Method for machining half-and-half casings of gas compressor of aero-engine

An aero-engine and processing method technology, which is applied in the field of aero-engine processing, can solve the problems of poor consistency of accuracy, easy deformation, and difficulty in ensuring the position of precision holes on the longitudinal bonding surface, etc., to achieve qualified flatness, eliminate combined deformation, and repeat Combination of good accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

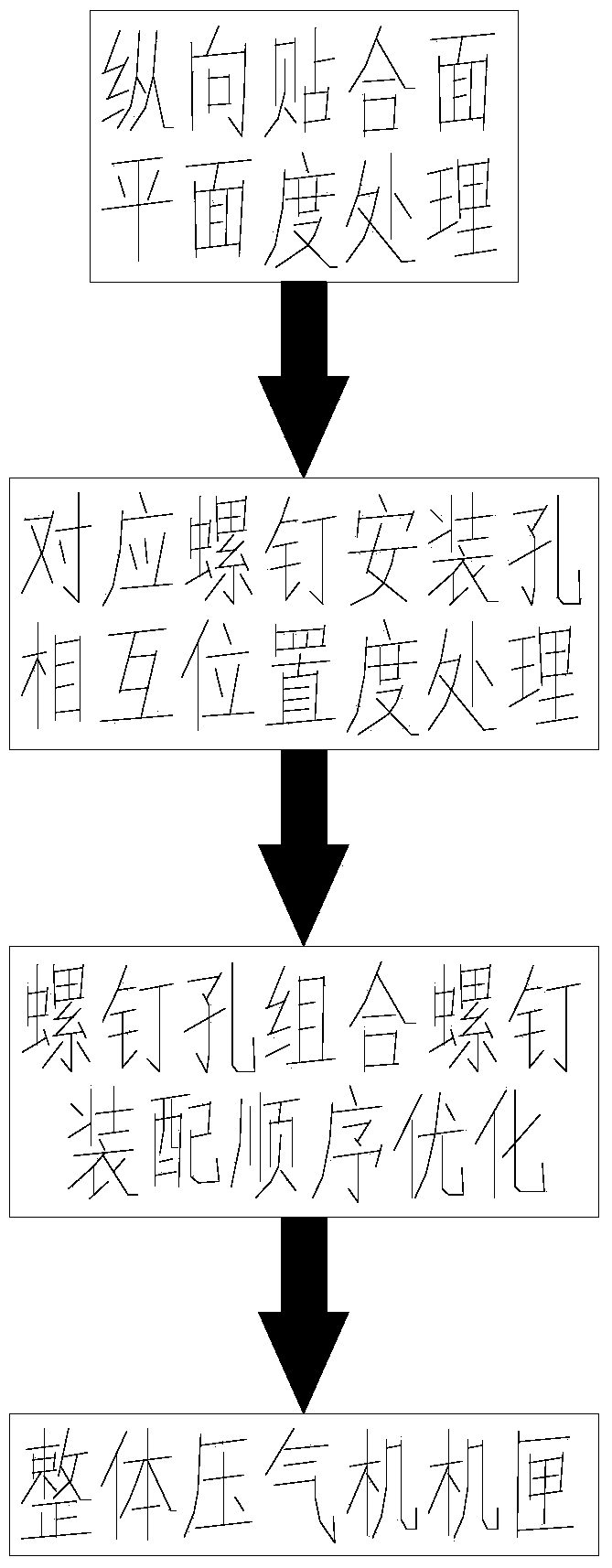

[0021] Such as figure 1 As shown, the processing method of the half casing of the compressor of the aero-engine of the present embodiment comprises the following steps: a, the flatness of the longitudinal bonding surface of the two half half casings is processed, and the two half half casings after the rough machining The casing is plane-processed in the way that the datum plane is close to ensure the flatness of the longitudinal bonding surface of the two halves of the casing; b. The mutual position of the corresponding screw mounting holes on the longitudinal bonding surface of the two halves of the casing , finish machining at least part of the correspondingly set screw mounting holes, and place screws with positioning cylinders in the finished s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com