Porous ceramsite made of low-silicon iron tailings and preparation method of porous ceramsite

A technology of porous ceramics and ferrosilicon, which is applied in the field of porous ceramsite from low-silicon iron tailings and its preparation, to achieve the effects of improving compressive strength, uniform strength distribution, and well-developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

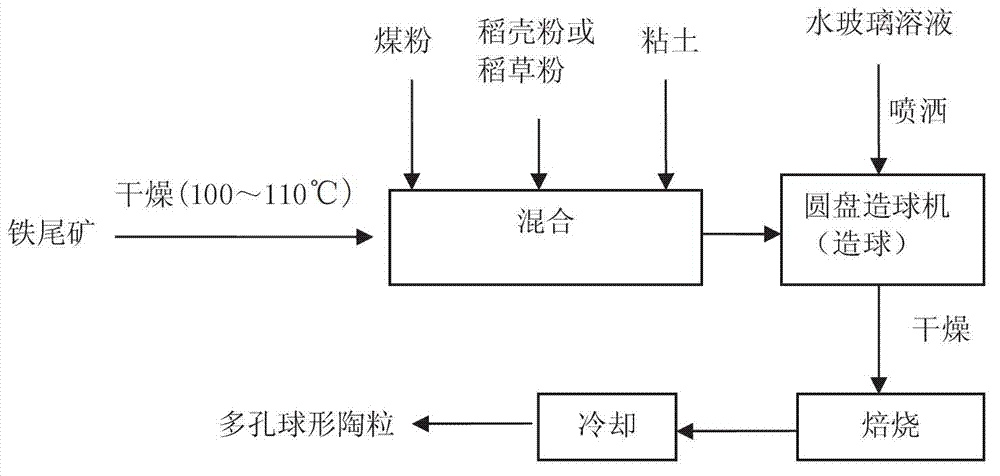

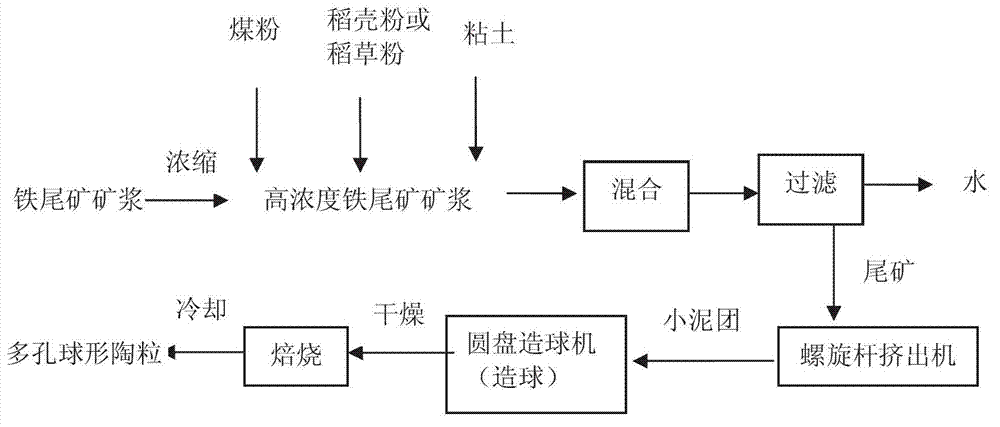

[0034] A preparation method for preparing ceramsite by using low-silicon iron tailings powder, comprising the following steps:

[0035] 1) The raw materials for the preparation of the ceramsite weighed 90 parts of low-silicon iron tailings powder, 6 parts of rice husk powder, 2 parts of coal powder, 1 part of limestone powder and 1 part of clay according to the weight ratio, and respectively at 105 ° C After drying for 4 hours, mix evenly to obtain a mixture;

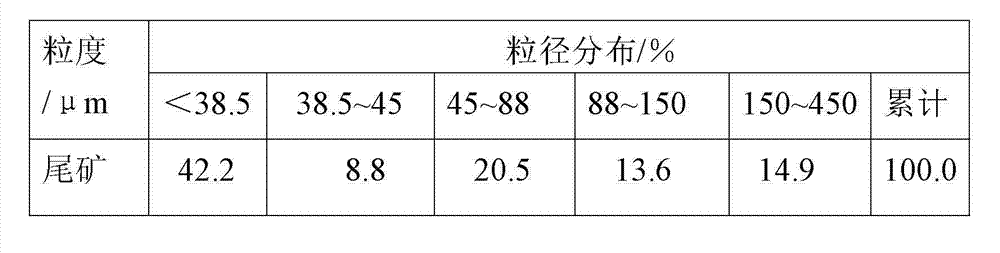

[0036] Among them, the particle size of iron tailings powder is less than 0.45mm, and the particle size of rice husk powder, coal powder and clay is all less than 0.15mm;

[0037] 2) Put the mixture prepared in step 1) into a disc pelletizer to form balls, spray industrial water glass solution with a concentration of 0.5% until the surface of the balls is wetted, and then dry the green balls at 130°C 4h;

[0038] 3) The dried green balls in step 2) were roasted at 1180° C. for 40 minutes, and cooled to obtain fired ir...

Embodiment 2

[0041] A preparation method for preparing ceramsite by using low-silicon iron tailings powder, comprising the following steps:

[0042] 1) The raw materials for the preparation of the ceramsite weighed 85 parts of low-silicon iron tailings powder, 5 parts of straw powder, 3 parts of coal powder, 1 part of limestone powder and 6 parts of clay according to the weight ratio, and dried them at 130°C After 2h, mix evenly to obtain a mixture;

[0043] Among them, the particle size of iron tailings powder is less than 0.45mm, and the particle size of rice husk powder, coal powder, limestone powder and clay is all less than 0.15mm;

[0044] 2) Put the mixture prepared in step 1) into a disc pelletizer to form balls, spray industrial water glass solution with a concentration of 1.0% until the surface of the balls is wetted, and then dry the raw balls at 160°C 2h;

[0045] 3) The dried green balls in step 2) were calcined at 1150° C. for 60 min, and cooled to obtain calcined iron tail...

Embodiment 3

[0048] A preparation method for preparing ceramsite by using low-silicon iron tailings powder, comprising the following steps:

[0049] 1) The raw materials for the preparation of the ceramsite weighed 80 parts of low-silicon iron tailings powder, 9 parts of rice husk powder, 3 parts of coal powder, and 8 parts of clay, and dried them at 120°C for 3 hours, then mixed Evenly, the mixture is prepared;

[0050] Among them, the particle size of iron tailings powder is less than 0.45mm, and the particle size of rice husk powder, limestone powder and clay is less than 0.15mm;

[0051] 2) Put the mixture prepared in step 1) into a disc pelletizer to form balls, spray industrial water glass solution with a concentration of 0.8% until the surface of the balls is wetted, and then dry the raw balls at 140°C 3h;

[0052] 3) The dried green balls in step 2) were roasted at 1160° C. for 50 minutes, and cooled to obtain fired iron tailings ceramsite.

[0053] The particle size of the cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com