Low-melting point polyester synthesis method

A technology of low melting point polyester and synthesis method, applied in the field of low melting point polyester synthesis, can solve the problems of serious side reactions, unstable product performance, etc., achieve stable product quality, easy mass production conversion, and solve serious side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The synthetic method of low melting point polyester is described in detail by 5 groups of examples below:

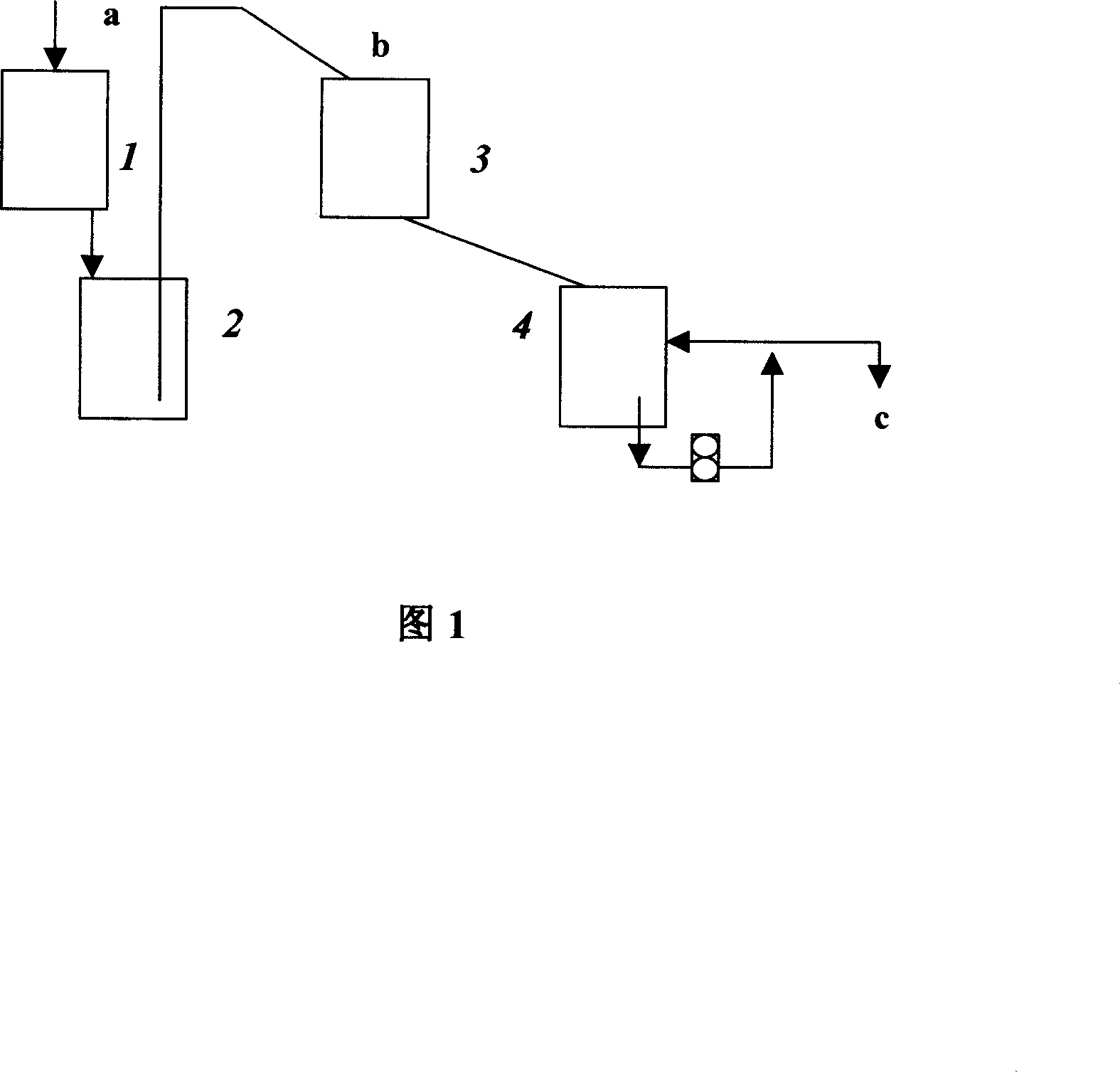

[0036] The semi-continuous polymerization process flow is adopted, and the test device is a 500kg / batch semi-continuous pilot-scale polymerization device, as shown in the main flow chart 1.

[0037] Accurately weigh each raw material according to the required molar ratio: terephthalic acid, isophthalic acid, azelaic acid, ethylene glycol, neopentyl glycol, put them into the beating kettle 1 from the feeding port a, and then add 0.01% by weight The stabilizer trimethyl phosphate (relative to the acid component) is made into a uniform slurry at room temperature, and the slurry screw pump speed is set to 25HZ, and the slurry is evenly added to the esterification kettle with half the amount of the previous batch of esterification liquid Carry out the esterification reaction in 2, control the reaction to carry out under normal pressure ~ 0.01MPa, the reaction temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com