Easily-detached anaerobic adhesive with controllable thread friction coefficients and preparation method of easily-detached anaerobic adhesive

A friction coefficient and easy disassembly technology, applied in the field of anaerobic glue, can solve the problems of the adverse effect of glue coloring, the reduction of friction coefficient, the difficulty of disassembly of fasteners, etc., to achieve controllable strength and easy disassembly. , the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

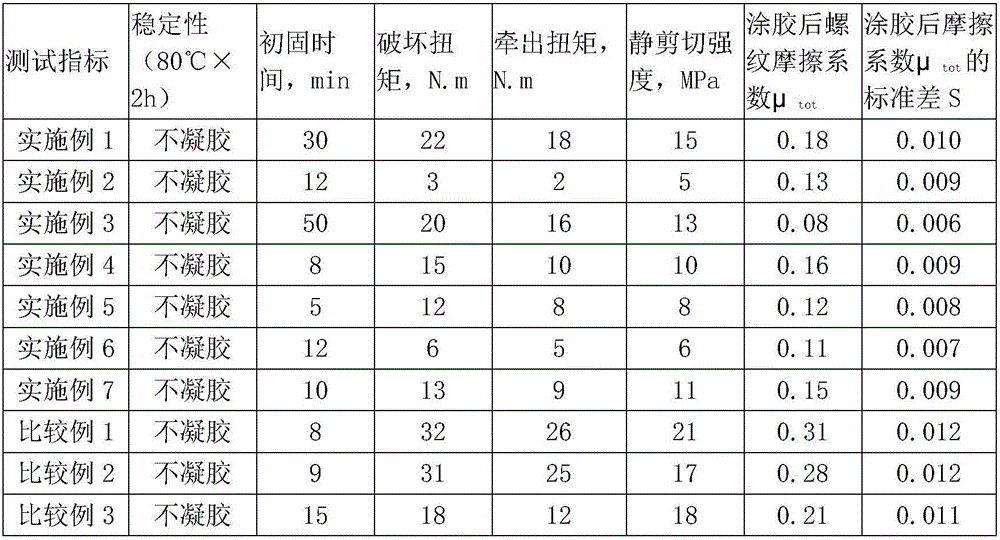

Examples

preparation example Construction

[0027] The invention also discloses a method for preparing an anaerobic adhesive with an easily detachable and controllable thread friction coefficient, which includes the following steps:

[0028] In parts by mass, 100 parts of acrylate monomer, 5-50 parts of saturated borate lubricant and / or fluorinated polyether lubricant, 0.02-1 part of polymerization inhibitor, 0.1-5 parts of accelerator additive, 0.3-5 parts of co-accelerator, and 0.01-0.1 part of metal ion chelating agent are sequentially added to the glue-making container, and stirred at 5°C-35°C for 30-90min until completely dissolved and uniform;

[0029] Add 0.1 to 5 parts of organic peroxide initiator and 0 to 10 parts of fumed silica into the rubber-making container, and stir at 5°C to 35°C for 20 to 40 minutes until uniform dispersion to obtain a crude product;

[0030] Vacuum degassing or centrifugal degassing: (vacuum degassing time 5min, vacuum pressure controlled at -0.09~-0.07MPa; centrifugal degassing time ...

Embodiment 1

[0033] The easy-to-disassemble controllable thread friction coefficient anaerobic adhesive provided in this embodiment includes

[0034] 100 parts of polyethylene glycol 200 dimethacrylate;

[0035] 5 parts of perfluoropolyether FI04;

[0036] 1.0 parts of 1,4-naphthoquinone;

[0037] 0.1 parts of N-acetylphenylhydrazine;

[0038] 2 parts of o-sulfonyl benzimide;

[0039] 0.01 parts of EDTA tetrasodium salt;

[0040] 1.8 parts of cumene hydroperoxide.

[0041] The preparation process of the above-mentioned anaerobic adhesive with easy disassembly and controllable thread friction coefficient is as follows:

[0042] 5 parts of perfluoropolyether FI04, 50 parts of polyethylene glycol 200 dimethacrylate, 50 parts of bisphenol A epoxy dimethacrylate, 1.0 parts of 1,4-naphthoquinone, 0.1 parts Add N-acetylphenylhydrazine, 2 parts of o-sulfonylbenzimide, and 0.01 part of EDTA tetrasodium salt into the gel-making container in sequence, and stir at 30°C for 90 minutes until compl...

Embodiment 2

[0044] The easy-to-disassemble controllable thread friction coefficient anaerobic adhesive provided in this embodiment includes

[0045]20 parts of hydroxyethyl methacrylate, 80 parts of polyethylene glycol 200 dimethacrylate;

[0046] 20 parts of perfluoropolyether FI80;

[0047] 0.02 parts of 1,4-naphthoquinone;

[0048] 0.5 parts of N-acetylphenylhydrazine;

[0049] 1.0 parts of o-sulfonyl benzimide;

[0050] 0.01 parts of EDTA tetrasodium salt;

[0051] 2.0 parts of cumene hydroperoxide;

[0052] 1.5 parts fumed silica.

[0053] The preparation process of the above-mentioned easy-detachable and controllable thread friction coefficient anaerobic adhesive is as follows:

[0054] 20 parts of perfluoropolyether FI80, 20 parts of hydroxyethyl methacrylate, 80 parts of polyethylene glycol 200 dimethacrylate, 0.02 parts of 1,4-naphthoquinone, 0.5 parts of N-acetophenone Add hydrazine, 1.0 parts of o-sulfonylbenzimide, and 0.01 parts of EDTA tetrasodium salt into the gel-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com