Hydrogenation process

A process method and hydrocracking technology, which is applied in the fields of hydroprocessing process, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as blockage of air coolers and fractionation towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

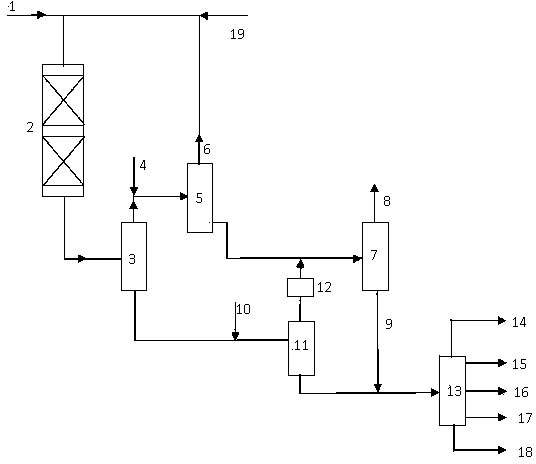

Image

Examples

Embodiment 1

[0021] Example 1 is a two-stage technological process for processing high-sulfur and high-nitrogen raw materials, and Example 2 is an example of processing a high-sulfur and high-nitrogen raw material with a series of technical processes, and the heat and low fraction oil are fed into the gas to extract hydrogen. Reference example 1 is two stages The technological process is for processing high-sulfur and high-nitrogen raw materials. Reference example 2 is a tandem process for processing high-sulfur and high-nitrogen raw materials. The hot low fraction oil is not fed into the gas stripping hydrogen to illustrate the advanced hydrocracking process for processing high-sulfur and high-nitrogen raw materials. sex. Conditions and results are shown in Table 1 below.

[0022] Table 1 Example of hot low-fraction oil passed through to strip hydrogen.

[0023] implementation plan Example 1 Example 2 Reference example 1 Reference example 2 Raw oil properties ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com