Delayed coking high-temperature-resistant defoaming agent and preparation method thereof

A technology of delayed coking and high temperature resistance, applied in the field of defoaming agents, can solve the problems of hydrotreating process hazards, high silicon content, and easy formation of deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

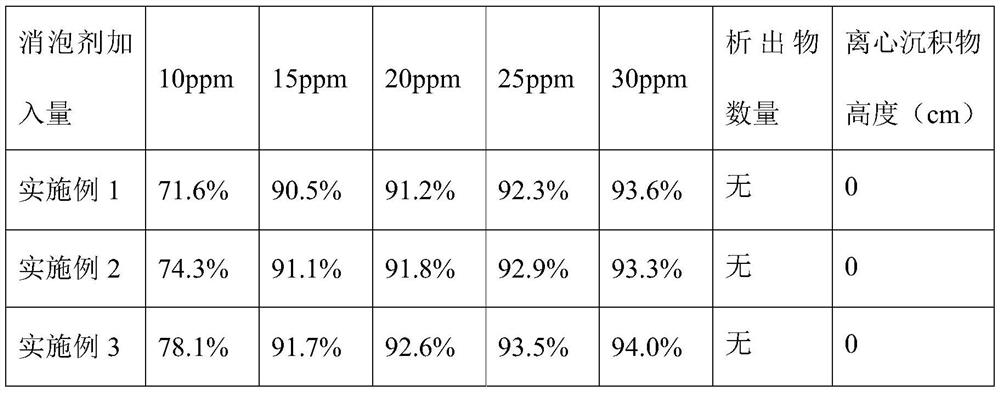

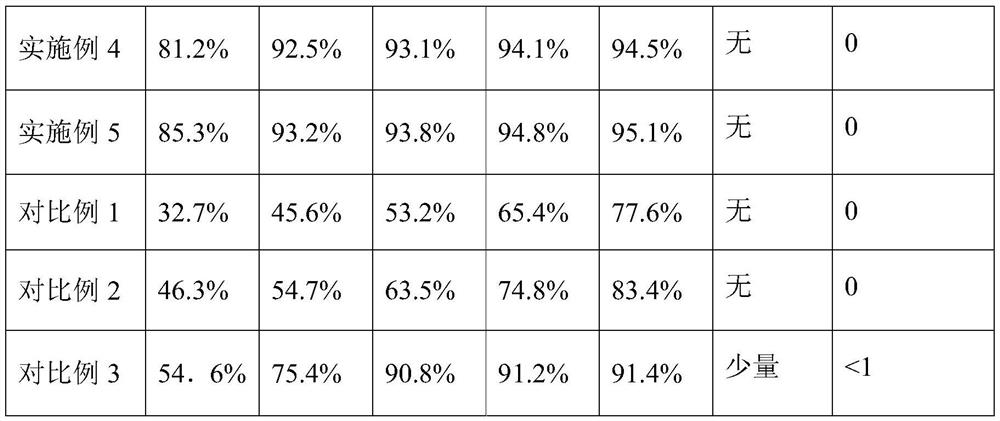

Examples

Embodiment 1

[0027] A delayed coking high-temperature resistant defoamer, characterized in that it comprises the following components in mass percentage: 6% of modified epoxy-based cage polysilsesquioxane, 4% of acrylamide-enoic acid methyl ester copolymer , fatty acid ester 4%, and the rest is solvent.

[0028] Preferably, the preparation method of described modified epoxy cage polysilsesquioxane comprises the steps of:

[0029] Step I, the preparation of the intermediate: add aminosiloxane and 2,2,3,3,4,4-hexafluoro-1,5-pentyl dimethacrylate into anhydrous tetrahydrofuran, nitrogen protection, at 40 Under the condition of ℃, react in the dark for 20h, distill under reduced pressure, then add methylcyclohexyldimethoxysilane, water, isopropanol and dibutyltin dilaurate, react at 30℃ for 6h, concentrate to obtain Intermediate;

[0030] Step II, preparation of modified epoxy cage polysilsesquioxane: adding epoxy cage polysilsesquioxane and the intermediate obtained through the step I to is...

Embodiment 2

[0040] A delayed coking high-temperature-resistant defoamer, characterized in that it comprises the following components in mass percent: 7% of modified epoxy-based cage polysilsesquioxane, 4.5% of acrylamide-enoic acid methyl ester copolymer , fatty acid ester 5%, and the rest is solvent.

[0041] Preferably, the preparation method of described modified epoxy cage polysilsesquioxane comprises the steps of:

[0042] Step I, the preparation of the intermediate: add aminosiloxane and 2,2,3,3,4,4-hexafluoro-1,5-pentyl dimethacrylate into anhydrous tetrahydrofuran, nitrogen protection, at 45 Under the condition of ℃, react in the dark for 22h, distill under reduced pressure, then add methylcyclohexyldimethoxysilane, water, isopropanol and dibutyltin dilaurate, react at 35℃ for 6.5h, concentrate, get intermediates;

[0043] Step II, preparation of modified epoxy cage polysilsesquioxane: adding epoxy cage polysilsesquioxane and the intermediate obtained through the step I to isopr...

Embodiment 3

[0053] A delayed coking high temperature resistant defoamer, characterized in that it comprises the following components in mass percent: 8% of modified epoxy-based cage polysilsesquioxane, 5% of acrylamide-enoic acid methyl ester copolymer , fatty acid ester 6%, and the rest is solvent.

[0054] Preferably, the preparation method of described modified epoxy cage polysilsesquioxane comprises the steps of:

[0055] Step I, the preparation of intermediates: add aminosiloxane and 2,2,3,3,4,4-hexafluoro-1,5-pentyl dimethacrylate into anhydrous tetrahydrofuran, nitrogen protection, at 50 Under the condition of ℃, react in the dark for 24h, distill under reduced pressure, then add methylcyclohexyldimethoxysilane, water, isopropanol and dibutyltin dilaurate, react at 40℃ for 7h, concentrate to obtain Intermediate;

[0056] Step II, preparation of modified epoxy cage polysilsesquioxane: adding epoxy cage polysilsesquioxane and the intermediate obtained through the step I to isopropa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com