Patents

Literature

34results about How to "Does not affect storage stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paint for H grade polyurethane enamelled wire with good saline water needle performace capable of directing welding at low temp.

InactiveCN1597815AImprove heat resistanceQuality improvementPlastic/resin/waxes insulatorsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to an H-grade wire coating enamel that has good salt water pinhole performance and can be directly welded at low temperature, containing hydroxyl component, sealed isocyanate component and solvent, where its hydroxyl component has an acid value less than 2, a hydroxyl value of 150-300, and number-average molecular weight of 1500-5000, and as synthesized, the raw materials has at least m-phthalic acid, p-phthalic acid, adilic acid, glycerin and a kind of dibasic alcohol in the weight ratio of 1 to (0.2-2) to (0.2-0.5) to (0.5-3) to (0.5-1.5); and its sealed isocyanate component is partially added of MDI by mixed polyalcohol that at least has a dibasic alcohol and a tribasic alcohol; in the paint base, the equivalent ratio of isocyanate base to OH is (0.9-1.2) : 1, and it reaches H-grade and has good salt water pinhole property of paint film, tin daubing temperature less than or equal to 375 deg.C.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

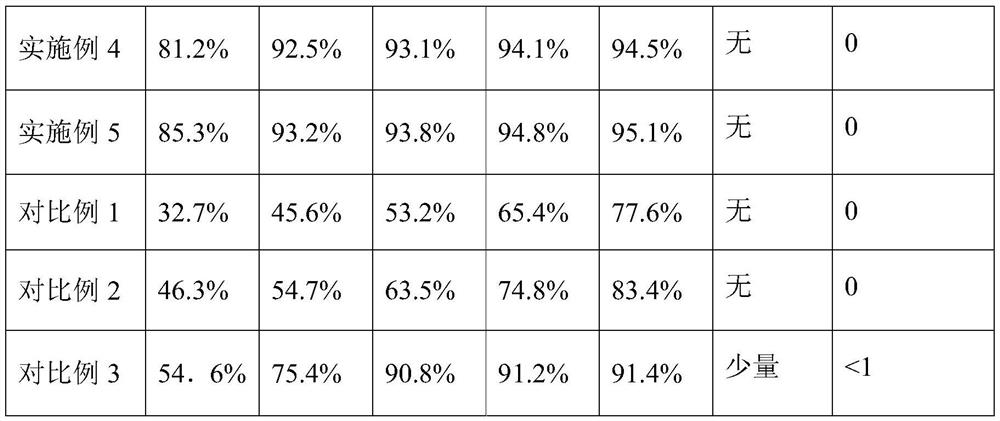

Environmentally-friendly water and oil repellent fluorinated acrylate emulsion and preparation method and application thereof

ActiveCN104418970AExcellent water and oil repellency and stain resistanceGood washing resistanceFibre treatmentEmulsionPolymer chemistry

The invention discloses environmentally-friendly water / oil-repellent fluorinated acrylate emulsion and a preparation method thereof. The fluorinated acrylate emulsion is mainly prepared from 3-chloro-2-hydroxy propyl methyl acrylate, a fluorine-containing alkyl acrylate monomer, an acrylate monomer, a crosslinking monomer, a non-ionic emulsifier, a cationic emulsifier, a modifier, an initiator and deionized water. The fluorinated acrylate emulsion prepared by using the method can be applied to a textile finishing agent; and the textile finished by the emulsion has excellent water and oil repellency and anti-pollution characteristic.

Owner:DYMATIC CHEM

Two-component polymer cement waterproof coating

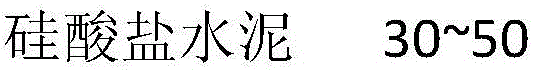

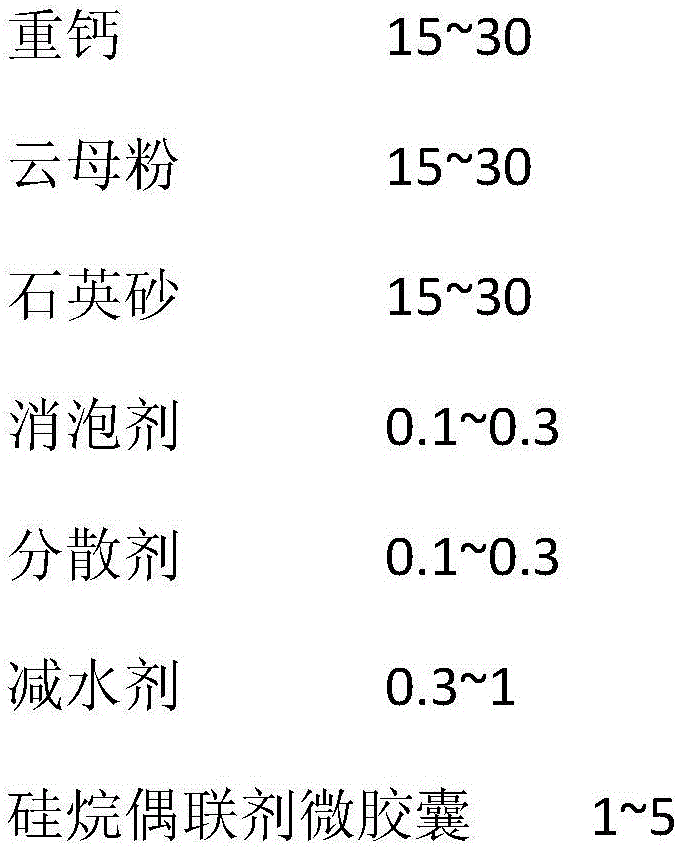

The invention discloses a two-component polymer cement waterproof coating, which is composed of a liquid material and a powdery material. The ratio of the liquid material to the powder material is 1:2-2:1. The liquid material is a pure acrylate emulsion. The powder material is composed of the following ingredients (by weight): 30-50 parts of Portland cement, 15-30 parts of ground calcium carbonate, 15-30 parts of mica powder, 15-30 parts of quartz sand, 0.1-0.3 part of an antifoaming agent, 0.1-0.3 part of a dispersant, 0.3-1 part of a water reducer and 1-5 parts of microcapsules of a silane coupling agent. By using water-soluble starch and water-soluble polymer compound as a wall material and using a silane coupling agent as a core material, an oil-in-water emulsion is firstly prepared, and then the emulsion is spray-dried so as to prepare the microcapsules of the silane coupling agent. The two-component polymer cement waterproof coating with addition of the microcapsules of the silane coupling agent has strong tensile strength and also has good flexibility and water resistance.

Owner:SOUTH CHINA UNIV OF TECH

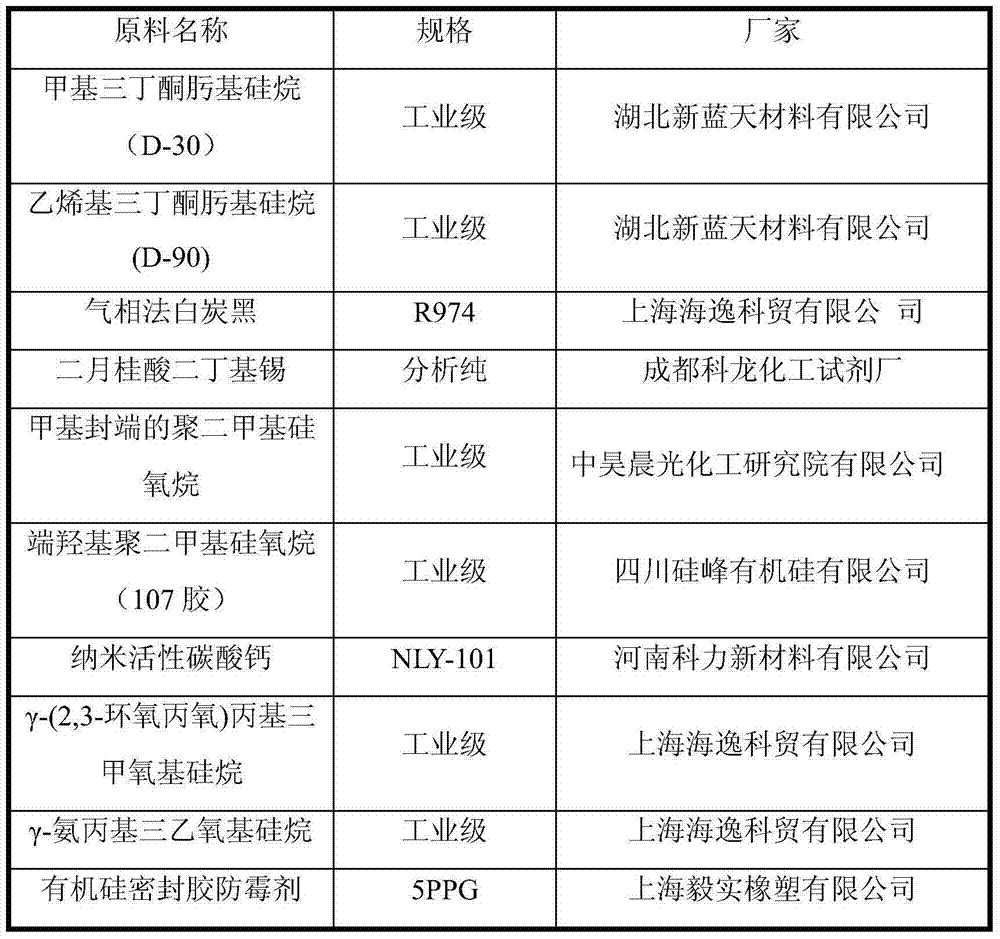

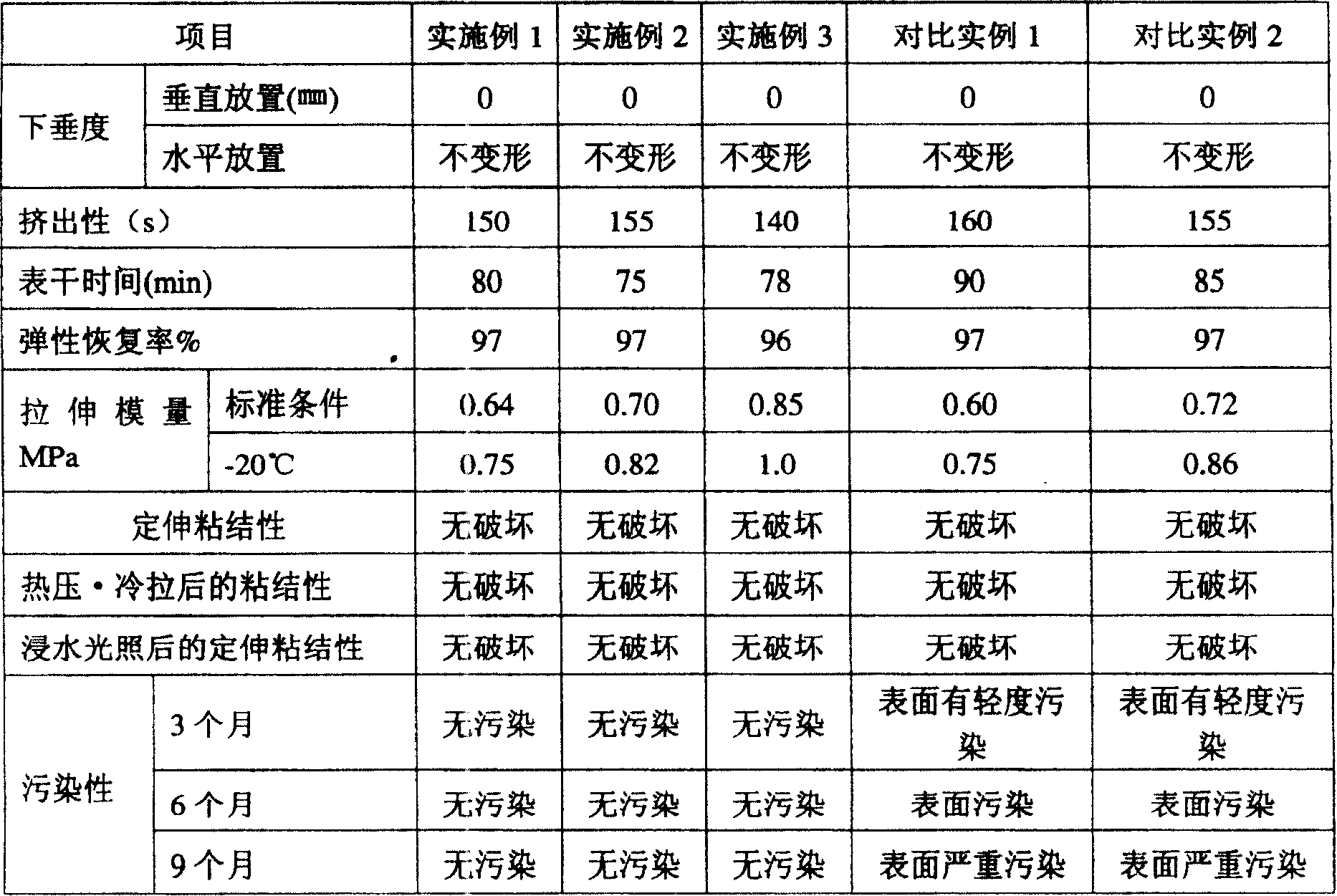

Mold-proof silicone sealant and preparation method thereof

InactiveCN104232012AGood compatibilityImprove thixotropyNon-macromolecular adhesive additivesOther chemical processesChemistrySilane coupling

The invention belongs to the field of the silicone sealants and specifically relates to a mold-proof silicone sealant and a preparation method thereof. The mold-proof silicone sealant and the preparation method thereof are used for solving the technical problems of an existing mold-proof silicone sealant product such as yellowing after solidification, relatively poor compatibility of a mold-proof agent and a basis adhesive material and degradation of the storage stability of the adhesive material after the mold-proof agent is added. The mold-proof silicone sealant is prepared from such components in parts by weight as 100 parts of hydroxyl-terminated polydimethylsiloxane, 0-80 parts of plasticizer, 5-35 parts of fumed silica, 1-10 parts of cross-linking agent, 0.05-1.8 parts of mold-proof agent, 0.5-5 parts of silane coupling agent and 0.1-5 parts of catalyst. The invention also provides the preparation method of the mold-proof silicone sealant. The mold-proof agent and the adhesive material of the mold-proof silicone sealant are good in compatibility with each other and have no influence on the mechanical performance index of the mold-proof silicone sealant and the storage stability of the adhesive material, and therefore, the mold-proof silicone sealant can be applied to different occasions.

Owner:LUZHOU NORTH CHEM IND

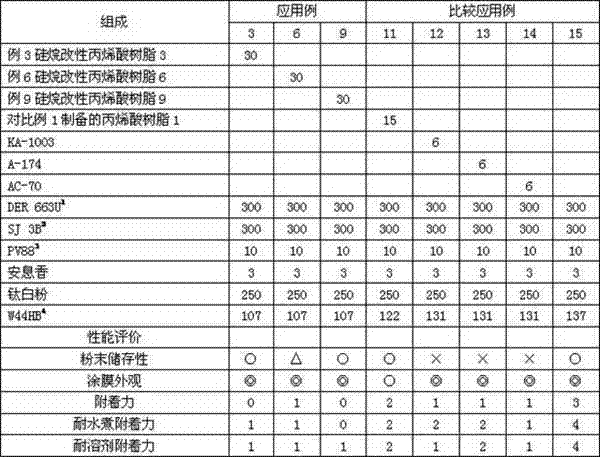

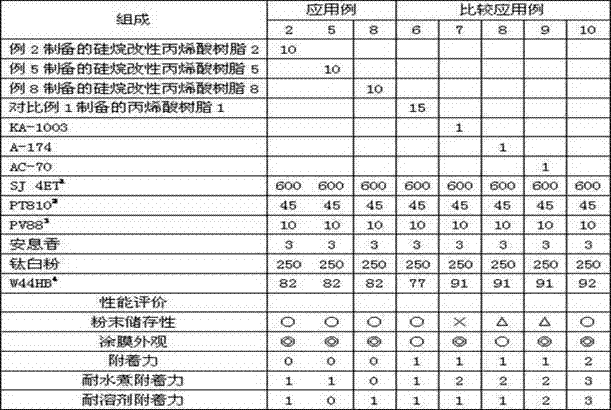

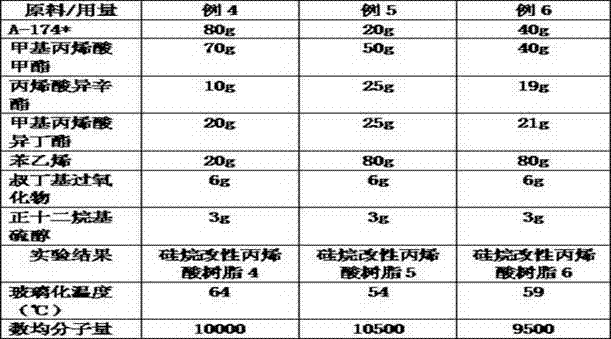

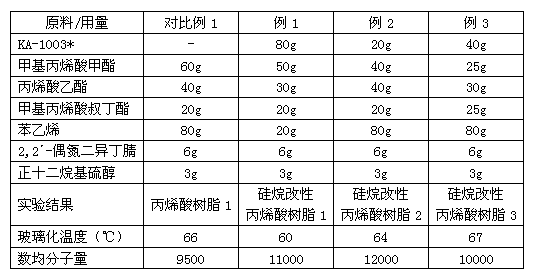

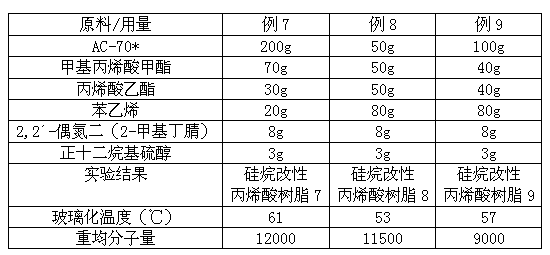

Method for preparing high-adhesive force solid acrylic resin modified by organosilane

ActiveCN103694409ADoes not affect storage stabilityImprove adhesionPowdery paintsPolyester coatingsPolymer scienceAcrylic resin

The invention discloses a method for preparing high-adhesive force solid acrylic resin modified by organosilane. The method disclosed by the invention can be used for preparing the high-adhesive force solid acrylic resin by introducing an organosilane monomer into acrylic resin through a chemically bonding mode; the prepared modified solid acrylic resin as an additive is added to a powder coating system, can outstandingly enhance the adhesive force of a powder coating layer on a substrate and specific substrates, such as a galvanized plate and stainless steel, especially, cannot influence the storage stability of the powder coating due to excellent self characteristics of the solid acrylic resin and achieves certain improvement on the solvent resistance and boiling resistance of the powder coating layer.

Owner:六安捷通达新材料有限公司

Anti-fouling single-component room temperature sealing silicone sulfide glue and its production process

The anti-fouling single-component room temperature sealing silicone sulfide glue features that silicon oil with molecular end radical Si-H and dry oil addition component as anti-fouling component in 5-30 weight portions, poly(alpha, omega-dihydroxy siloxane in 100 weight portions and active calcium carbonate in 70-130 weight portions are dewatered and mixed in a vacuum stirrer at 100-150 deg.c and vacuum degree of 0.06-0.099 MPa for 30-200 min, and cooled to obtain the base material. At room temperature, cross-linking agent in 5-15 weight portions, silane coupler in 0.5-5 weight portions and catalyst in 0.5-1.5 weight portions are then added inside a high speed dispersing stirrer or a planetary stirrer at vacuum degree 0.06-0.099 MPa and rotation speed 200-600 rpm for 30-150 min.

Owner:CHENGDU GUIBAO SCI & TECH

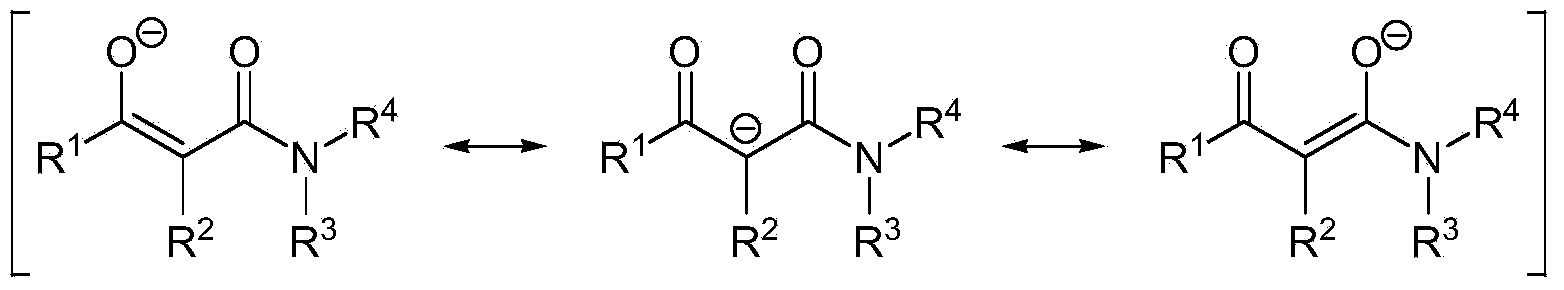

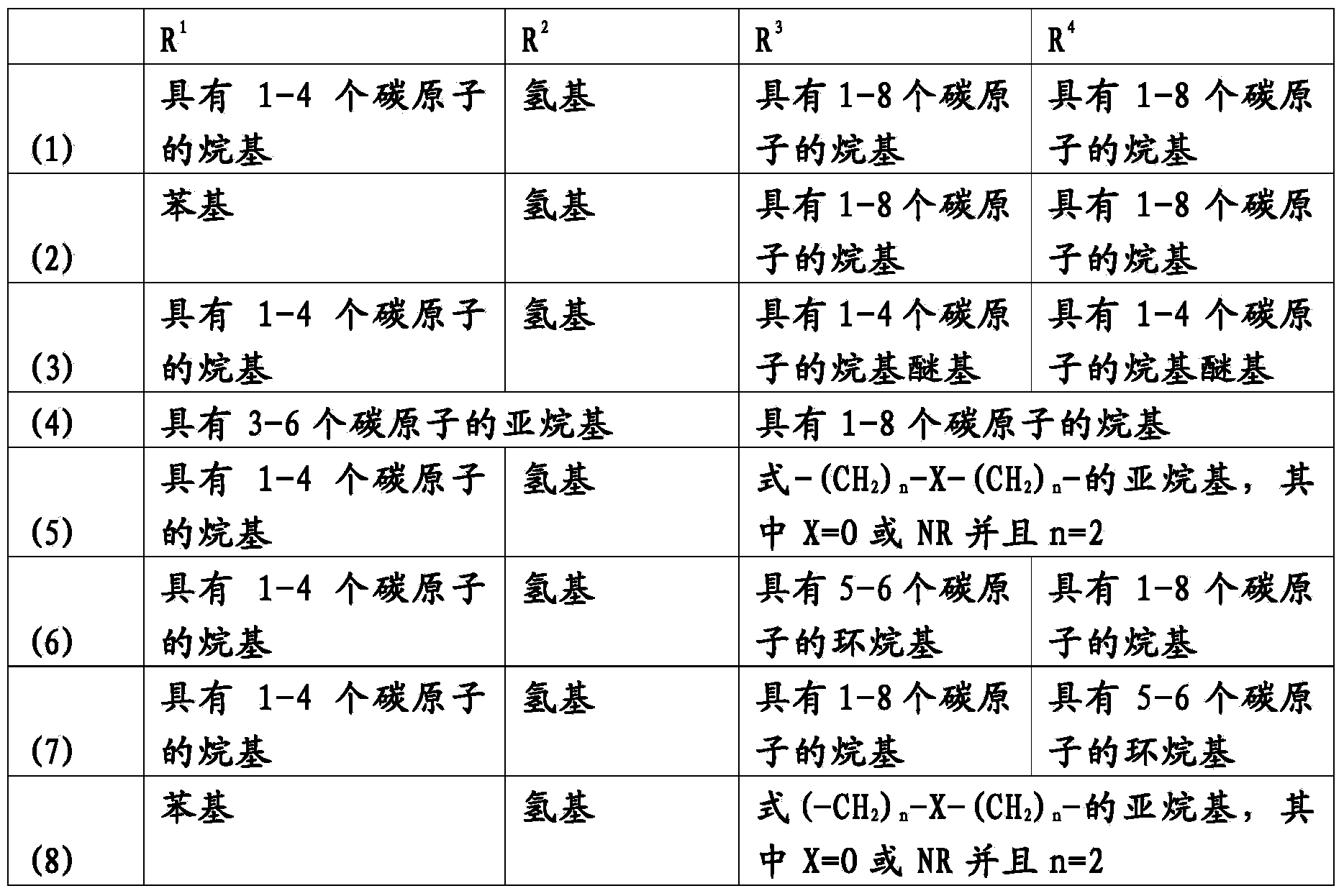

Zinc(ii) complex compounds as catalysts for polyurethane compositions

Zinc(II)-complex compound (I), is new. Zinc(II)-complex compound of formula (Zn(L) x(Y) 2-x) (I), is new. x : 1 or 2; Y : single negatively charged ligand; L : ligand of formula (R1-C(O ->)=C(R2)-C(=O)-N(R3)(R4)) (II); R1, R2 : H, optionally saturated 1-10C hydrocarbyl or 3-6C divalent alkylene; and R3, R4 : H, monovalent saturated hydrocarbyl (optionally containing 1-12C heteroatoms), or divalent alkylene (optionally containing 3-6C heteroatoms). Independent claims are also included for: (1) preparing (I); and (2) two-component polyurethane composition comprising at least one polyol as first component, at least one polyisocyanate as second component and zinc(II)-complex compound.

Owner:SIKA TECH AG

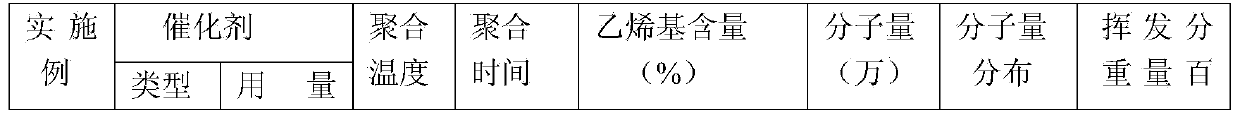

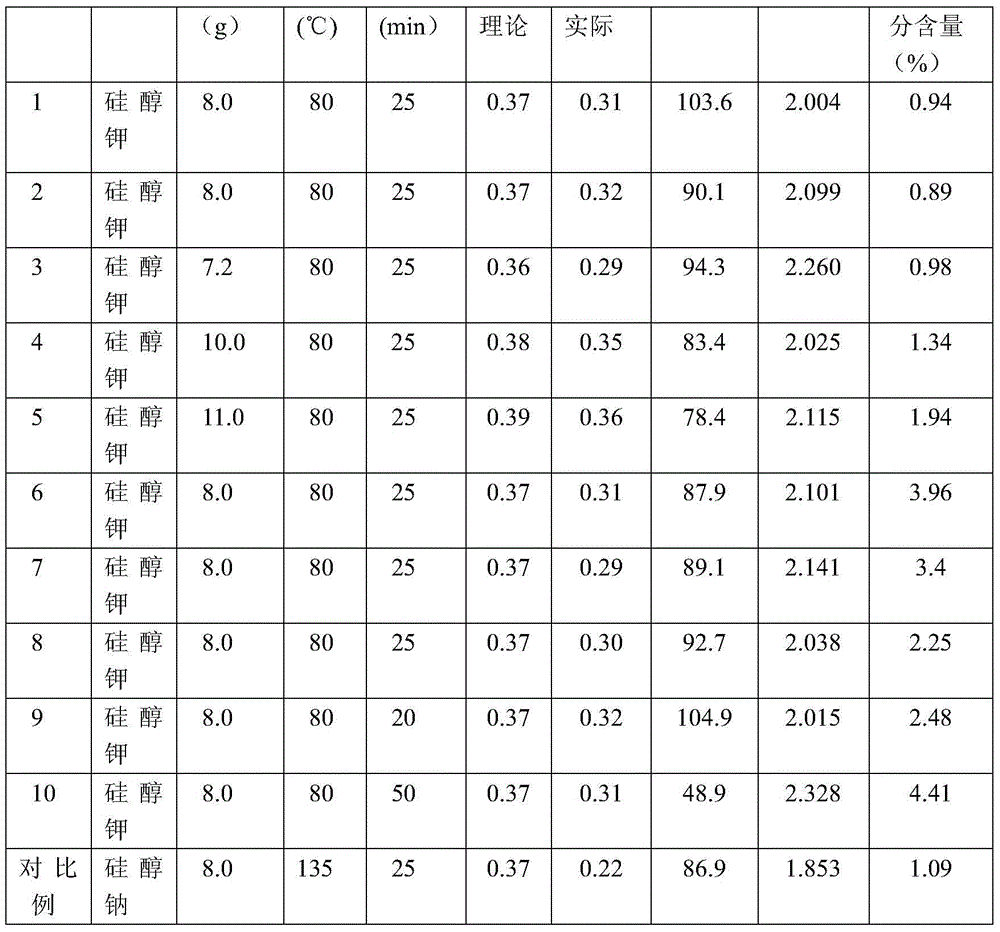

Preparation method of heat curing fluorosilicone raw rubber

The invention relates to a preparation method of heat curing fluorosilicone raw rubber. The preparation method comprises the following steps: adding D3F and D4Vi into a reactor and then dehydrating D3F and D4Vi, adding prepared potassium silanolate catalyst pre-polymer, heating, introducing nitrogen and stirring to carry out polymerization, wherein the temperature is 60-115 DEG C and the reaction time is 20-100min, neutralizing with a neutralizer until the reactant is neutral, and finally, removing small molecular substances from the material, reducing temperature and discharging. Due to the adoption of the potassium silanol catalyst pre-polymer with high activity, the reaction temperature is low, the accelerant is not required, an end-capping reagent is not required in the polymerization process, and the nitrogen purging manner is adopted in the stage of removing the small molecular substances from the material, the volatile matter of the heat curing fluorosilicone raw rubber is reduced; the prepared heat curing fluorosilicone raw rubber can be widely used in the fields of aerospace, petrochemical industry, automobiles, artificial organ, and the like, and has a good promotional value.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Novel efficient insulating mould coating

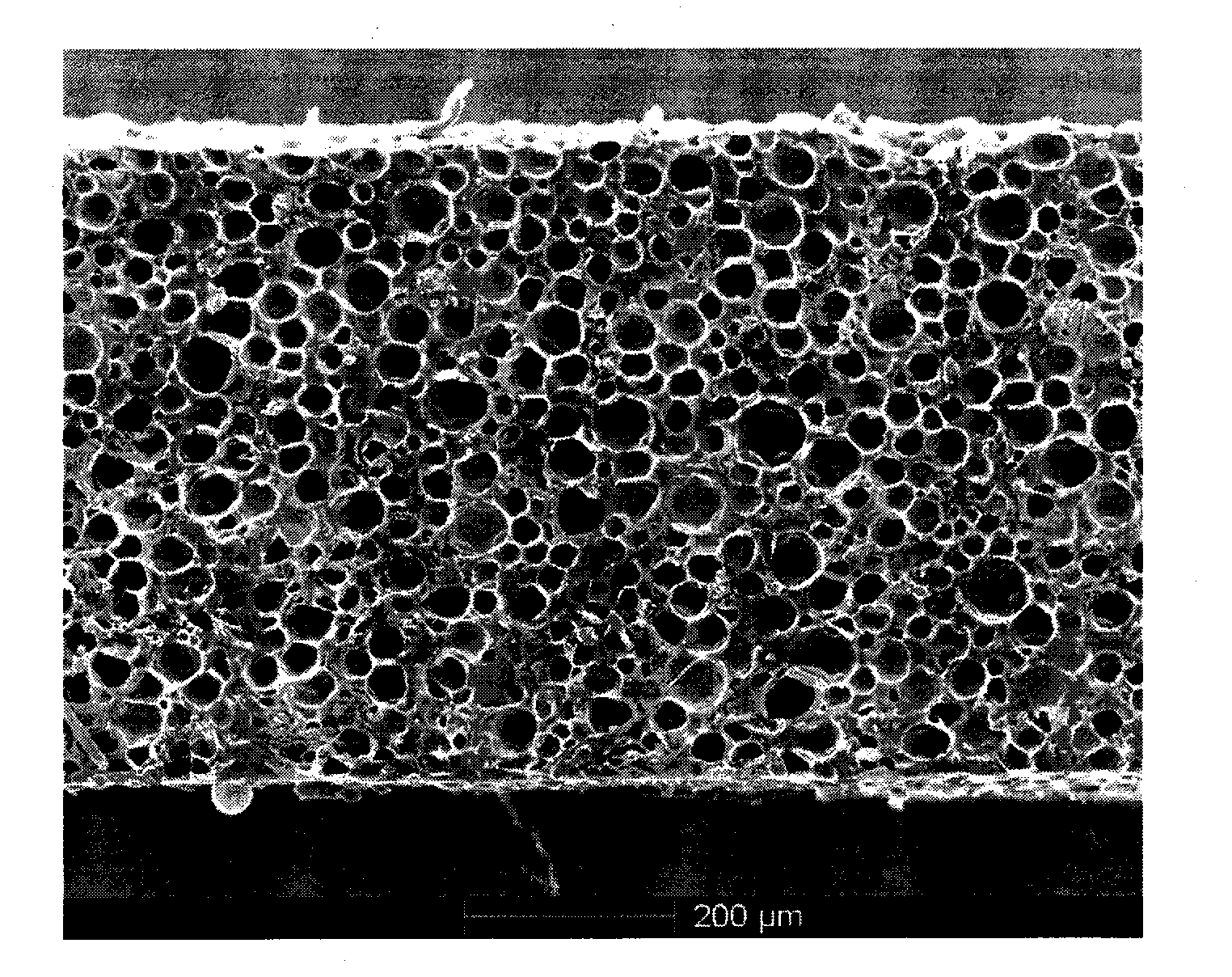

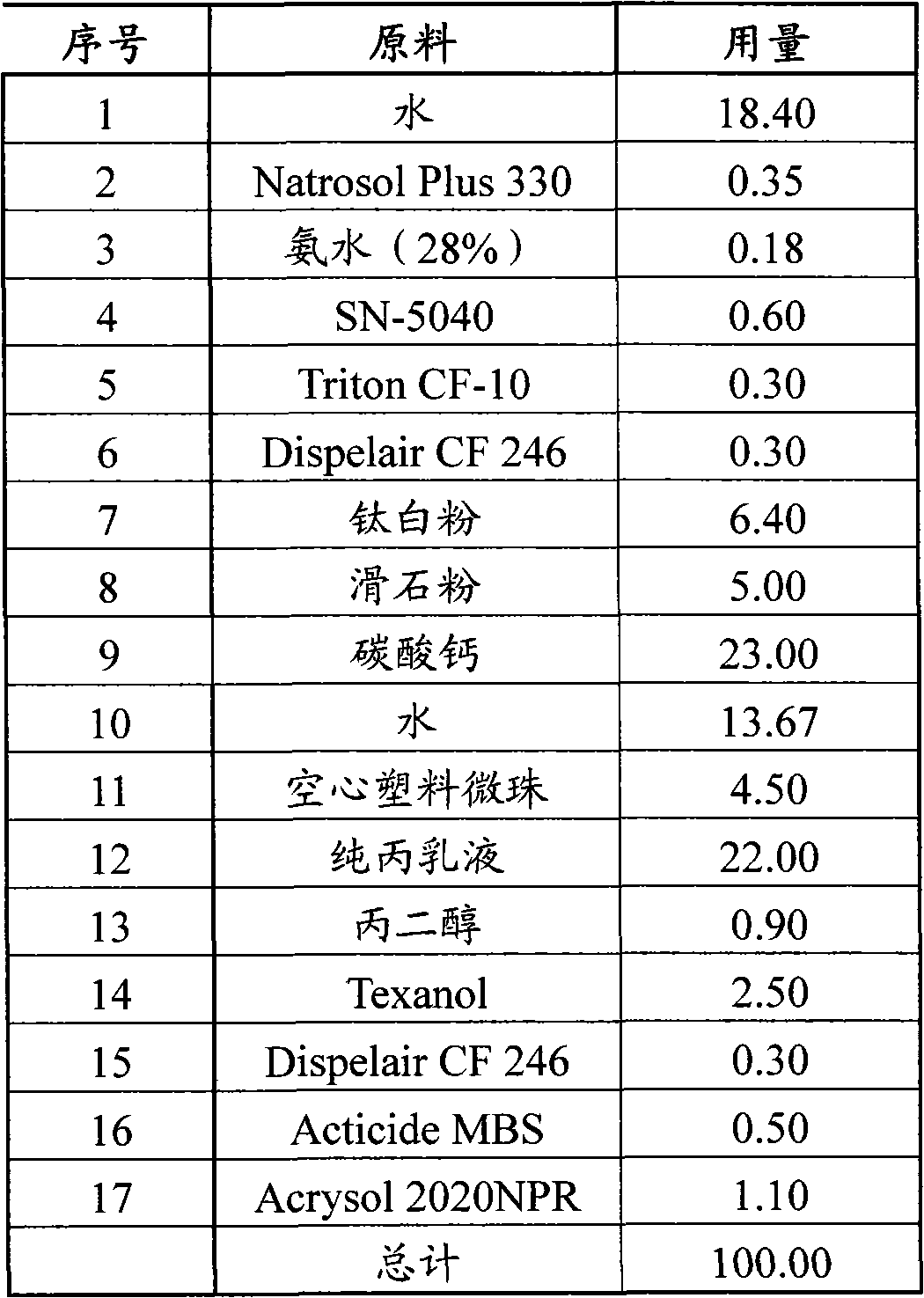

The invention relates to a novel efficient insulating mould coating which is formed by a functional filler plastic cenosphere with low density and insulation effect and an assistant based on synthetic resin as a base material. The novel efficient insulating mould coating comprises the following raw materials in percent by weight: 10-45 percent of emulsion, 2-25 percent of titanium white, 10-45 percent of pigment padding, 10-40 percent of water, 2-10 percent of plastic cenosphere, 0-6 percent of film-forming additive, 0.5-2.0 percent of thickening agent, and less amount of dispersing agent, defoaming agent, fungicide, surface activating agent and the like. Compared with the traditional insulating coating adopting glass cenosphere or ceramic cenosphere, the novel efficient insulating mould coating has the characteristics of good insulation effect, convenient construction production and better storage stability; meanwhile, because of having the characteristics of efficient filling property, low oil suction and low density, the plastic cenosphere can effectively reduce the unit volume cost of the coating, and can be widely applied to indoor decoration of various high-standard hotels, office buildings and homes.

Owner:PPG Coatings (Shanghai) Co Ltd

Acrylic acid structural adhesive with good weatherability and stability

InactiveCN104327752AGood high and low temperature resistanceLong operating timeOrganic non-macromolecular adhesiveChemistryPlasticizer

The invention relates to an acrylic acid structural adhesive with good weatherability and stability and a preparation method thereof, the acrylic acid structural adhesive comprises a component A and a component B, the component A is composed of an acrylic acid ester monomer, an elastomer, a promoter, a coupling agent, a stabilizing agent and an auxiliary agent, and the component B is composed of an oxidizing agent, a plasticizer, epoxy resin and an auxiliary agent. The prepared acrylic acid structural adhesive has the characteristics of good weatherability, high stability, good manufacturability and high strength.

Owner:YANTAI DARBOND TECH

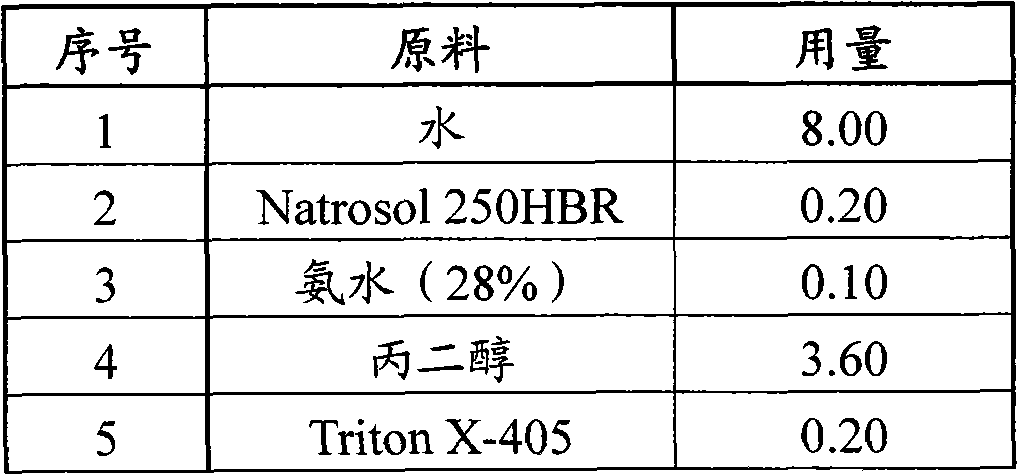

Electrostatic flocking water-based adhesive for iron hanger and preparation method of water-based adhesive

InactiveCN107936899AOvercome the disadvantage of poor water resistanceImprove firmnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedEmulsion

The invention provides an electrostatic flocking water-based adhesive for an iron hanger. The water-based adhesive comprises the following raw materials in parts by weight: 100 parts of aqueous polyurethane emulsion, 1-5 parts of an antifoaming agent, 1-5 parts of a flatting agent, 0.1-0.5 part of a thickening agent and 1-5 parts of a closed crosslinking agent. According to the electrostatic flocking water-based adhesive disclosed by the invention, the self-crosslinking water-based adhesive serves as a flocking adhesive, so that the defects of waterborne acrylic emulsion in aspects such as wear resistance, water resistance, temperature resistance and softness are overcome.

Owner:东莞智炜新材料股份有限公司

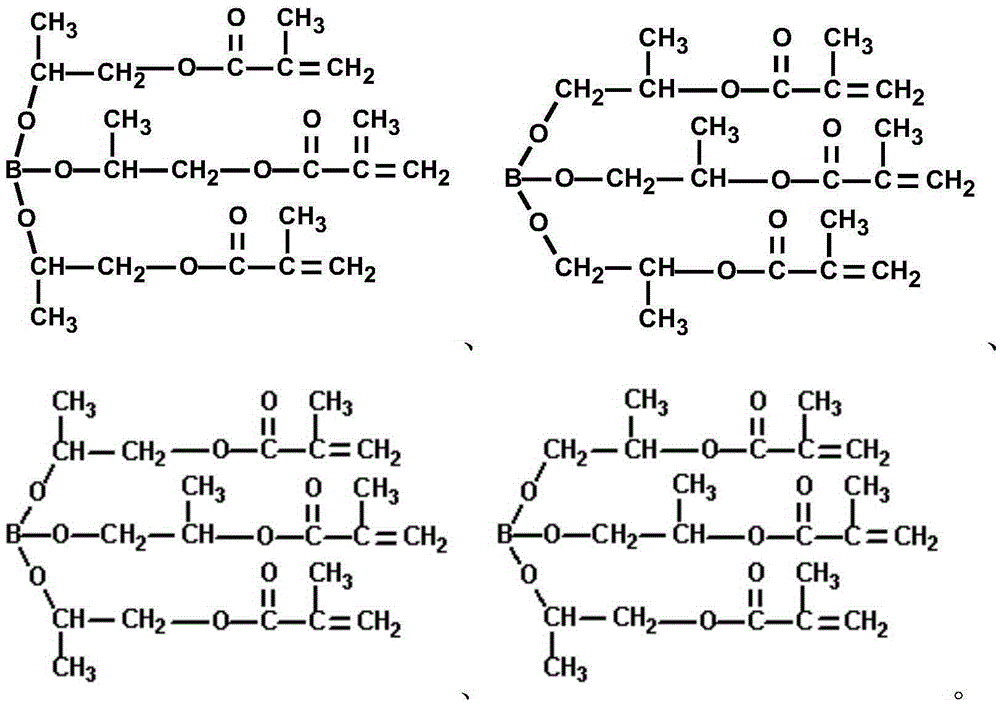

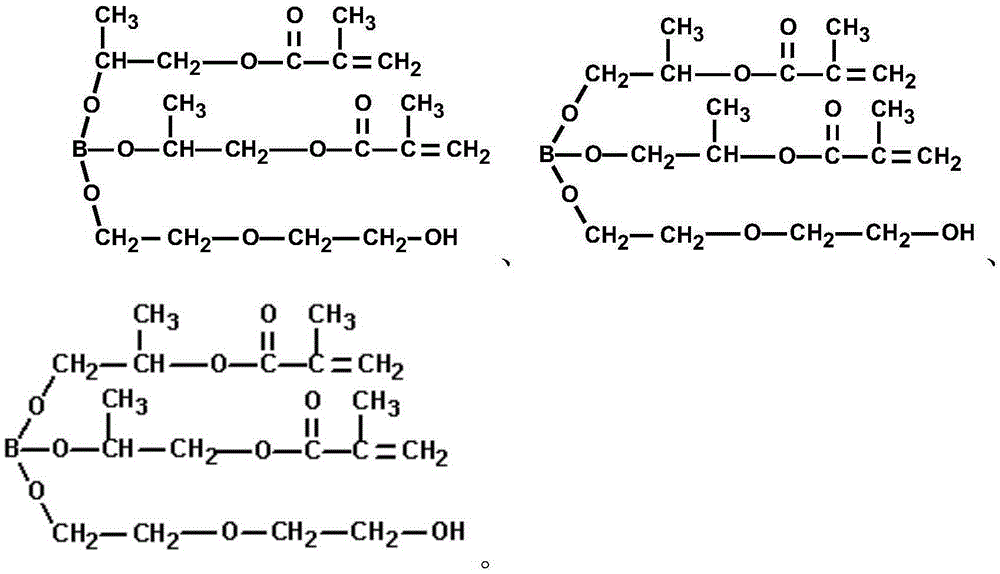

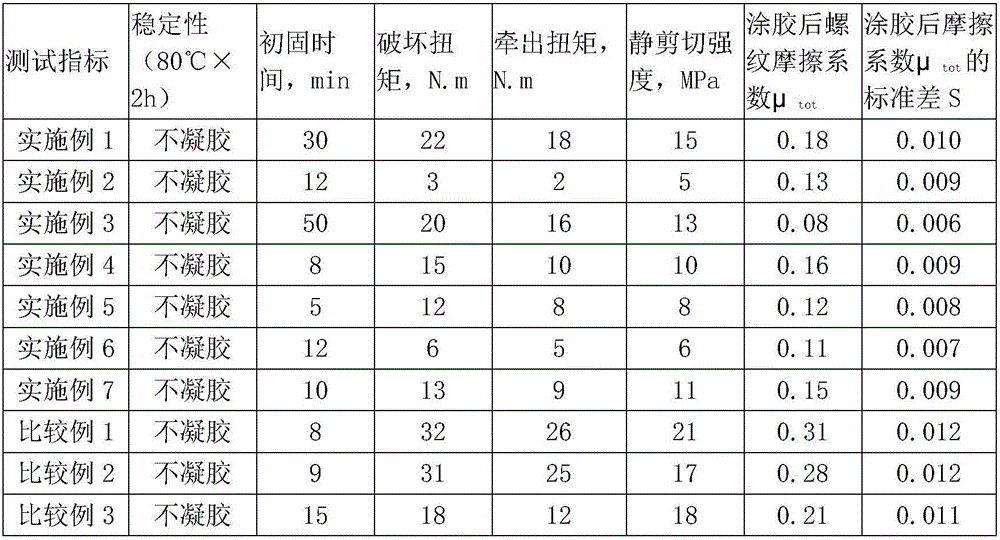

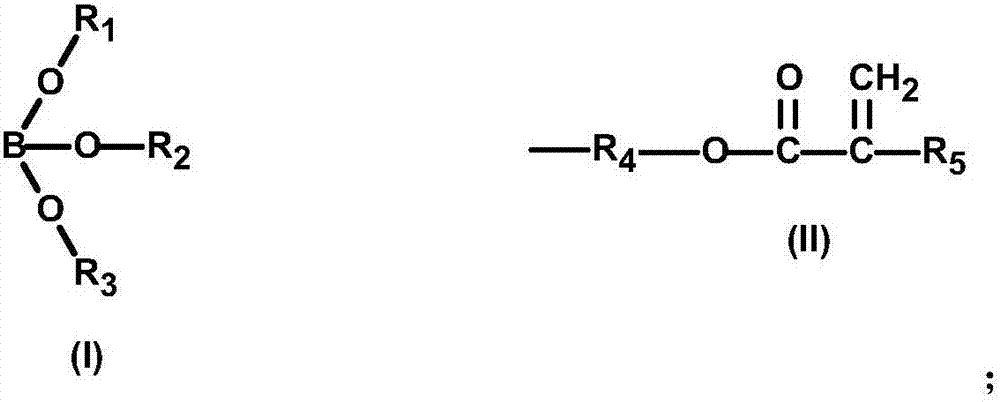

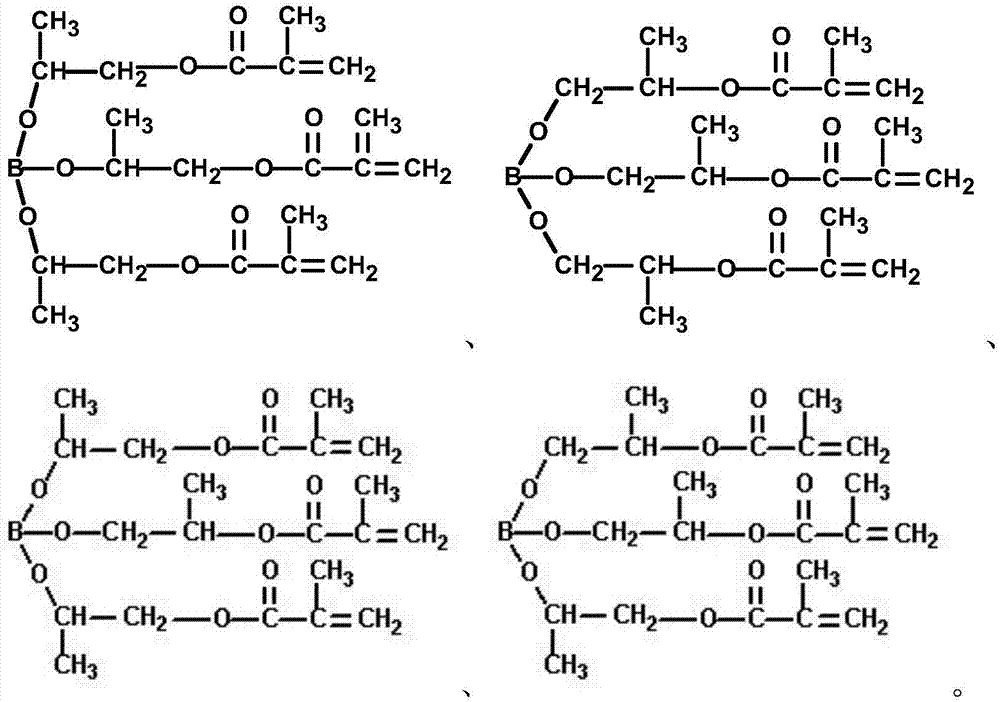

Lubricating type threaded locking sealing anaerobic adhesive and preparation method

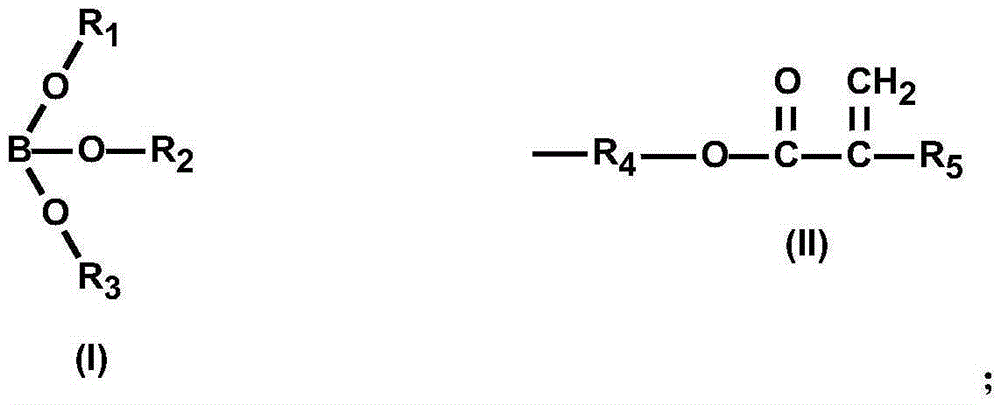

ActiveCN105295747AImprove the lubrication effectLubricatingNon-macromolecular adhesive additivesOther chemical processesAdhesiveGas phase

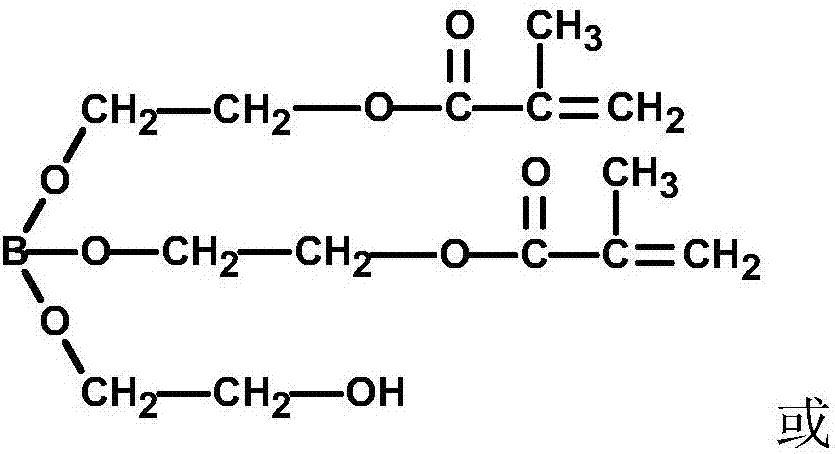

The present invention discloses a lubricating type threaded locking sealing anaerobic adhesive and a preparation method thereof, and relates to the field of threaded locking sealing anaerobic adhesives, wherein the anaerobic adhesive comprises 20-90% of an acrylic ester self-lubricating type monomer with boron contained on the molecular chain, 0-76% of a boron-free acrylic ester monomer, 0.02-1% of a polymerization inhibitor, 0.1-5% of an accelerator, 0.3-5% of an auxiliary accelerator, 0.01-0.1% of a metal ion chelating agent, 0.1-5% of an organic peroxide initiator, 0-10% of fumed silica, and 0-30% of a plasticizer. According to the present invention, the acrylic ester self-lubricating type monomer with the boron contained on the molecular chain is added during the preparation process, such that the lubricating property of the threaded locking sealing anaerobic adhesive can be improved, the friction coefficient and the torque coefficient during the fastener tightening can be reduced, and the torque strength of the cured threaded locking sealing anaerobic adhesive, the storage stability of the adhesive liquid, and the late coloring on the adhesive can not be affected.

Owner:湖北南北车新材料有限公司

Paint for H grade polyurethane enamelled wire with good saline water needle performace capable of directing welding at low temp.

InactiveCN100345924CImprove heat resistanceQuality improvementPlastic/resin/waxes insulatorsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to an H-grade wire coating enamel that has good salt water pinhole performance and can be directly welded at low temperature, containing hydroxyl component, sealed isocyanate component and solvent, where its hydroxyl component has an acid value less than 2, a hydroxyl value of 150-300, and number-average molecular weight of 1500-5000, and as synthesized, the raw materials has at least m-phthalic acid, p-phthalic acid, adilic acid, glycerin and a kind of dibasic alcohol in the weight ratio of 1 to (0.2-2) to (0.2-0.5) to (0.5-3) to (0.5-1.5); and its sealed isocyanate component is partially added of MDI by mixed polyalcohol that at least has a dibasic alcohol and a tribasic alcohol; in the paint base, the equivalent ratio of isocyanate base to OH is (0.9-1.2) : 1, and it reaches H-grade and has good salt water pinhole property of paint film, tin daubing temperature less than or equal to 375 deg.C.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Easily-detached anaerobic adhesive with controllable thread friction coefficients and preparation method of easily-detached anaerobic adhesive

InactiveCN106752985AReduce coefficient of frictionDoes not affect storage stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveFumed silica

The invention discloses an easily-detached anaerobic adhesive with a controllable thread friction coefficient, relating to the technical field of the anaerobic adhesive. The easily-detached anaerobic adhesive contains the following components in parts by weight: 100 parts of acrylate monomers, 5-50 parts of a saturated borate lubricant and / or a fluorinated polyether lubricant, 0.02-1 part of a polymerization inhibitor, 0.1-5 parts of an accelerant, 0.3-5 parts of a promotion aid, 0.01-0.1 part of a metal ion chelating agent, 0.1-5 parts of an organic peroxide initiator and 0-10 parts of fumed silica. By adding the saturated borate lubricant and / or the fluorinated polyether lubricant, the friction coefficient of a fastener during the fastening can be reduced and can be stably controlled at a certain range, and the storage stability of adhesive liquid and the later-period coloring of the adhesive liquid are not influenced; and meanwhile, the strength of the anaerobic adhesive is controllable, and the detachment is easy. The invention further discloses a preparation method of the easily-detached anaerobic adhesive with the controllable thread friction coefficient.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

Preparation method of neodymium-iron-boron magnet with corrosion resistance

InactiveCN111974655AAntisepticImprove corrosion resistancePretreated surfacesAnti-corrosive paintsElectric machineryPermanent magnet motor

The invention relates to the field of neodymium-iron-boron magnets, in particular to a preparation method of a neodymium-iron-boron magnet with corrosion resistance. The preparation method comprises the following steps that 1, surface impurity removal is carried out, particularly, the surface of the neodymium-iron-boron magnet is cleaned, and after surface impurities are removed, drying treatmentis carried out; 2, a corrosion-resistant coating is prepared; 3, coating treatment is carried out, particularly, a neodymium-iron-boron magnet blank is preheated, and then the surface of the neodymium-iron-boron magnet is coated with the prepared corrosion-resistant coating at the high temperature; and 4, curing treatment is carried out, and particularly the neodymium-iron-boron magnet coated withthe corrosion-resistant coating is placed in a drying oven for curing treatment. The preparation method is simple and easy to operate, can meet multiple function requirements of various permanent magnet motor fields for neodymium-iron-boron magnets, and is wider in application range.

Owner:宁波美固力磁电有限公司

Graphene electrothermal paint

InactiveCN106085211AExcellent adhesionImprove metal surfacePolyurea/polyurethane coatingsPolypyrroleOxygen

The invention relates to the technical field of paint and especially relates to graphene electrothermal paint. The graphene electrothermal paint comprises, by mass, 10-15 parts of graphene, 5-10 parts of antimony pentoxide, 5-12 parts of tungsten oxide, 2-8 parts of aluminum powder, 1-3 parts of a halogen-free fire retardant, 8-16 parts of screen printing resin, 1.8-6.4 parts of acetone, 8-16 parts of polyurethane resin, 10-20 parts of polypyrrole, 0.8-1.6 parts of an adhesion promoter and 10-20 parts of melamine resin. The graphene electrothermal paint does not discolor under high temperature rapid baking, has excellent coating weatherability, keeps effects under baking at a high temperature of 280 DEG C or more, has good resin intermiscibility, does not influence paint storage stability, can form a very thin electrothermal coating, has high electrothermal conversion efficiency and a fast heating rate, saves energy, prevents conductive belt oxidation and prevents oxygen burning in heating.

Owner:汤海涛

Preparation method of polymer precursor bridged polysilsesquioxane silane-coupling agent

InactiveCN103965479APerformance is not affectedDoes not affect activityMacromolecular adhesive additivesPressure reductionTrimethylolpropane

The invention discloses a preparation method of a polymer precursor bridged polysilsesquioxane silane-coupling agent and relates to the field of chemical raw material preparation. The preparation method comprises the following steps of mixing a hydrogenous ring, allyl glycidyl ether and vinyltriethoxysiloxane to obtain a uniform mixture, dropwisely adding chloroplatinic acid as a catalyst into the mixture with stirring, carrying out a reaction process for 3h, heating the reaction system to a temperature of 80 DEG C, carrying out a reaction process for 3h to obtain a yellow transparent oily liquid, adding a dimethyl siloxane ring, trimethylolpropane diallylether and vinyltrimethoxysilane into the yellow transparent oily liquid, carrying out a reaction process at a temperature of 100 DEG C for 2h, adding titanium diisopropoxydiacetylethyl acetate into the reaction product, carrying out an aging reaction process for 4h and carrying out pressure-reduction removal of low-boiling point substances so that the product is obtained. The product has molecular weight larger than that of a common coupling agent and solves the problem that silane molecules unconsumed by a reaction in the crosslinking process are gradually transferred to the surface of the organosilicon crosslinked polymer. A large amount of the product does not influence the performances of the whole system.

Owner:CHENGDU SILICON FIELD TECH CO LTD

Anti-fouling single-component room temperature sealing silicone sulfide glue and its production process

The anti-fouling single-component room temperature sealing silicone sulfide glue features that silicon oil with molecular end radical Si-H and dry oil addition component as anti-fouling component in 5-30 weight portions, poly(alpha, omega-dihydroxy siloxane in 100 weight portions and active calcium carbonate in 70-130 weight portions are dewatered and mixed in a vacuum stirrer at 100-150 deg.c and vacuum degree of 0.06-0.099 MPa for 30-200 min, and cooled to obtain the base material. At room temperature, cross-linking agent in 5-15 weight portions, silane coupler in 0.5-5 weight portions and catalyst in 0.5-1.5 weight portions are then added inside a high speed dispersing stirrer or a planetary stirrer at vacuum degree 0.06-0.099 MPa and rotation speed 200-600 rpm for 30-150 min.

Owner:CHENGDU GUIBAO SCI & TECH

A low-temperature fast-curing organic resin carrier for printed electronics and its preparation method and application

The invention discloses a low-temperature fast curing setting organic resin carrier for printing electronics and a preparation method and application thereof. The method comprises the steps that curing can be completed at the temperature of 120-150 DEG C for 1-9 min, the room temperature storage stability is good, continuous printing can be achieved, a curing film layer has the good electrical conductivity, solvent resistance, adhesive force, surface hardness and other comprehensive performances, the braking curing time is prolonged, and the resistance changing rate is smaller than 5%. Compared with the application performance of traditional printing electronic paste, damage caused by thermal treatment to organic materials and preparation devices is effectively lowered, the production yield is improved, the prepared rare and precious metal electronic paste is stably attached to various elastic substrate materials which are high surface energy and hard to adhere, high in reliability and suitable for a large-scale continuous production technology, and the production energy consumption cost is greatly lowered. The organic resin carrier is prepared from, by mass, 30-40% of organic resin, 45-59% of mixed solvents, 8-12% of curing agents and 3-5% of rapid curing accelerators.

Owner:KUNMING INST OF PRECIOUS METALS

A kind of silicone resin, its preparation method and application

ActiveCN103834178BReasonable structureImprove thermal shock resistanceSemiconductor devicesPlatinumHydrogen

The invention discloses organic silicon resin. The organic silicon resin comprises a component A and a component B, the mass ratio of which is 0.1:1-1:10, wherein the component A comprises vinyl phenyl polysiloxane, vinyl phenyl silicone oil, a platinum-containing polysiloxane catalyst and a tackifier, the mass ratio of which is 100: (10-55): (0.5-1): (1-1.5), and the component B comprises phenyl vinyl polysiloxane, hydrogen-containing phenyl polysiloxane and an inhibitor, the mass ratio of which is 100: (40-80): (0.05-0.1). The invention also discloses a preparation method of the organic silicon resin and an application of the organic silicon resin in LED (Light Emitting Diode) encapsulation. The organic silicon resin provided by the invention has the following advantages that 1. Ba(OH)2 can be completely removed, and the storage stability of the resin is not affected; 2. the problem of low curing rate is solved; and 3. the organic silicon resin has high thermal shock resistance, high refractive index and high hardness.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

A kind of wood coating combination of heat transfer roller coating and preparation method thereof

ActiveCN112646443BReduce production energy consumptionDoes not affect storage stabilityPolyurea/polyurethane coatingsPriming paintsPolymer sciencePolymer chemistry

The invention discloses a thermal transfer roller-coated wood coating combination and a preparation method thereof. The wood coating combination consists of a roller-coated white primer and a roller-coated white finish paint, wherein the roller-coated white primer and roller-coated white The topcoat consists of film formers, additives, pigments, fillers and water. The beneficial effects of the invention are: the preparation process is simplified and energy-saving; the covering power is good, the filling property is excellent, the leveling property is good, and the storage viscosity is stable; the surface tension is large, and the paint film heat transfer printing adhesion is good.

Owner:SOUTH CHINA UNIV OF TECH

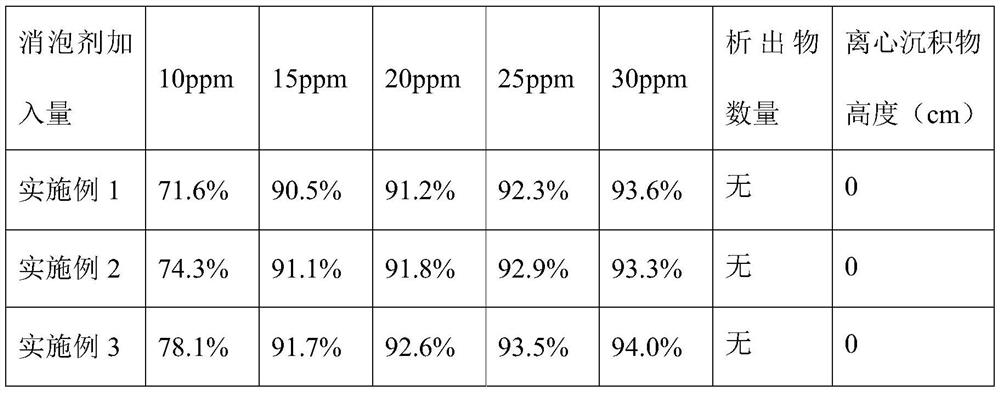

Delayed coking high-temperature-resistant defoaming agent and preparation method thereof

PendingCN112980496AImprove stabilityImprove lipophilicityThermal non-catalytic crackingFoam dispersion/preventionMethyl methacrylateDefoamer

The invention belongs to the technical field of defoaming agents, and particularly relates to a delayed coking high-temperature-resistant defoaming agent which is characterized by comprising the following components in percentage by mass: 6-10% of modified epoxy polyhedral oligomeric silsesquioxane, 4-6% of an acrylamide-methyl methacrylate copolymer, 4-8% of fatty acid ester and the balance of a solvent. The invention also provides a preparation method of the delayed coking high-temperature-resistant defoaming agent. The invention discloses a delayed coking high-temperature-resistant defoaming agent which still has good defoaming and foam-inhibiting performance under a high-temperature condition, can achieve a good defoaming and foam-inhibiting effect only by adding a small amount of defoaming agent, does not contain polyether chains, and is low in silicon content and good in storage stability.

Owner:西安威弗莱环境控制技术有限责任公司

A kind of environment-friendly water-repellent and oil-repellent fluorine-containing acrylate emulsion and its preparation method and application

The invention discloses environmentally-friendly water / oil-repellent fluorinated acrylate emulsion and a preparation method thereof. The fluorinated acrylate emulsion is mainly prepared from 3-chloro-2-hydroxy propyl methyl acrylate, a fluorine-containing alkyl acrylate monomer, an acrylate monomer, a crosslinking monomer, a non-ionic emulsifier, a cationic emulsifier, a modifier, an initiator and deionized water. The fluorinated acrylate emulsion prepared by using the method can be applied to a textile finishing agent; and the textile finished by the emulsion has excellent water and oil repellency and anti-pollution characteristic.

Owner:DYMATIC CHEM

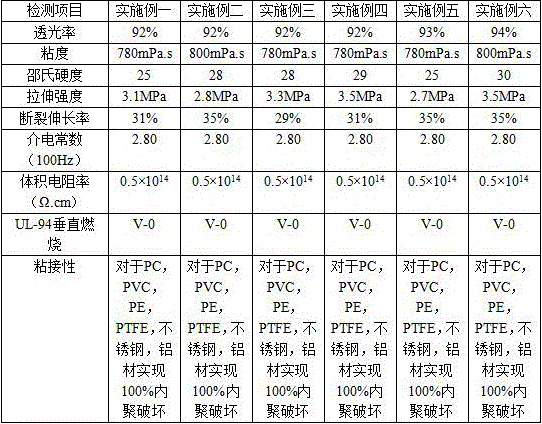

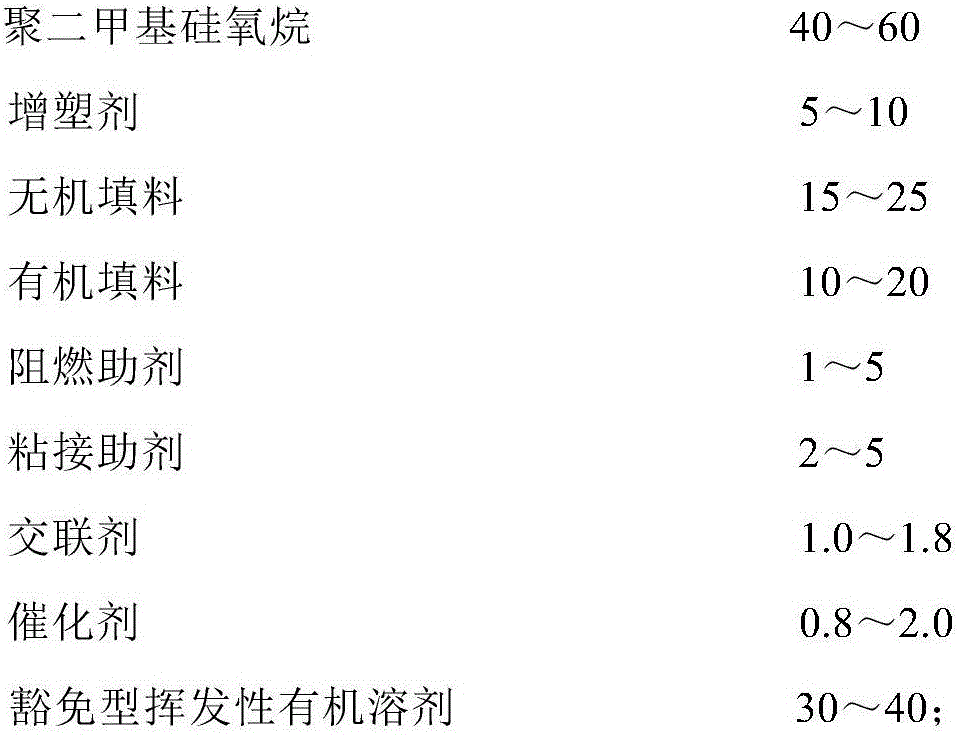

A kind of organosilicon electronic packaging material and preparation method thereof

ActiveCN104762057BGood adhesionWon't releaseNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsLow speedSolvent

The invention discloses an organic silicon electronic packaging material and a preparation method thereof. The organic silicon electronic packaging material comprises methyl-terminated polydimethylsiloxane, a plasticizer, an inorganic filler, an organic filler, a flame-retardant assistant, a functional assistant, a crosslinking agent, a catalyst and an exempt volatile organic solvent. The preparation method comprises the following steps: uniformly dispersing the polydimethylsiloxane and organic filler by high-speed stirring and mixing; previously carrying out high-temperature baking on the inorganic filler, adding, dispersing by stirring, adding the plasticizer, and uniformly dispersing by high-speed stirring; adding the flame-retardant assistant and bonding assistant, dispersing by high-speed stirring, dispersing, adding the crosslinking agent, dispersing, adding the catalyst, dispersing by low-speed stirring, adding the solvent to regulate the viscosity, continuing dispersing, vacuumizing, and discharging to obtain the product. The organic silicon electronic packaging material has favorable bonding performance for PC (polycarbonate), PTFE (polytetrafluoroethylene), stainless steel and aluminum products. By using the exempt volatile organic solvent for preparation, the organic silicon electronic packaging material is green and safe, and has the advantages of favorable storage stability, favorable temperature tolerance and excellent electric properties.

Owner:广东皓明有机硅材料有限公司

A kind of lubricating thread locking and sealing anaerobic adhesive and preparation method thereof

ActiveCN105295747BImprove the lubrication effectLubricatingNon-macromolecular adhesive additivesOther chemical processesAdhesiveGas phase

The invention discloses a lubricating thread locking and sealing anaerobic adhesive and a preparation method thereof, and relates to the field of thread locking and sealing anaerobic adhesives. In terms of mass percentage, the anaerobic adhesive includes 20% to 90% of molecular chains containing Boron acrylate self-lubricating monomer, 0-76% boron-free acrylate monomer, 0.02%-1% polymerization inhibitor, 0.1%-5% accelerator, 0.3%-5% Accelerator, 0.01%-0.1% metal ion chelating agent, 0.1%-5% organic peroxide initiator, 0-10% fumed silicon dioxide, 0-30% plasticizer. In the preparation process, the present invention adds boron-containing acrylate self-lubricating monomers in the molecular chain, which can improve the lubricity of the thread locking and sealing anaerobic adhesive, reduce the friction coefficient and torque coefficient when the fastener is tightened, and do not It affects the torque strength of the thread locking and sealing anaerobic adhesive after curing, the storage stability of the glue, and the coloring of the glue in the later stage.

Owner:湖北南北车新材料有限公司

A kind of preparation method of organic silane modified high adhesion solid acrylic resin

ActiveCN103694409BDoes not affect storage stabilityGood solvent resistancePowdery paintsPolyester coatingsAcrylic resinSolvent

The invention discloses a method for preparing high-adhesive force solid acrylic resin modified by organosilane. The method disclosed by the invention can be used for preparing the high-adhesive force solid acrylic resin by introducing an organosilane monomer into acrylic resin through a chemically bonding mode; the prepared modified solid acrylic resin as an additive is added to a powder coating system, can outstandingly enhance the adhesive force of a powder coating layer on a substrate and specific substrates, such as a galvanized plate and stainless steel, especially, cannot influence the storage stability of the powder coating due to excellent self characteristics of the solid acrylic resin and achieves certain improvement on the solvent resistance and boiling resistance of the powder coating layer.

Owner:六安捷通达新材料有限公司

A kind of preparation method of thermally vulcanized fluorosilicone rubber raw rubber

ActiveCN103739844BHigh catalytic activityPolymerization reaction temperature is lowPolymer sciencePotassium

The invention relates to a preparation method of heat curing fluorosilicone raw rubber. The preparation method comprises the following steps: adding D3F and D4Vi into a reactor and then dehydrating D3F and D4Vi, adding prepared potassium silanolate catalyst pre-polymer, heating, introducing nitrogen and stirring to carry out polymerization, wherein the temperature is 60-115 DEG C and the reaction time is 20-100min, neutralizing with a neutralizer until the reactant is neutral, and finally, removing small molecular substances from the material, reducing temperature and discharging. Due to the adoption of the potassium silanol catalyst pre-polymer with high activity, the reaction temperature is low, the accelerant is not required, an end-capping reagent is not required in the polymerization process, and the nitrogen purging manner is adopted in the stage of removing the small molecular substances from the material, the volatile matter of the heat curing fluorosilicone raw rubber is reduced; the prepared heat curing fluorosilicone raw rubber can be widely used in the fields of aerospace, petrochemical industry, automobiles, artificial organ, and the like, and has a good promotional value.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

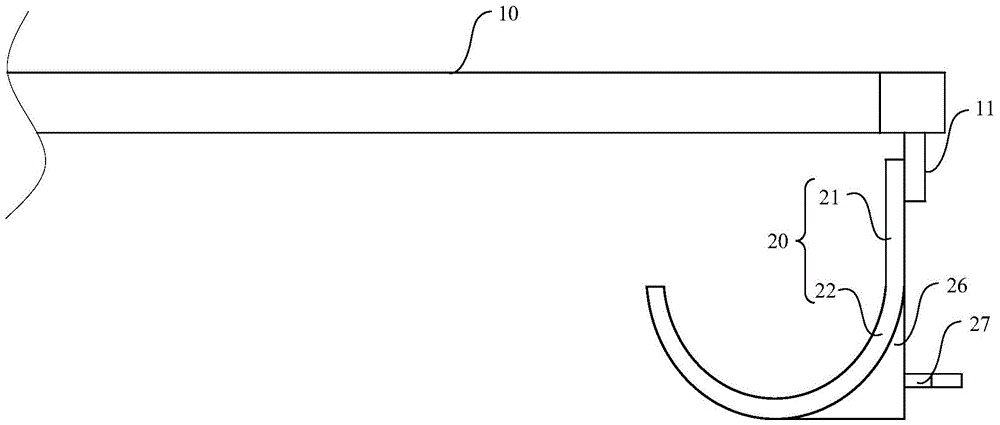

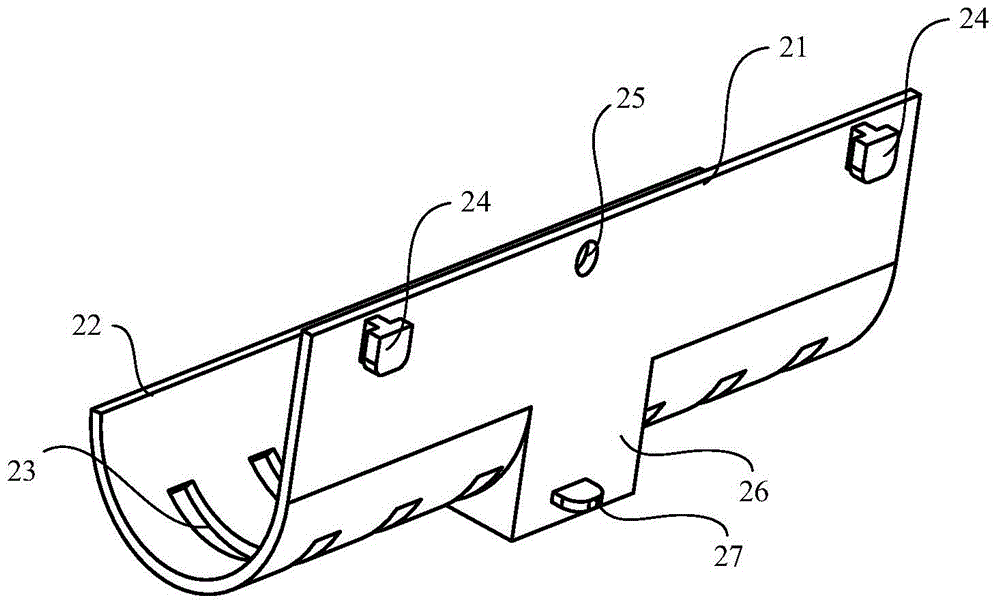

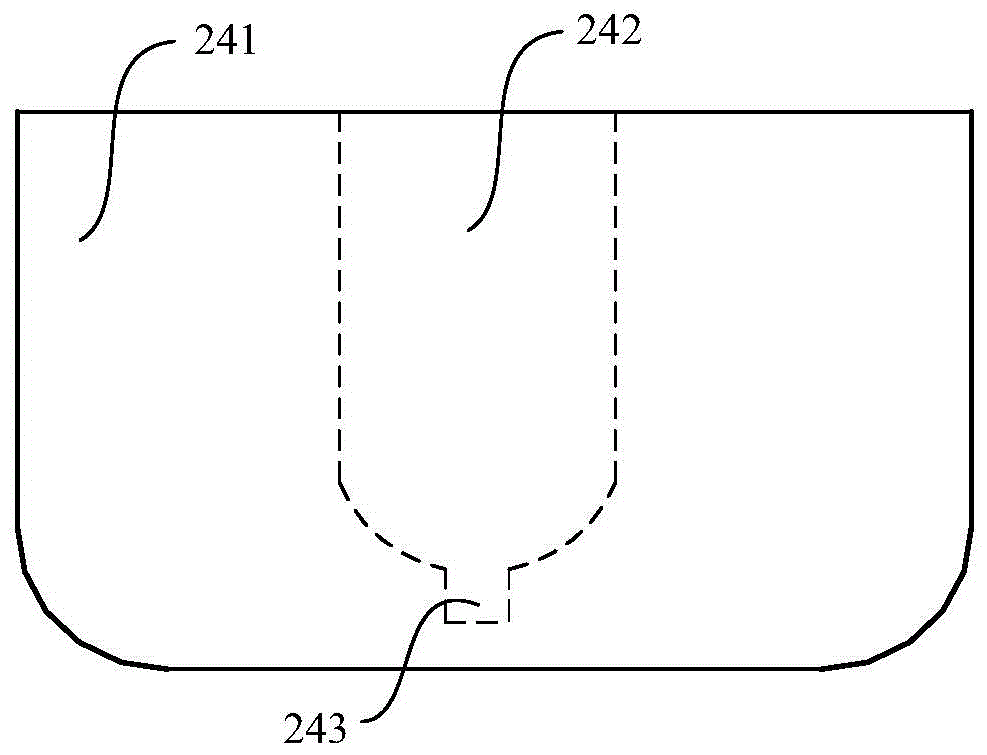

A shelf in a refrigerator

ActiveCN103994630BIncrease available spaceDoes not affect accessLighting and heating apparatusCooling fluid circulationIceboxWine bottle

The invention discloses a rack inside a refrigerator body, and relates to the technical field of refrigerators. In order to solve the problem that materials are inconvenient to store, the rack inside the refrigerator body comprises a shelf installed inside the refrigerator body, and a bottle rack located below the shelf. A connecting portion protruding to the bottom of the refrigerator body is arranged on the shelf. The bottle rack comprises a flat plate and an arc-shaped plate, wherein the flat plate is detachably connected with the connecting portion, one end of the arc-shaped plate is tangent to the flat plate and is fixedly connected with the flat plate so as to support a wine bottle, and projections of the arc-shaped plate and the flat plate are located inside the shelf. The rack inside the refrigerator body is used for storing objects (except for the wine bottle) and the wine bottle in a separated mode, and a user can conveniently store the objects through the refrigerator.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

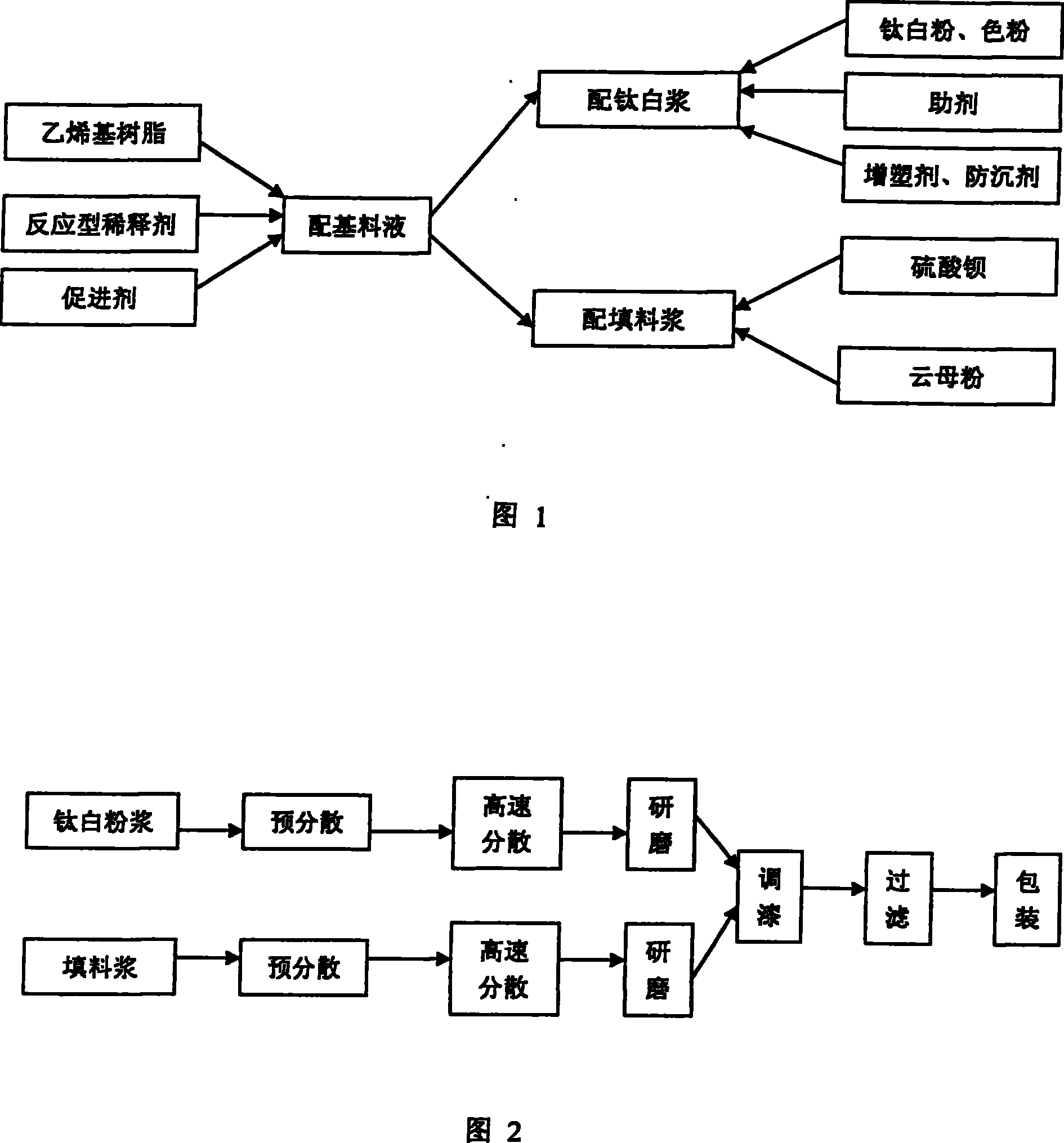

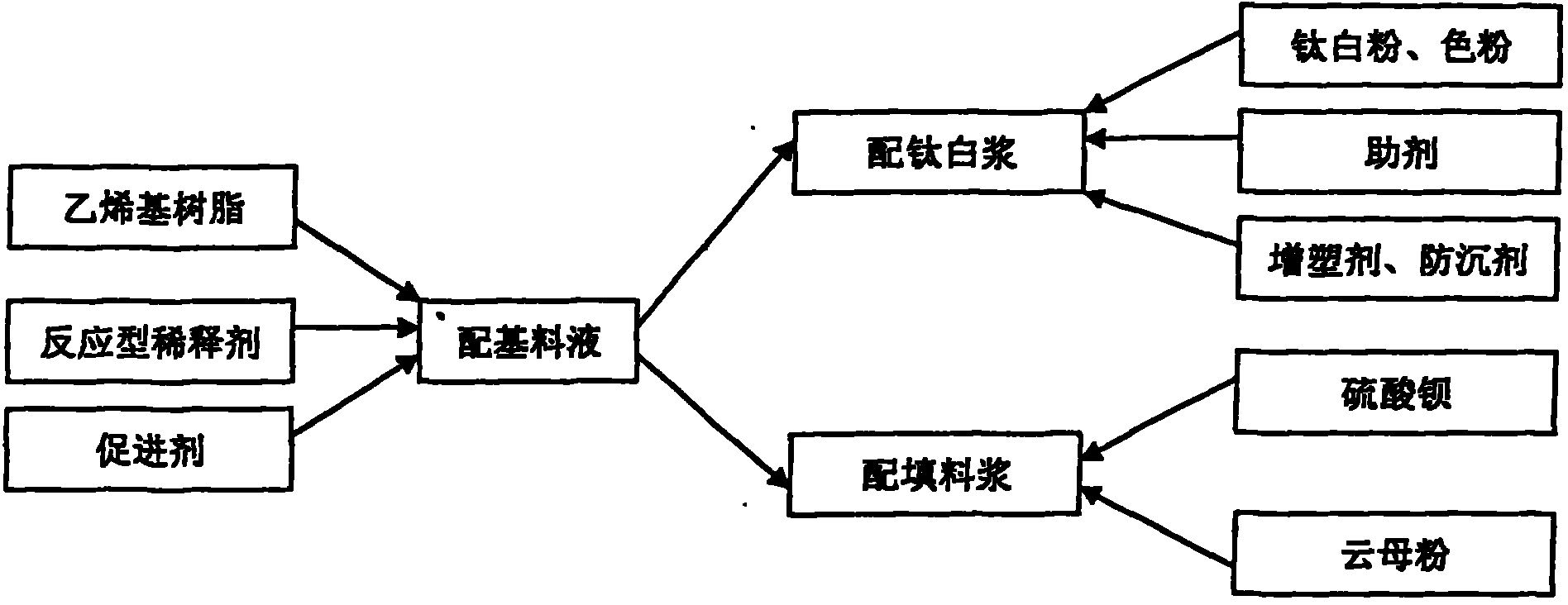

Technique for preparing two-component epoxy vinyl ester resin paint

The invention discloses a preparation process for two-component epoxy vinyl ester resin coating and is characterized in that: according to the weight proportion, vinyl ester resin 100-120 is diluted by response type diluting agent 14-20, accelerant 2-5 is added to pre-accelerate to form basic material liquid, then titanium white slurry and filler paste are routinely prepared, a finished componentA is obtained by dispersing, grinding, mixing and evenly filtering, a component B is evocating agent; methyl ethyl ketone is peroxidized, the proportion during the use is that A:B is equal to 1:0.02 to 1:0.04. The preparation process has the advantages that: the preparation process adopts a pre-acceleration method to make the product change into two components from the prior three components, eliminates the safety hidden trouble such as combustion, explosion and so on, also decreases the shrinkage ratio of the product, improves the viscosity of the coating, improves the bonding strength, enhances the abrasion resistance, and is solvent-free coating which meets the requirement of environmental protection.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Mirror silver ink, preparation method and product thereof

The invention relates to the field of inks, in particular, it provides a mirror silver ink, a preparation method and a product thereof. The water-based acrylic modified polyester resin in the mirror silver ink can improve the chemical resistance of the mirror silver ink coating. Water-based baking varnish epoxy resin can improve the alkali resistance of the mirror silver ink coating. Water-based blocked isocyanate curing agent and water-based phenylamino resin can increase the crosslinking density between raw materials. The modified silane coupling agent can be directly added to the mirror silver ink without affecting the storage stability, while improving the water resistance of the ink coating and the bonding force with the substrate. The mirror silver ink is harmless to the human body and the environment, and does not require a protective layer. A single layer of coating can be cleaned with 4% NaOH at 70°C without removing silver, and does not affect adhesion and mirror effect.

Owner:广州昊毅新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com