Aluminoborosilicate glass and method for the production of crystallite-free gradient index lenses

a technology of borosilicate glass and gradient index, which is applied in the field of aluminoborosilicate glass, can solve the problems of generating imaging defects or scattered light disadvantages, affecting transmission, and unwanted coloration of silver colloids, etc., and achieves good optical quality, reduced crystallization tendency, and high refractive index gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

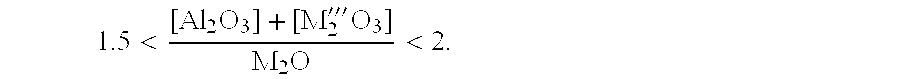

Method used

Image

Examples

example 1

[0076]A glass composed of 25 Na2O.25 Al2O3.12.5 B2O3.37.5 SiO2 (in mole %) was melted at 1500° C. After temperature treatment for 1 hour at temperatures ≦850° C., no crystallization was evident. At temperatures of 900° C. and 950° C., the crystallization rate was about one fourth of the value of the reference glass.

example 2

[0077]A glass composed of 25 Na2O.25 Al2O3.12.5 B2O3.37.5 SiO2 showed no discernible crystallization in the temperature range of 700° C. to 950° C.

example 3

[0078]A glass composed of 24.5 Na2O.1 NaF.30 Al2O3.12.5 B2O3.32.5 SiO2 showed no crystallization at temperatures ≦850° C. With temperature treatment at 900° C. and 950° C. for 1 hour, the crystallization rate reached values of about one fifth of the reference glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com