Double-groove finish machining process for starter shaft of new energy automobile

A new energy vehicle, starter technology, applied in the direction of shafts, couplings, shafts and bearings, etc., can solve the problems of easily affecting the processing effect, no material surface pretreatment, etc., to improve the effect, reduce the roughness, and improve the durability. The effect of grinding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

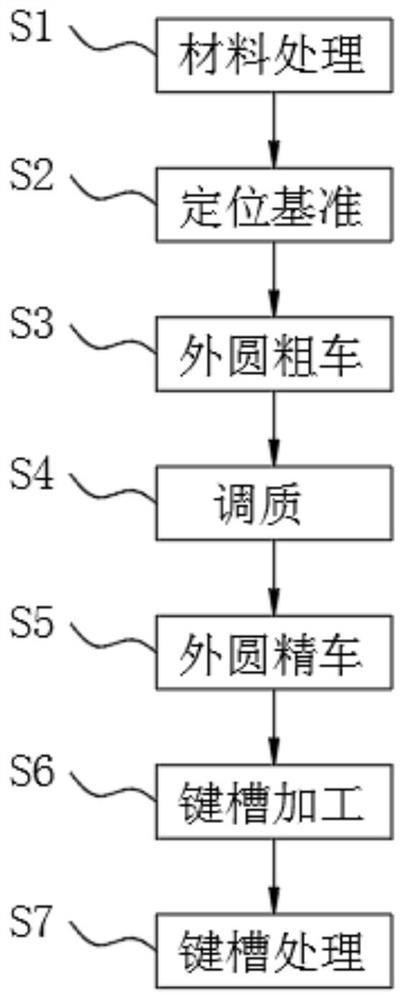

[0028] A new energy vehicle starter shaft double groove finishing process, comprising the following steps:

[0029] S1. Material treatment: Prepare a round steel, put the round steel into the shot blasting machine, and process the surface of the round steel. The shot blasting time is 10 minutes. After the shot blasting is completed, take out the round steel, and then use sandpaper The surface of the round steel will be polished. After grinding, put the round steel into a container containing pickling agent and pickle to remove the rust on the surface of the round steel. The pickling time is 5 minutes. After washing, wipe the surface of the round steel with a dry cloth;

[0030] S2. Positioning reference: In step S1, after the round steel is processed, use a lathe to turn out the end faces of the two ends of the round steel. After the end faces are turned, drill a center hole at both ends of the round bar to keep the two center holes on the same axis. After the center hole is ...

Embodiment 2

[0044] A new energy vehicle starter shaft double groove finishing process, comprising the following steps:

[0045] S1. Material processing: Prepare a round steel, put the round steel into the shot blasting machine, and process the surface of the round steel. The shot blasting time is 15 minutes. After the shot blasting is completed, take out the round steel, and then use sandpaper The surface of the round steel will be polished. After the grinding is completed, put the round steel into a container containing pickling agent for pickling to remove the rust on the surface of the round steel. The pickling time is 8 minutes. After washing, wipe the surface of the round steel with a dry cloth;

[0046] S2. Positioning reference: In step S1, after the round steel is processed, use a lathe to turn out the end faces of the two ends of the round steel. After the end faces are turned, drill a center hole at both ends of the round bar to keep the two center holes on the same axis. After...

Embodiment 3

[0060] A new energy vehicle starter shaft double groove finishing process, comprising the following steps:

[0061] S1. Material processing: Prepare a round steel, put the round steel into the shot blasting machine, and process the surface of the round steel. The shot blasting time is 13 minutes. After the shot blasting is completed, take out the round steel, and then use sandpaper The surface of the round steel will be polished. After the grinding is completed, put the round steel into a container containing pickling agent for pickling to remove the rust on the surface of the round steel. The pickling time is 7 minutes. After washing, wipe the surface of the round steel with a dry cloth;

[0062] S2. Positioning reference: In step S1, after the round steel is processed, use a lathe to turn out the end faces of the two ends of the round steel. After the end faces are turned, drill a center hole at both ends of the round bar to keep the two center holes on the same axis. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com