Two-component polymer cement waterproof coating

A waterproof coating and polymer technology, applied in the field of waterproof coatings and two-component polymer cement waterproof coatings, can solve the problems of reduced coating performance, unstable storage, affecting the storage stability of coatings, etc., to improve adhesion and stable properties. , enhance the effect of the combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

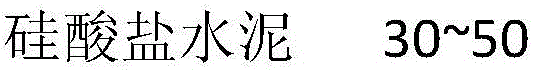

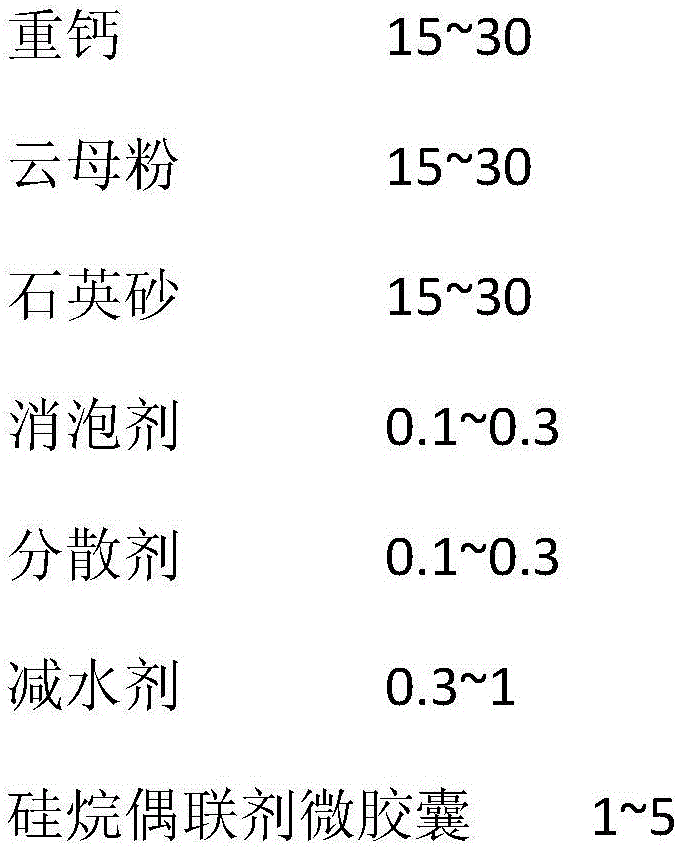

[0028] A two-component polymer cement waterproof coating, which is composed of a liquid material and a powder material. The liquid material is a pure acrylate emulsion, and the powder material is composed of the following components in parts by mass:

[0029]

[0030] The preparation method of silane coupling agent microcapsules is as follows: 20 parts of quality of soluble starch and 5 parts of quality of polyvinylpyrrolidone K30 are dissolved in 50 parts of quality of water, and then 10 parts of quality of γ-(2,3-epoxy Propoxy)propyltrimethoxysilane, disperse the mixed liquid with a high-speed disperser at 2000r / min for 5 minutes, and then spray dry to obtain silane coupling agent microcapsules; the parameters of spray drying are set as follows: inlet temperature 110°C, outlet temperature The temperature is 72°C, the feed rate is 2kg / h, and the rotation speed of the atomizer is 20000r / min.

[0031] Mix the liquid material and the powder material in a mass ratio of 1:2, mi...

Embodiment 2

[0033] The two-component polymer cement waterproof coating of this embodiment is composed of a liquid material and a powder material. The liquid material is a pure acrylate emulsion, and the powder material is composed of the following components in parts by mass:

[0034]

[0035] The preparation method of silane coupling agent microcapsules is as follows: 30 parts of quality of maltodextrin and 10 parts of quality of polyvinyl alcohol 1788 are dissolved in 60 parts of quality of water, and then 20 parts of quality of 3‐glycidyl ether propyl For methyldiethoxysilane, disperse the mixed liquid with a high-speed disperser at 3000r / min for 10 minutes, then spray dry to obtain silane coupling agent microcapsules; the parameters of spray drying are set as follows: inlet temperature 160°C, outlet temperature 108°C , the feed rate is 1kg / h, and the rotation speed of the atomizer is 30000r / min.

[0036]The liquid material and the powder material are mixed according to the mass rat...

Embodiment 3

[0038] The two-component polymer cement waterproof coating of this embodiment is composed of a liquid material and a powder material. The liquid material is a pure acrylate emulsion, and the powder material is composed of the following components in parts by mass:

[0039]

[0040] The preparation method of silane coupling agent microcapsules is as follows: 30 parts of quality cyclodextrin and 10 parts of quality of polyvinyl alcohol 1788 are dissolved in 60 parts of quality of water, and then 10 parts of quality of γ‐(methacryloyloxy ) Propyltrimethoxysilane and 10 parts of quality vinyltrimethoxysilane, the mixed solution is dispersed at 3000r / min for 10min with a high-speed disperser and then spray-dried to obtain silane coupling agent microcapsules; the parameter setting of spray-drying It is: inlet temperature 160°C, outlet temperature 108°C, feed rate 1kg / h, atomizer speed 30000r / min.

[0041] The liquid material and the powder material are mixed according to the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com