High-velocity phenylmethyl silicone oil and preparation method thereof

A technology of phenylmethyl silicone oil and high viscosity, which is applied in the chemical industry, can solve the problems of low viscosity and difficult control of viscosity, and achieve the effect of controllable viscosity, good uniformity and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

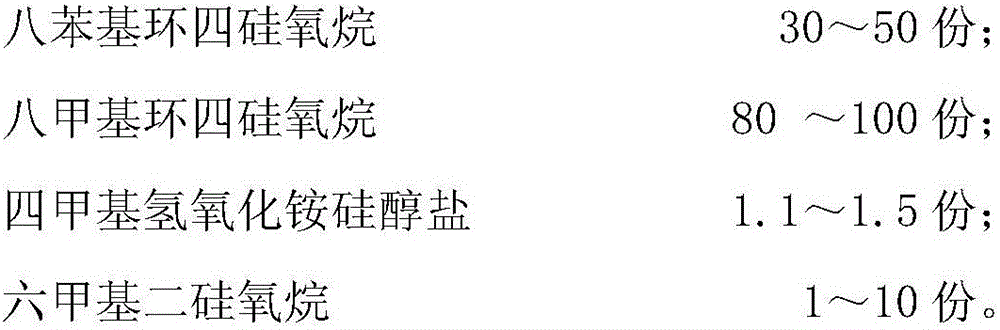

Method used

Image

Examples

Embodiment 1

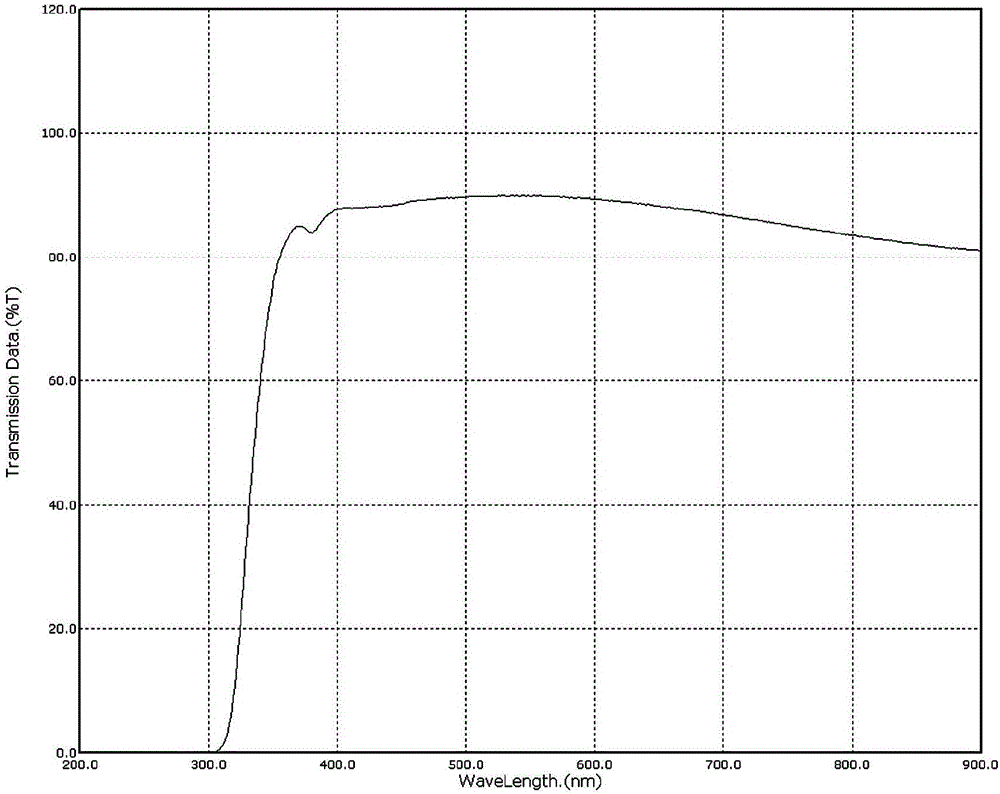

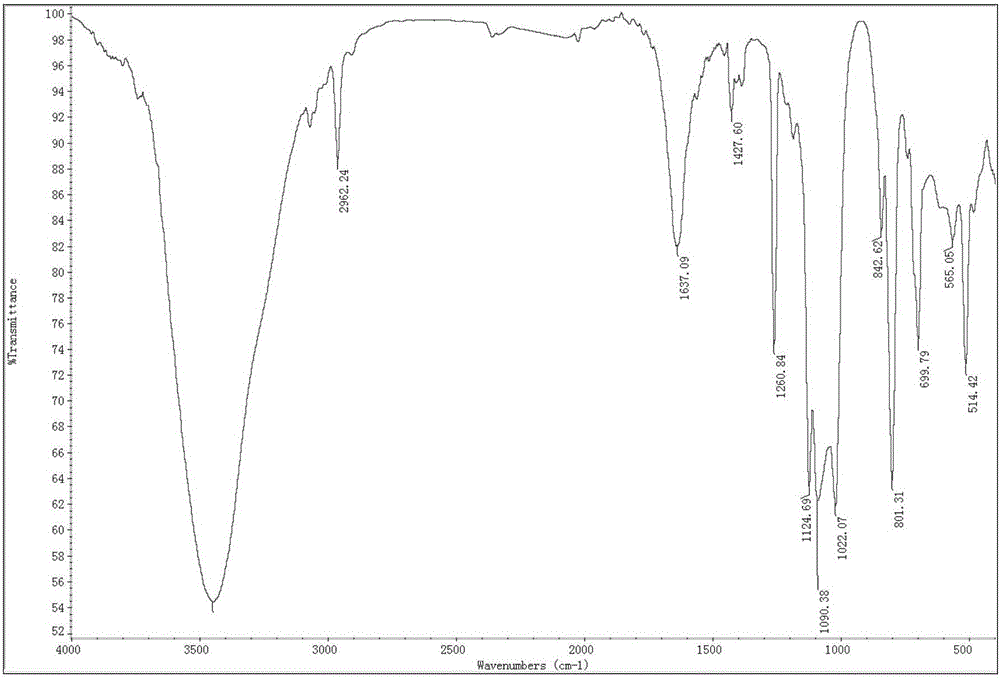

[0033] In a reactor, 40 parts of octaphenylcyclotetrasiloxane was dissolved in 100 parts of octamethylcyclotetrasiloxane at 85°C, and the dissolved system was dehydrated at -0.09MPa and 40°C for 1 hour. Then the temperature of the system was raised to 90°C, 1.4 parts of tetramethylammonium hydroxide silicon alkoxide was added, and the reaction was carried out at -0.09MPa. Under online viscosity measurement, when the viscosity of the system rises faster, add 7.5 parts of hexamethyldisiloxane, and continue to react at 90°C under normal pressure for 2 hours. After the reaction, the temperature of the reaction system was raised to 150° C. to decompose (inactivate) tetramethylammonium hydroxide silicon alkoxide for 30 minutes. Then remove low-molecular compounds at 180°C and -0.09MPa for 30 minutes, cool down and filter the material to obtain high-viscosity benzyl silicone oil. After measurement, the product has a refractive index of 1.4948, a viscosity of 2060 mPa·s, and a visibl...

Embodiment 2

[0036] In a reactor, 40 parts of octaphenylcyclotetrasiloxane was dissolved in 100 parts of octamethylcyclotetrasiloxane at 90°C, and the dissolved system was dehydrated at -0.09MPa and 30°C for 2 hours. Then the system was heated up to 95°C, 1.4 parts of tetramethylammonium hydroxide silicon alkoxide was added, and the reaction was carried out at -0.09MPa. Under online viscosity measurement, when the viscosity of the system increases rapidly, add 5 parts of hexamethyldisiloxane, and continue to react at 95°C under normal pressure for 1 hour. After the reaction, the temperature of the reaction system was raised to 150° C. to decompose (inactivate) tetramethylammonium hydroxide silicon alkoxide for 30 minutes. Then remove low-molecular compounds at 180°C and -0.09MPa for 30 minutes, cool down and filter the material to obtain high-viscosity benzyl silicone oil. After measurement, the product has a refractive index of 1.4997 and a viscosity of 4990mPa·s.

Embodiment 3

[0038] In a reactor, 40 parts of octaphenylcyclotetrasiloxane was dissolved in 90 parts of octamethylcyclotetrasiloxane at 87°C, and the dissolved system was dehydrated at -0.09MPa and 40°C for 1 hour. Then the system was heated up to 85°C, 1.3 parts of tetramethylammonium hydroxide silicon alkoxide was added, and the reaction was carried out at -0.09MPa. Under online viscosity measurement, when the viscosity of the system rises faster, add 2.5 parts of hexamethyldisiloxane, and continue to react at 85° C. under normal pressure for 3 hours. After the reaction, the temperature of the reaction system was raised to 150° C. to decompose (inactivate) tetramethylammonium hydroxide silicon alkoxide for 50 minutes. Then remove low-molecular compounds at 170°C and -0.09MPa for 40 minutes, cool down and filter the material to obtain high-viscosity benzyl silicone oil. After measurement, the product has a refractive index of 1.5052 and a viscosity of 6000mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com