Hot-melt adhesive of thermal shrinkage polyester amide in use for material of thermal shrinkage, and preparation method

A polyester amide, hot melt adhesive technology, applied in the direction of adhesives, etc., can solve the problems of high price, complex process, increased product cost, etc., and achieve the effect of low cost, simple process, and reduced opportunities for hydrogen bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

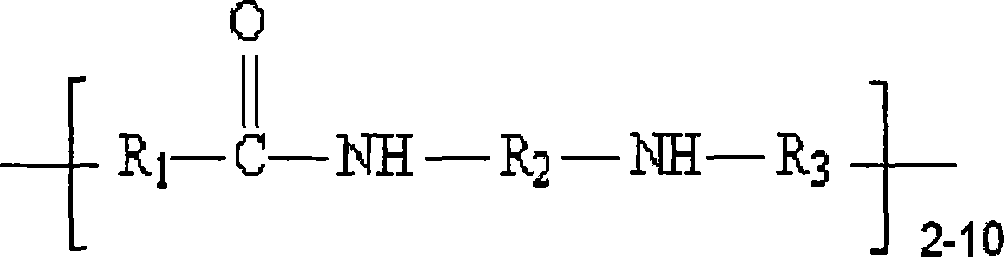

[0029] Mix 584g of low-molecular-weight polyamide (trade name: 011 resin, Zhejiang Pujiang Resin Factory, softening point: 90-120°C) with 58g of waste polyester, add it to a reaction kettle with a vacuum and condensation system, heat up until the material melts, and stir Continue to raise the temperature to 250° C., blend for 1.5 hours, then add 50 g of ethylene glycol, alcoholyze for 0.5 hours, and finally compress and polymerize under reduced pressure for 1.5 hours, with a vacuum degree of 0.065 MPa. The obtained product is an amber viscous liquid, which becomes a tough solid after cooling, with a softening point of 166° C. and a viscosity (190° C.) of 6000 mPa·S. Its structural formula is as follows:

[0030]

[0031] where: R 1 is the residue of dimer acid; R 2 for -(CH 2 ) 3 -; R 3 Ethylene terephthalate oligomers of waste polyester residues.

Embodiment 2

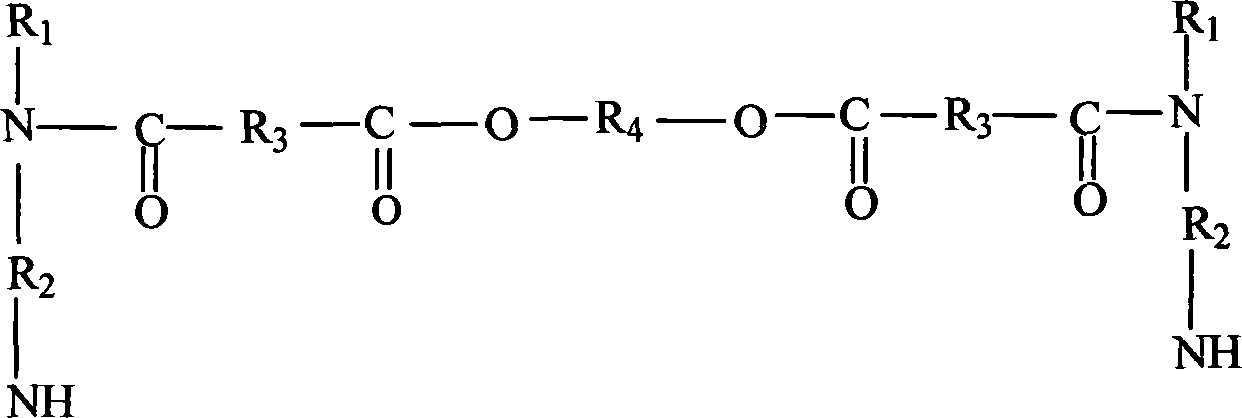

[0033]Mix 584g of low-molecular-weight polyamide (trade name: 010 resin, Yonglin Oil Chemical Factory, softening point: 90-120°C) with 30g of waste polyester, add it to a reactor with a vacuum and condensation system, heat up until the material melts, Continue to raise the temperature to 250°C under stirring, blend for 1.5 hours, then add 72 g of 1,3-butanediol, alcoholyze for 0.5 hours, and finally compress and polymerize under reduced pressure for 1.5 hours, with a vacuum of 0.065 MPa. The resulting product was an amber viscous liquid which cooled to a tough solid. Its structural formula is as follows:

[0034]

[0035] where: R 1 is the residue of dimer acid; R 2 for -(CH 2 ) 2 -, R 3 Ethylene terephthalate and 1,3-butylene terephthalate oligomers which are waste polyester residues.

Embodiment 3

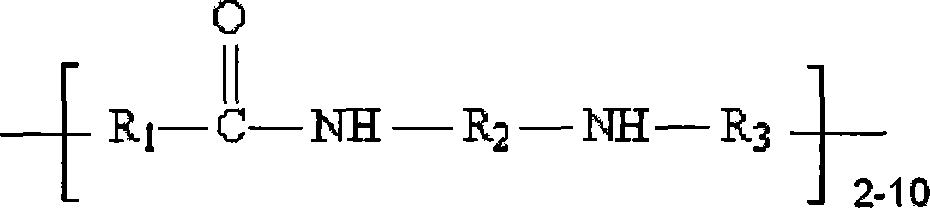

[0037] Mix 584g of low-molecular-weight polyamide (trade name: 010 resin, Zhejiang Pujiang Resin Factory, softening point: 90-120°C) with 58g of waste polyester, add it to a reaction kettle with a vacuum and condensation system, heat up until the material melts, and stir Continue to raise the temperature to 250° C., blend for 1.5 hours, then add 15 g of ethylene glycol and 35 g of 1,6-hexanediol, alcoholyze for 0.5 hours, and finally compress and polymerize under reduced pressure for 1.5 hours with a vacuum of 0.065 MPa. The resulting product was an amber viscous liquid which cooled to a tough solid. Its structural formula is as follows:

[0038]

[0039] where: R 1 is the residue of dimer acid; R 2 for -(CH 2 ) 2 -, R 3 Ethylene terephthalate and 1,6-hexanediol terephthalate oligomers which are waste polyester residues.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com