Soluble fluorinated polyimide material and preparation method thereof

A fluorinated polyimide and soluble technology, which is applied in the field of soluble fluorinated polyimide materials and its preparation, can solve problems rarely involving three-monomer fluorinated polyimide, and achieve good solubility, Excellent thermal stability and low absorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

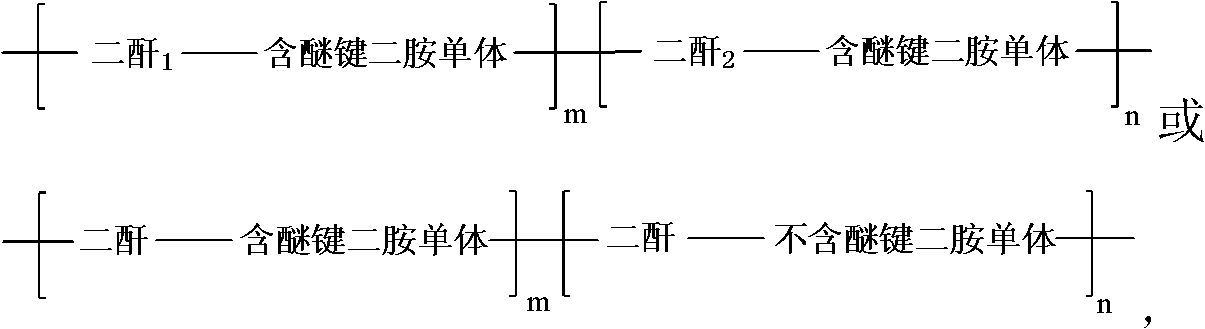

[0037] The preparation method of this soluble fluorinated polyimide optical material is:

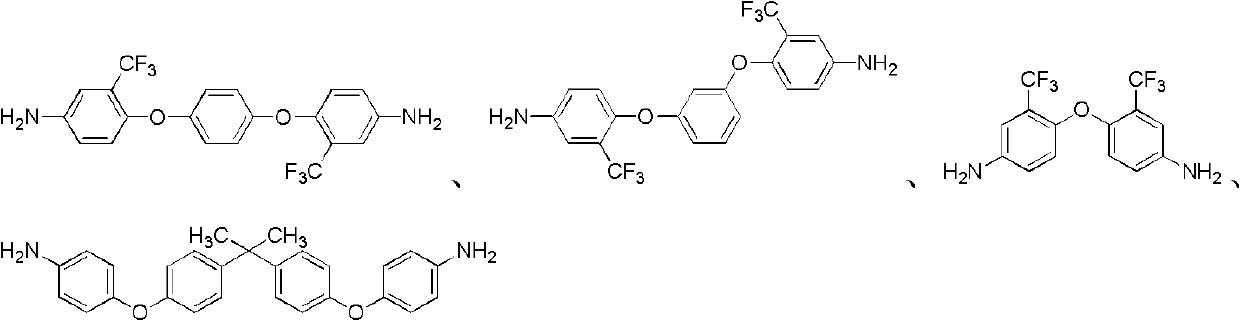

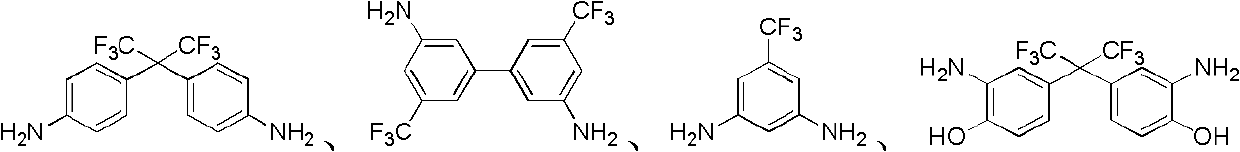

[0038] a) The molar ratio of the total moles of the two dianhydride monomers to the ether bond-containing diamine monomer is 1:1, wherein the molar ratio of the two dianhydride monomers is 1:1 to 1:10. Under the conditions of nitrogen protection and ice bath, N, N-dimethylformamide solutions of two dianhydride monomers with a mass concentration of 5wt% to 50wt% and 5wt% to 50wt% of diamine monomers containing ether bonds Add the N, N-dimethylformamide solution into the reaction kettle, mix it and react at room temperature for 12-72 hours. Based on the total monomer mass of the polymerized monomers added, 5-5 10mL of xylene, heat up to 140-200°C, continue to react for 3-10 hours, the water formed by the reaction and xylene forms an azeotrope and evaporates, and after cooling to room temperature, a solution of soluble fluorinated polyimide material is obtained; The ratio of the total moles ...

Embodiment 1

[0043] The dianhydride 4,4'-(hexafluoroisopropyl)-phthalic anhydride (0.1111g, 0.25mmol, 6FDA), 4,4'-(4,4'-isopropyl-di-phenoxy ) bis(phthalic anhydride) (0.1301 g, 0.25 mmol, BPADA) and 1,4-bis(4-amino-2-trifluoromethylphenoxy) benzene (0.2140 g, 0.5 mmol, pBATB) were dissolved in N,N-dimethylformamide. Under nitrogen protection and ice bath conditions, the N,N-dimethylformamide solution of two dianhydride monomers with a mass concentration of 50wt% and 1,4-bis(4-amino-2- The N,N-dimethylformamide solution of trifluoromethylphenoxy)benzene was added to the reaction kettle, and at room temperature, it was reacted for 24 hours, and then 2 mL of xylene was added, and the thermal cyclization reaction was carried out at 165°C for 6 hours, and the reacted The solution was added dropwise to a mixed solution of 150 mL of methanol / water (the volume ratio of methanol to water was 1:1) and 1N HCl (2 mL), and a precipitate was precipitated, followed by suction filtration to obtain a cru...

Embodiment 2

[0047] The dianhydride 4,4'-(hexafluoroisopropyl)-phthalic anhydride (0.2222g, 0.5mmol, 6FDA), 1,4-bis(4-amino-2-trifluoromethylphenoxy) Benzene (0.1070g, 0.25mmol, pBATB) and 2,2'-bis[4-(4-aminophenoxy)phenyl]propane (0.1026g, 0.25mmol, BAPP) were dissolved in N,N-dimethyl In base formamide. A saturated solution was obtained. Under nitrogen protection and ice bath conditions, the N,N-dimethylformamide solution of two diamine monomers with a mass concentration of 50wt% and 4,4'-(hexafluoroisopropyl) of 50wt% were respectively - Add the N,N-dimethylformamide solution of phthalic anhydride into the reaction kettle, react at room temperature for 24 hours, then add 2 mL of xylene, heat cyclization reaction at 165°C for 6 hours, and add the reacted solution dropwise to 150 mL In a mixed solution of methanol / water (the volume ratio of methanol to water is 1:1) and 1N HCl (2mL), a precipitate was precipitated, and then filtered with suction to obtain a crude soluble fluorinated pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com