Flaskless V-method casting process

A technology of casting process and molding process, which is applied in the boxless V-method casting process and the field of small and medium-sized castings. It can solve the problems of high manufacturing cost and high design difficulty, and achieve the advantages of saving manufacturing cost, simple structure, and reducing design and manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with an example.

[0020] This example is a casting example of bucket teeth:

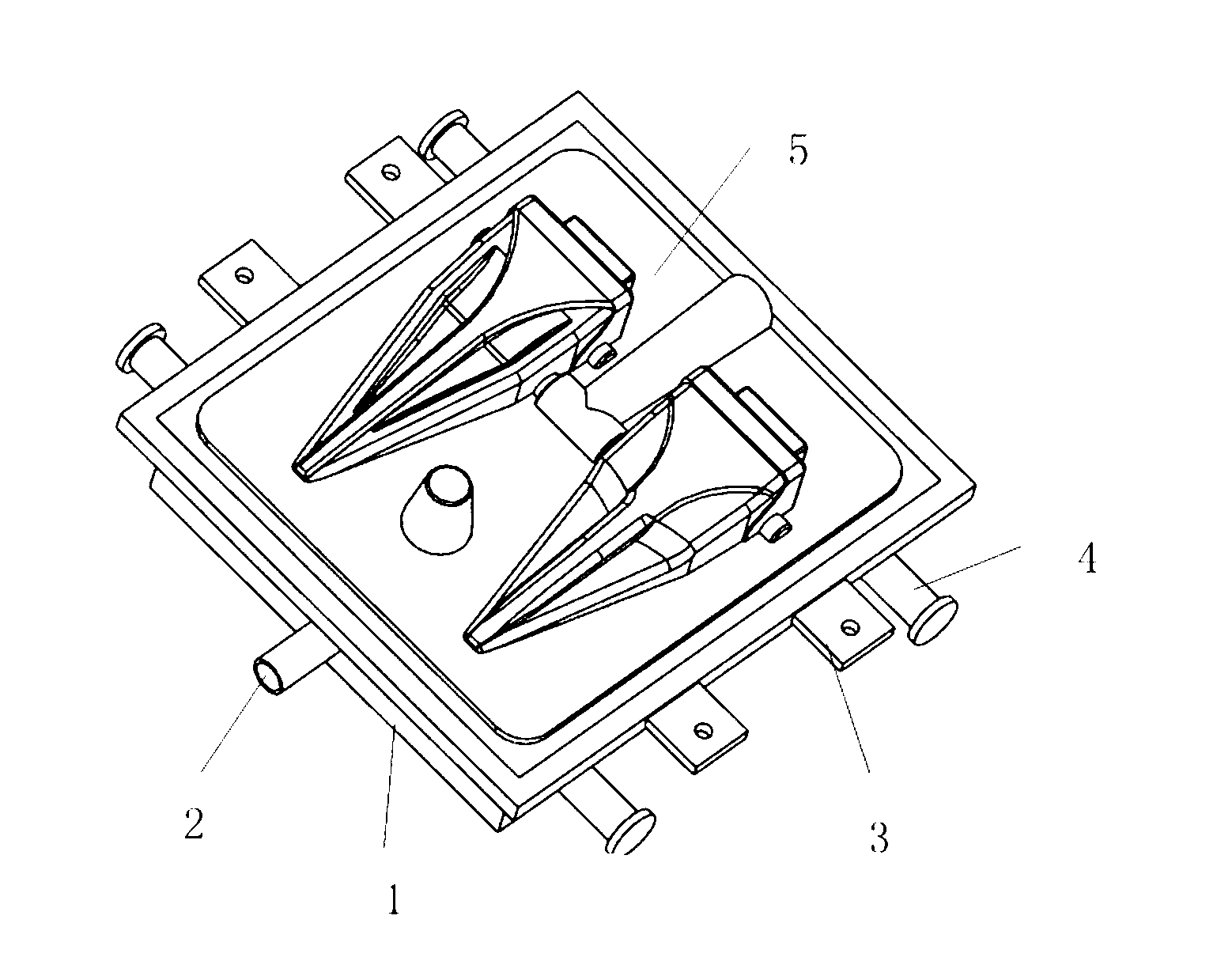

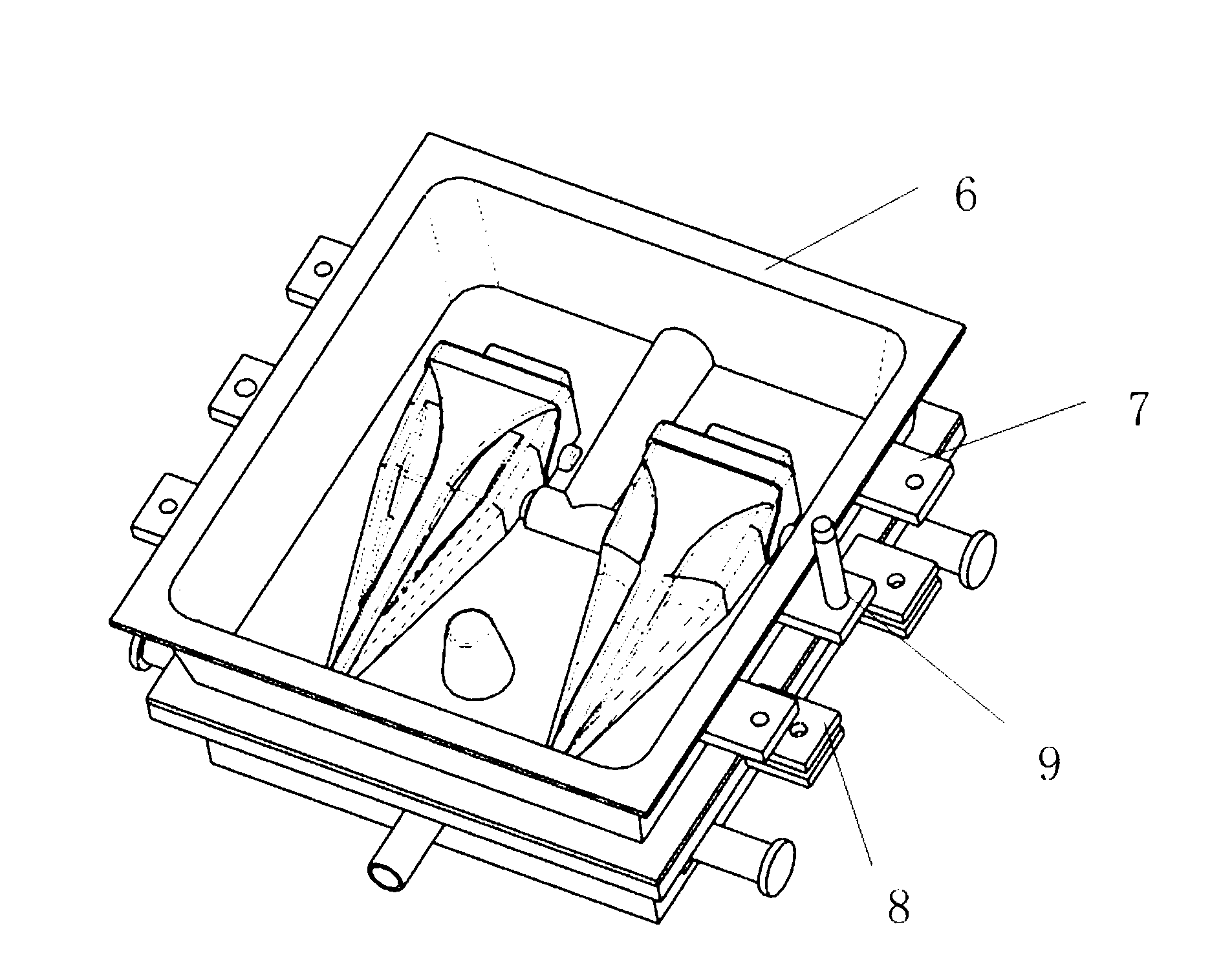

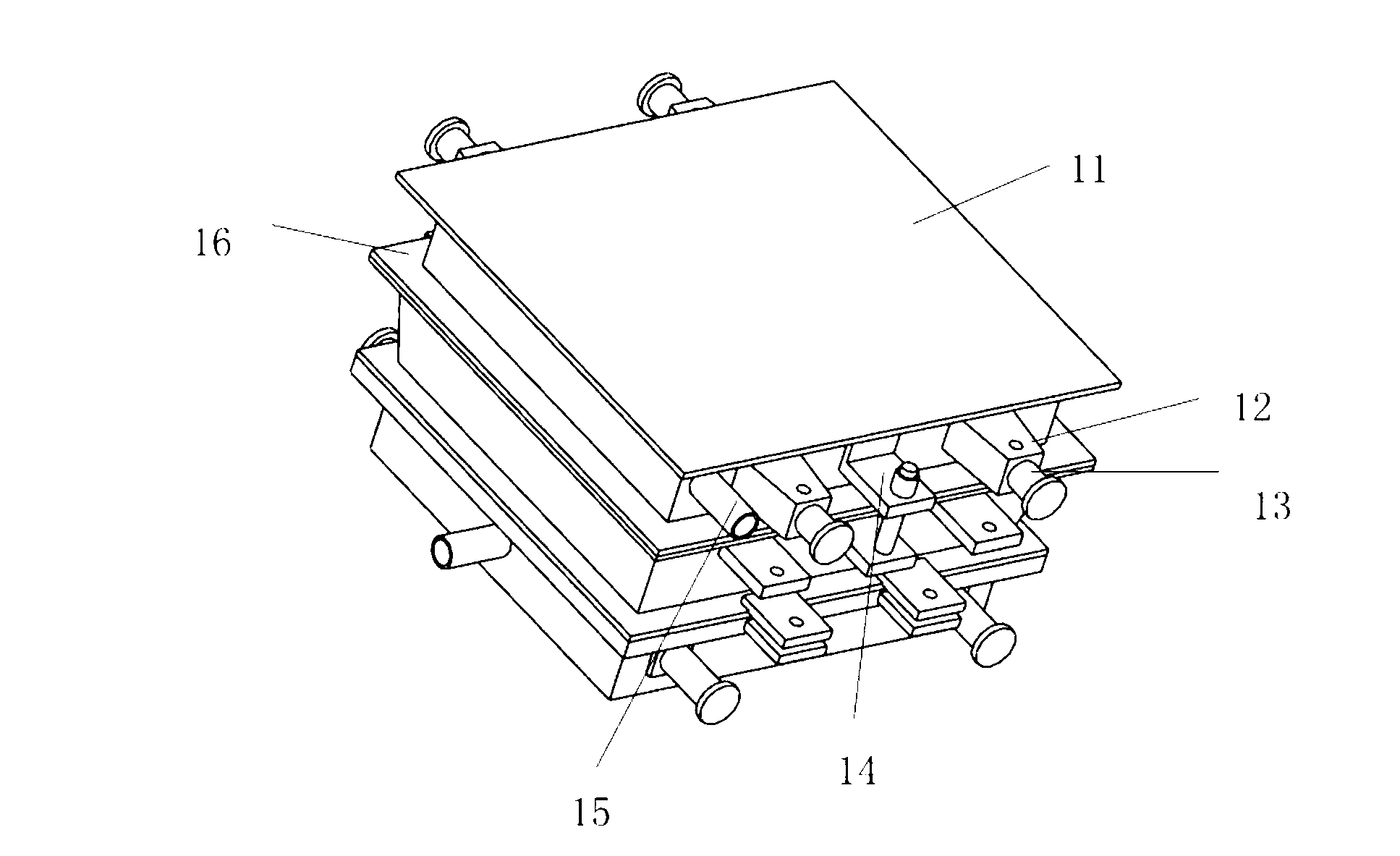

[0021] First, the template 5 is fixed on the pumping chamber 1 (the template and the pumping chamber can be integrated or separated). The molding frame can have a certain draft angle (generally 8~10 degrees), so as to facilitate the detachable installation between the molding frame and the template. After the template 5 is installed, the loose block is filled on the top of the runner and locked through the locking holes 3 and 8.

[0022] Then, the molding frame 6 is assembled together with the pumping chamber 1, and the pumping chamber 1 is used to assist subsequent film coating. Because molding frame 6 directly contacts with facial film, so the surface of molding frame should be relatively smooth and unlikely to scratch film, molding frame can be selected metal material, considers cost then preferred aluminum alloy or ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com