sodium hydroxide content, accounting for 0.002% of the total mass of raw materials) and 102.6g 1,1,3,5, 7,9,9-Heptamethyl-1,3,5,7,9-penta(3,3,3-trifluoropropyl)pentasiloxane, with high purity N 2 Replace the air in the reactor, raise the temperature to 90°C, start the reaction, program the temperature to 130°C at a rate of 2°C / min, maintain the temperature for 0.5h, reduce the system pressure to 26Pa for 1.5h, add 69.2g of fluorine-containing silicon Phosphoric acid ester (phosphoric acid content: 3.55%), neutralized under normal pressure for 2 hours, and finally heated to 180~200°C, maintained for 2 hours under ultimate vacuum, removed low boiling matter, cooled to obtain raw rubber. Eight par...

Embodiment 3

[0045] Preparation of fluorosilicone raw rubber with an average molecular weight of 1 million and a vinyl content of 0.08%

[0046] Add 100KgD to the reactor 3 F and 44.2gD 3 Vi , heated to 55~60°C, dehydrated under 130Pa pressure for 1.5h, added 30.8g sodium silanolate catalyst (3.25% sodium hydroxide content, accounting for 0.001% of the total mass of raw materials) and 57.2g 1,1,3,5, 7,9,9-Heptamethyl-1,9-divinyl-3,5,7-tris(3,3,3-trifluoropropyl)pentasiloxane, with high purity N 2 Replace the air in the reactor, raise the temperature to 90°C, start the reaction, program the temperature to 130°C at a rate of 1°C / min, maintain the temperature for 0.5h, reduce the system pressure to 26Pa for 1.5h, add 34.5g of fluorine-containing silicon Phosphoric acid ester (phosphoric acid content: 3.55%), neutralized under normal pressure for 2 hours, and finally heated to 180~200°C, maintained for 2 hours under ultimate vacuum, removed low boiling matter, cooled to obtain raw rubber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com