Steel ball casting die

A technology for casting molds and steel balls, applied in the field of steel ball casting molds, can solve problems such as short pouring time, and achieve the effects of short pouring time, reduced labor intensity, and improved product finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

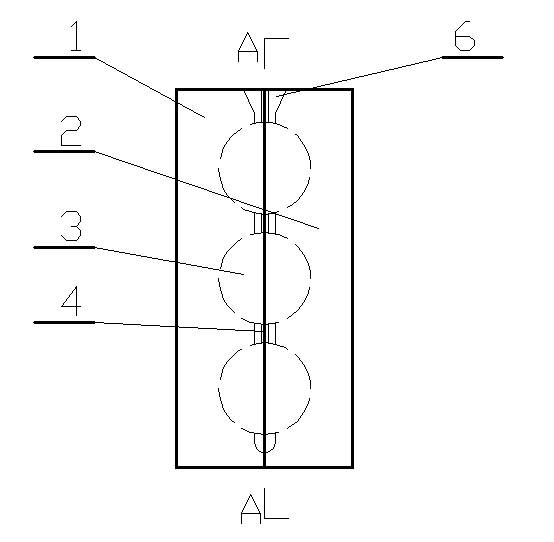

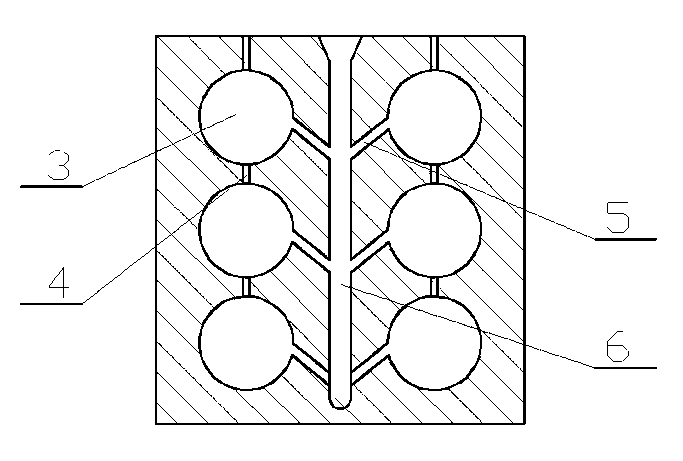

[0013] In the accompanying drawings, the steel ball casting mold includes two half molds. The mold adopts the mode of left and right mold closing. The bonding surfaces of the two half molds are correspondingly provided with a plurality of semicircular ball grooves 3 from top to bottom. When the two half-moulds are closed, two semicircular ball grooves 3 form a complete ball groove 3; the upper and lower adjacent ball grooves 3 are communicated by an air groove 4; one side of the ball groove 3 is provided There is a vertical runner 6, and the runner 6 and the ball groove 3 are connected by a pouring branch 5.

[0014] The air outlet of the air groove 4 and the pouring port of the runner 6 are all arranged on the top of the mould.

[0015] The air groove 4, the runner 6 and the pouring branch 5 are divided into two parts longitudinally and symmetrically with the connecting surfaces of the left and right half molds as the midline, and are respectively arranged on the left half mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com