Full-coupling magnetic element

A magnetic component and full coupling technology, applied in the field of coupled inductors, can solve the problems of irregular input/output ports, circuit ripple and output current ripple not reaching the best, poor scalability, etc., to achieve good battery life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

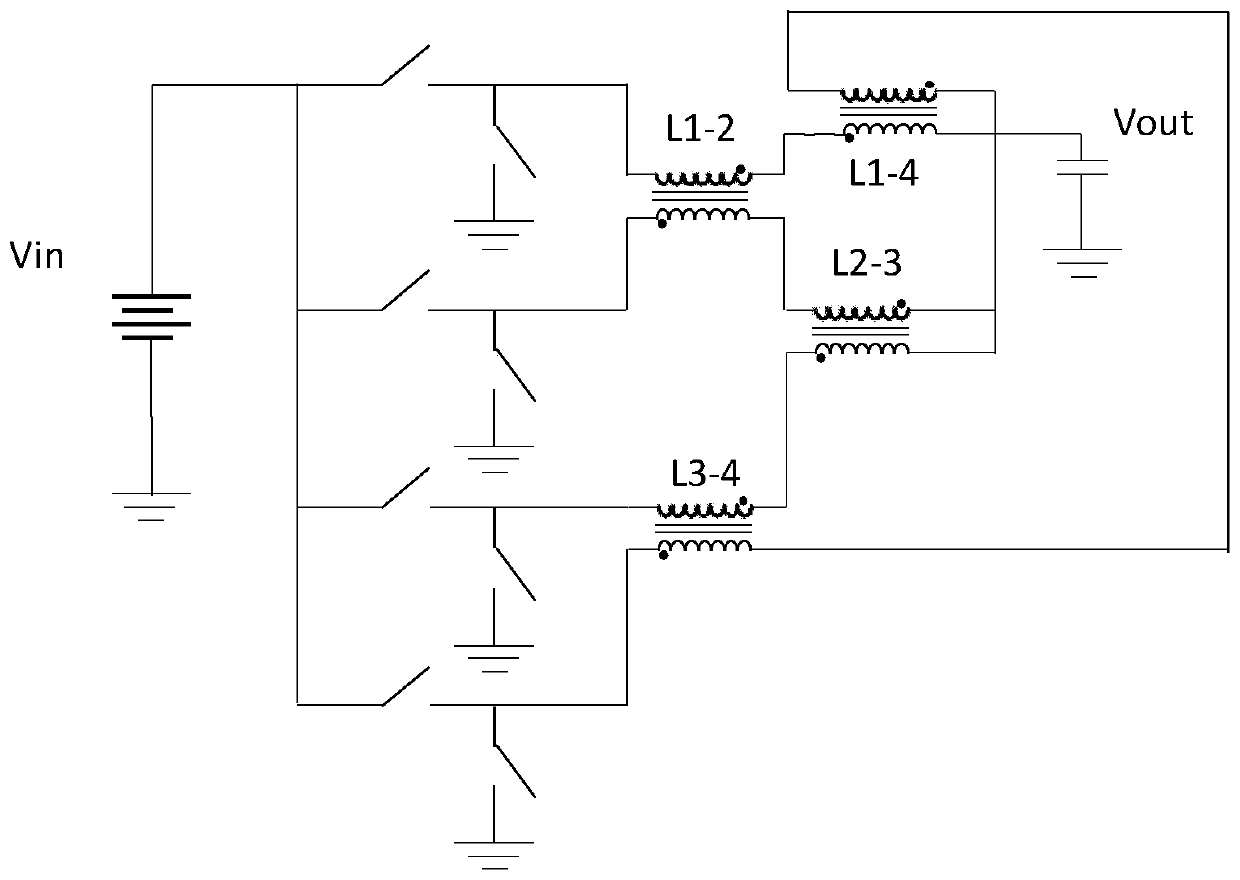

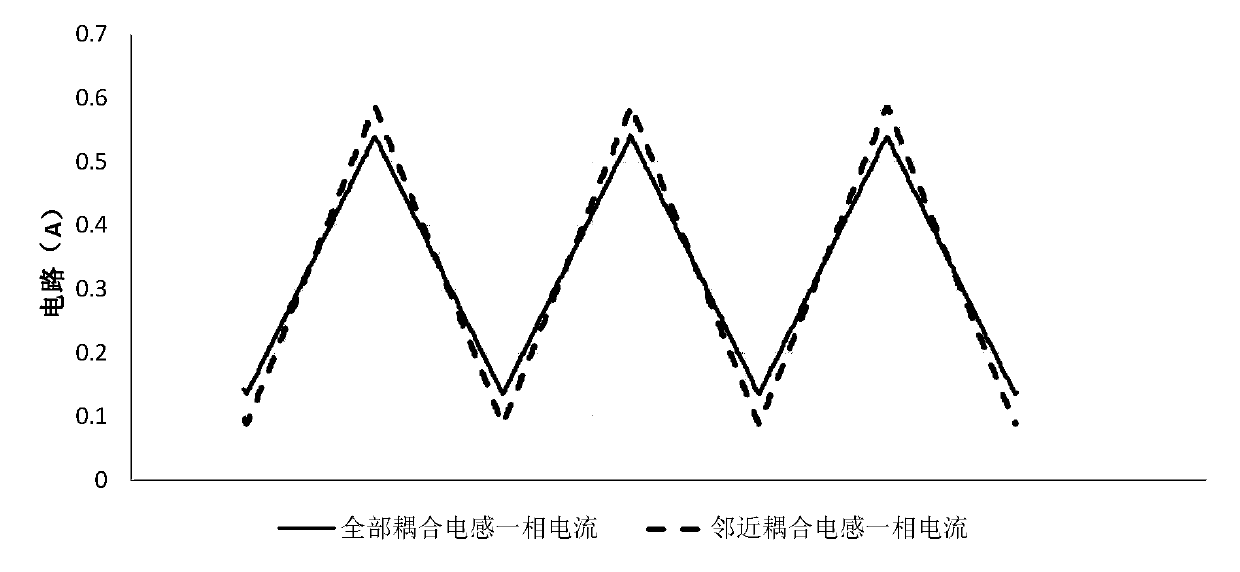

[0055] A fully coupled magnetic element, including at least two-phase circuits, each phase circuit is formed by connecting several coupling units 1, each two-phase circuit is directly coupled through at least one coupling unit 1, and the respective DC components in the two-phase circuit currents generate The direction of the magnetic field is opposite.

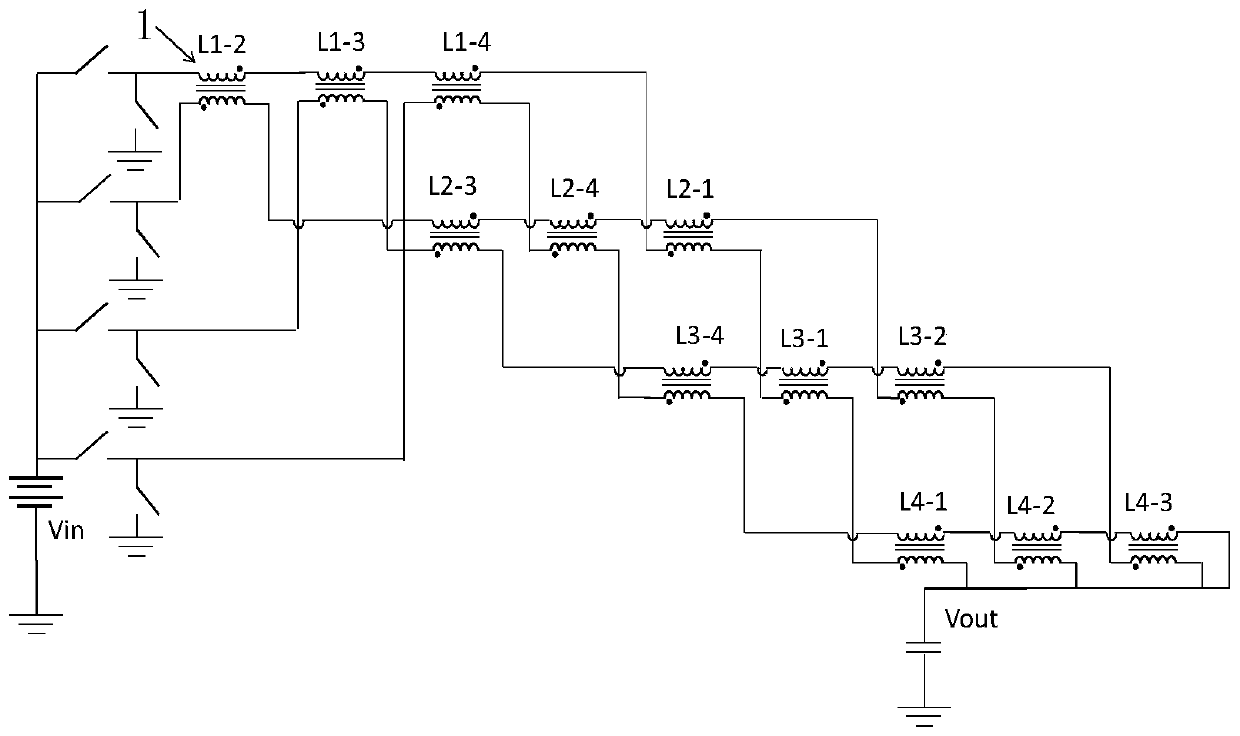

[0056] as attached figure 2 As shown, taking a 4-phase step-down switching power supply as an example, the circuit uses 12 coupling units 1, namely L1-2, L1-3, L1-4, L2-1, L2-3, L2-4, L3-1 , L3-2, L3-4, L4-1, L4-2, L4-3, the current of the first phase starts from the input end and flows through L1-2, L1-3, L1-4, L2-1 in sequence . L3-2, L4-2 reach the output end, forming the second phase current path; the third phase current starts from the input end and flows through L1-3, L2-3, L3-4, L3-1, L3 successively -2, L4-3, reaching the output end, forming the third phase current path; the fourth phase current starts from the inp...

Embodiment 2

[0061] A fully coupled magnetic element, including N rows × (N-1) columns of coupling units 1 with the same structure arranged in a matrix, the matrix is recorded as: A=(a ij ) N×N-1 , where a ij is the coupling unit 1 in the i-th row and j-column of matrix A, N is a natural number ≥ 2, i=1, 2, 3,...N, j=1, 2, 3,...N-1, each coupling The unit (1) has a magnetic core 2, a forward winding coil 3 and a reverse winding coil 4, the two winding coils are wound on the magnetic core 2 or the magnetic core 2 wraps the two winding coils, the number of turns of the two winding coils The same, and the direction of the magnetic field lines generated by the coil currents of the two windings in the core 2 is opposite. The N input terminals are located on the same side of the matrix, and the N output terminals are located on the other side of the matrix. When p=1, the first input ends through a 11 , a 12 , a 13 ,...a 1(N-1) The forward winding coil 3, and then through a 2(N-1) , a ...

Embodiment 3

[0076] Other parts are as shown in embodiment 2, the difference is: as attached Figure 11a , 11b , 11c are schematic diagrams of four-phase, three-phase, and two-phase full-coupling magnetic components in this embodiment, wherein the magnetic core 2 is a closed loop, which can form a closed magnetic flux loop and increase the inductance per unit area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com